Patents

Literature

44 results about "Cyclic number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cyclic number is an integer in which cyclic permutations of the digits are successive integer multiples of the number.

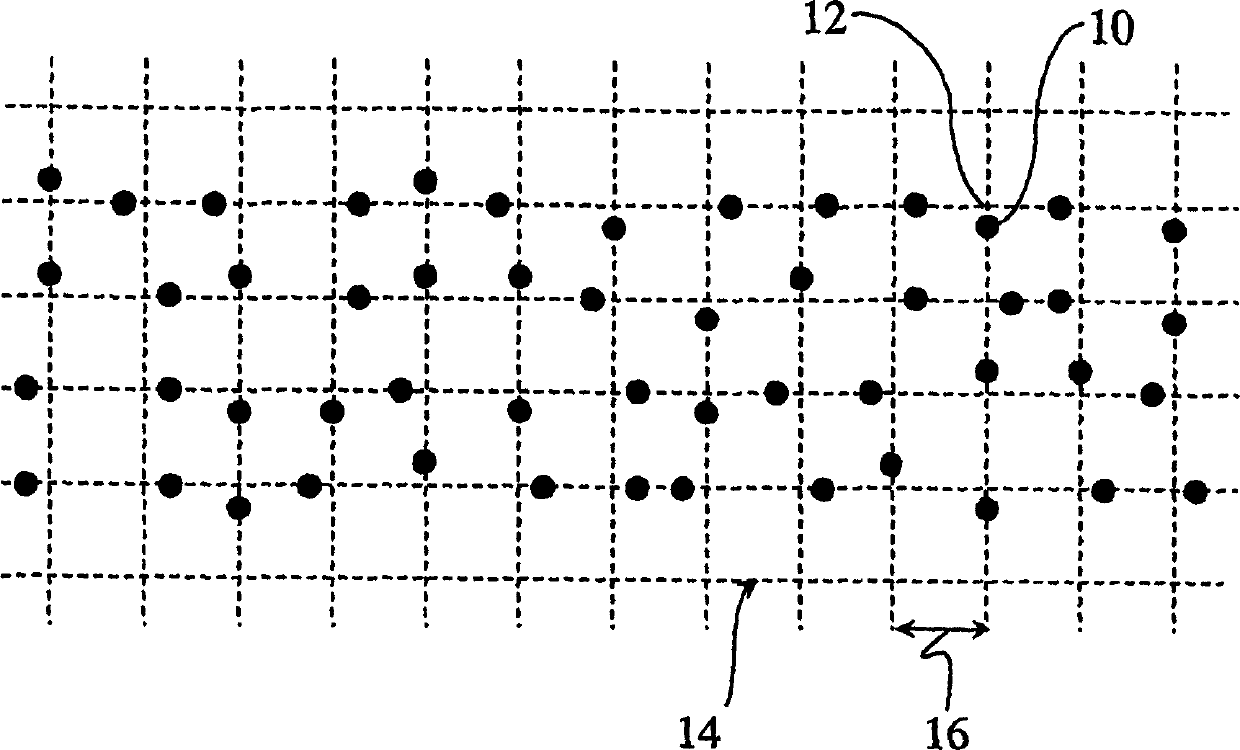

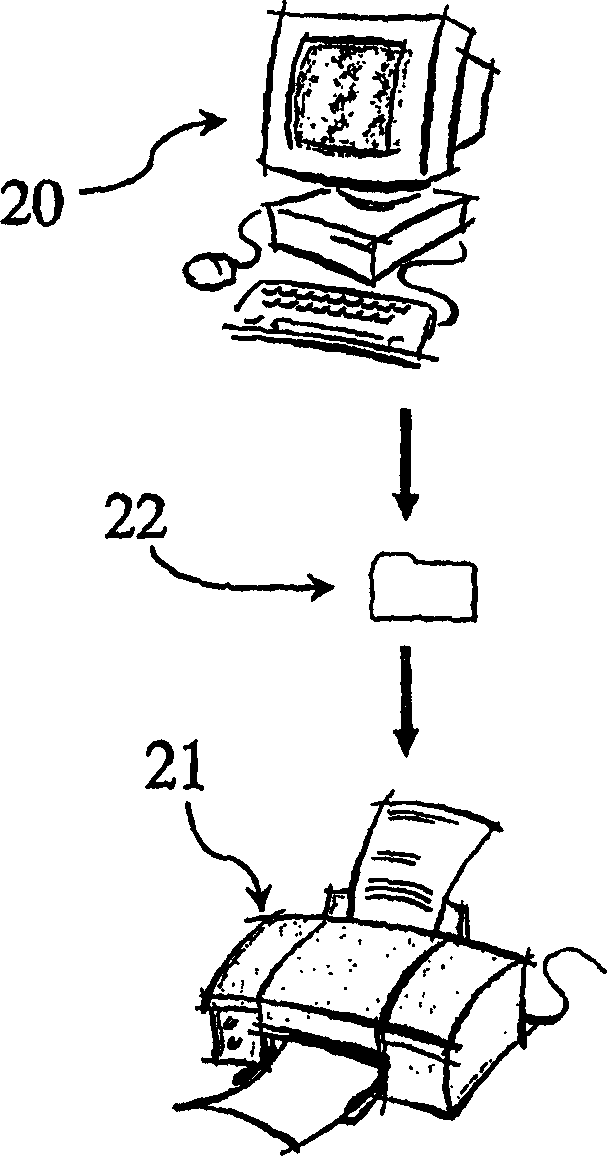

