Fine blanking flange parallel multiple circular groove processing center posttreatment knife handle cutter combination

A machining center and tool handle technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of small cutting amount, time-consuming and labor-intensive guarantee of accuracy, and time-consuming, etc., to reduce tool consumption and improve product quality. The effect of high quality and economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

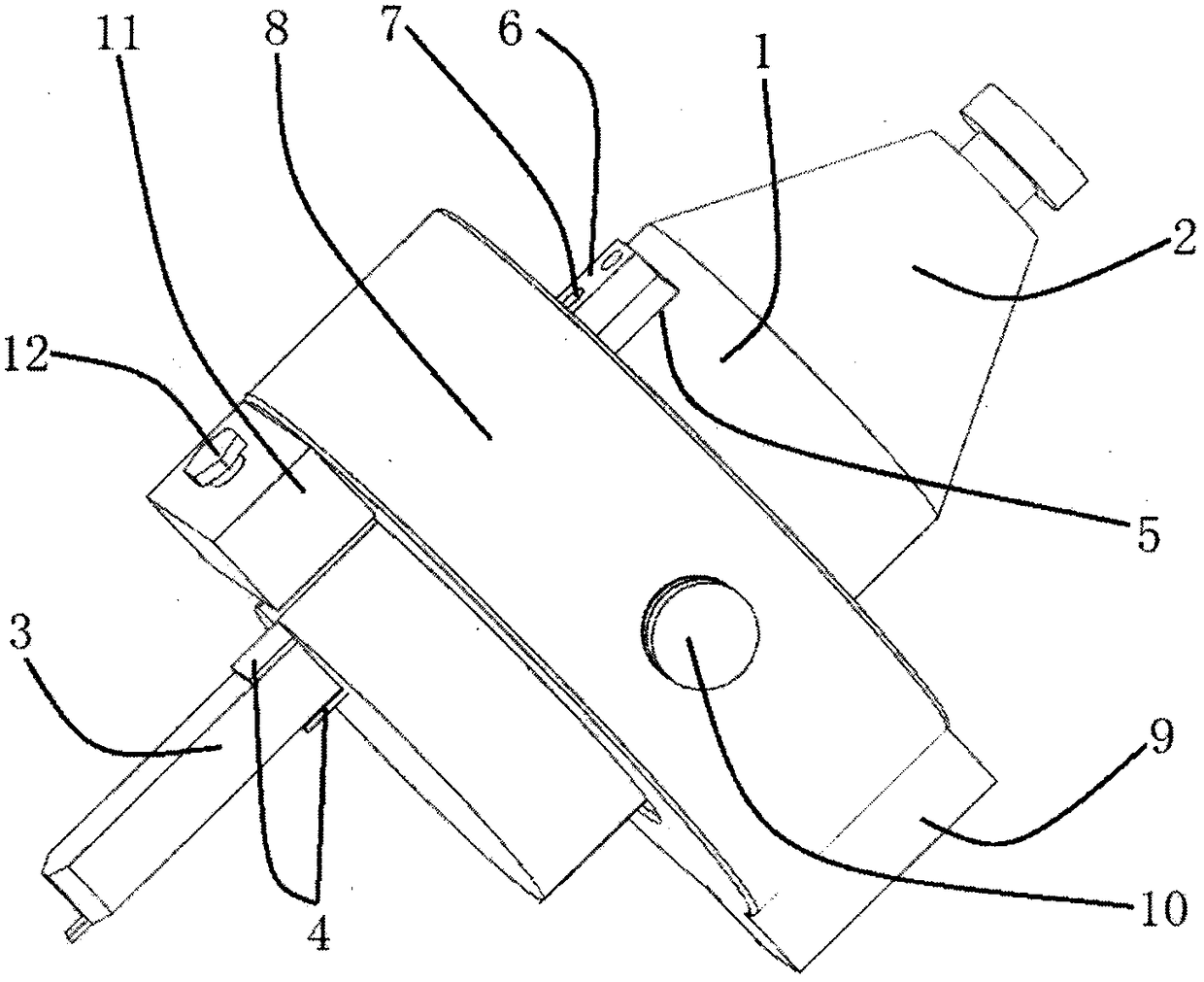

