Spinning cake clamp

A silk cake and jig technology, which is applied in the field of silk cake jigs, can solve the problems of increased jig manufacturing costs, inability to move jigs synchronously, and low clamping efficiency, so as to reduce the number of parts, improve clamping efficiency, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

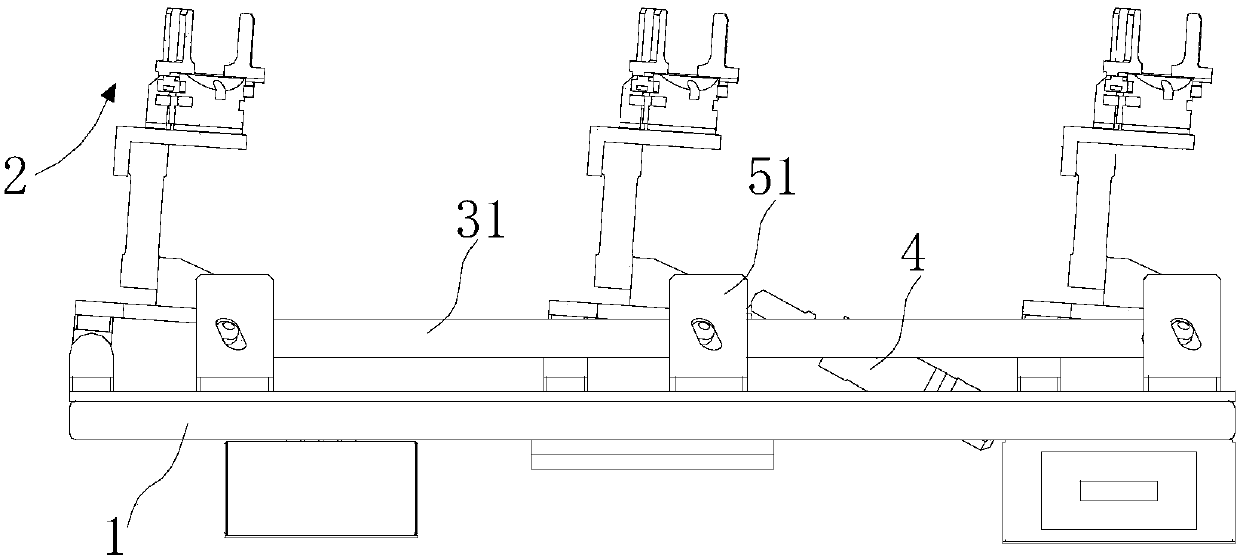

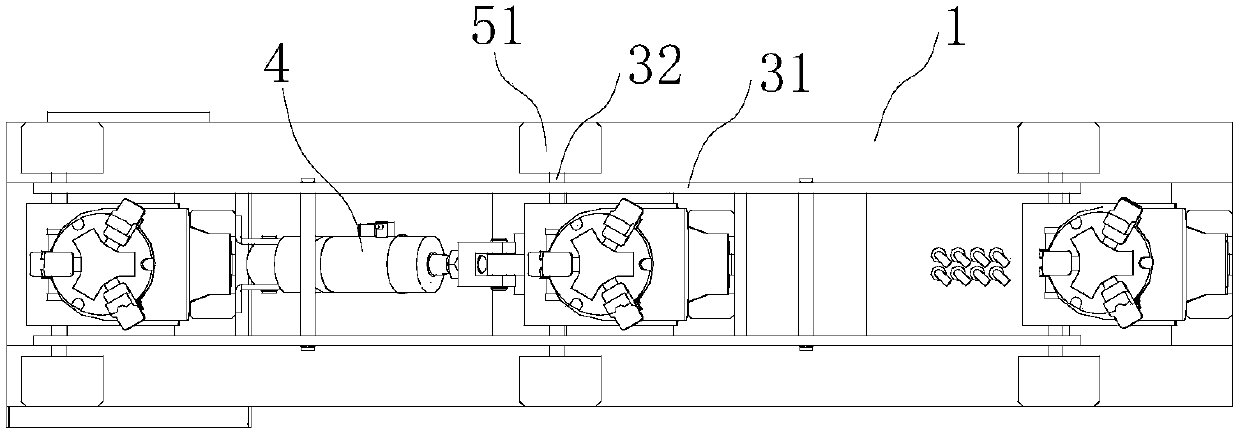

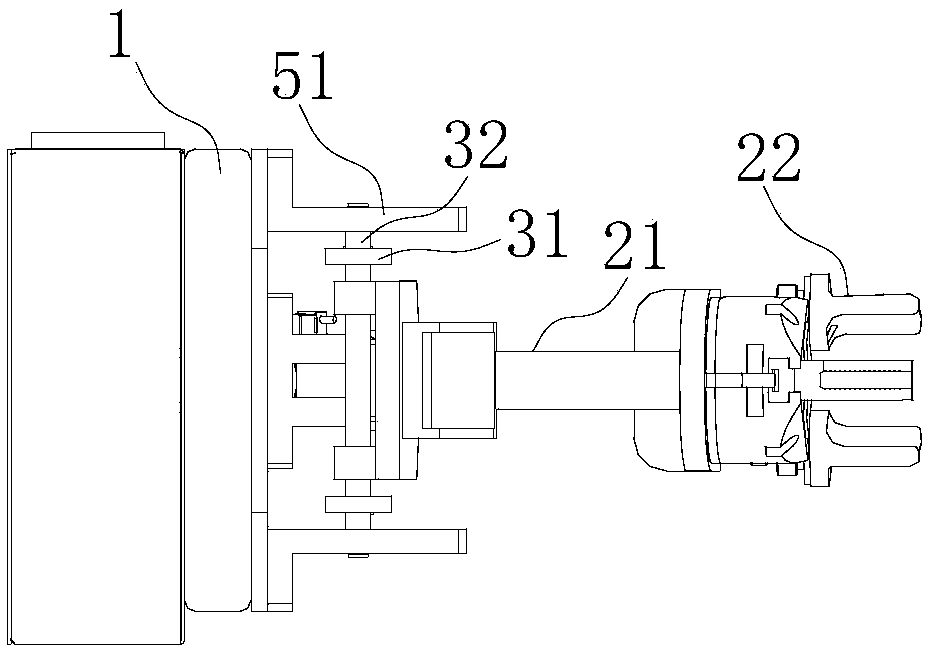

[0032] Such as Figure 1 ~ Figure 4 As shown, the present invention includes:

[0033] The mounting plate 1 is provided with a plurality of mounting positions 11 arranged along the same direction on the mounting plate 1,

[0034] A plurality of jaws 2, the plurality of jaws 2 are respectively hingedly arranged on the installation position 11,

[0035] The linkage mechanism 3 is used to link and connect multiple jaws 2,

[0036] The driving mechanism 4 is used to drive the driving mechanism 4 linked by multiple jaws 2;

[0037] Wherein linkage mechanism 3 comprises:

[0038] The linkage rod 31 is arranged along the direction of the installation position 11,

[0039] A plurality of driving rods 32 , the plurality of driving rods 32 are respectively fixedly threaded on the jaw 2 , and the ends of the driving rods 32 corresponding to the position of the linkage rod 31 are fixedly threaded on the linkage rod 31 .

[0040] In the present invention, the silk cake fixture coopera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com