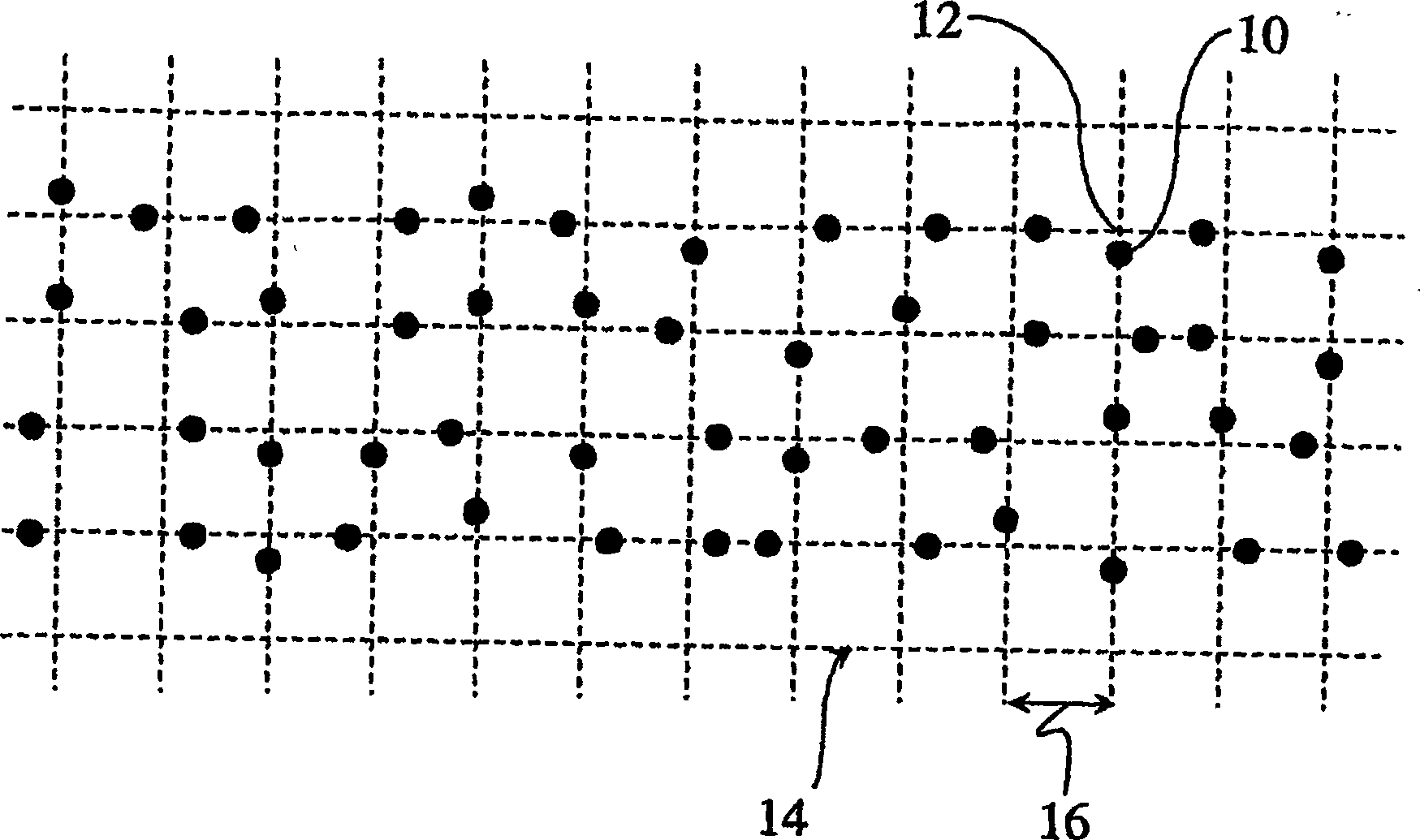

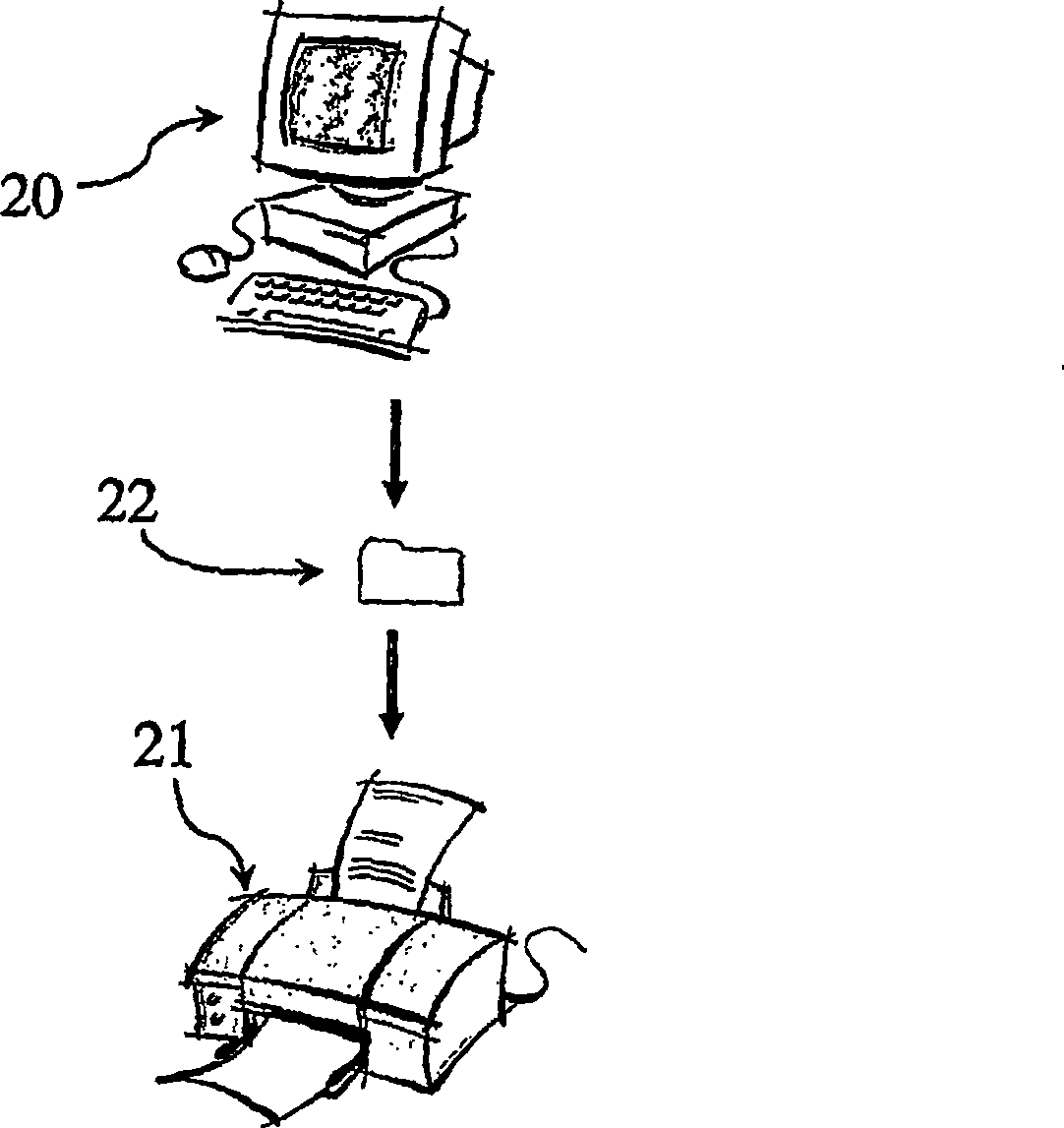

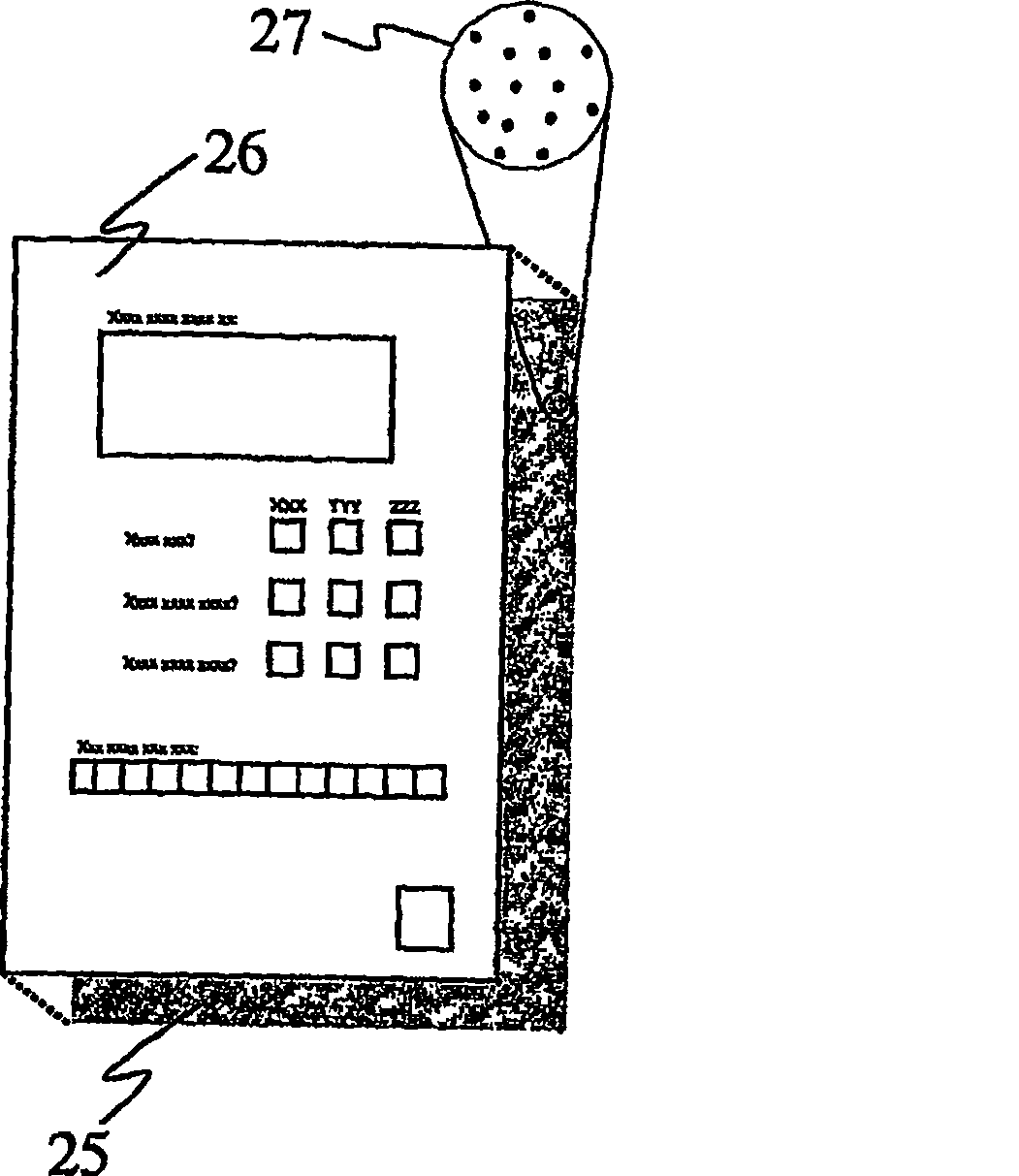

On-demand printing of coding patterns

InactiveUS7753283B2Input/output for user-computer interactionCharacter printing data arrangement from carrierCoding blockPhase difference