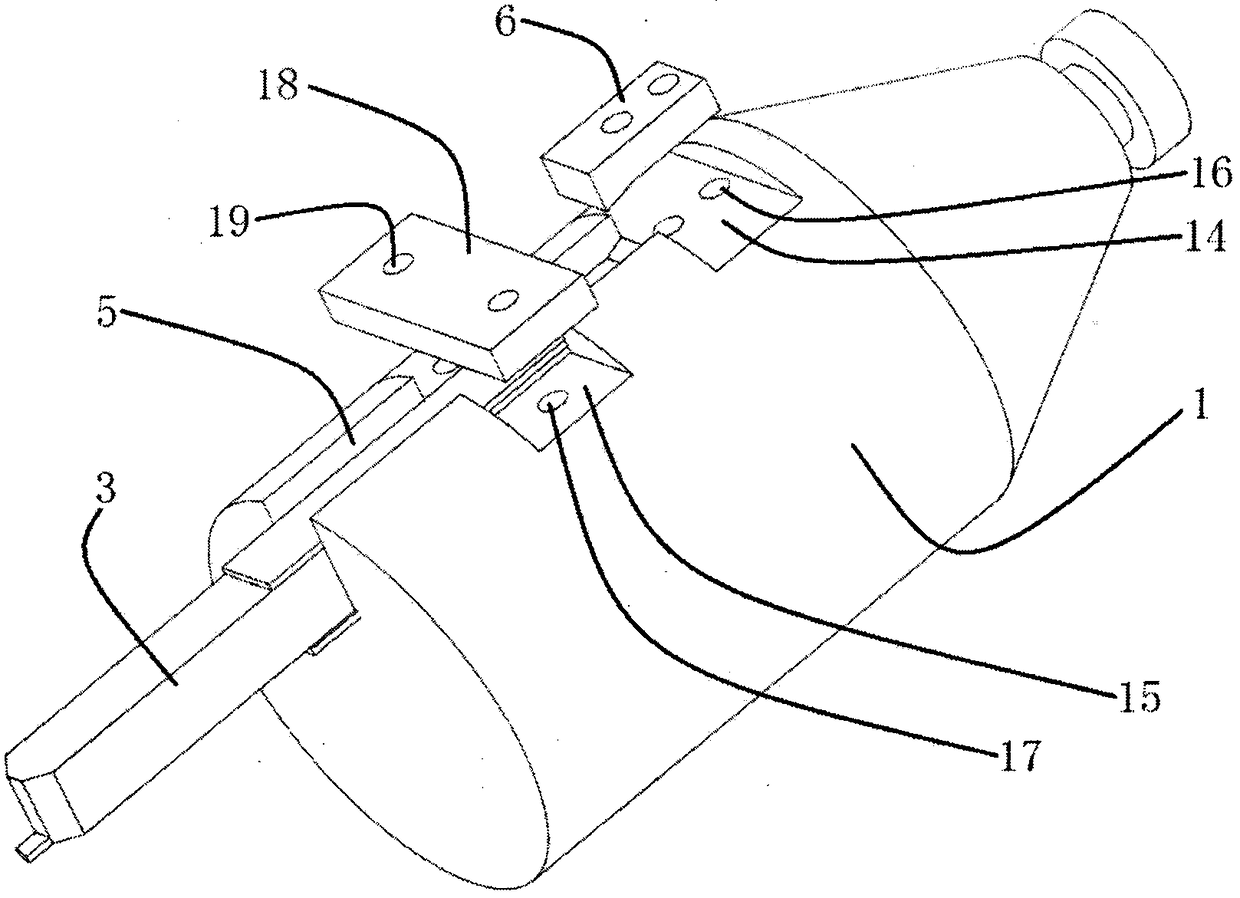

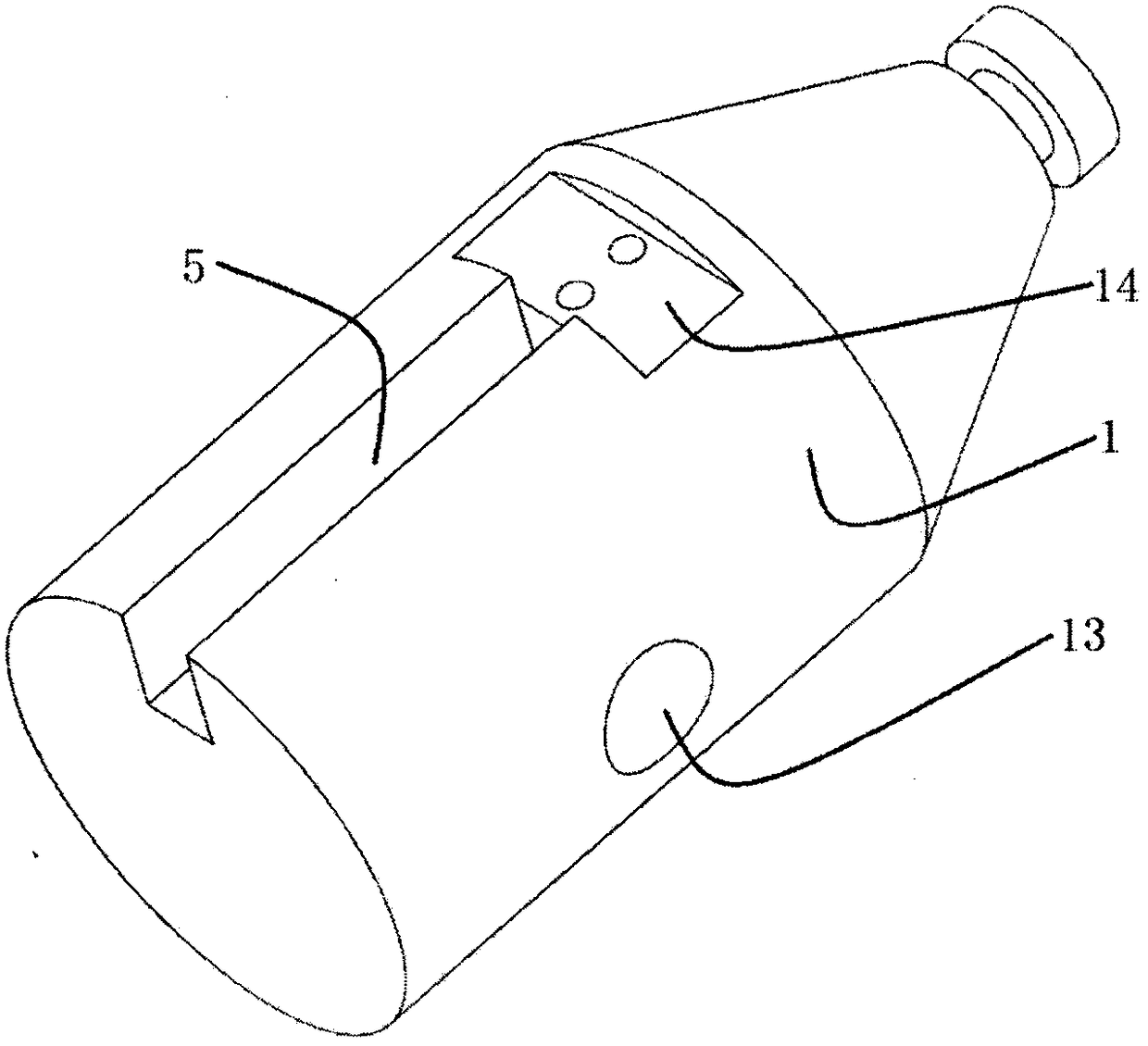

[0015] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 And attached Figure 6 , a fine blanking flange side by side multi-circular groove machining center post-processing tool handle combined structure features: the processed flange 23 has four large holes 25, each large hole has a circular groove 24, such parts as The fixture is very complicated when using a lathe, and every time a circular groove is processed, it needs to be re-clamped, which is time-consuming and laborious. Therefore, the solution of the present invention is adopted. The grooved tool holder 1 has a mounting structure 2 on the machining center. The installation groove 5 of the end face groove cutter 3 has a depth of 40 mm and a width of 15 mm. The end face groove cutter 3 adjusts its position in the installation groove 5 by increasing or decreasing the adjustment pad blade 4, and the thickness of the adjustment pad blade 4 is 0.5 mm. , 1mm an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com