Auxiliary apparatus for plate part thermal spraying technology

A technology for disc parts and auxiliary devices, applied in metal material coating process, coating, melting spray plating, etc., can solve problems such as affecting the operation process, reducing production efficiency, waste of resources, etc., achieving a simple overall structure and ensuring processing. Quality, effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

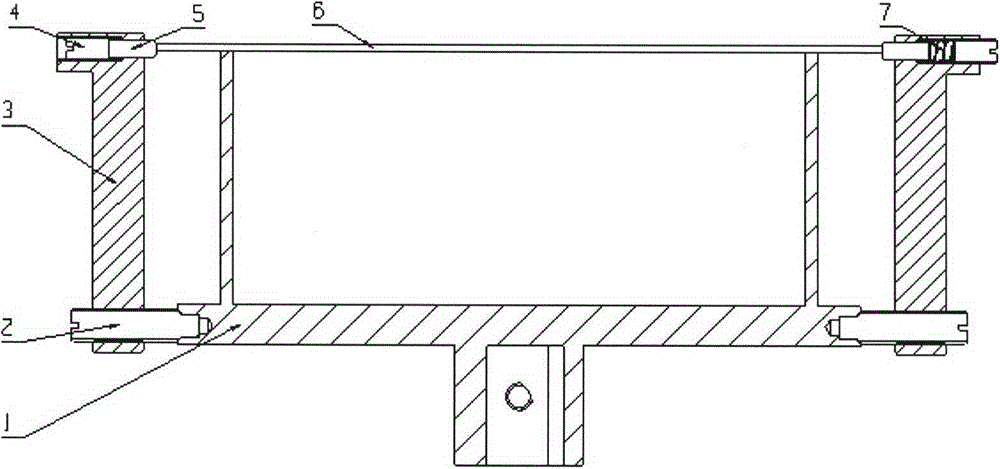

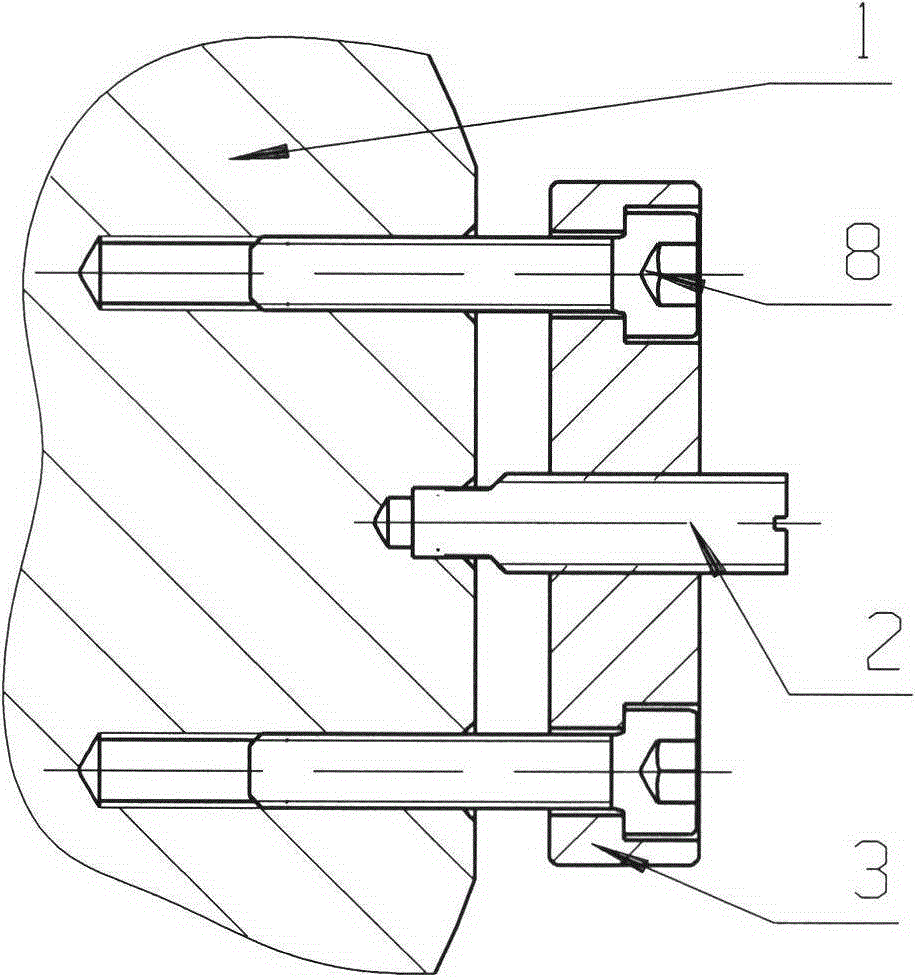

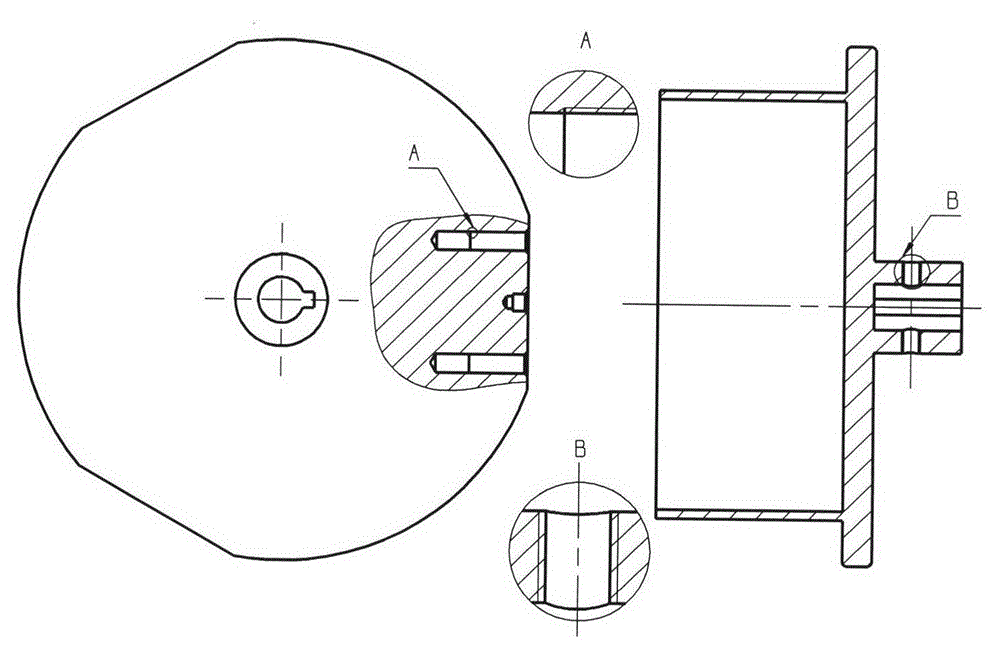

[0026] The details and working conditions of the device of the present invention will be described below in conjunction with the accompanying drawings.

[0027] like figure 1 , 2 As shown, the device of the present invention is composed of a powder collection bowl (1), a distance adjusting screw (2), a T-frame (3), a set screw (4), a ball head pin (5), a spring (7), Install the screws (8). One end of the powder collection bowl is a cylindrical cavity with a wall thickness of 2mm, and three planes are uniformly processed on the sides, and positioning holes and threaded holes are processed on the planes. When spraying, an appropriate amount of water is filled in the cavity, and the unused alloy powder falls into the water, which effectively prevents oxidation and achieves the purpose of alloy powder recovery.

[0028] The T-frame (3) is connected to the powder collection bowl (1) through the distance adjustment screw (2) and the installation screw (8). According to the needs,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com