A circular glazing line

A circular and circular conveying technology, which is applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of reducing the glaze efficiency of ceramic cups and difficult to connect devices with different functions, so as to improve the glaze efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

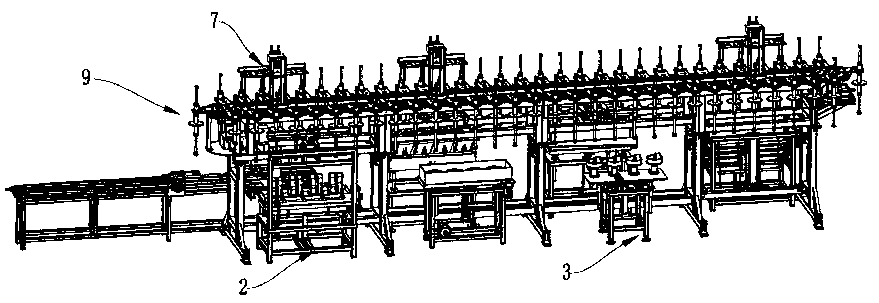

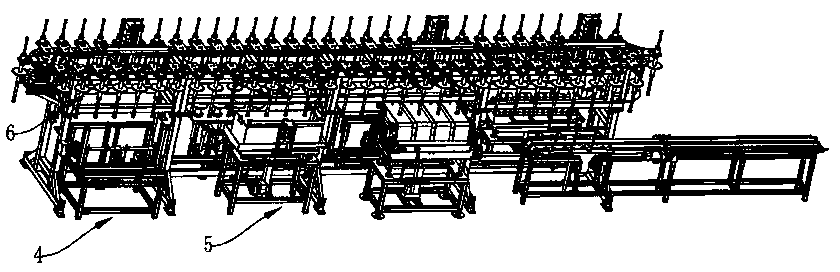

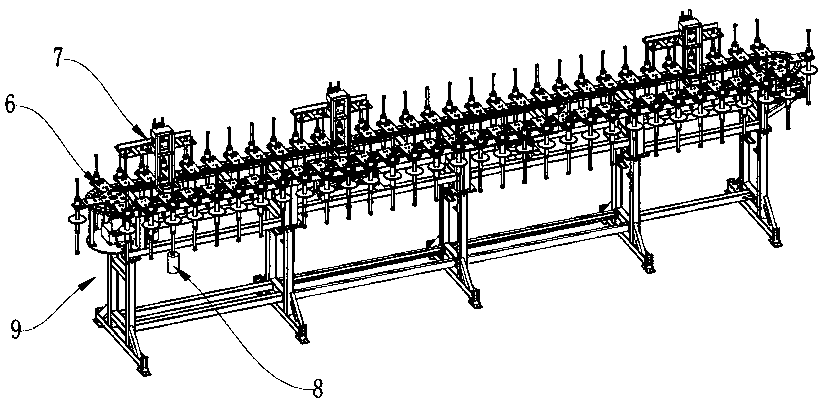

[0038] Such as Figure 1-21 As shown, a ring-shaped glazing line includes a ring-shaped conveying line 9, a cup rim edging device 2, a roller-type glazing device 3, a turning device 4 and a glaze stirring device 5, the cup rim edging device 2, a roller The type mouth glaze device 3, the turning device 4 and the glaze material stirring device 5 are distributed along the said circular conveying line 9.

[0039] An annular glazing line of this embodiment is applied in the production of ceramic cups. The annular conveying line 9 is used to transport the body 8 to be glazed to each station for processing. Therefore, the edge of the cup is ground The device 2, the roller-type mouth glaze device 3, the turning device 4 and the glaze stirring device 5 are arranged to be distributed along the circular conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com