Fuel injection control method and system for four-stroke electronic-control single cylinder diesel

A technology of fuel injection and control method, which is applied in fuel injection control, electrical control, engine control and other directions to achieve cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

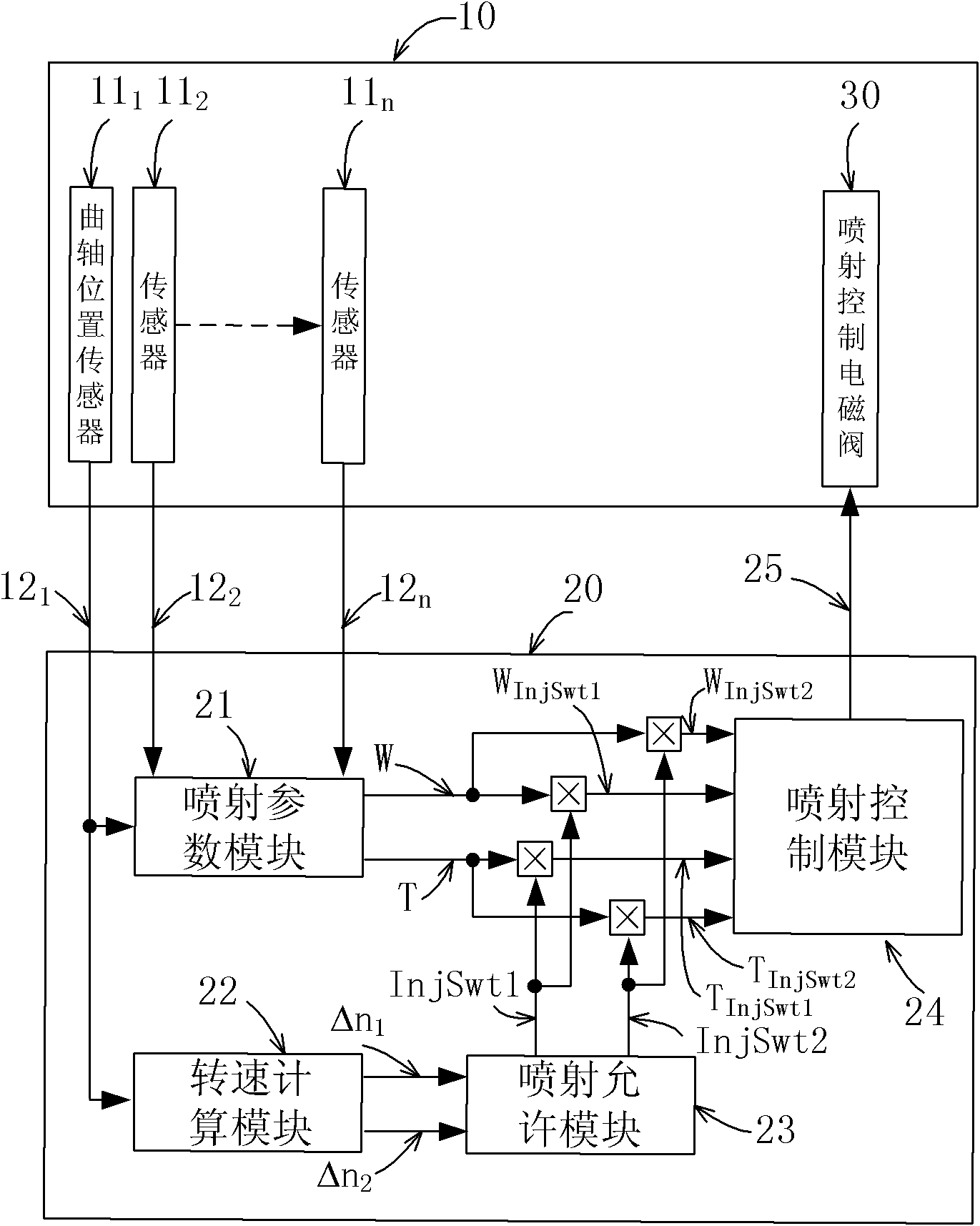

[0031] Such as figure 1 As shown, the four-stroke electronically controlled single-cylinder diesel engine fuel injection control system of the present invention is functionally divided into three parts, including signal transmission, control processing and command execution. The signal transmission is completed by various sensors in the engine 10, and these sensors must include the crankshaft position sensor 11 1 , and may include a water temperature sensor 11 2 , intake air pressure sensor 11 n etc., but must not include the camshaft position sensor. Each sensor 11 1 、11 2 ... 11 n Signals 12 representing the corresponding state of the engine are respectively issued 1 、12 2 ... 12 n .

[0032]The control processing of the signal depends on an engine management module 20 preset in the locomotive processor to complete. The engine management ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com