Automatic precision loading device

A sample adding device, automatic technology, applied in the direction of instruments, biological testing, analyzing materials, etc., to achieve the effect of simple structure, reduce transmission error and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

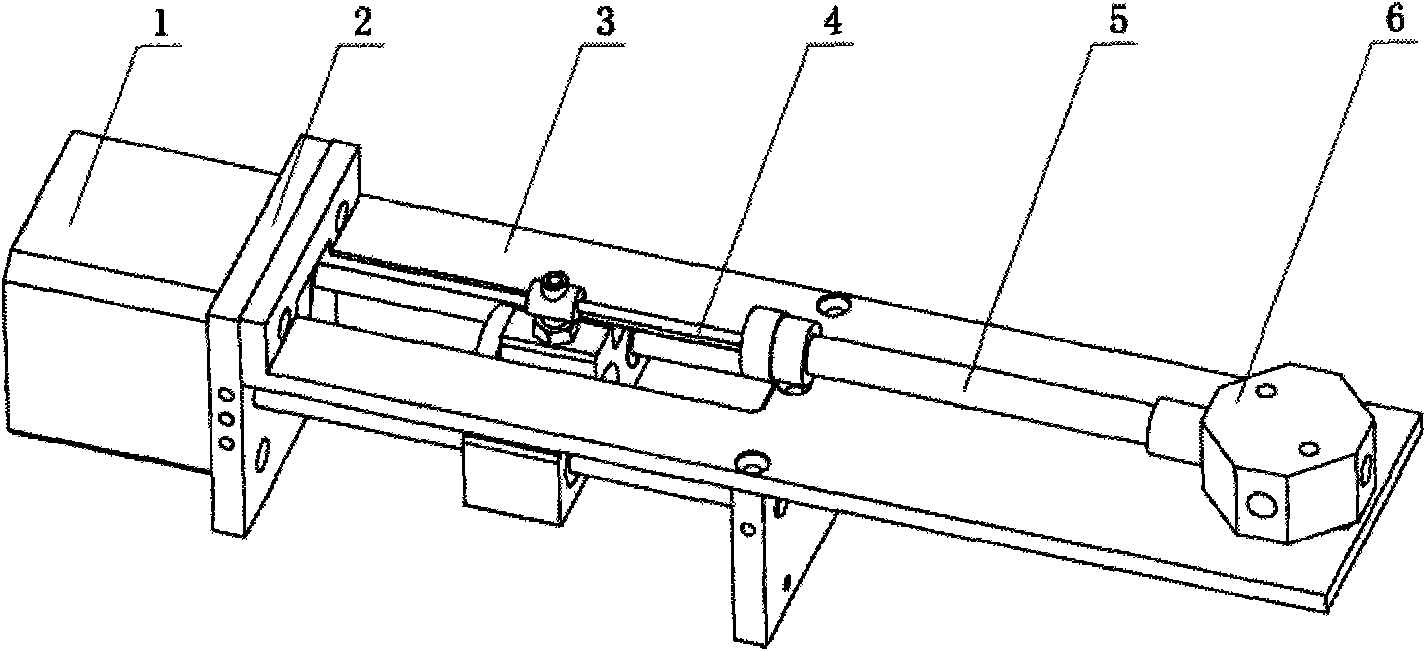

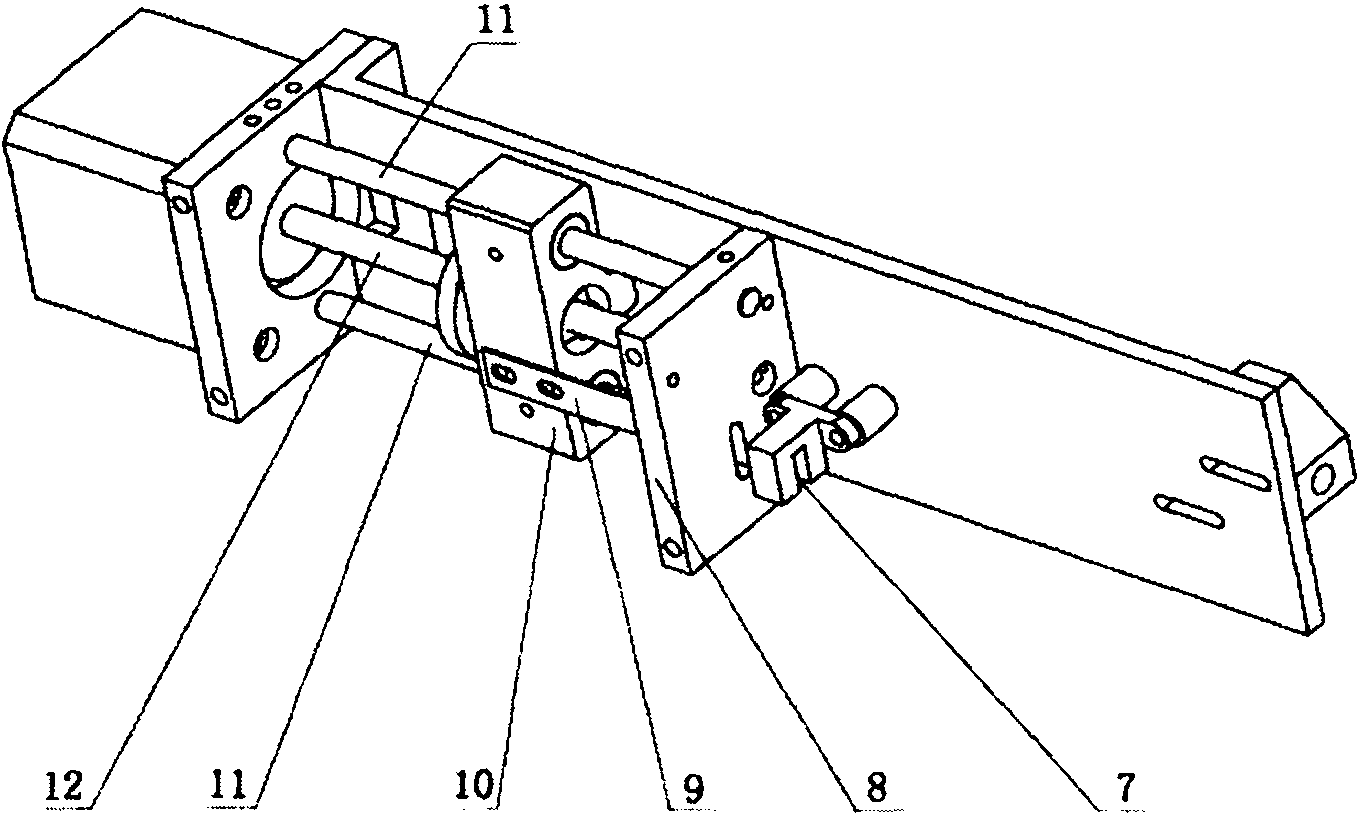

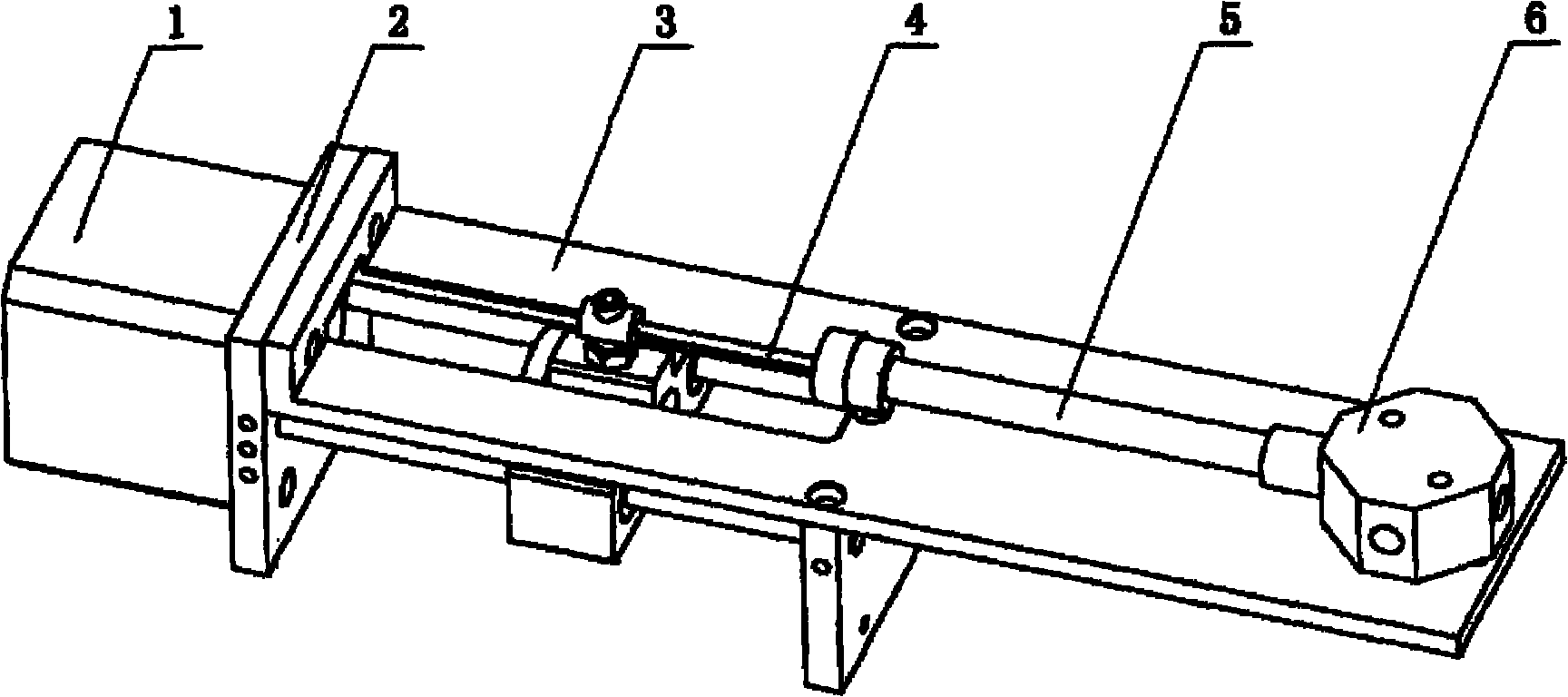

[0024] Specific embodiments of the present invention are described in further detail below in conjunction with accompanying drawing:

[0025] The motor clamping plate 2, the motor front plate 3, the motor baffle plate 8, and the two optical axis guide rails 11 of the present invention are closely matched and connected to each other to form the support structure of the entire sample loading device; the stepping motor 1 is connected On the motor clamp 2, the precision screw 12 matched with the stepping motor 1 passes through the motor clamp 2 and the motor baffle 8, and the drive nut of the screw 12 is fixed on the injection slider 10; the injection slider 10 is equipped with a linear bearing The two guide holes are matched with the optical axis guide rail 11. Driven by the stepping motor 1, they can slide smoothly and freely along the optical axis guide rail 11 between the motor clamp 2 and the motor baffle 8; the injection slider 10 is equipped with an optocoupler 9, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com