Full-automatic atomization glaze spraying device for ceramic ornaments

A fully automatic, atomizing spray technology, used in ceramic molding machines, manufacturing tools, etc., can solve problems such as glaze overflowing and affecting the working environment, and achieve the effect of preventing sputtering, improving the working environment and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

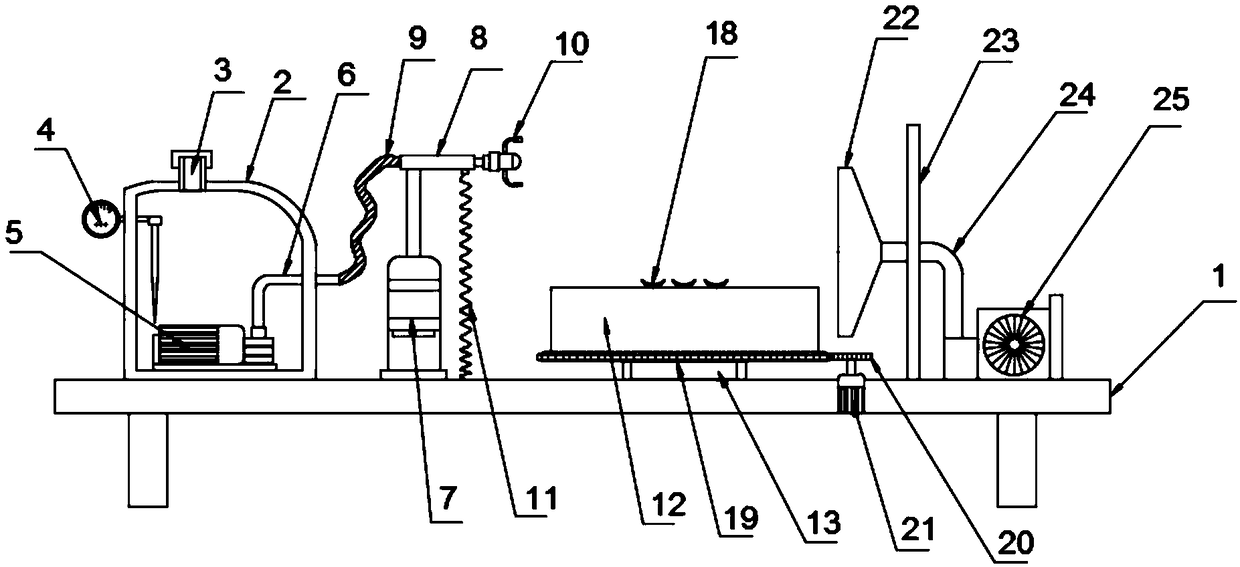

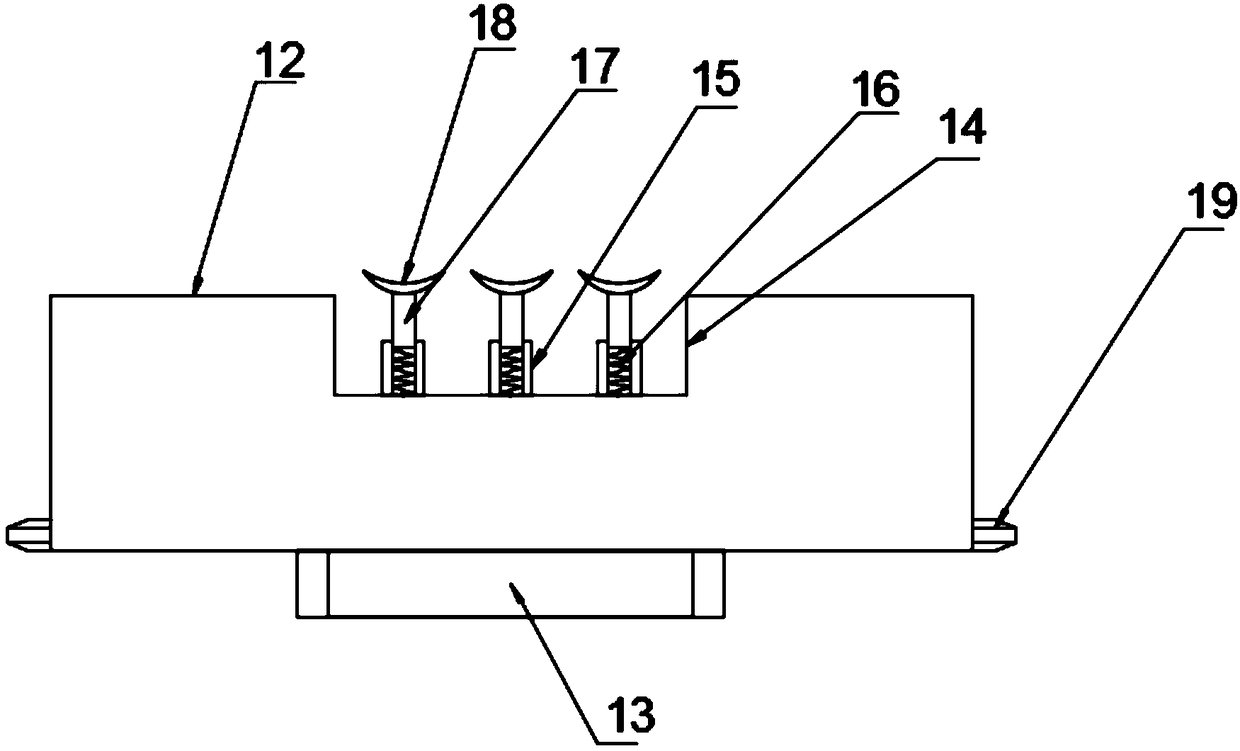

[0024] Such as Figure 1-3 The shown automatic atomization and glaze spraying device for ceramic ornaments includes a workbench 1, a glaze tank 2 is arranged on the workbench 1, a feed pipe 3 is arranged on the top of the glaze tank 2, and the glaze A liquid level gauge 4 is provided on the material tank 2, a pressure pump 5 is provided at the bottom of the inner cavity of the glaze tank 2, a first connecting pipe 6 is provided on the pressure pump 5, and a pressure pump 5 is provided on one side of the glaze tank 2. Electric push rod 7, the top of the electric push rod 7 is provided with a second connecting pipe 8, one end of the second connecting pipe 8 is provided with a connecting hose 9 and the other end is provided with a rotary nozzle 10, and the electric push rod 7 is a The side is provided with isolation cloth 11;

