Upstream injection sucker-rod pump same well mining and injecting device

A technology of production and injection in the same well with a rod pump, which is applied to the components of the pumping device for elastic fluids, pumps with flexible working elements, pumps, etc. rod bending, injection difficulties, etc., to achieve accurate and effective production-injection flow ratio, control the production-injection flow ratio, and avoid malfunctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

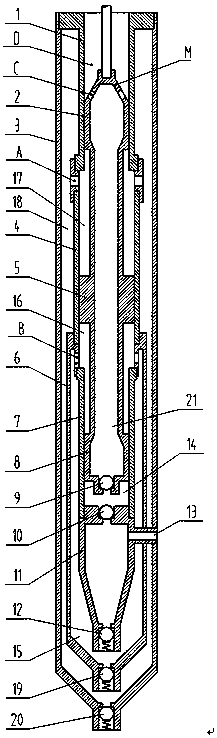

[0027] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0028] as attached figure 1 As shown, the moving assembly M of the swabbing part includes an upper plunger 2, a middle plunger 5, a lower plunger 8, and a one-way check valve 9 that opens to the inside of the moving assembly; the upper plunger 2, the middle plunger 5, the lower plunger The plungers 8 are connected in sequence, and the inner spaces communicate to form a cavity 21, and the check valve 9 is arranged at a proper position inside the moving assembly. A hole C is opened on the top of the moving assembly, and the hole C connects the plunger cavity 21 inside the moving assembly with the inner space D of the working string in the upper part of the whole device. In this embodiment, the outer diameter specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com