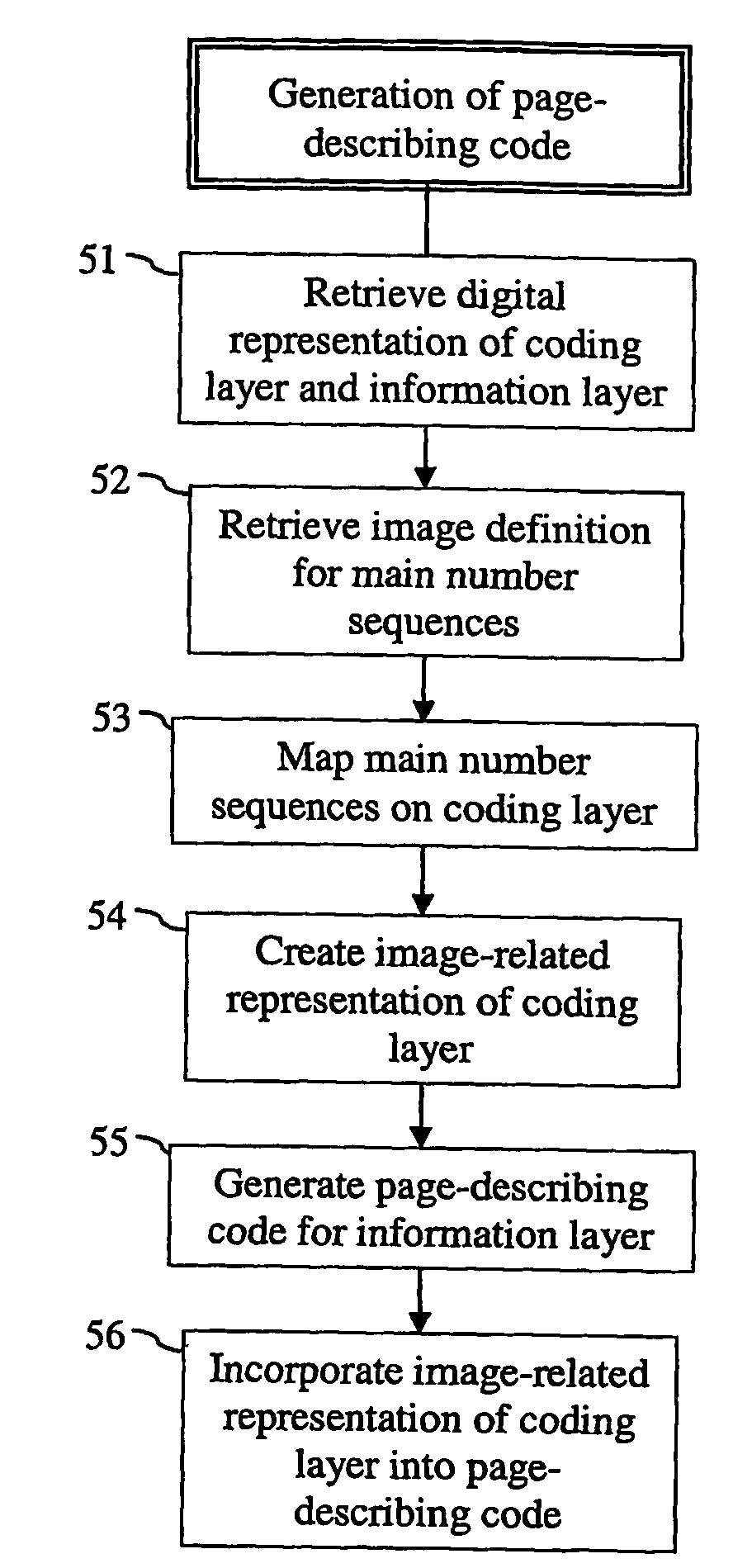

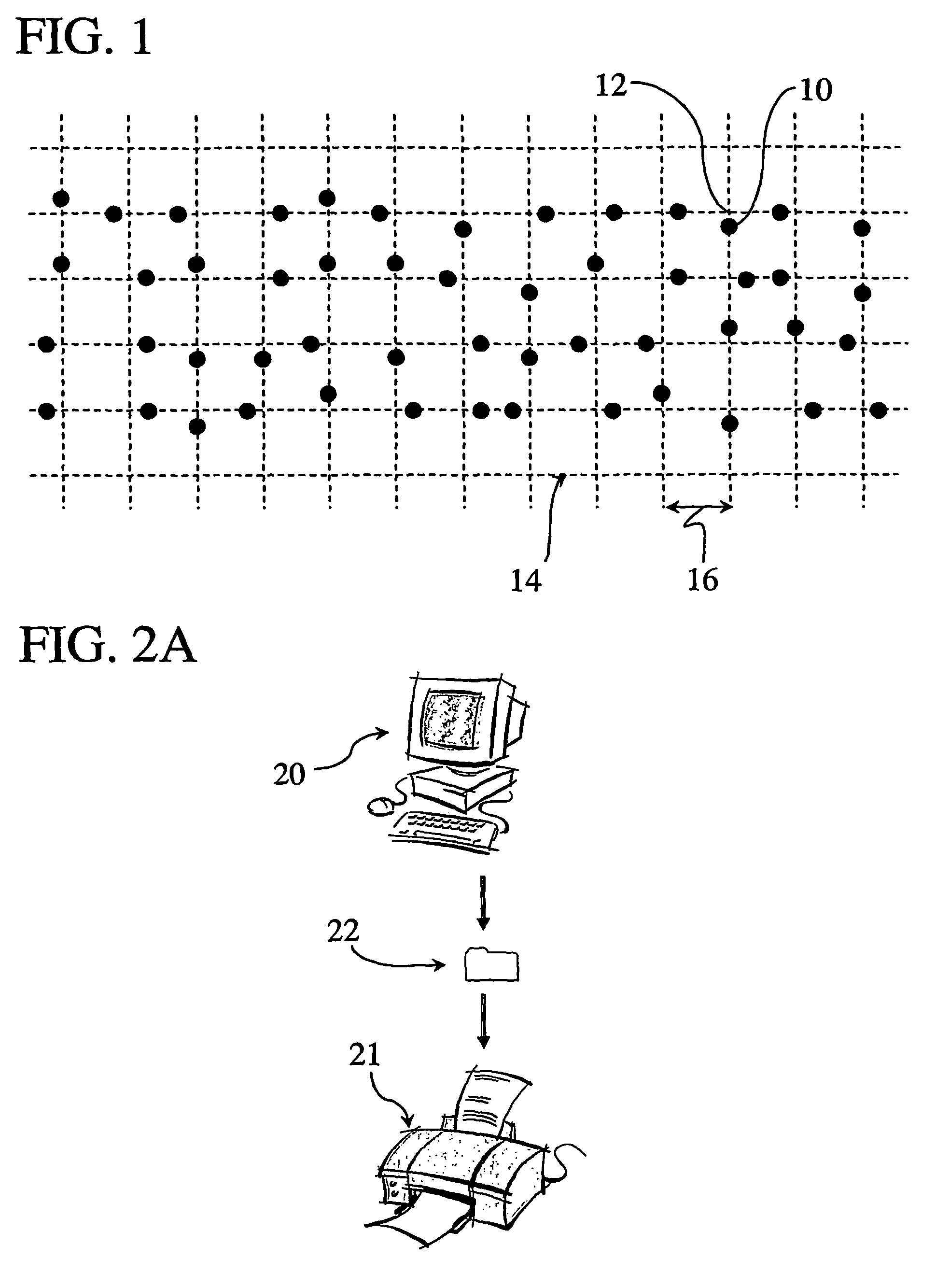

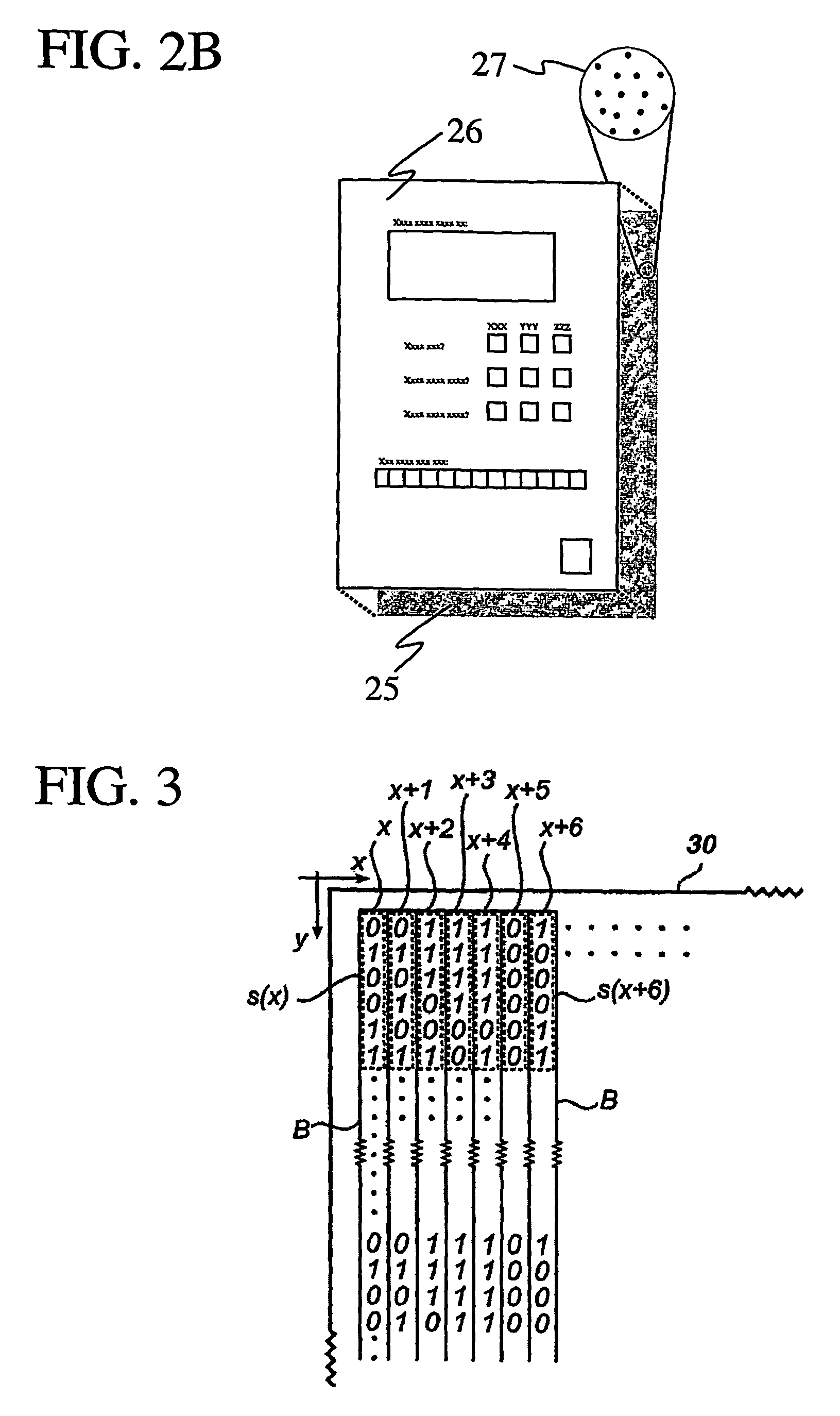

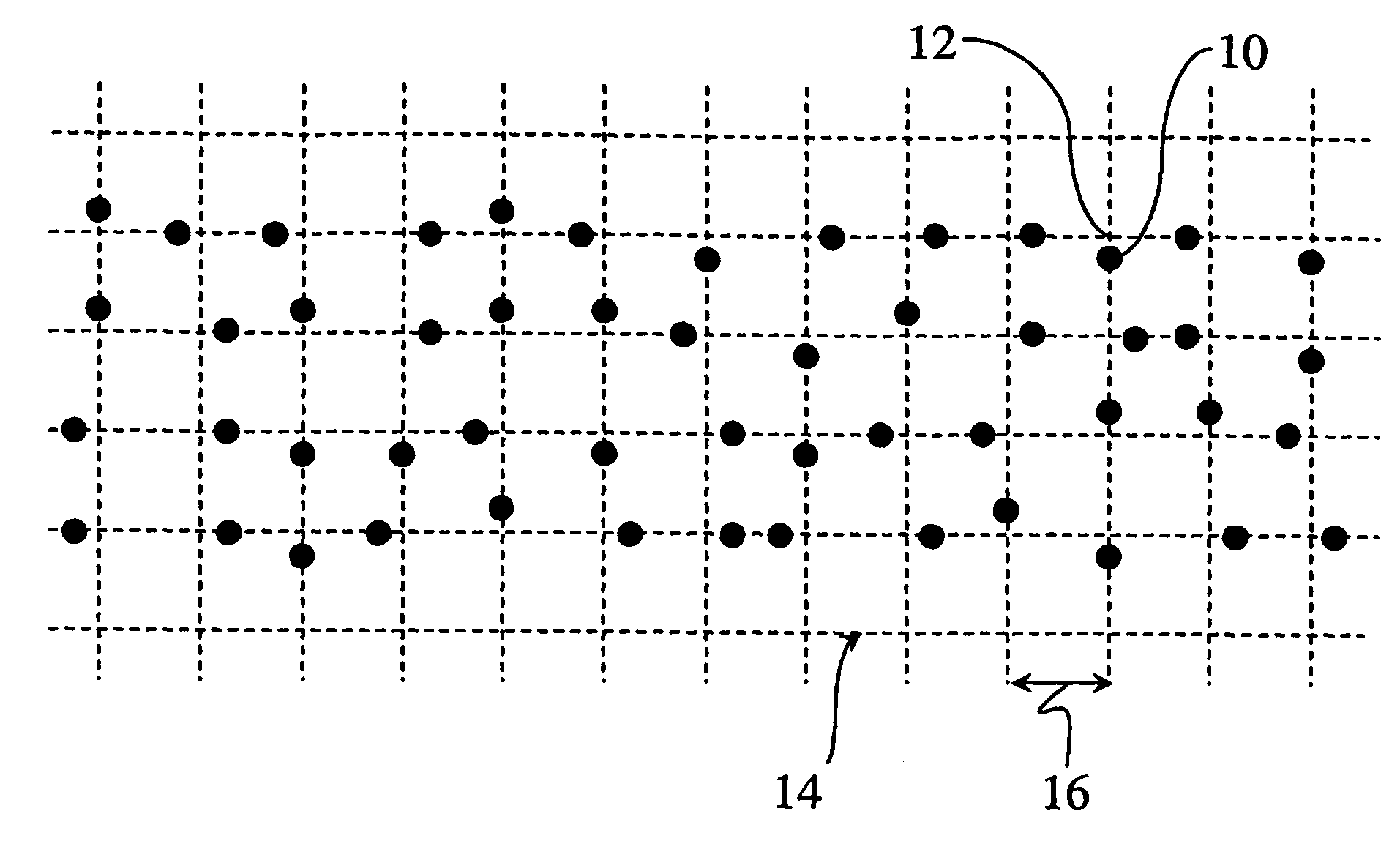

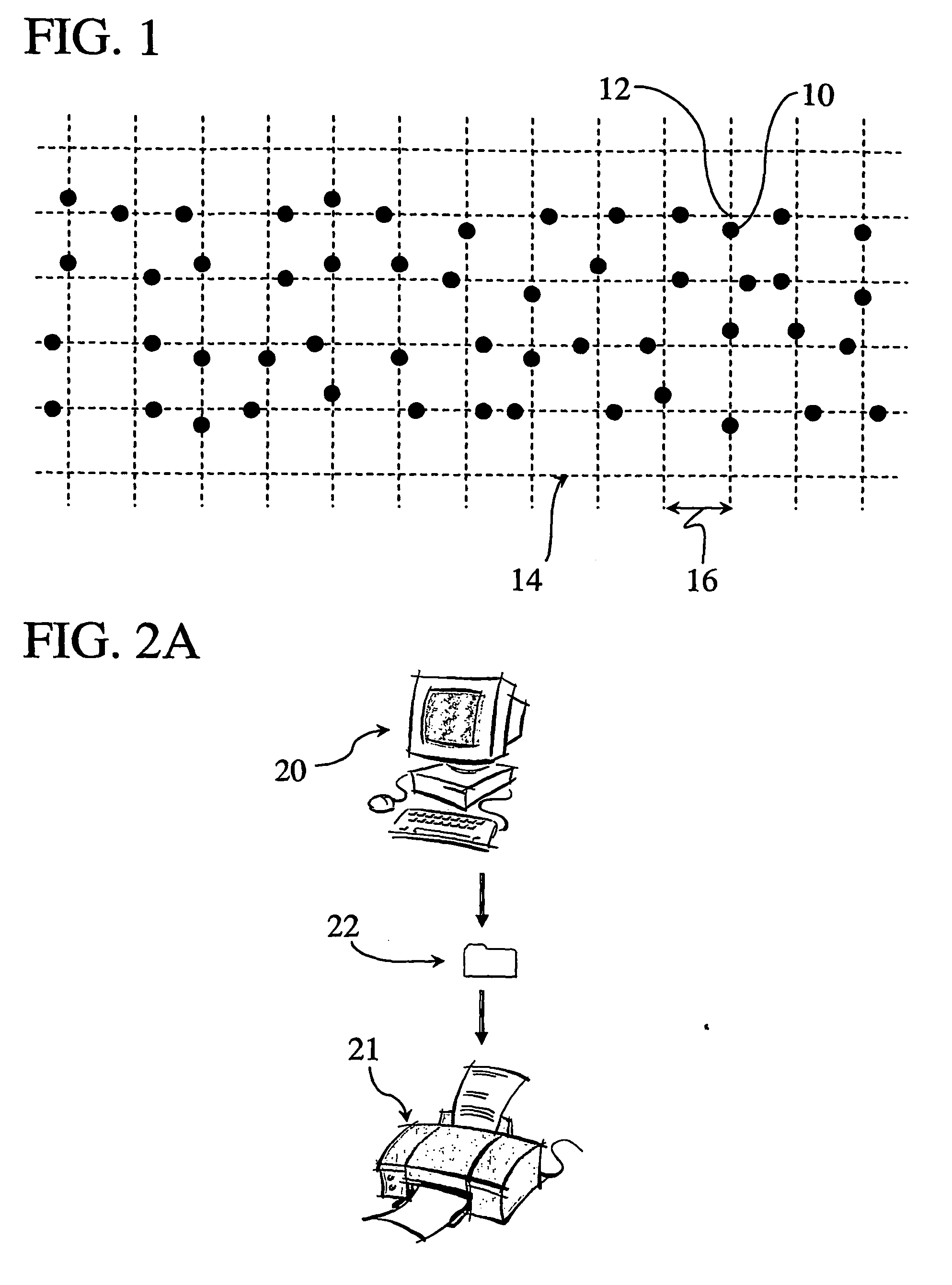

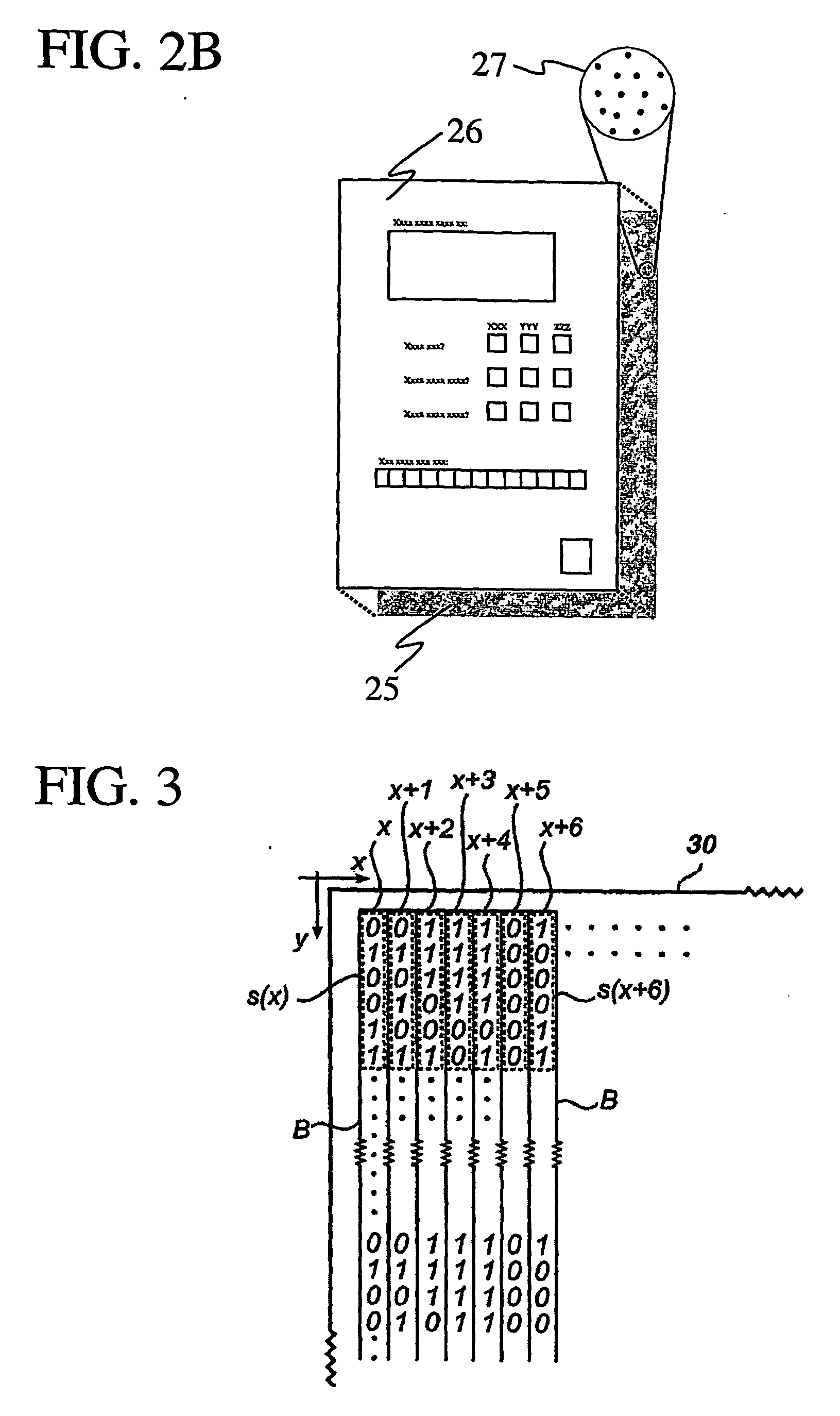

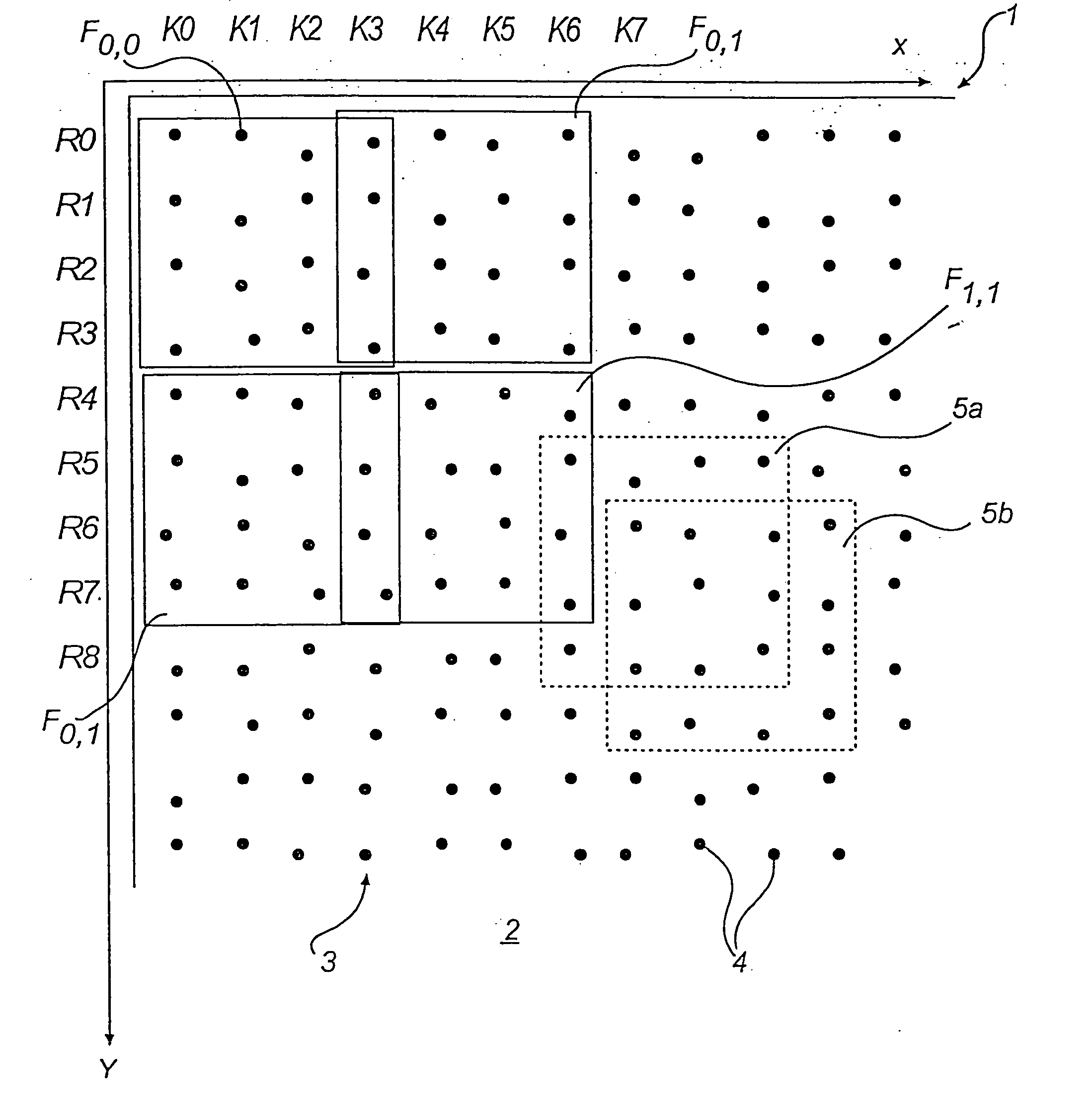

