Clamping tooling for pipe

A tooling and pipe technology, which is applied in the field of pipe tightening tooling, can solve the problem that pipes of different specifications cannot be applied, and achieve the effects of simple structure, convenient operation and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

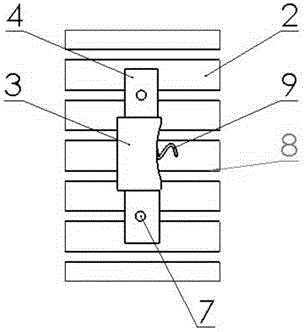

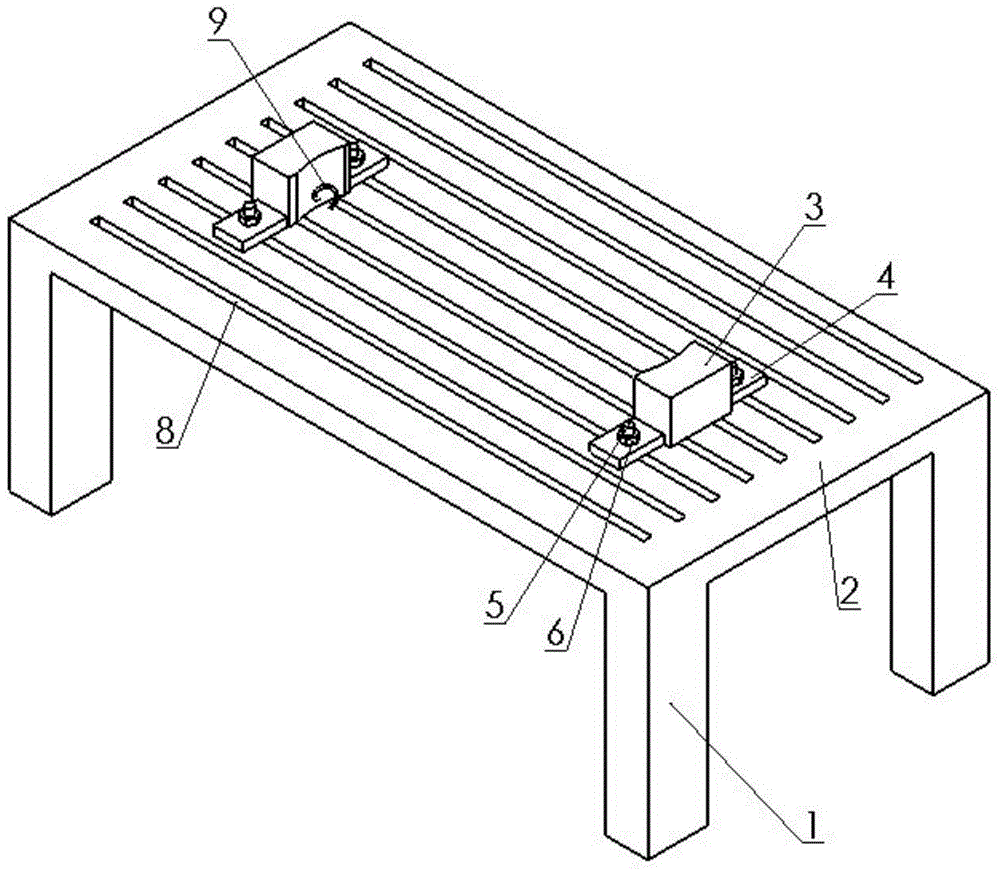

[0016] Now in conjunction with accompanying drawing, this pipe tightening tool is described in further detail.

[0017] Such as figure 1 As shown, a pipe tightening tooling includes a plurality of pillars 1, an operating platform 2 and two tightening elements 3;

[0018] The console 2 is fixedly connected to the pillar 1, and the console 2 is provided with a plurality of slideways 8, and the plurality of slideways 8 are parallel to each other on the console 2;

[0019] The two tightening elements 3 are respectively slidably connected to the console 2 through slideways 8, and the middle part of one side of the tightening element 3 is provided with an arc surface, and the arc surfaces of the two tightening elements 3 are opposite to each other. The arc surface is provided with several springs 9, and the springs are set to make the tightening operation more stable.

[0020] Such as figure 1 As shown, the bottoms of a group of opposite sides of the tightening element 3 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com