Operation Method of Discrete Stepping Control for Permanent Magnet Brushless DC Motor

A permanent magnet brushless DC, operating method technology, applied in motor generator control, electronic commutation motor control, control system and other directions, can solve the problems of difficult positioning and low positioning accuracy, achieve accurate positioning and improve position resolution , the effect of high-precision positioning control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

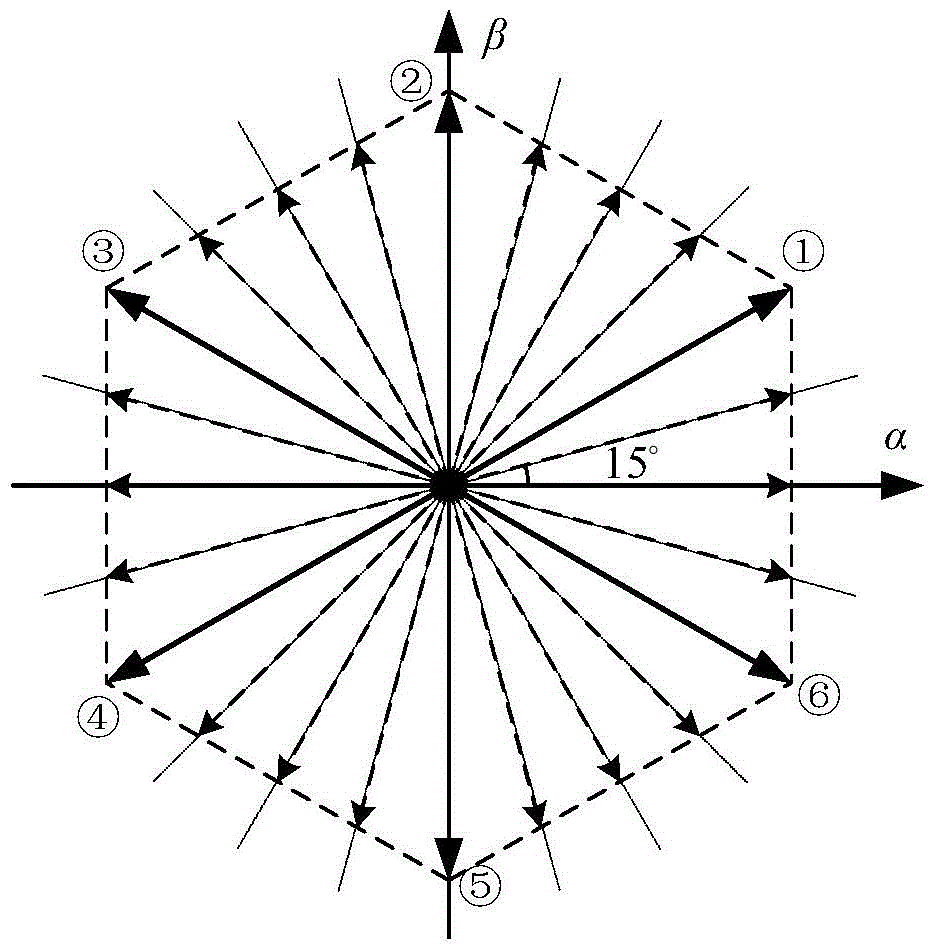

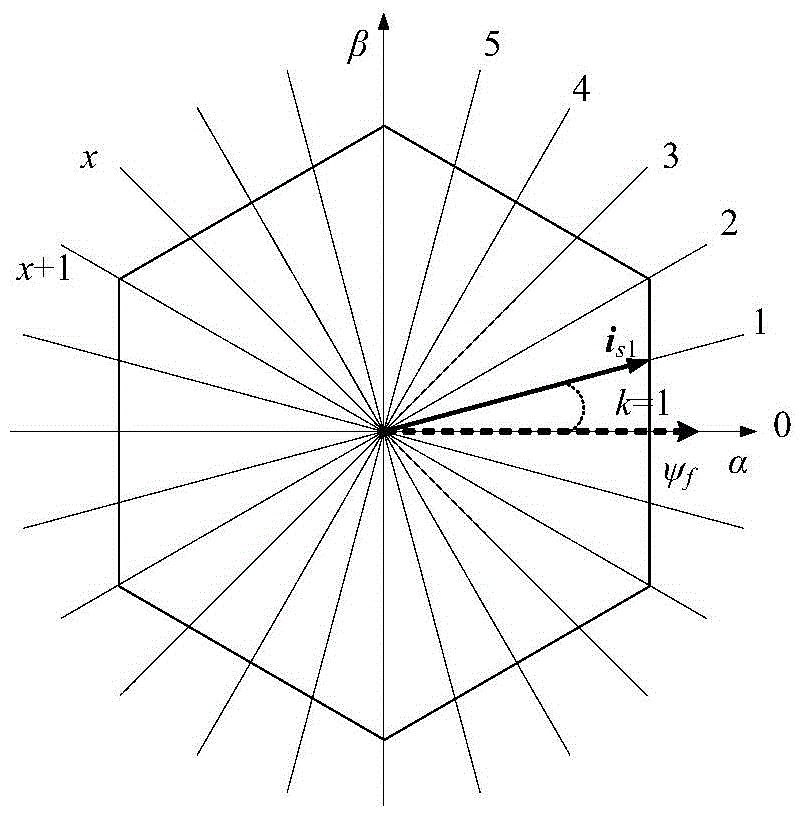

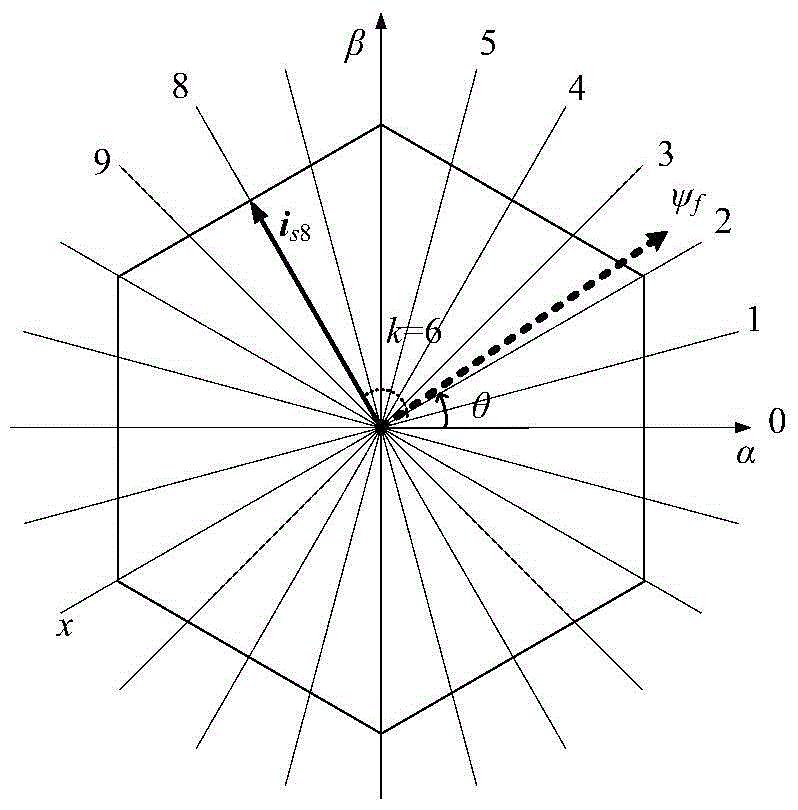

Method used

Image

Examples

Embodiment 1

[0054] A. The device and operation used in the operation method:

[0055] The device used in the operation method of the discrete step control of the permanent magnet brushless DC motor includes a DSP control module 1, a power circuit 2, a permanent magnet brushless DC motor 3, an encoder position detection module 4 and an input power supply module 5, wherein the input power supply Module 5 supplies power for DSP control module 1, power circuit 2 and encoder position detection module 4, DSP control module 1, power circuit 2, permanent magnet brushless DC motor 3 and encoder position detection module 4 are connected with wires in sequence, and the encoding The encoder position detection module 4 is connected to the DSP control module 1 with wires; first, the input power supply module 5 supplies power to the DSP control module 1, the power circuit 2 and the encoder position detection module 4, and then the encoder position detection module 4 detects the permanent magnet The init...

Embodiment 2

