Energy-saving cast-in-place hollow floor

A hollow floor and cast-in-place technology, which is applied to the preparation of floors and building components on site, and structural elements, etc., can solve the problems of simultaneous construction of floor heating devices, increased building development and construction costs, and unbalanced force transmission, etc. problem, achieve the effect of improving the anti-seismic cracking effect, light weight, and preventing concrete cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

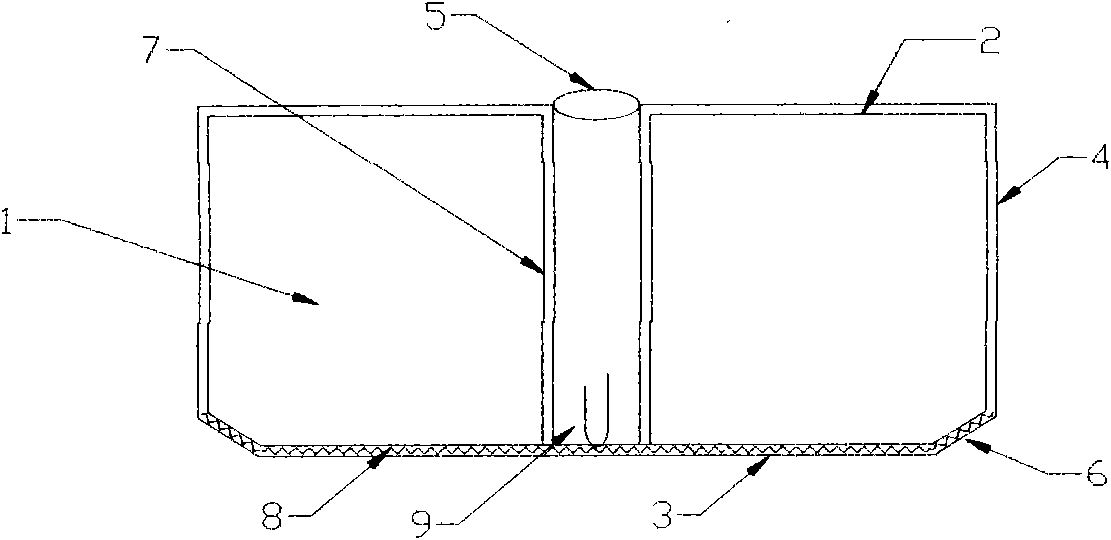

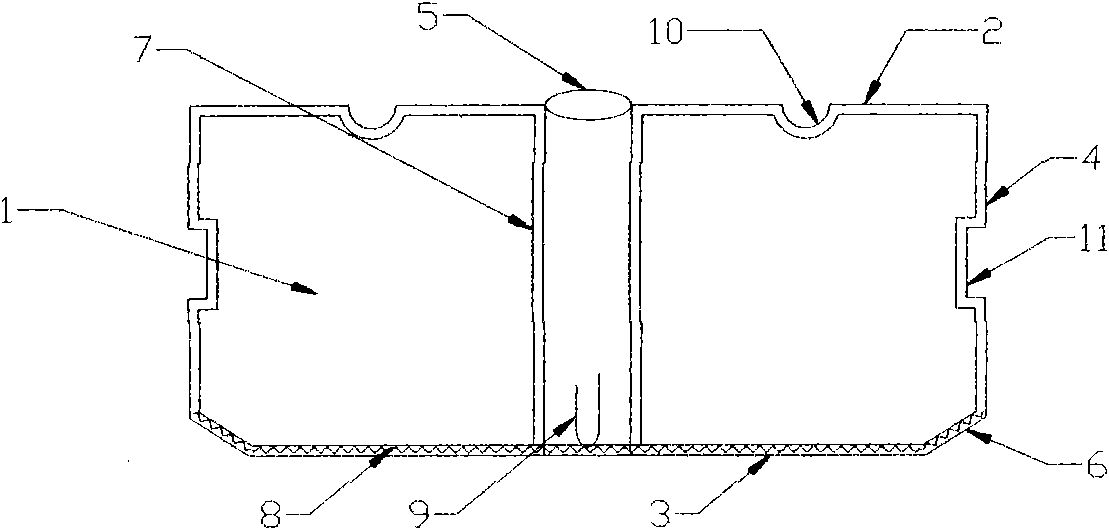

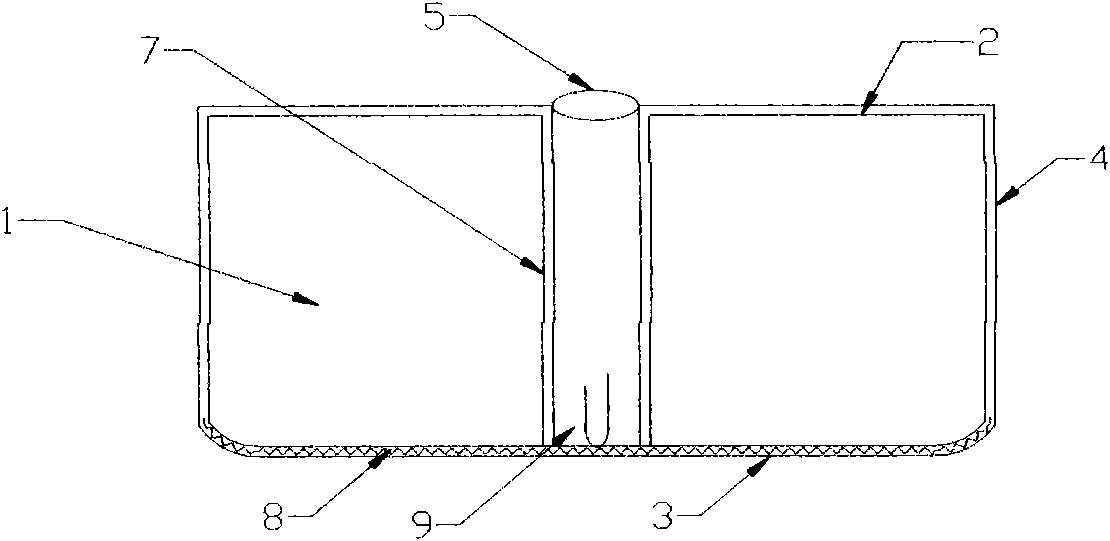

[0029] The present invention will be further described now in conjunction with accompanying drawing, as Figure 1a As shown, the thin-walled box body 1 used in the energy-saving cast-in-place hollow floor of this scheme is composed of bottom surface 3, side surface 4, top surface 2, inclined surface 6 and hole wall 7, and is formed by combining the bottom surface formwork, side formwork and inclined surface formwork. The finished one-time molding mold is applied to the inner wall of the mold with cement mortar to form the bottom surface 3, the side surface 4 and the inclined surface 6 of the thin-walled box body 1. In order to enhance the strength of the thin-walled box, reinforcing materials can be added to the cement mortar. The reinforcing materials can be steel wire mesh, glass fiber cloth, short fiber wire, short iron wire, etc. Preferably, steel wire mesh 8 is used as reinforcing material on the bottom surface 3 and inclined surface 6 of the thin-walled box body, and iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com