Injection pressure monitoring method of full electric injection molding machine

An injection pressure and injection molding machine technology, applied in the field of injection pressure monitoring, can solve problems such as damage to mold equipment, inability to guarantee normal production of injection molding machines, and major accidents, and achieve the effect of preventing damage to molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] An injection pressure monitoring method for an all-electric injection molding machine, comprising the following steps:

[0023] (1) Initial setting of injection pressure monitoring value

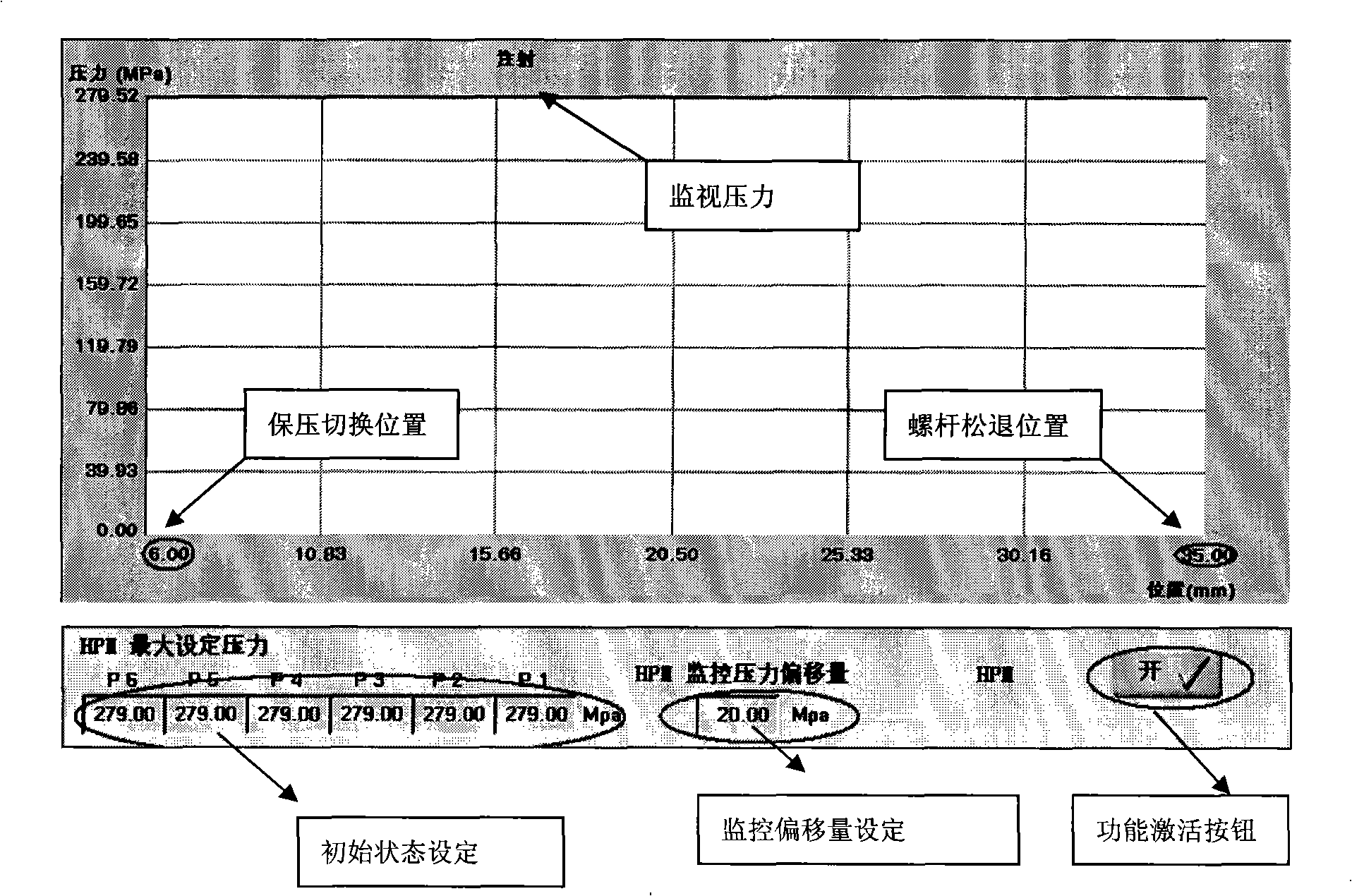

[0024] Such as figure 1 is the initial state diagram for injection pressure monitoring, where:

[0025] (1) Line 5 is the initial pressure monitoring curve for injection pressure monitoring. The initial curve can be changed arbitrarily. In order not to affect the normal process, it is generally set to the maximum pressure of the machine system;

[0026] (2), "Pressure holding switching position" and "screw loosening position" are automatically collected from the customer's process settings, and automatically calculated and divided into 6 equal parts;

[0027] (3) "Monitoring pressure offset" is an artificial setting value, in order not to affect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com