[0072] In this embodiment, within a cycle period, the three-phase current is discrete according to the operation method of the present invention, and the number of cycles is b H = 24, when the current vector is 1 step ahead, the motor is controlled to run step by step, I m =5A, give the current vector one step forward every 0.1s, observe the motor A phase current waveform (current-time curve) (see Figure 6 (1)), the rotor stepping operation position graph (position-time curve) (see Figure 6 (2)) and the output electromagnetic torque figure (electromagnetic torque-time curve) (referring to Fig. 6 (3)), as can be seen from the result, the present embodiment uses the B operation method according to embodiment 1, phase current ( Figure 6 (1)) presents a stepped trapezoidal wave, and the initial electromagnetic torque of each step (see Figure 6 (3)) presents periodic fluctuations due to position changes, and the rotor operates under the action of the electromagnetic torque. When t...

Embodiment 3

[0074] In this embodiment, within a cycle period, the three-phase current is discrete according to the above-mentioned discrete step control, and the number of cycles is b H =24, setting motor mechanical speed 125r / min, the maximum current vector amplitude is I m =5A, adopt the advance step number k=6 to control, calculate the corresponding current vector according to the B operation method of embodiment 1, calculate and observe the A phase current-time curve obtained under the constant speed running state of the motor (referring to Fig. 7 ( 1)), the rotor step running position-time curve (see Figure 7 (2)) and the output electromagnetic torque-time curve (see Figure 7 (3)), the electromagnetic torque has certain regular fluctuations, but the up and down fluctuations It does not exceed 0.5Nm, and its change process is gentle. The electromagnetic torque provided provides a relatively stable load capacity in practice, can maintain the smooth operation of the motor, and is easy t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com