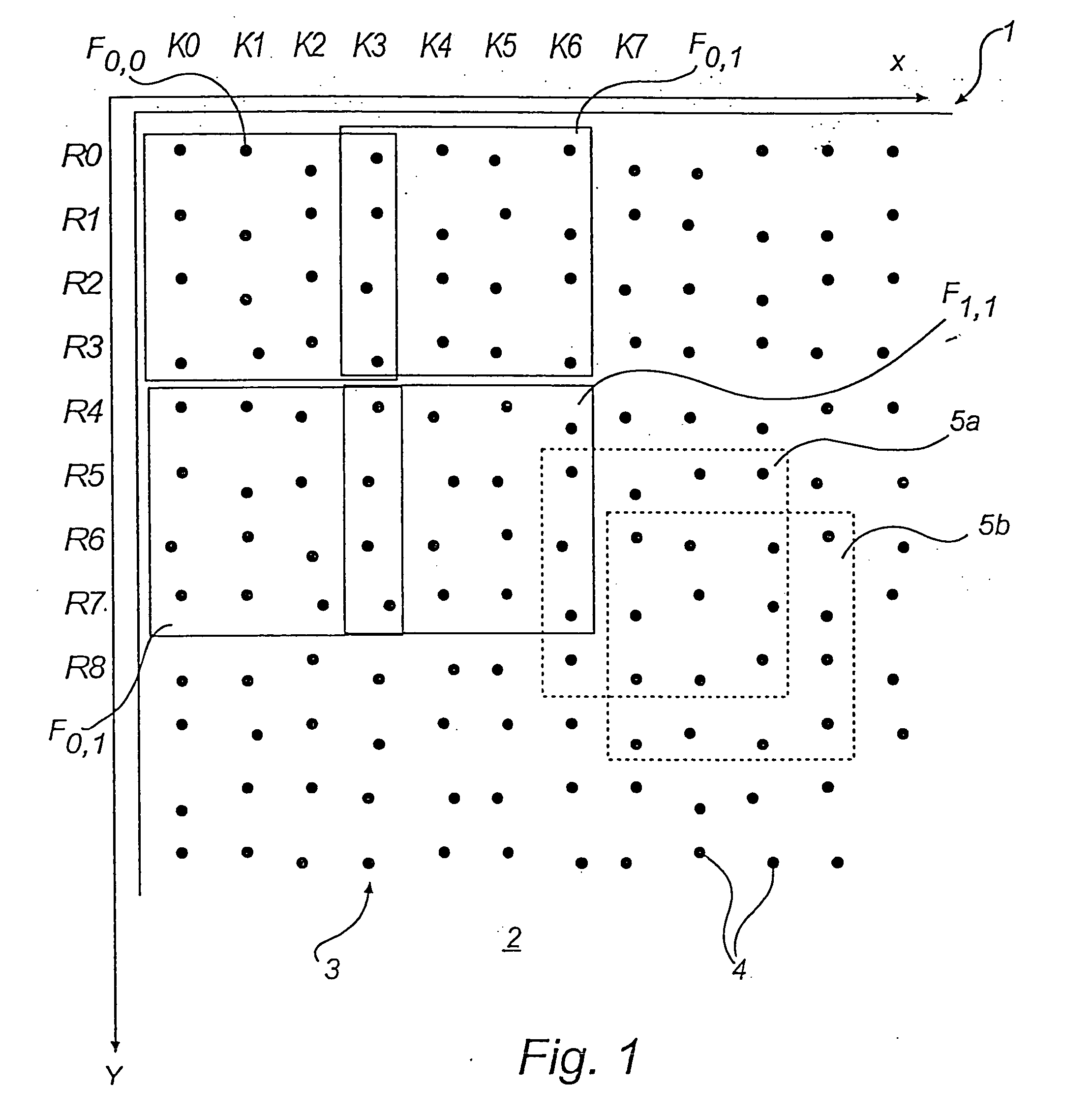

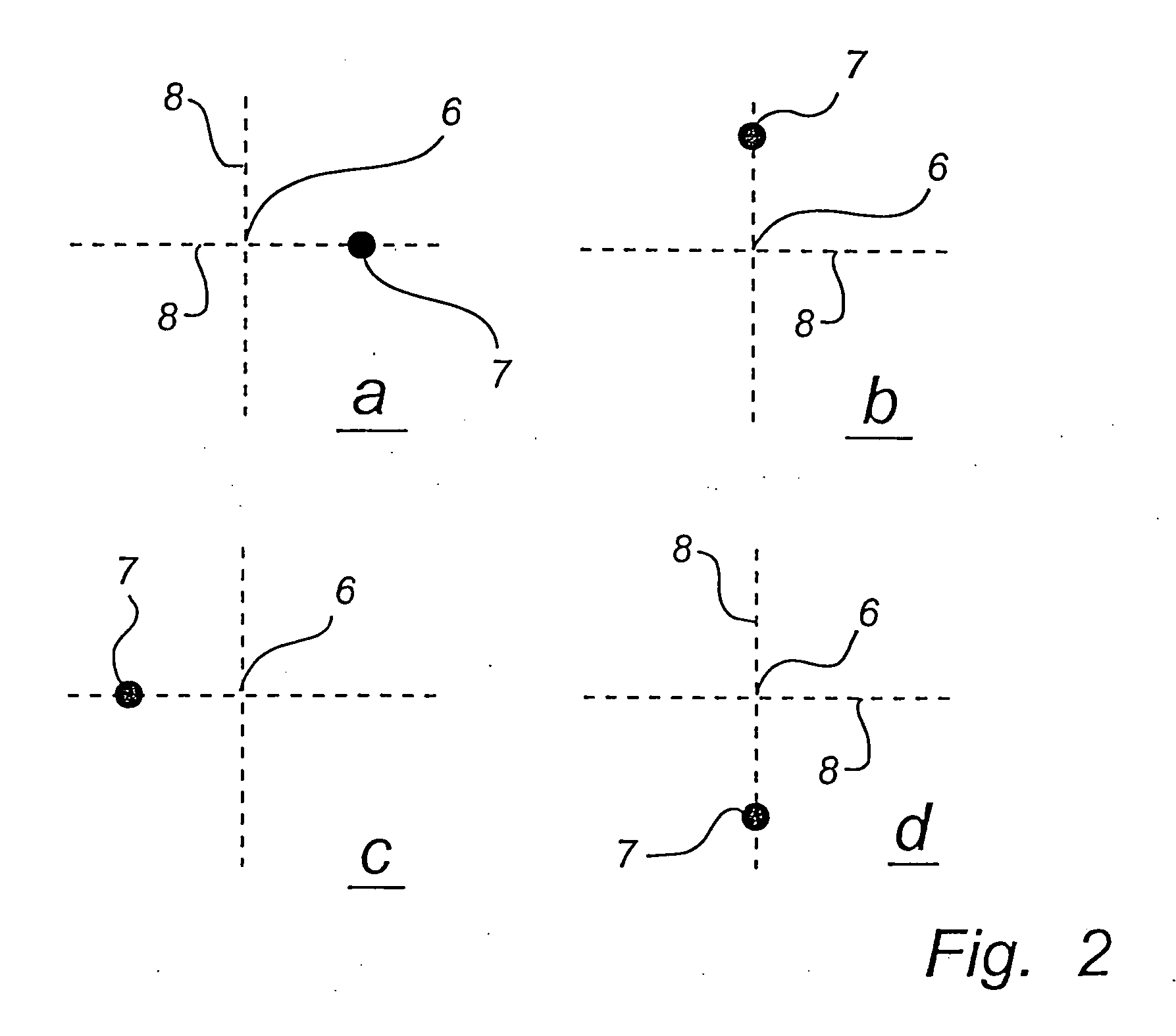

A computer-implemented method is designed for on-demand printing on digital printers of a coding pattern to code data on a surface. The coding pattern comprises a plurality of parallel number sequences which represent different rotations of a cyclic number sequence. The method could involve retrieving a digital representation of the coding pattern, and identifying the rotations therein to derive shift information which designates a phase difference between each rotation and the cyclic number sequence. In the printing operation, all the different rotations may be represented by the cyclic number sequence embodied as at least one code block image. This code block image is repeated in accordance with the shift information to form a printable image in the printer.