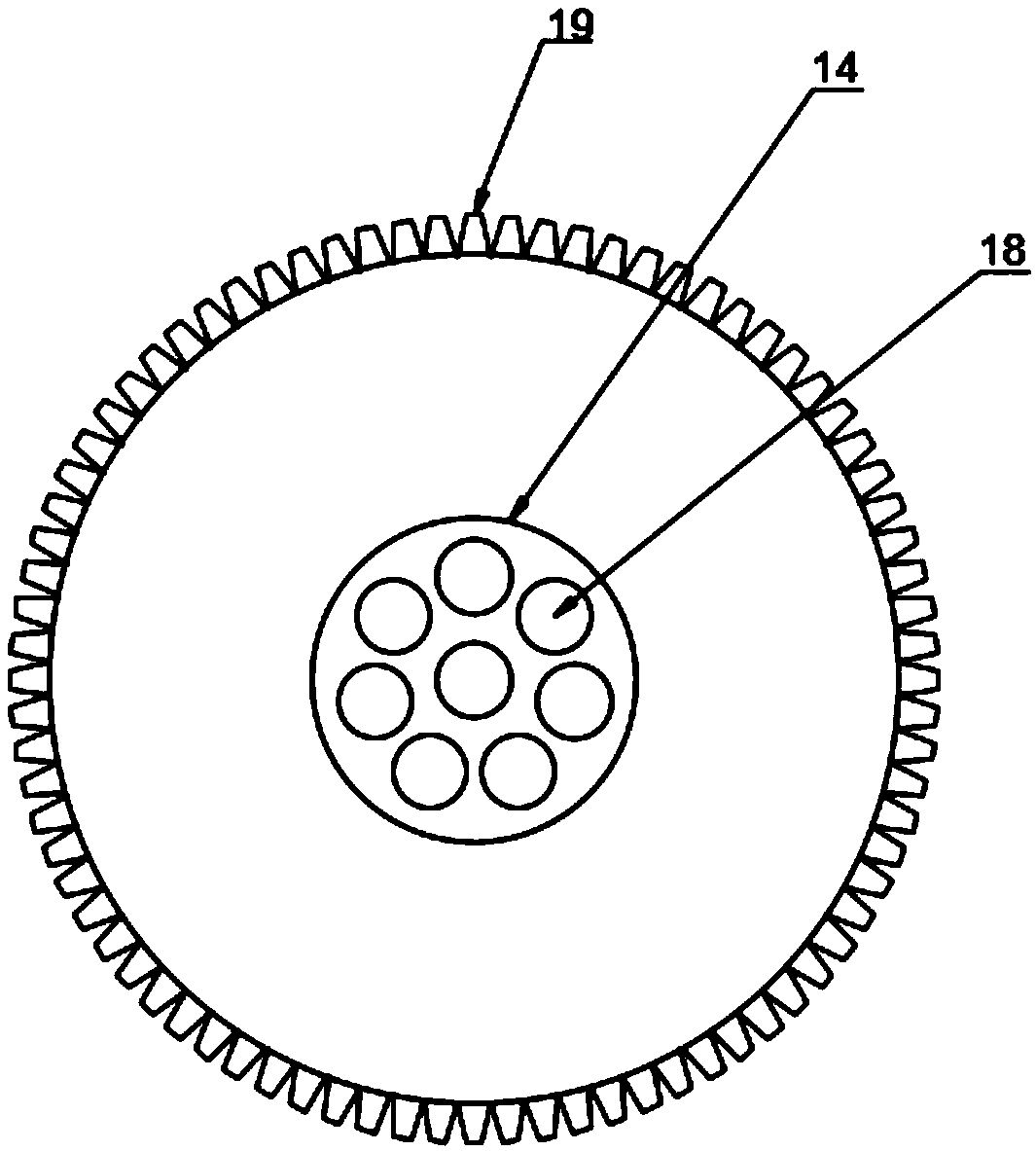

[0025] One side of the insulating cloth 11 is provided with a placement platform 12, the bottom of the placement platform 12 is provided with a turntable...

Embodiment 2

[0028] Such as Figure 1-3 Shown is a fully automatic atomization glaze spraying device for ceramic ornaments, the liquid level gauge 4 is set on the side wall of the glaze tank 2, the top of the feeding pipe 3 is provided with a spiral tube, and the spiral tube is connected to the inlet The material pipe 3 is detachably connected, the first connecting pipe 6 runs through the glaze tank 2 and extends to one side of the glaze tank 2 , and the end of the first connecting pipe 6 is connected to the end of the connecting hose 9 .

[0029] The inner wall of the end of the second connecting pipe 8 is provided with threads, the rotary nozzle 10 is detachably connected to the second connecting pipe 8, the top of the insulating cloth 11 is fixedly connected to the bottom wall of the second connecting pipe 8 and the bottom is connected to the workbench. 1 The top is fixedly connected, the electric push rod 7, the turntable bearing 13, the fixed plate 23 and the vacuum cleaner 25 are all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com