A ceramic glazing process

A process and ceramic technology, applied in the field of ceramic production equipment, can solve the problems such as the difficulty of keeping the thickness of ceramic pigments consistent, the uneven thickness of ceramic pigments affecting the firing effect, etc., and achieve high glazing efficiency, ingenious design, and improved quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

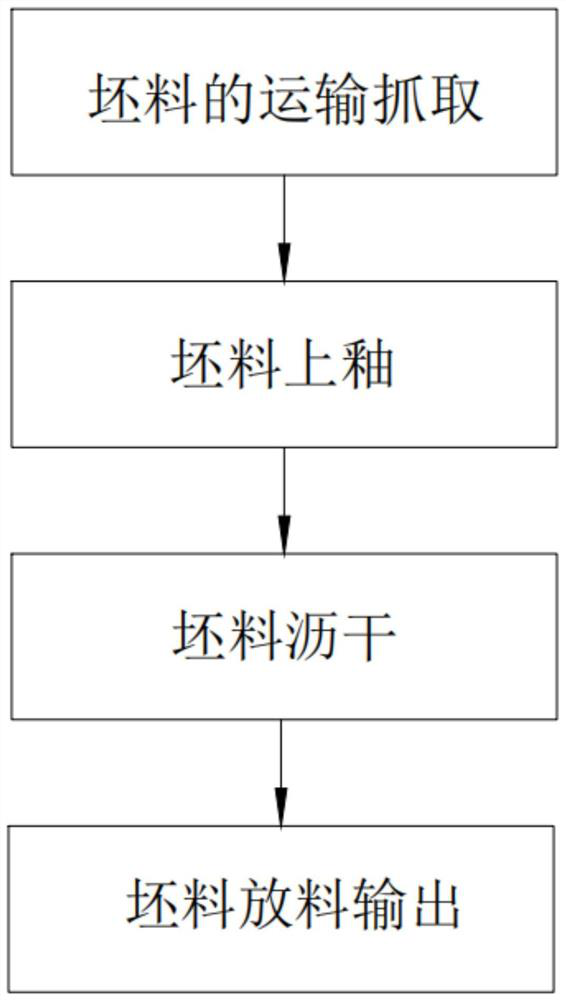

[0040] Such as figure 1 Shown, a kind of ceramic glazing process, comprises the following steps:

[0041] Step 1: transportation and grabbing of the blank, the transportation component a11 transports the blank to be glazed to the bottom of the transportation component b21, and then the transportation component a11 and the transportation component b21 move synchronously, the guide rod 231 is positioned between the limit ring 243 Moving downward under the action, the guide wheel 236 enters the inside of the blank, and in the subsequent moving process, the stop bar 2374 and the contact rod 2371 move down to drive the guide wheel 236 to move outward to support and grab the blank;

[0042] Step 2: The blank is glazed. After step 1, the transportation component b21 carries the blank and moves to the top of the glaze pool 31. During the subsequent movement, the guide rod 231 moves down again, and the blank is immersed in the glaze pool 31 , after that, the rotary assembly 32 drives ...

Embodiment 2

[0055] The present invention also provides a kind of ceramic glazing equipment:

