A crop handling device based on arduino single chip microcomputer

A technology of crops and single-chip microcomputers, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of increasing the cost and complexity of the control system, poor automation, unstable performance of motion control cards, etc., to promote promotion and application, promoting the whole process of mechanization and automation, with distinctive and innovative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

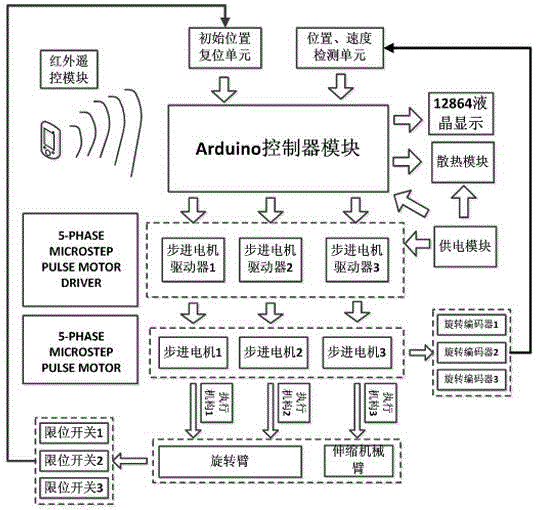

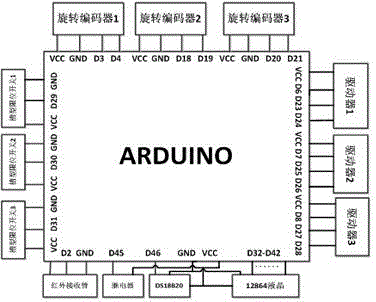

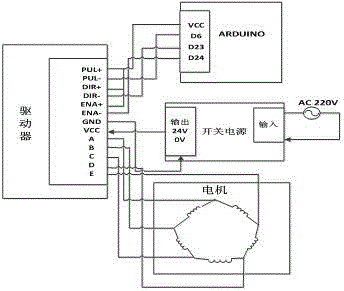

[0035] refer to Figure 1 to Figure 9, the present invention relates to a crop handling device based on an Arduino single-chip microcomputer, comprising two parts of a mechanical mechanism and a control circuit, the mechanical mechanism includes a frame 1, and one side of the frame is longitudinally provided with a The spline shaft 2, the other side of the frame is longitudinally provided with a screw 3, the screw is sleeved with a lift nut 4, the lift nut is fixedly connected with a spline shaft slidingly connected Lifting platform 5, the lower part of the lifting platform located at the side of the spline shaft is provided with a U-shaped groove, the lower part of the spline shaft is fixedly connected with a second synchronous pulley 6, and the middle part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com