A control method of crop handling based on arduino single chip microcomputer

A control method and crop technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of increasing the cost and complexity of the control system, the automation is not well realized, and the performance of the motion control card is unstable, so as to promote Promote and apply, promote the whole process of mechanization and automation, and have distinctive and innovative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

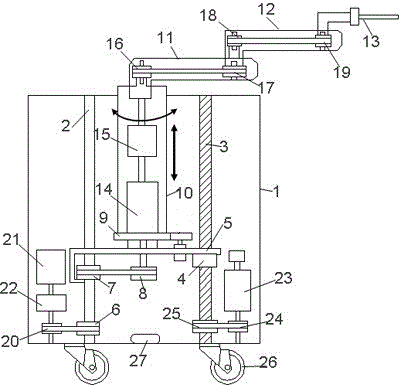

[0045] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

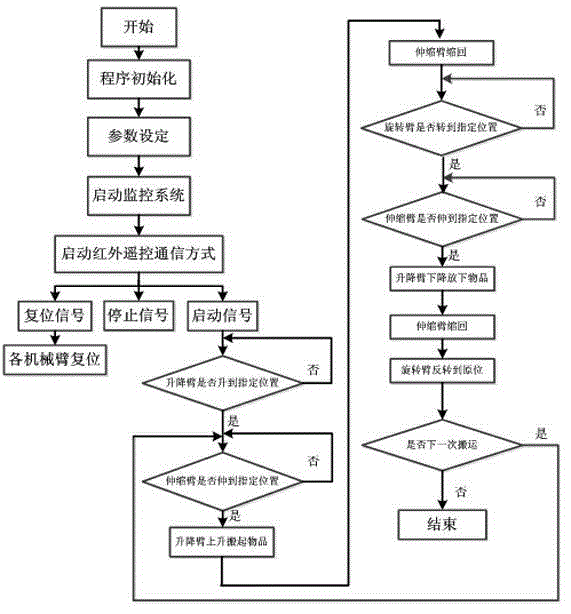

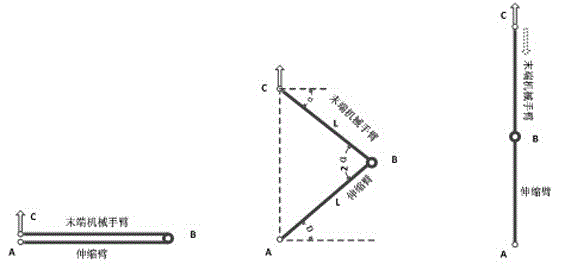

[0046] refer to Figure 1 to Figure 10 , the present invention relates to a kind of control method based on the crop handling of Arduino single-chip microcomputer, comprises handling device, and described handling device comprises lift arm, telescopic arm, rotating arm execution part, carries out as follows:

[0047] 1) Initialization, parameter setting, and start the monitoring system and infrared remote control communication mode;

[0048] 2) Detect whether the reset signal, stop signal, and start signal are in a normal state, wherein the reset signal is used to drive each execution robot arm to reset;

[0049] 3) After the start signal is sent out, the lifting arm starts to work until it reaches the designated position and then stops working;

[0050] 4) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com