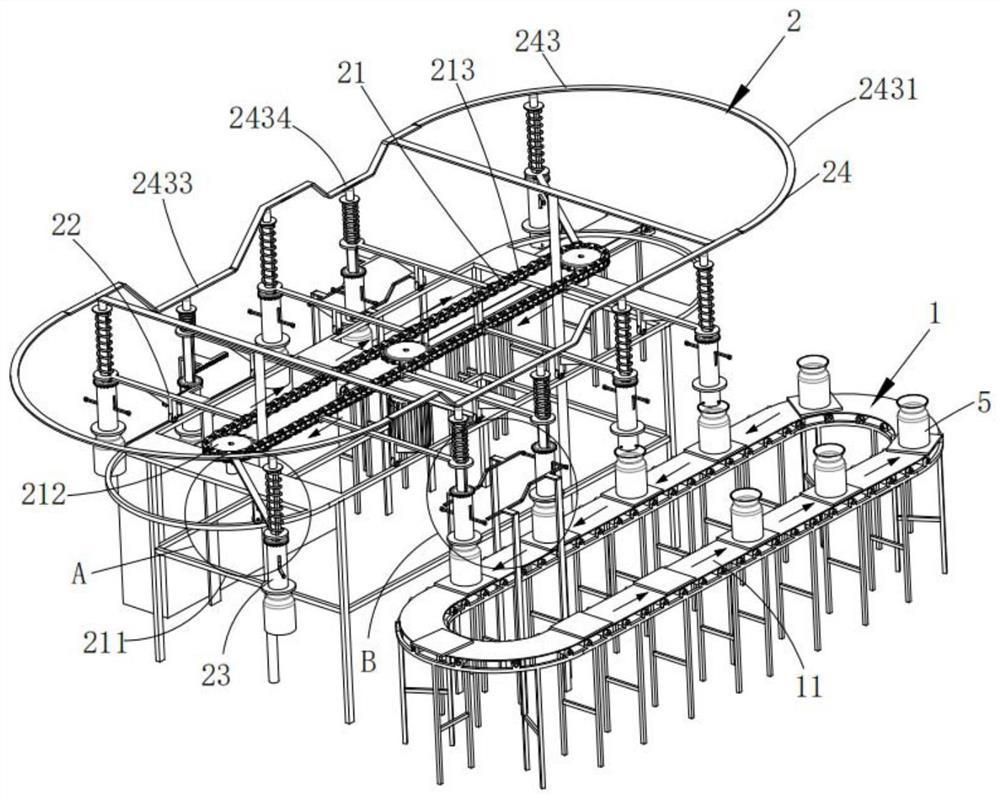

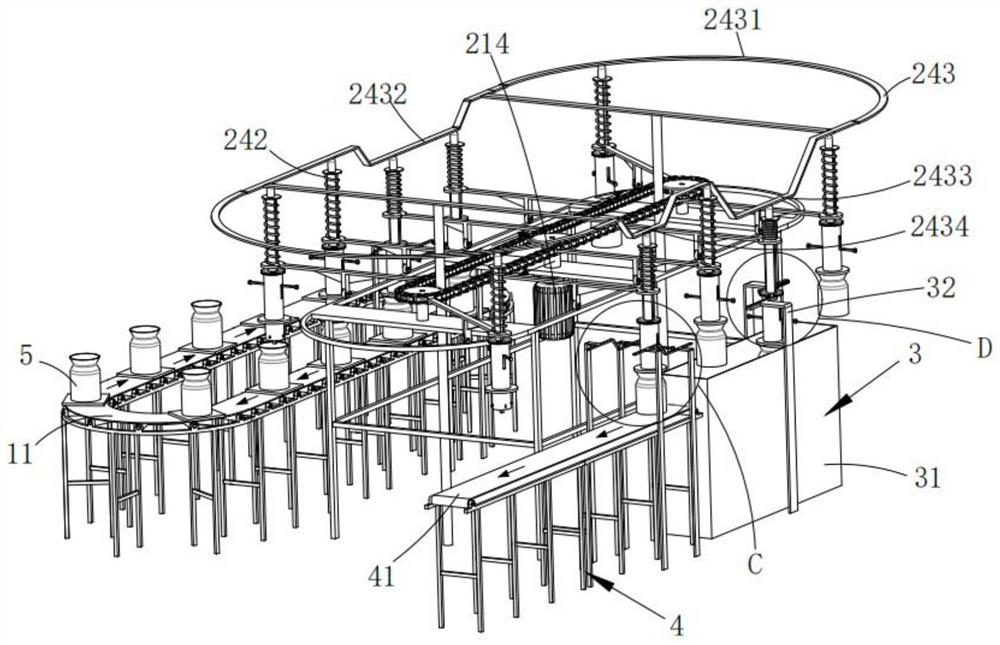

[0056] Such as figure 2 and image 3 Shown, a kind of ceramic glazing equipment comprises:

[0057] Feeding device 1, said feeding device 1 comprising a transport assembly a11;

[0058] The transfer component 2, the transfer component 2 includes a transport component b21, an installation component 22, a grasping component 23 and a control component 24, the transport component b21 is arranged on the side of the transport component a11; the installation component 22 is set by sliding up and down On the side of the transportation component a11, several installation components 22 are arrayed along the delivery path of the transportation component b21, and the installation components 22 pass above the transportation component a11; the grabbing component 23 and the The installation components 22 are provided in one-to-one correspondence, and they are telescopically arranged at the bottom of the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com