Motor-pulled tape tension control mechanism

A technology of tension control mechanism and tape, which is applied in the direction of thin material processing, conveying filamentous materials, transportation and packaging, etc., which can solve the problems that the tension change cannot be adjusted in time, the friction force of the cylinder and potentiometer is large, and the tension of the battery tape Unbalanced and other problems, to achieve the effect of small friction, uniform tension control, and small motion inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

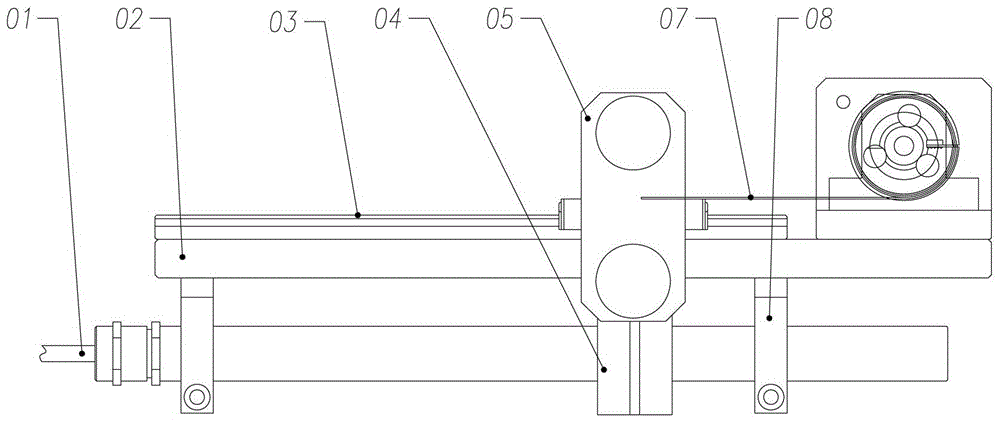

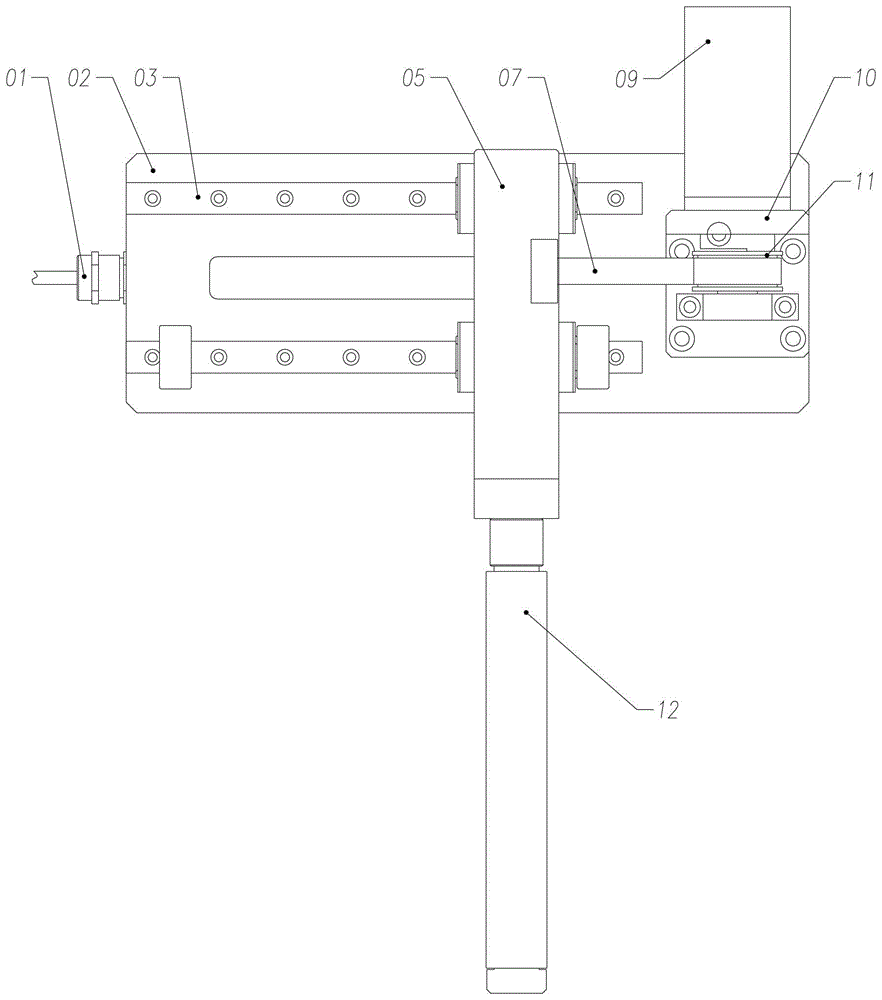

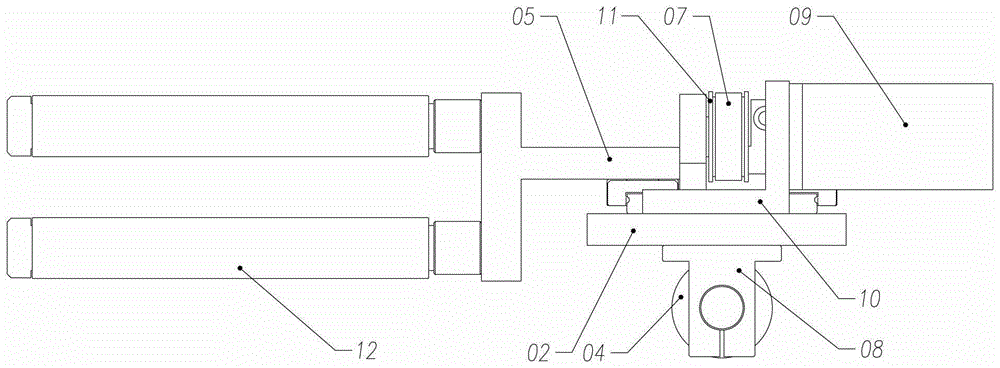

[0017] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0018] The motor-pulled strip tension control mechanism of the present invention includes a sliding line rail fixed on the bottom plate 02, for the floating roller 12 to slide linearly, and is located in the tension buffer zone of the strip; the floating roller 12 installed on the sliding line rail 03, It is used to tension the material belt in the tension buffer zone; the tension motor 09 installed on the bottom plate 02 pulls the floating roller 12 to move linearly along the sliding line rail 03 through the flexible transmission part, and is used to maintain the tension of the material belt; the position sensor uses It is used to detect the position value of the floating roller 12 on the sliding line rail 03 and transmit it to the control system of the equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com