Owner:ANOTO AB

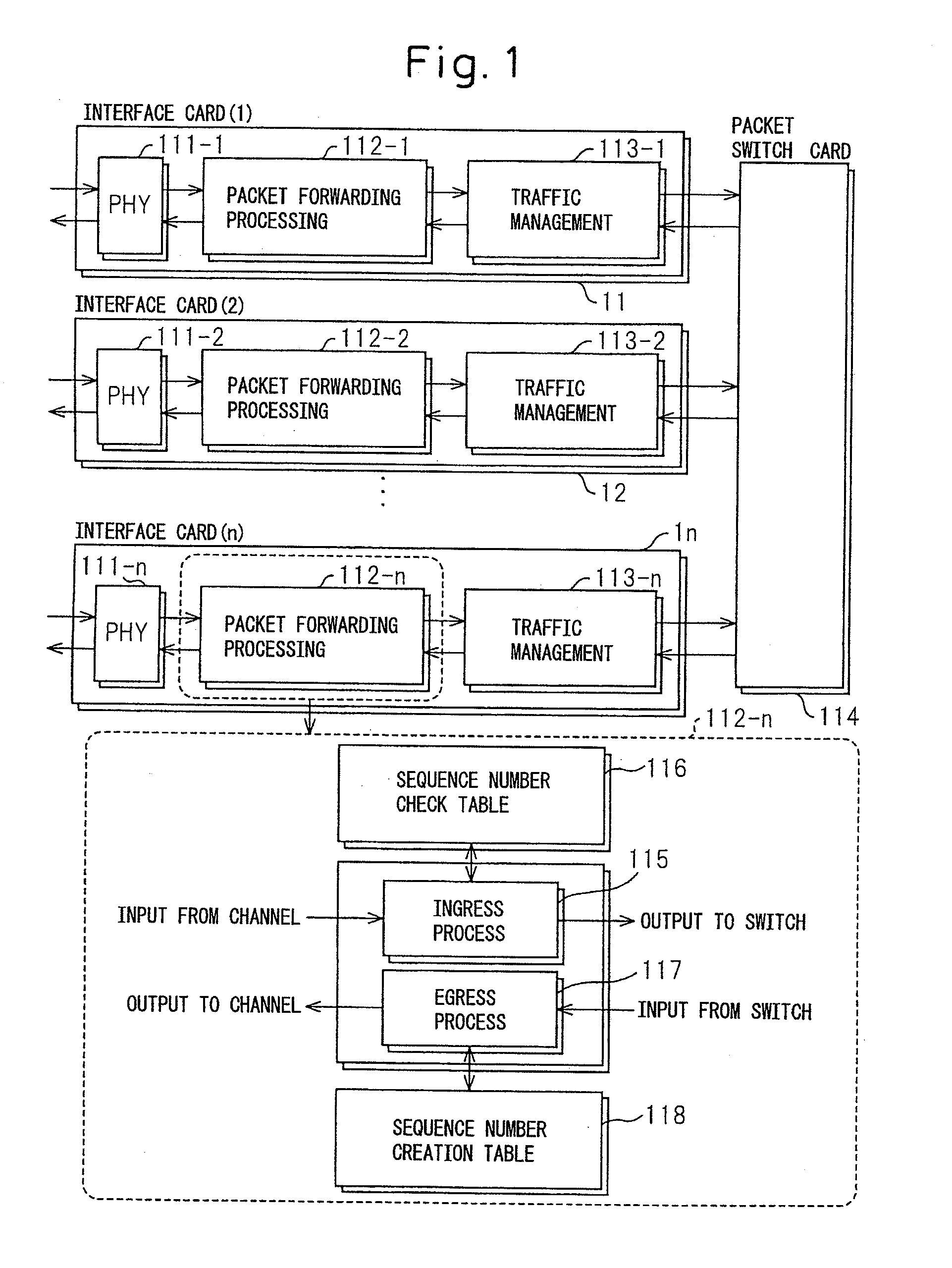

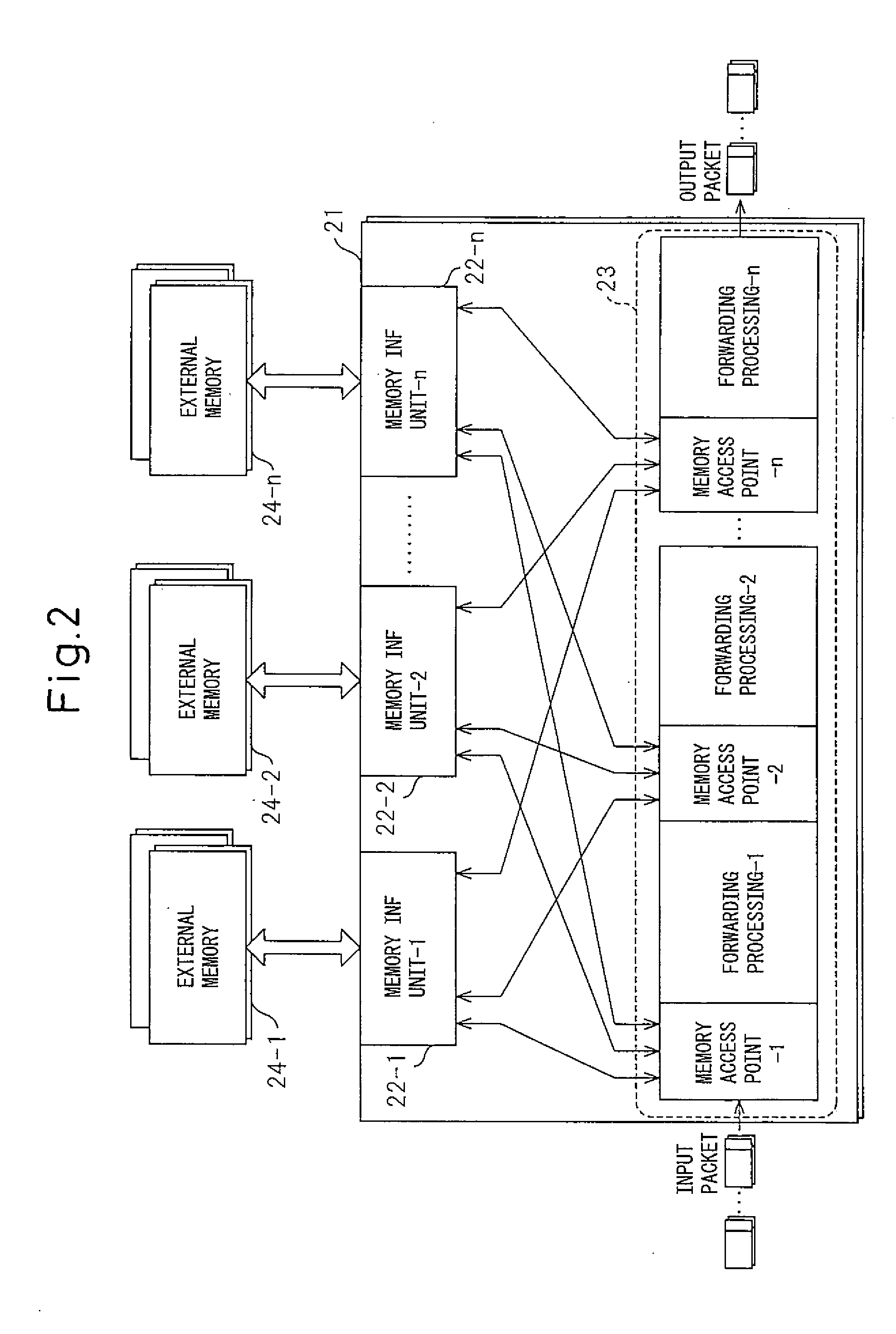

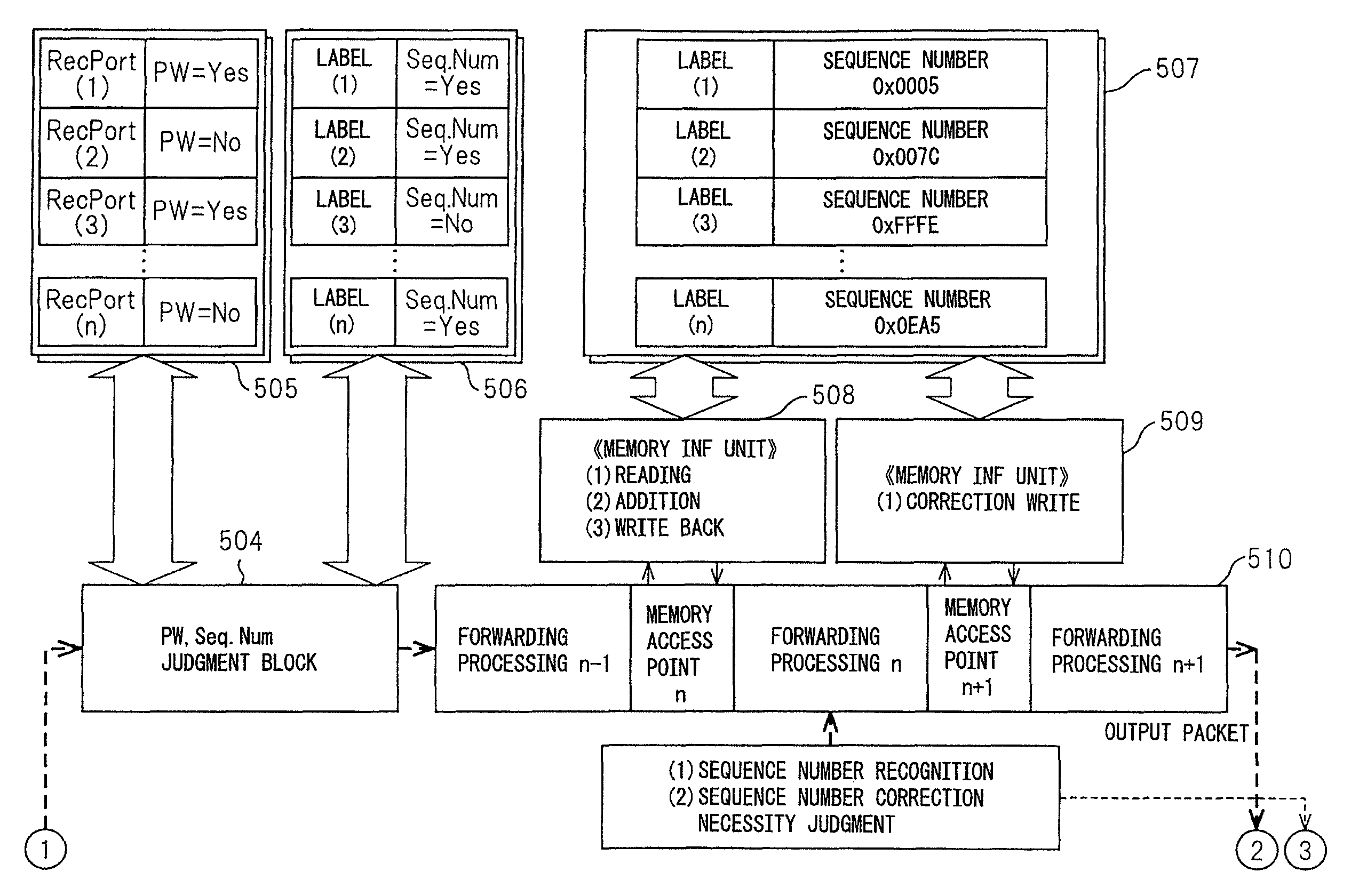

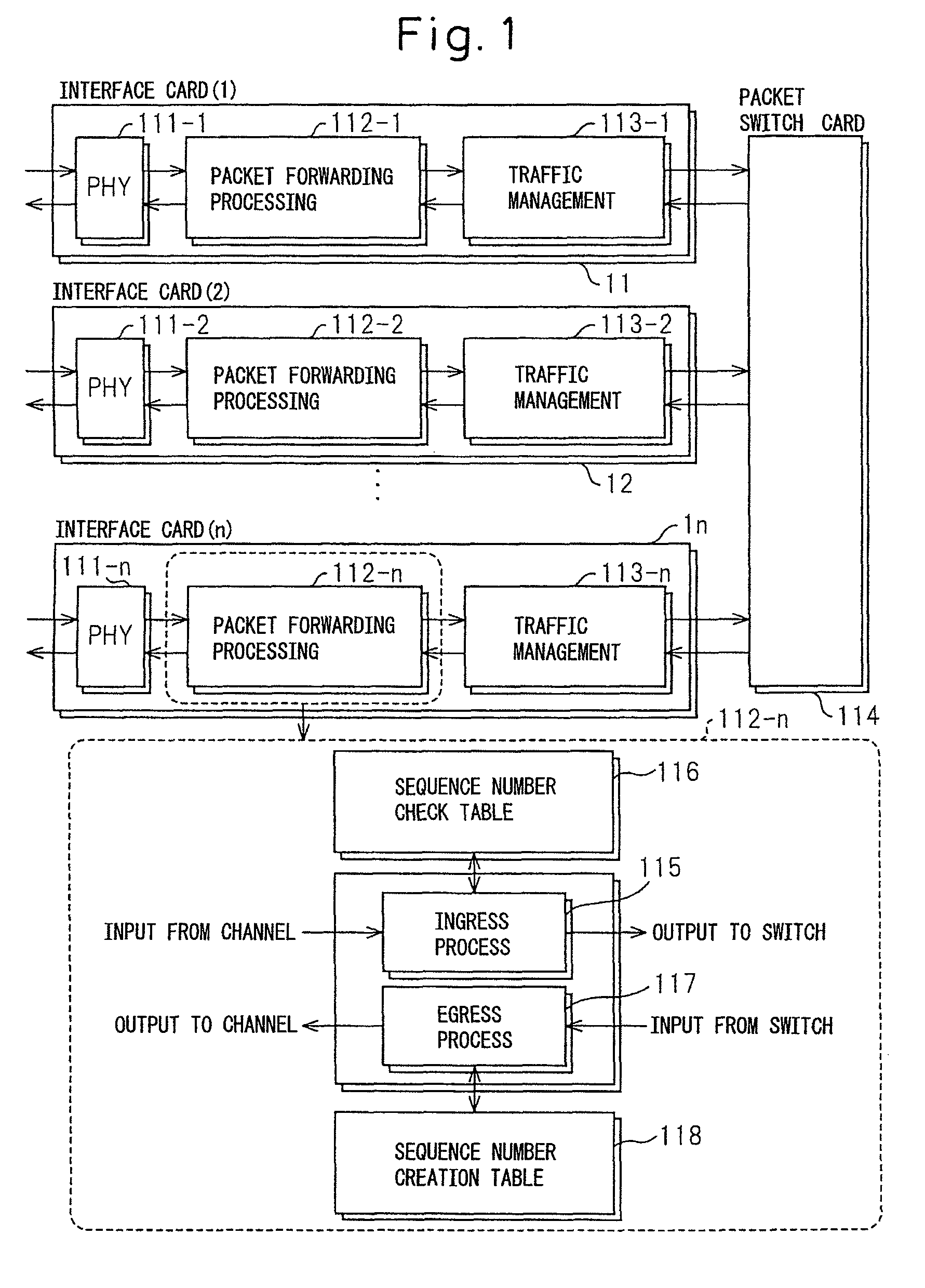

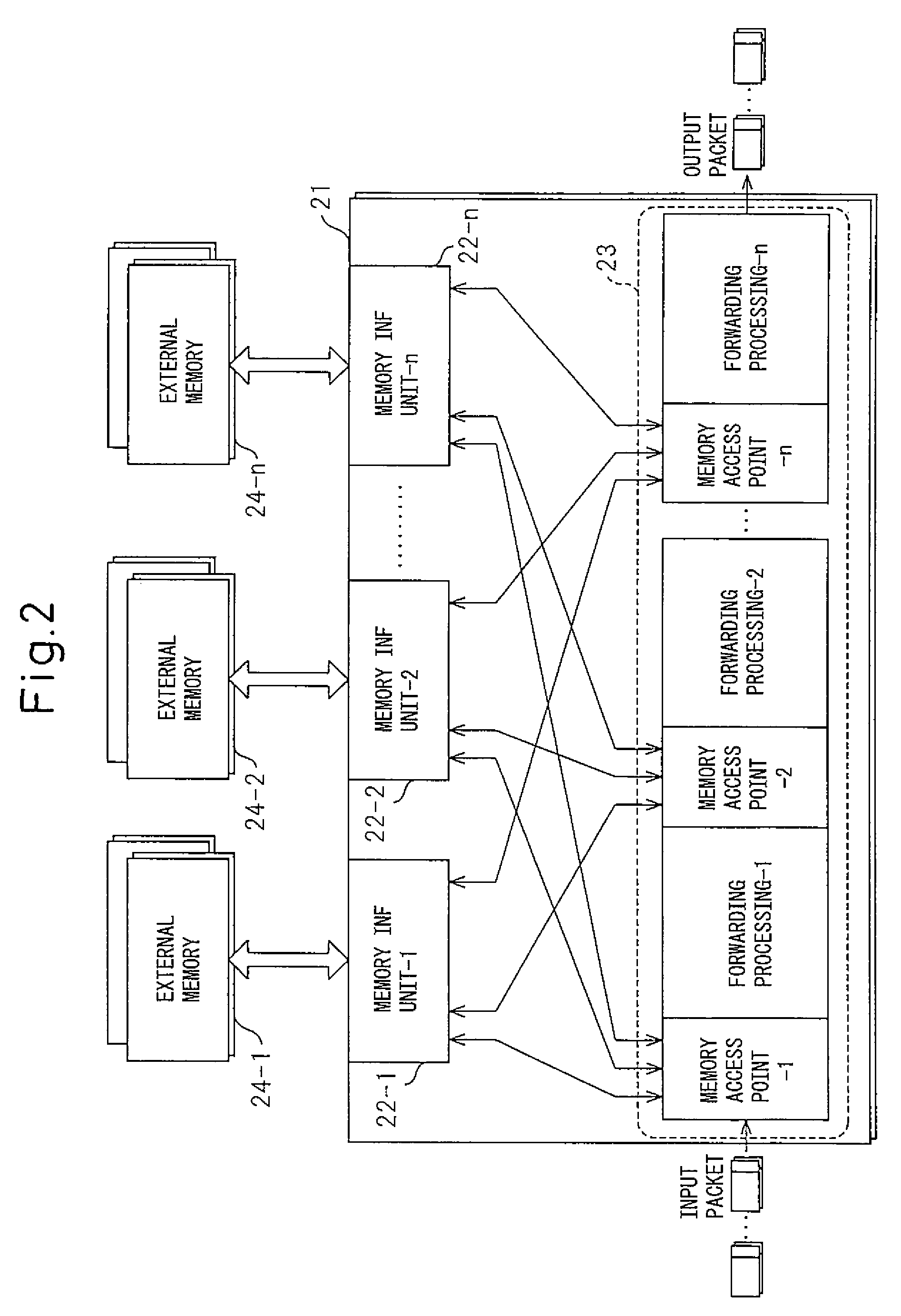

Packet switching system

InactiveUS20100091775A1The processing result is accurateData switching by path configurationStatic storageComputer hardwareFast packet switching

