Mechanical gripper

A technology of mechanical grippers and clamping blocks, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., and can solve the problems of low gripping efficiency, poor stability, and shedding of woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

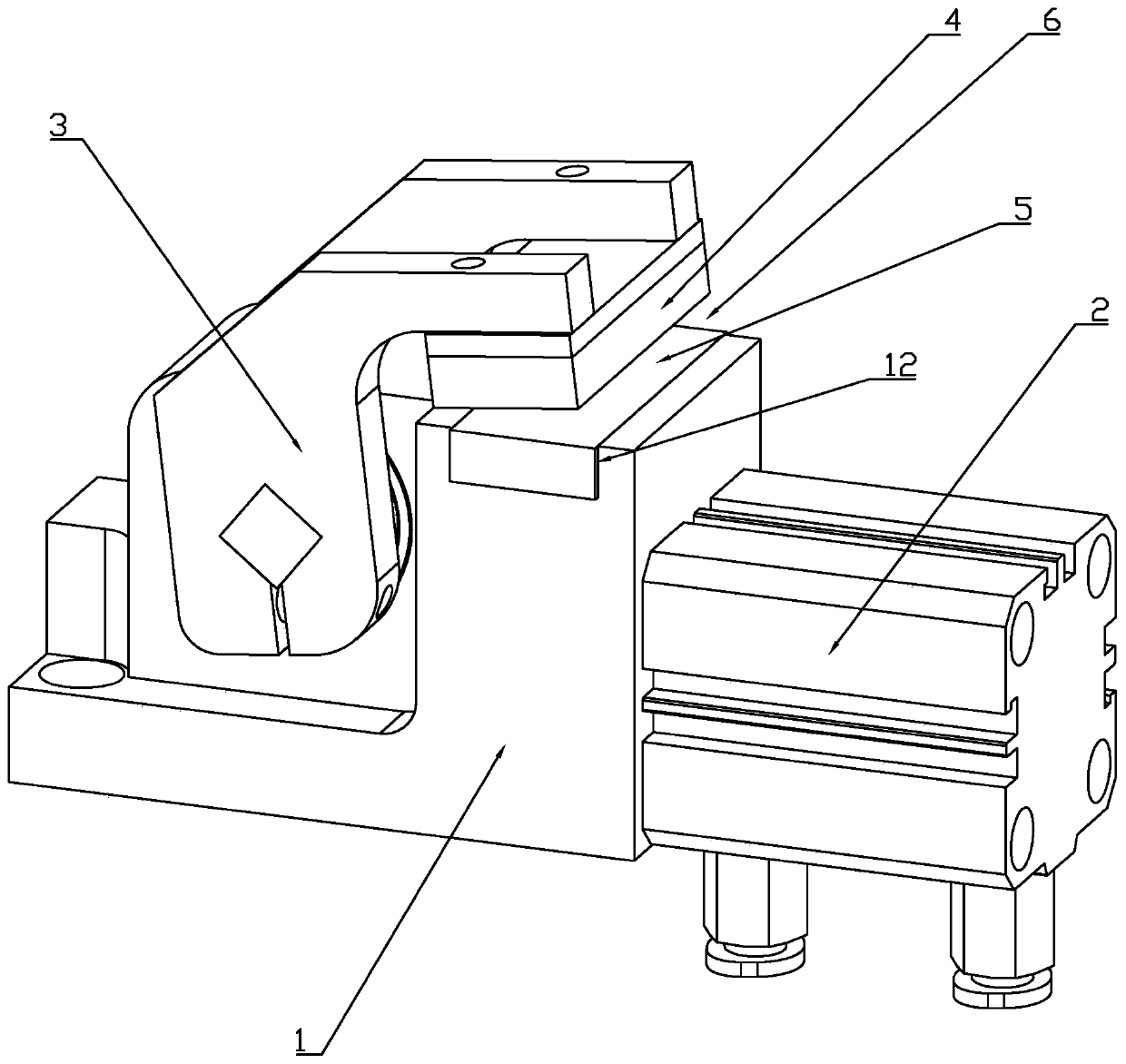

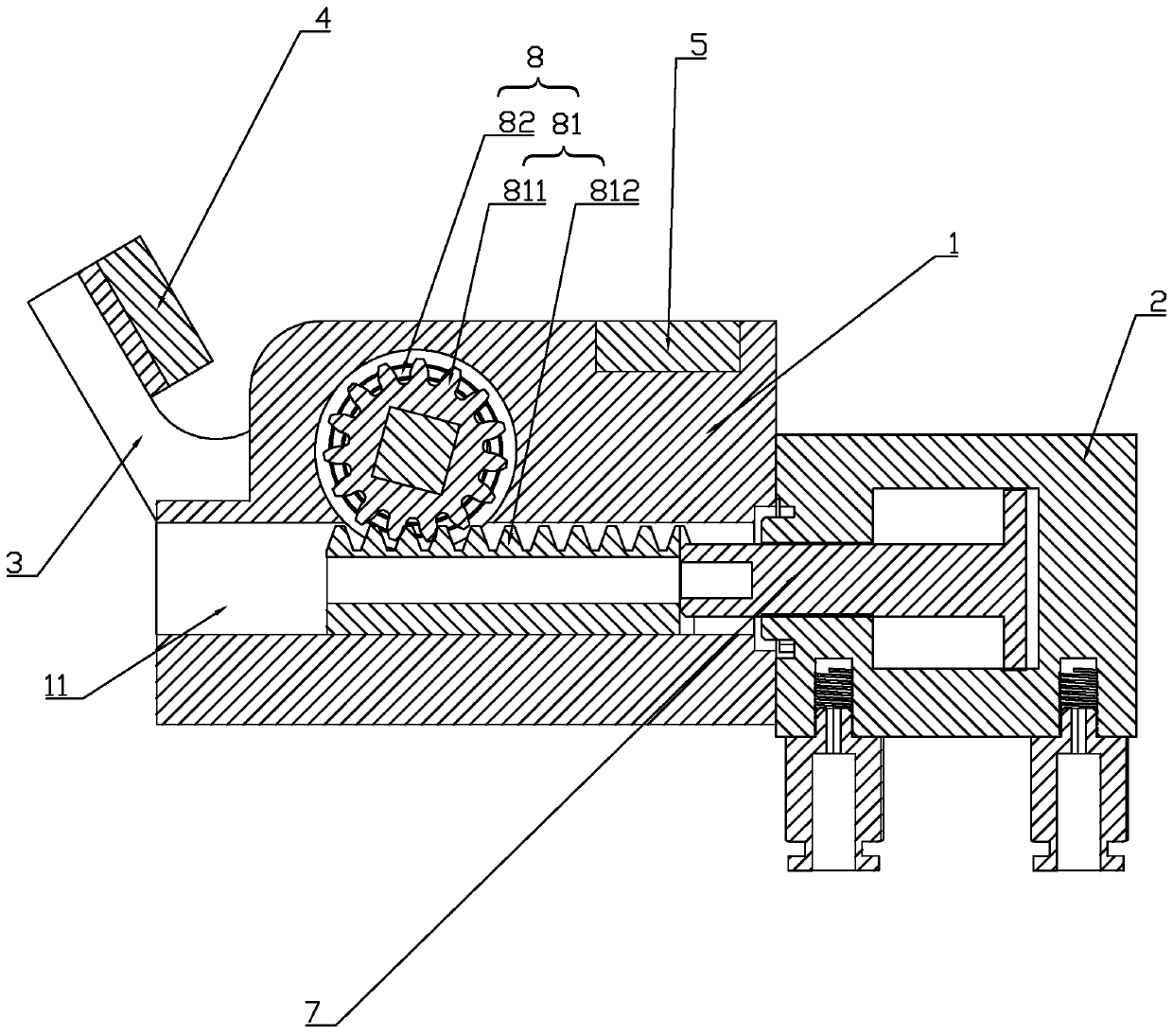

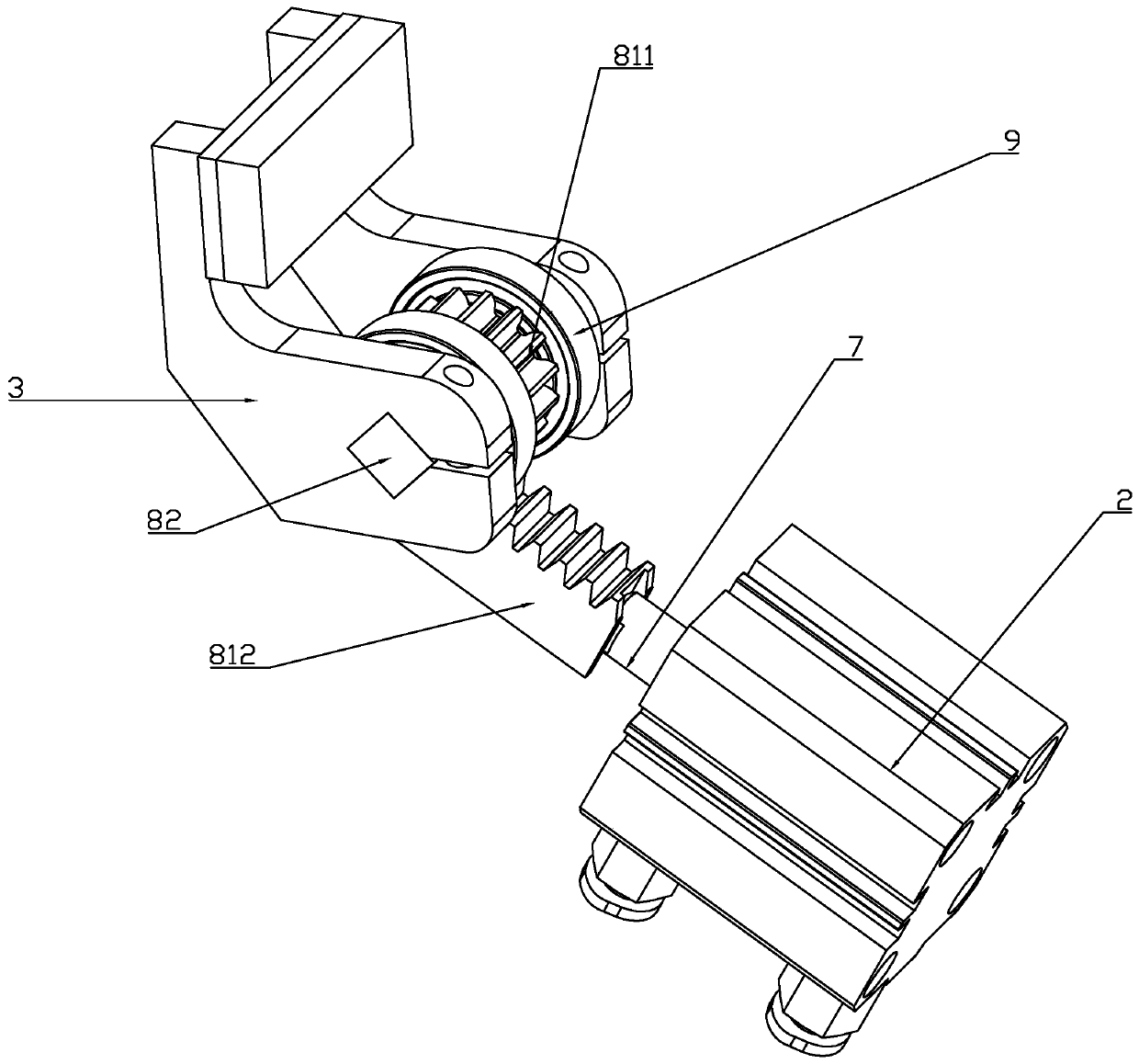

[0020] Specific embodiments of the present invention such as Figure 1-3 As shown, a mechanical gripper includes a mounting shell 1 and a driving cylinder 2, a rotating arm 3 is hinged on the outer wall of the mounting shell 1, and a first clamping block 4 is arranged on the rotating arm 3, The installation shell 1 is provided with a second clamping block 5, and a clamping port 6 for clamping a woven bag is formed between the first clamping block 4 and the second clamping block 5, and the driving cylinder 2 The output end is provided with a telescopic rod 7, and the rotating arm 3 is connected to the telescopic rod 7 through a transmission mechanism 8. The beneficial effect of such setting: adopt the above-mentioned scheme, before clamping, firstly fold an appropriate amount of woven cloth and lay it flat on the second clamping block 5, then start the driving cylinder 2 so that the telescopic rod 7 protrudes from the cylinder, Thereby the transmission mechanism 8 drives the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com