Multipoint mechanical hand for myriametre well drill

A mechanical gripper, drilling machine technology, applied in the directions of manipulators, manufacturing tools, chucks, etc., can solve the problems of few contact points, unreliable grasping, uneven distribution of contact points, etc., and achieve the effect of increasing friction area and tightening reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

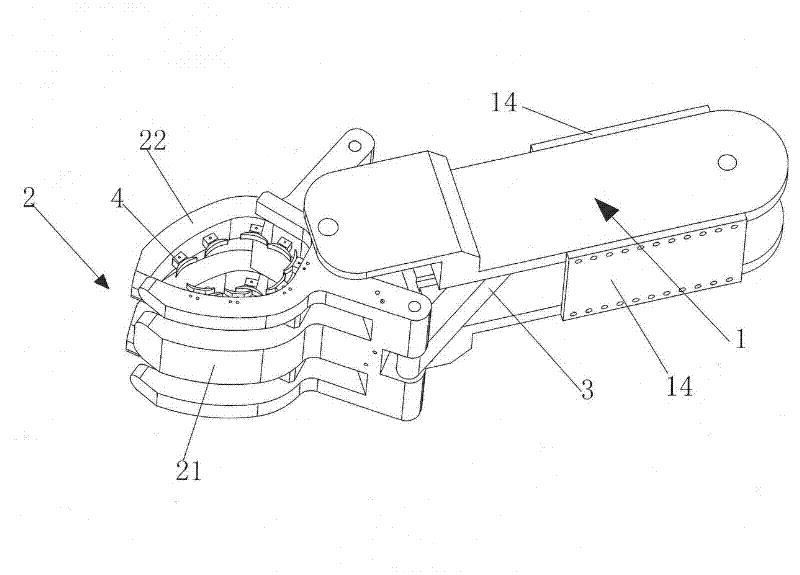

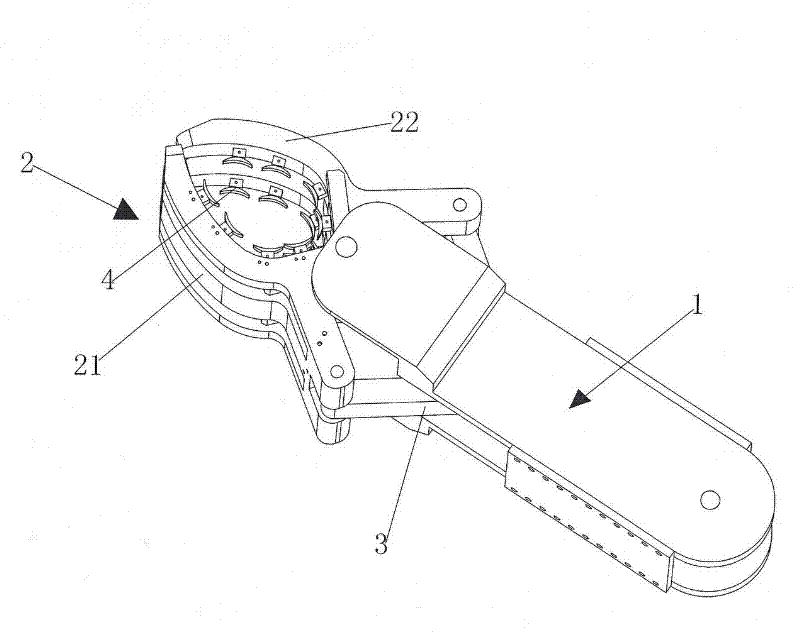

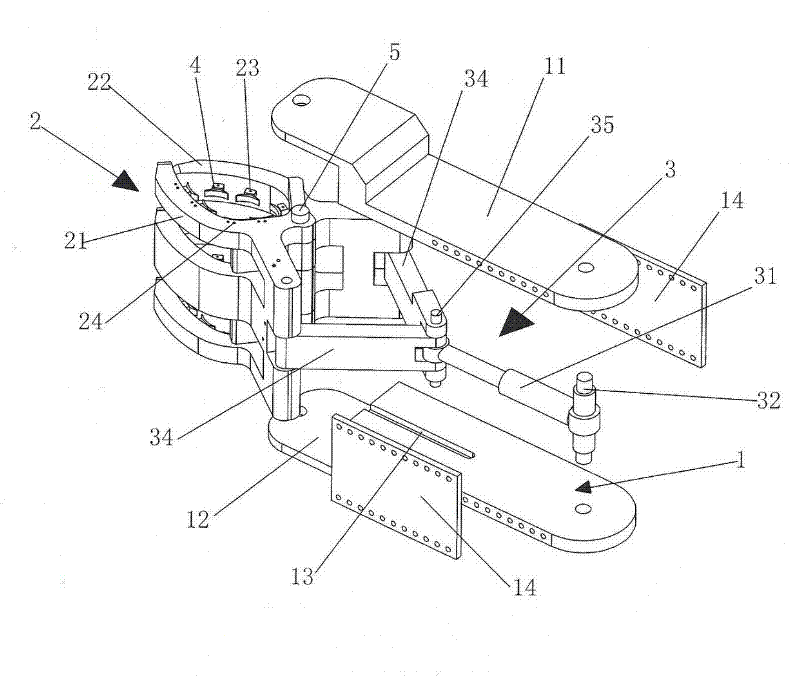

[0018] See figure 1 , figure 2 with image 3 As shown, the present invention is composed of an arm 1 and a crossed gripper 2, a gripper drive mechanism 3 and an elastic floating friction mechanism 4, wherein the crossed gripper 2 is as Figure 4 with Figure 5 As shown, it is composed of a left finger 21 and a right finger 22. The middle of the rear ends of the left finger 21 and the right finger 22 are hinged together by the first shaft 5. The left finger 21 and the right finger 22 are respectively extended with force arms 211 and Force arm 222; the gripper drive mechanism 3 is composed of a hydraulic cylinder 31, a vertical shaft 32, a left link 33 and a right link 34. The front ends of the left link 33 and the right link 34 are hinged on the force arm 211 and the force arm 222, respectively The rear end of the left link 33 and the rear end of the right link 34 are jointly hinged with the front end of the hydraulic cylinder 31 through the second shaft 35. The rear end of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com