Movable plant clamping and fixing device with automatically-separable clamping jaws

An automatic separation, clamping and fixing technology, applied in planting methods, transplanting machinery, applications, etc., can solve problems such as slow rotation, claws that cannot be automatically separated, and poor stability, and achieve the effect of tightening and firming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

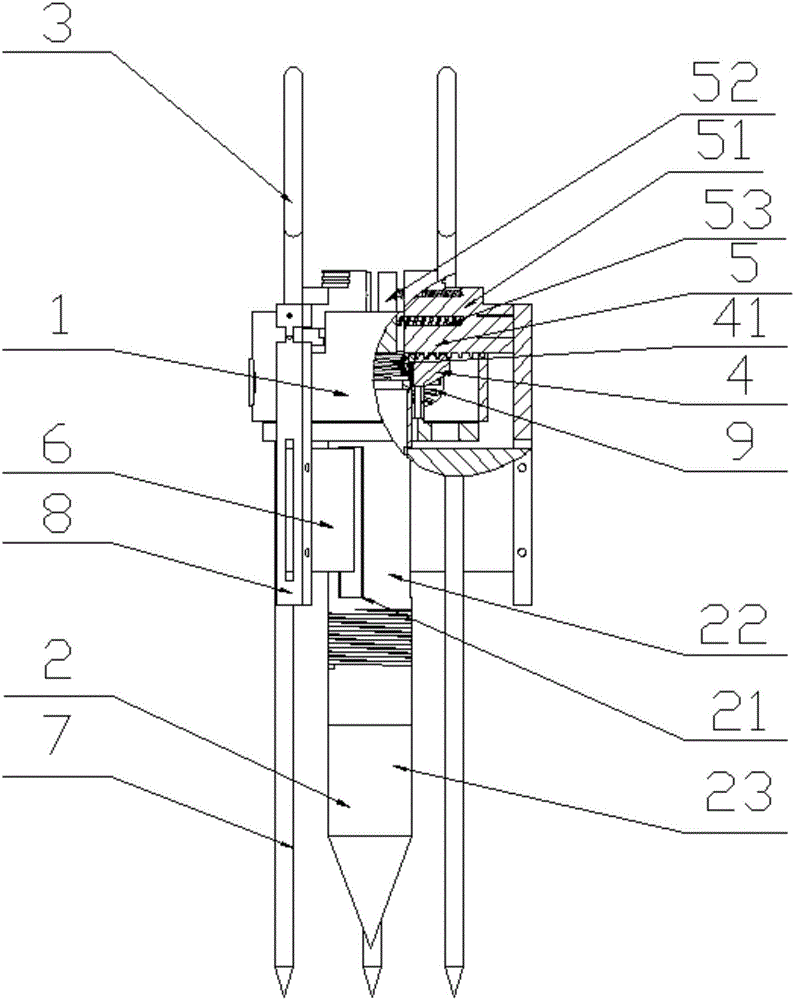

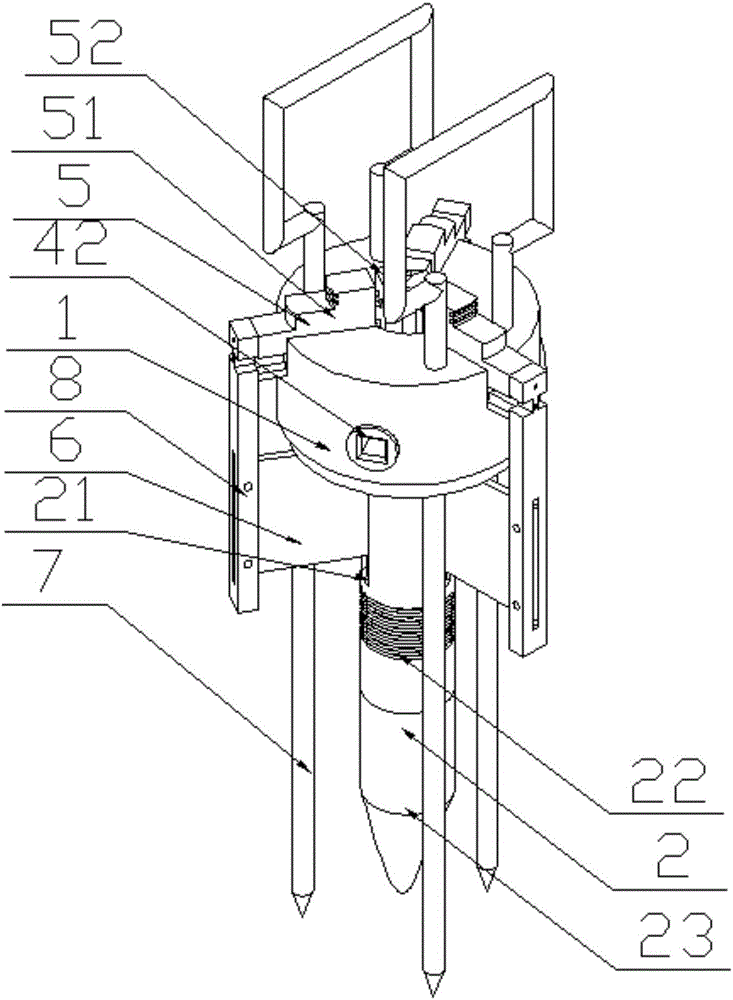

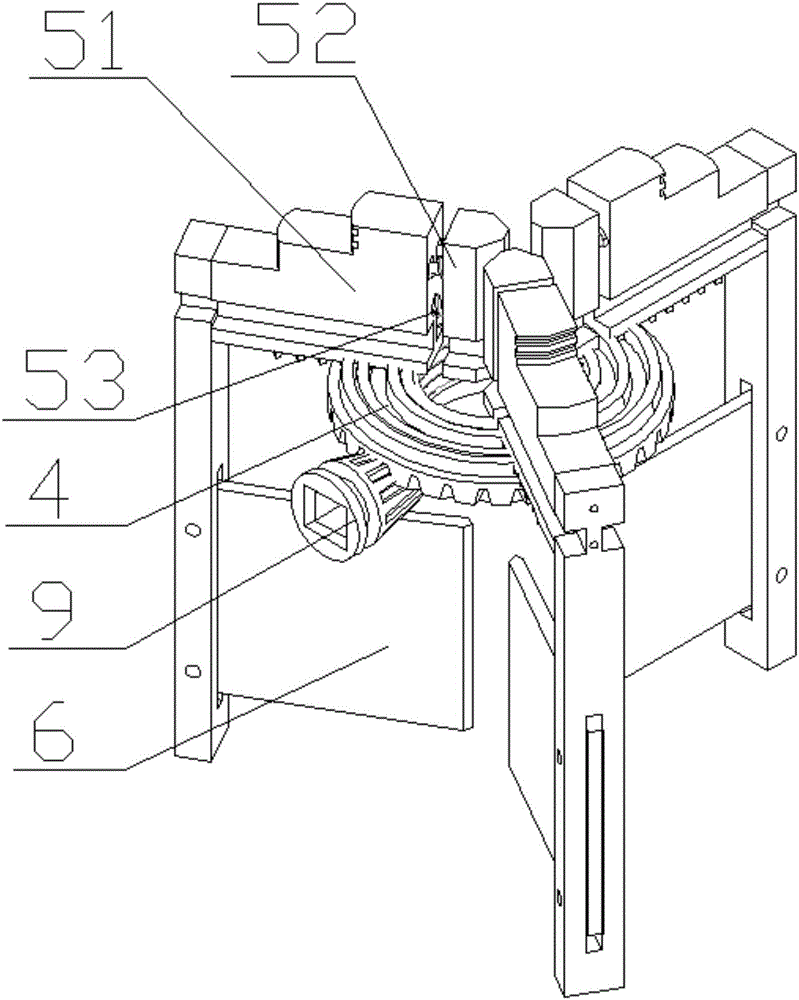

[0021] Such as figure 1 with figure 2 As shown, a movable plant clamping and fixing device with automatically separable jaws includes a base 1, a multi-jaw chuck clamping device, a sleeve 2 and a handle 3. The multi-jaw chuck clamping device includes The universal chuck wire 4 and a plurality of elastic jaw devices 5 matched with the universal chuck wire 4, the sleeve 2 is composed of a hollow cylinder and a conical barrel arranged at the lower end of the hollow cylinder, and the cone The diameter of the shaped barrel and the hollow cylinder are the same; the multi-jaw chuck clamping device is installed on the base 1, and the center of the base 1 is provided with a first through hole 11 that is consistent with the inner diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com