Inward contracting type spring sleeve clamp

A spring sleeve and retractable technology, which is applied in the field of mechanical processing, can solve the problems of high labor intensity, poor processing quality, time-consuming disassembly of parts, etc., and achieve time-saving and labor-saving disassembly of workpieces, low labor intensity and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

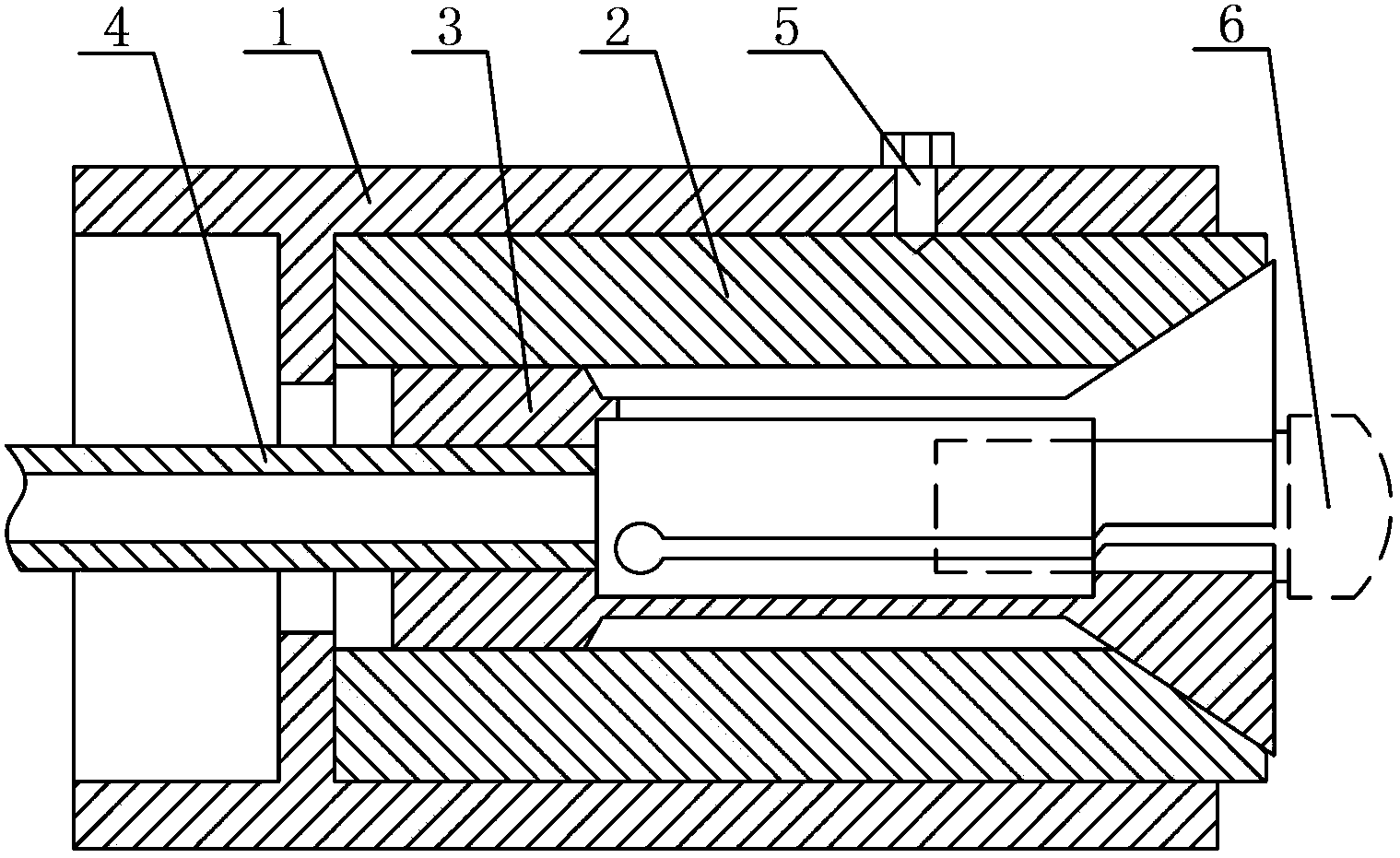

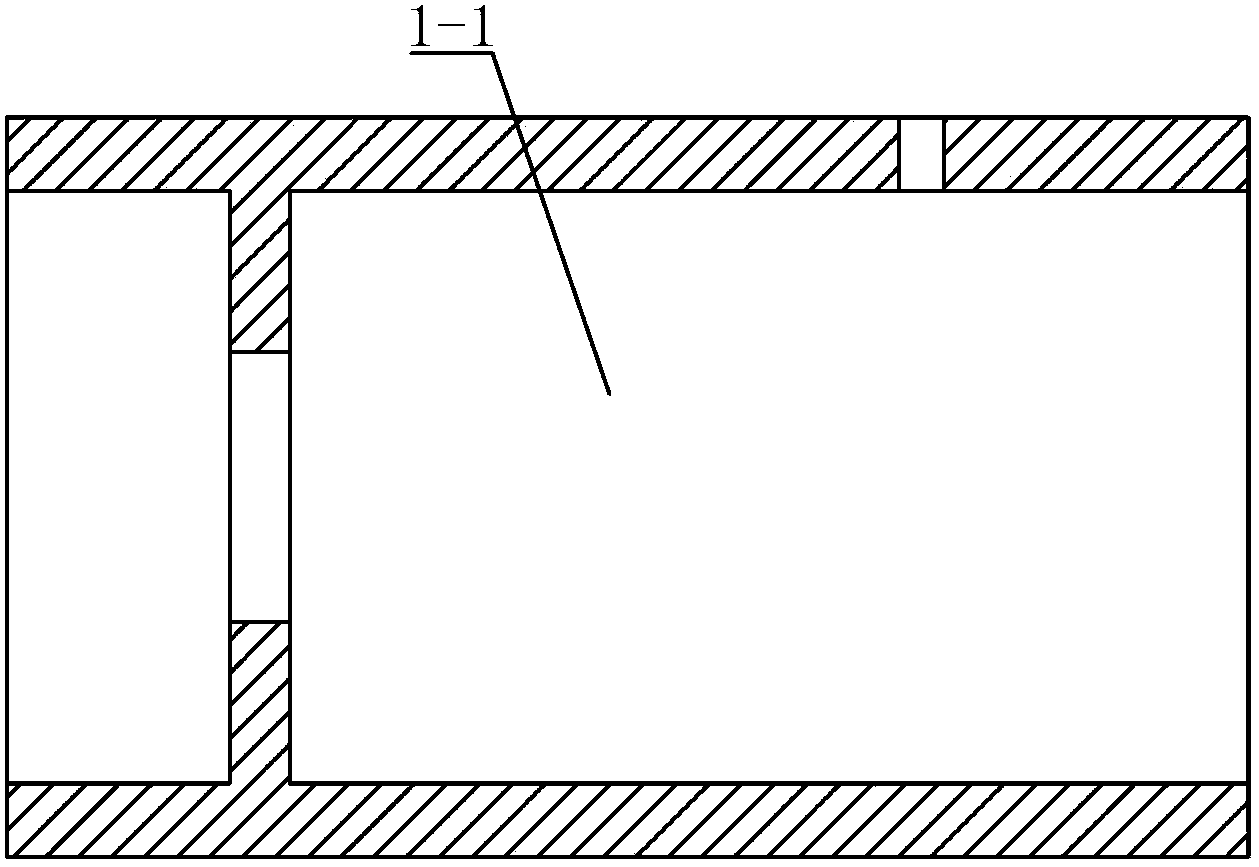

[0024] Such as Figure 2 to Figure 6 The shown retractable spring sleeve clamp includes a housing 1 with a cavity 1-1, a fixed sleeve 2 is arranged inside the cavity 1-1 of the housing 1, and the fixed sleeve 2 ends The end is provided with a tapered surface 2-1, the inside of the fixed sleeve 2 is provided with an elastic sleeve 3, the elastic sleeve 3 includes a sleeve seat 3-1, and the sleeve seat 3-1 is connected with a plurality of elastic petals 3 -2 connections, the number of the elastic petals 3-2 is at least two, preferably three. The tails of the plurality of elastic petals 3-2 are all provided with guide seats 3-3 matched with the tapered surface 2-1, and the sleeve seats 3-1 of the elastic sleeve 3 are connected with the pull rod 4.

[0025] Such as figure 2 As shown, the fixed sleeve 2 and the elastic sleeve 3 are fixedly connected by a set screw 5, the screw connection is safe and reliable, and the price is low.

[0026] The working process of the retractable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com