Water pouring device for electroplating travelling crane

A technology for electroplating cranes and electroplating tanks, which is applied in the direction of electrolysis process and electrolysis components, etc. It can solve the problems of affecting the electroplating quality of the workpiece to be plated, the quality of the workpiece is not high, and the water cannot be poured out, so as to avoid the mutual pollution of the electroplating solution and improve the quality of electroplating. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

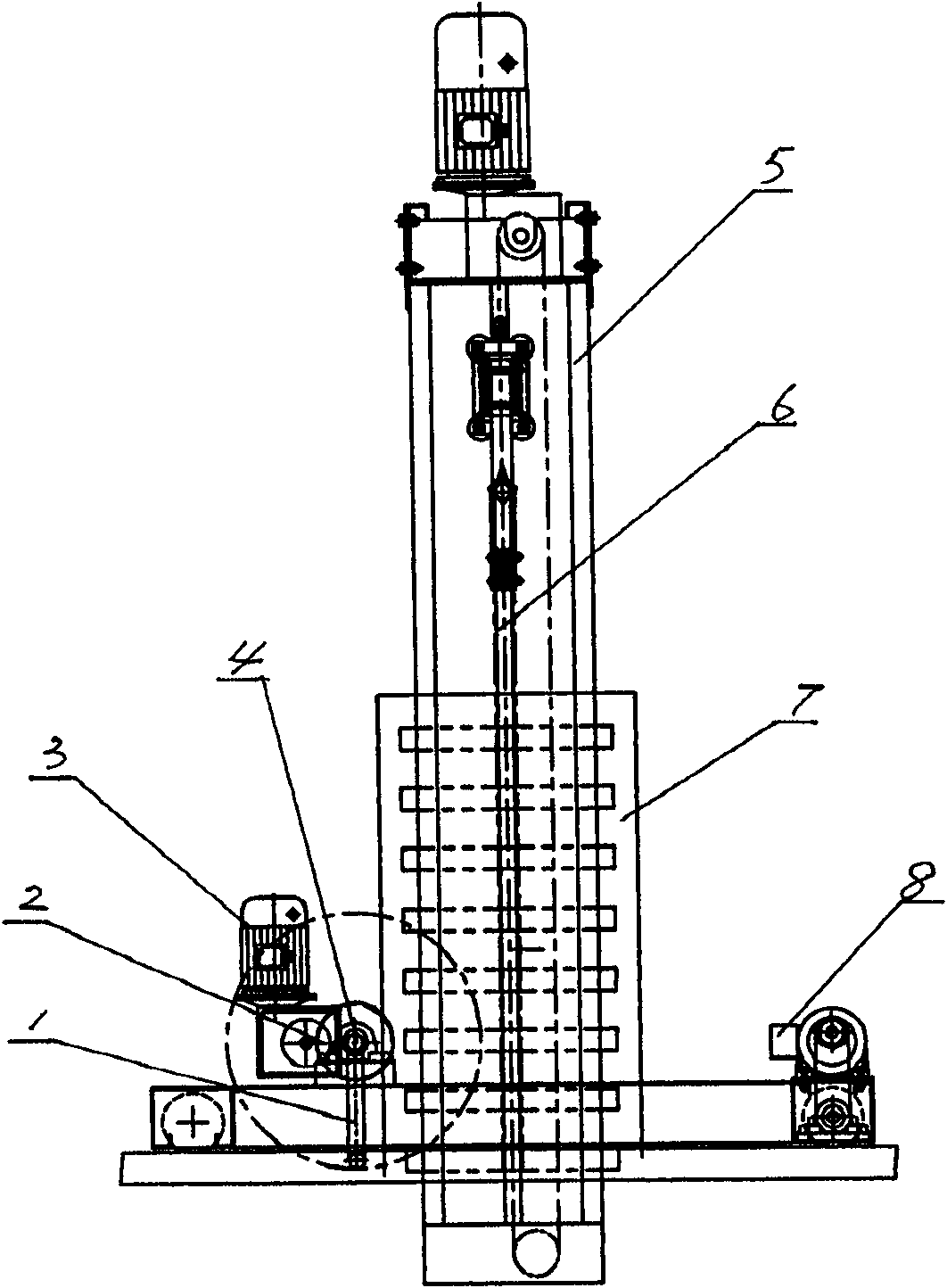

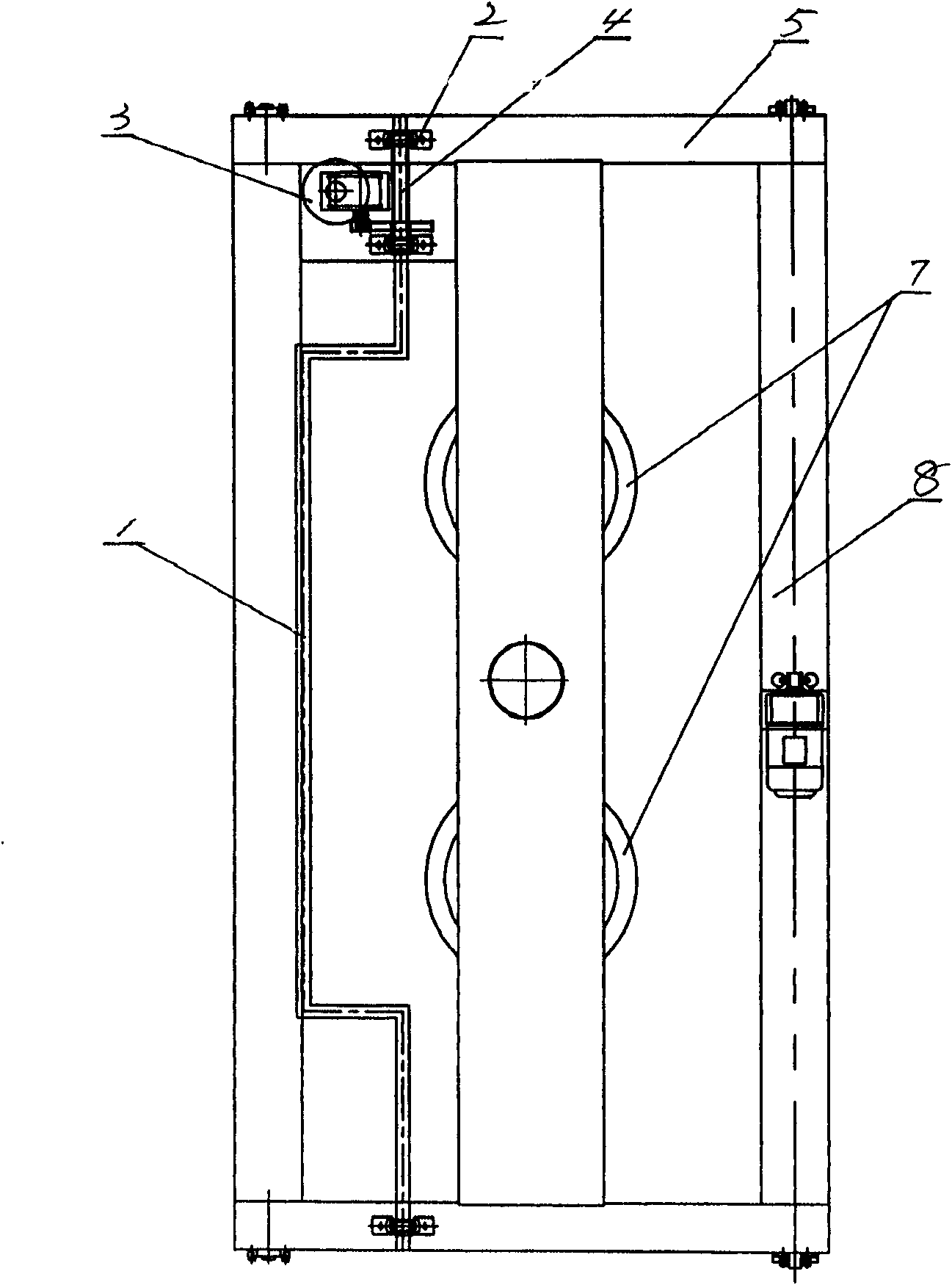

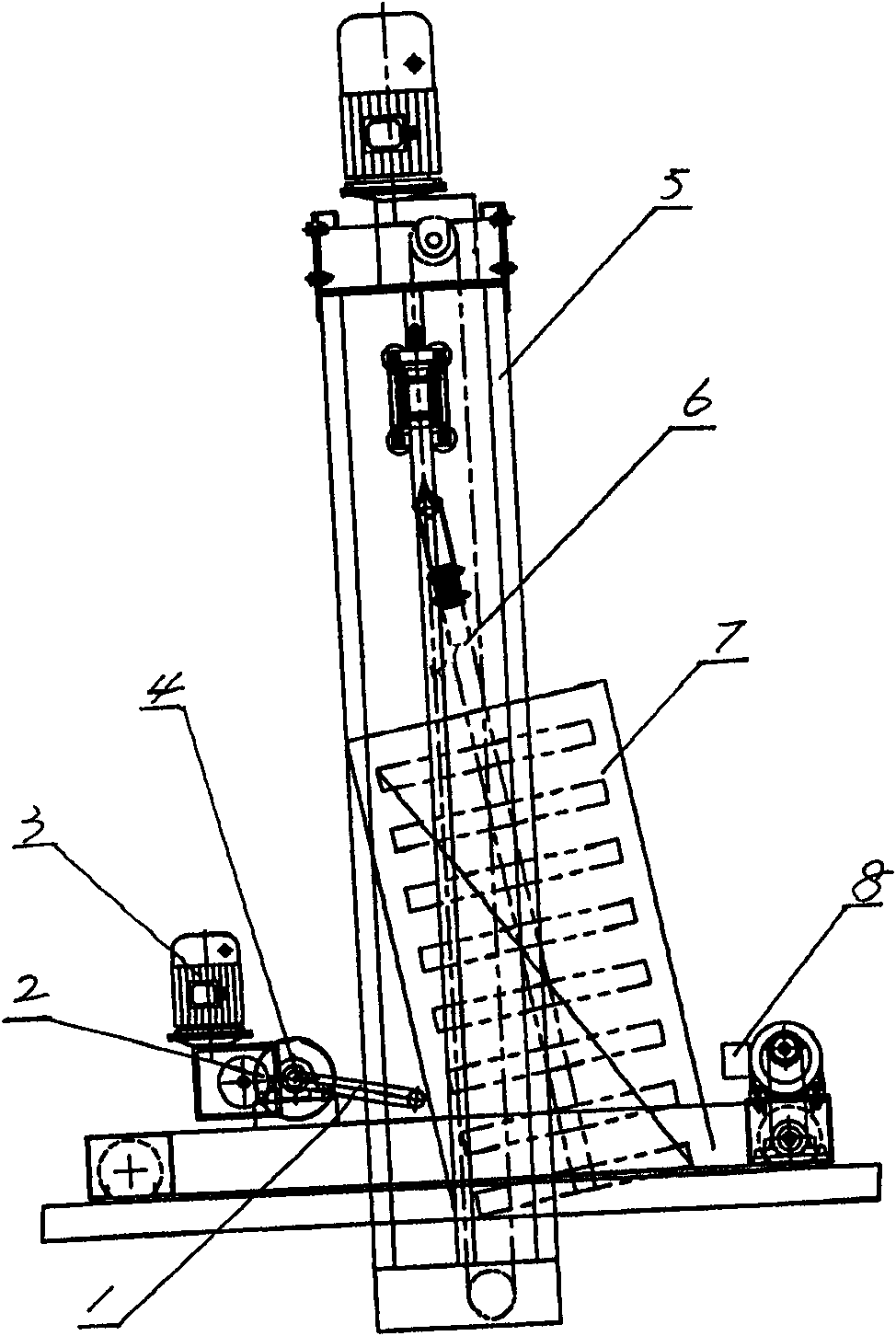

[0011] Such as figure 1 with figure 2 As shown, the electroplating vehicle pouring device of the present invention includes a door frame 5, which is installed on the electroplating tank. The door frame 5 is provided with a fixture 7 for placing the workpiece to be plated. There are two clamps 7, both of which are basket-type clamps, and they are suspended on the top beam of the door frame 5 by means of hangers 6. The top of the hanger 6 is hinged with the top of the door frame 5, and the hanger 6 can swing in the door frame 5 along its hinge point with the door frame 5, see image 3 . There are shaft seats 2 on the same side of the two vertical walls of the door frame 5, and there are coaxial shaft holes on the two shaft seats. There is a connecting rod 4 between the two shaft seats 2, and the two ends of the connecting rod 4 are respectively rotatable and inserted into the corresponding A power mechanism 3 is connected to one end of the connecting rod 4 in the shaft hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com