Vertical chili bundle remover

A chili, vertical technology, applied in the field of vertical chili handling machine, can solve the problem of consuming manpower and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

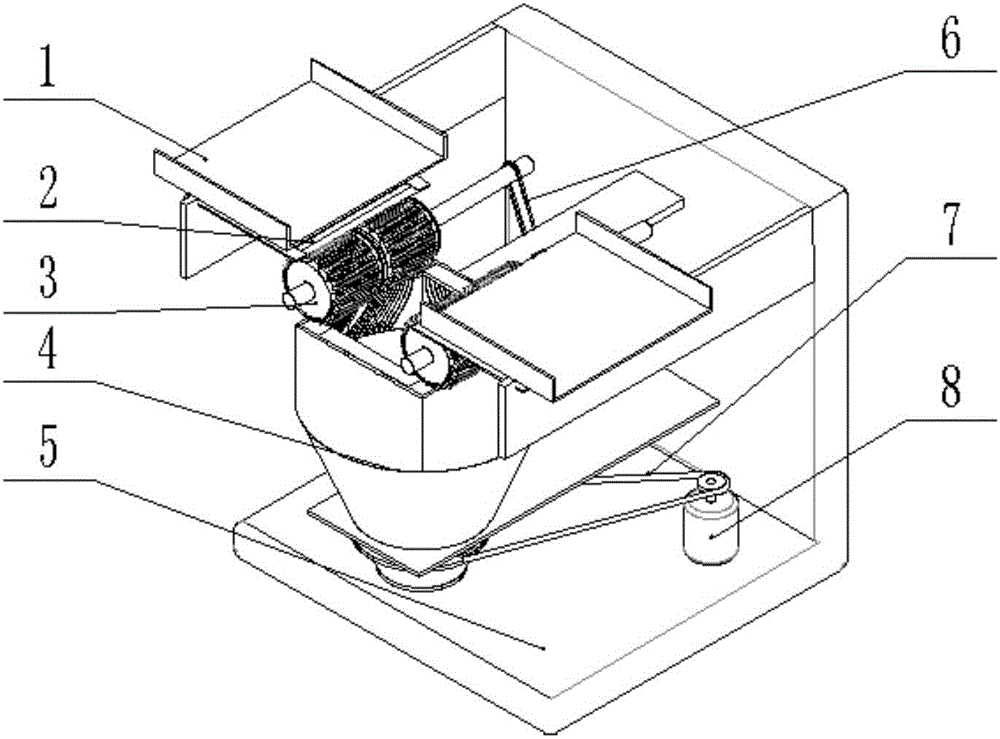

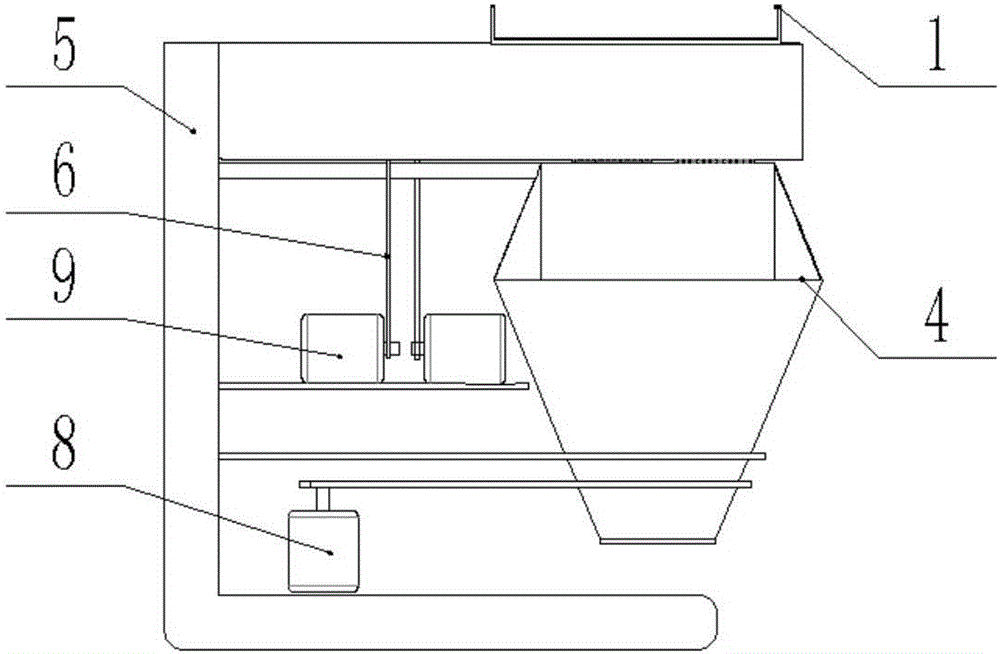

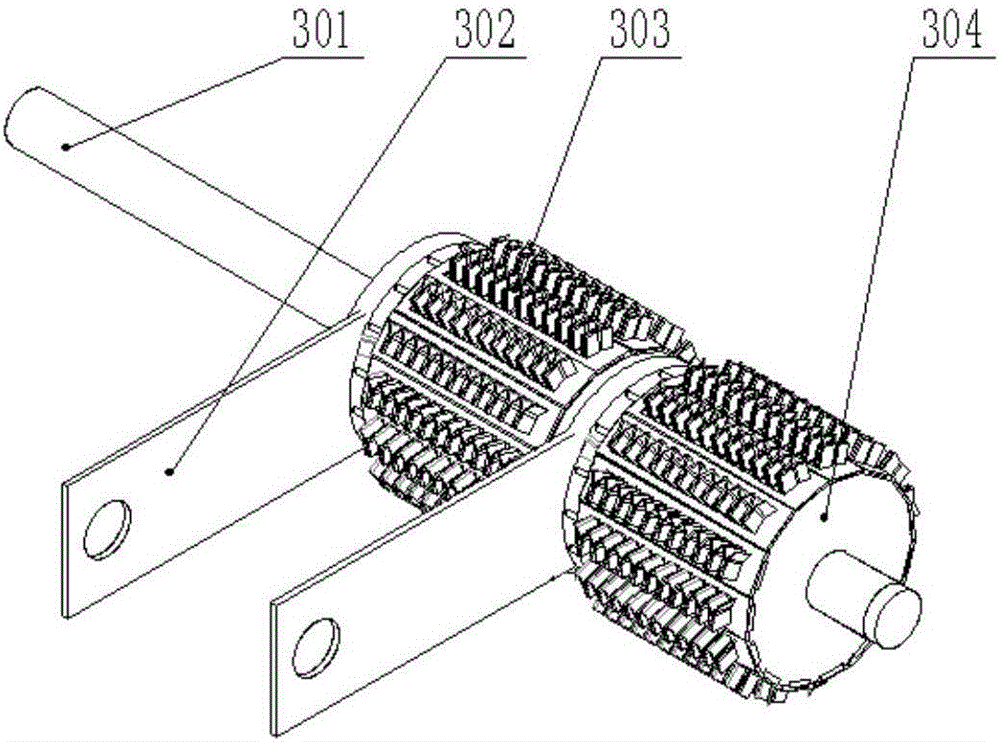

[0026] A vertical chili remover is composed of a discharge plate 1, a cutter 2, a rotating fixture 3, a material barrel 4, a frame 5, a belt 6, a chain 7, a first motor 8 and a second motor 9. It is characterized in that: two discharge plates 1 are symmetrically installed on the frame 5, the material barrel 4 is installed on the frame 5, two rotating fixtures 3 are symmetrically installed on the frame 5, and the radial lowest point of the rotating fixture 3 is close to the material On the edge of the bucket 4 and above the bucket 4, two cutters 2 are horizontally and symmetrically installed on the frame 5, and a section of the blade of the cutter 2 is close to the radially highest point of the rotating fixture 3, and above the radially highest point, the first A motor 8 is installed on the frame 5, the chain 7 connects the first motor 8 and the bucket 4, two second motors 9 are installed on the frame 5 in opposite directions, and the belt 6 connects the rotating fixture 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com