Fully-automatic ceramic green body processing technology and device

A technology of processing device and processing technology, which is applied in the field of ceramic product processing, can solve the problems affecting the quality of finished products, the size of porcelain blanks, and the porcelain blanks are not round, so as to achieve continuity, improve product quality, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

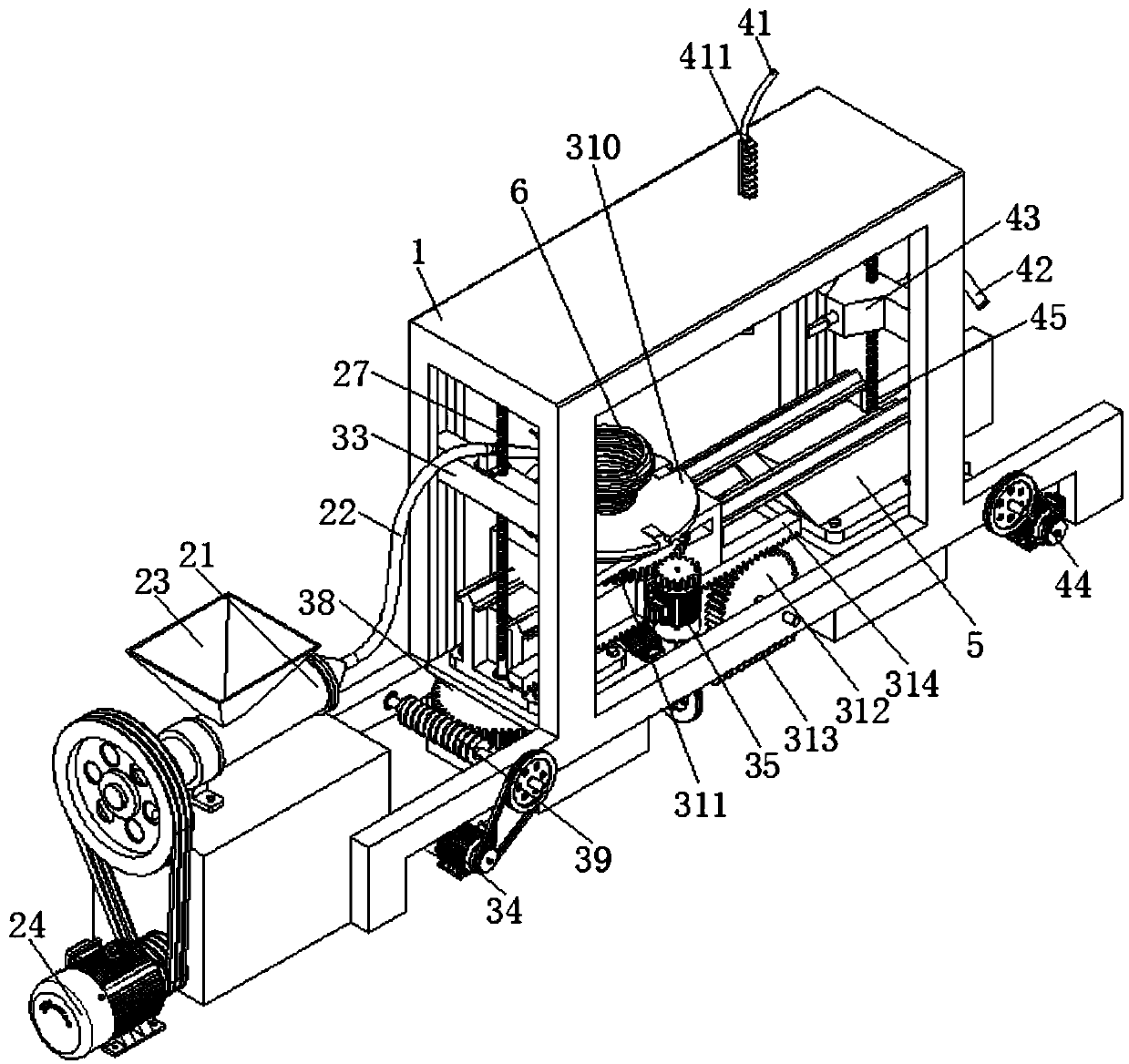

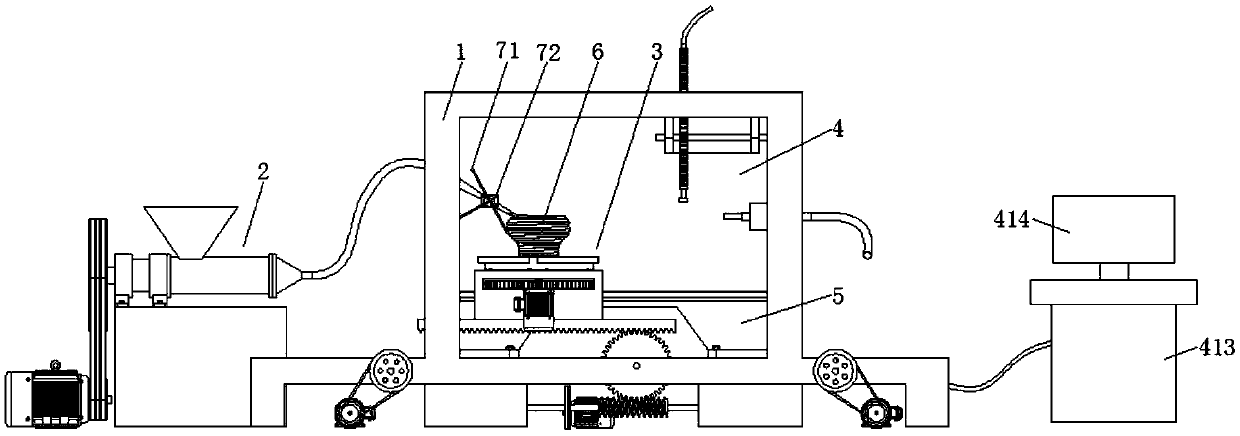

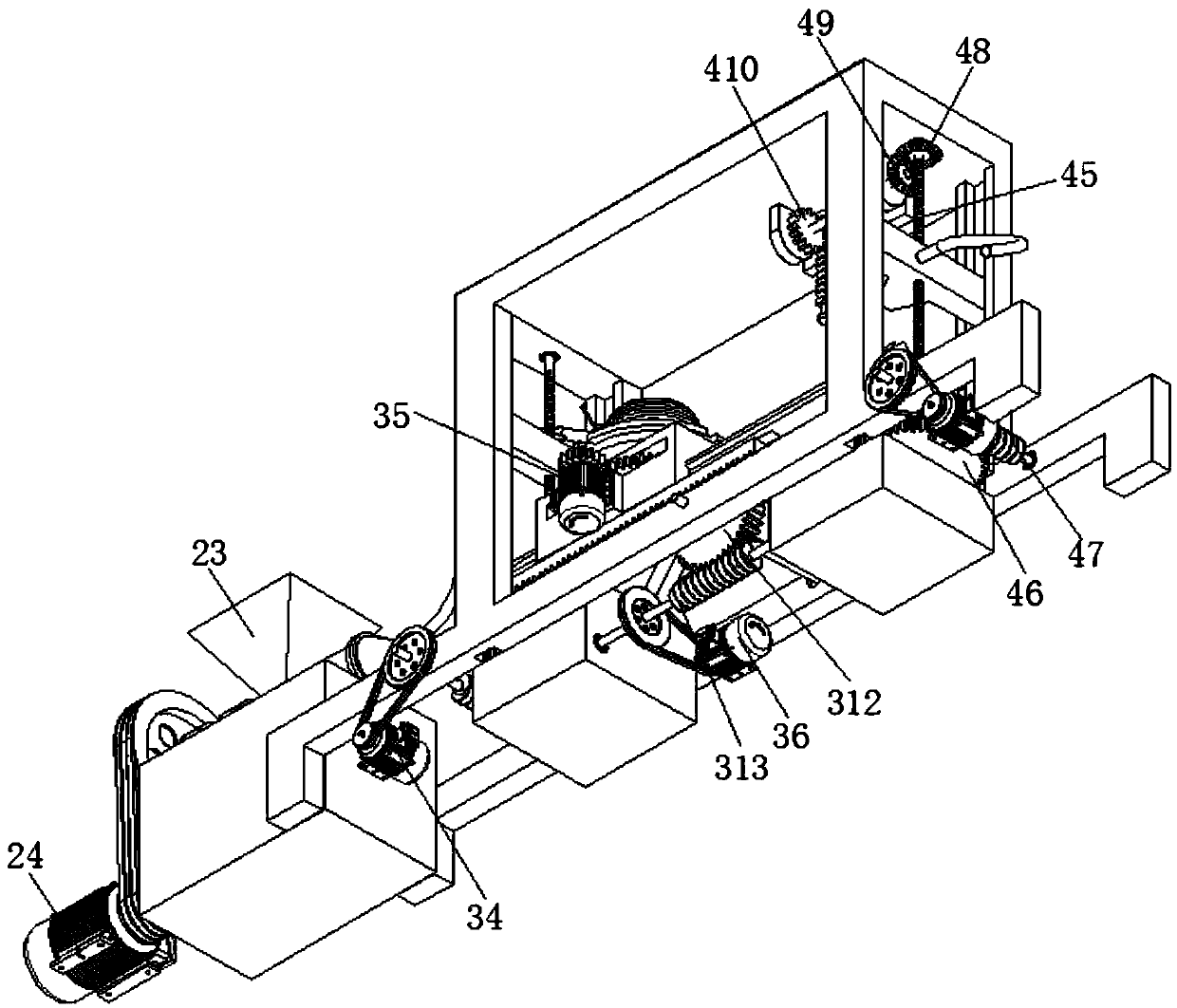

[0033] Such as Figure 1-6 As shown, a fully automatic ceramic billet processing technology includes the following steps:

[0034] Step 1), forming clay strips: extruding and transporting the clay through a compression pump, extruding the clay into a strip structure, and extruding and outputting from the delivery pipe 22 .

[0035] Step 2), the clay strips are formed around the blank: the clay strips produced in step 1) will be continuously extruded from the nozzle 221 of the delivery pipe 22 through the delivery pipe 22, and fall onto the turntable 31. At the same time, the turntable 31 rotates at a constant speed and translates back and forth, and the nozzle 221 of the delivery pipe continues to rise. Then the nozzle 221 of the feed pipe and the turntable 31 have different positional relationships at different times, so that the clay bars produced in step 1) wind around the blank on the turntable 31 to form a semi-finished porcelain body 6 .

[0036] During this process, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com