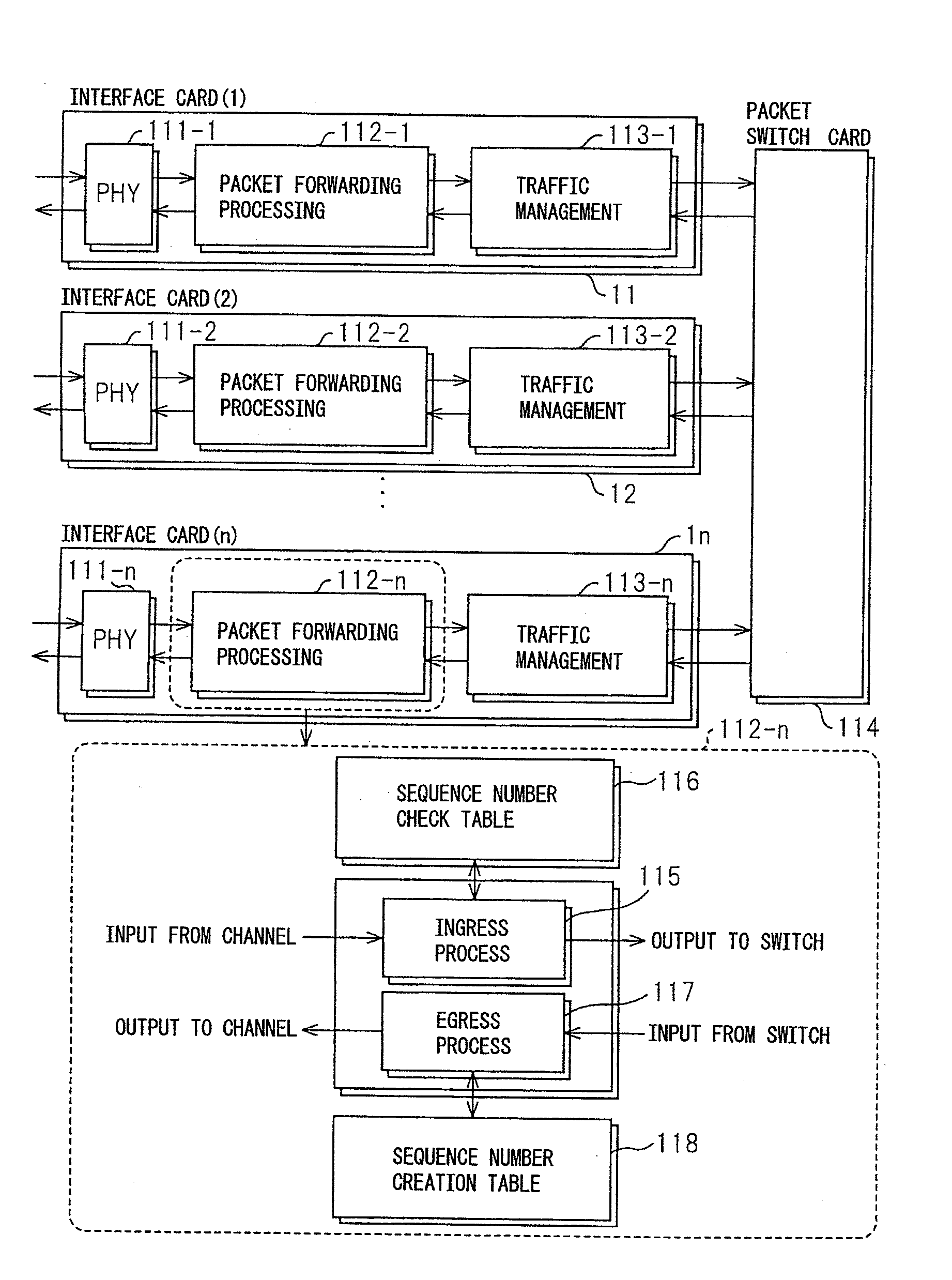

A packet switching system includes a forwarding processing unit determining a destination of an input packet by analyzing the input packet and outputting it as an output packet, the forwarding processing unit comprises an ingress interface card checking if the input packet has a sequential cyclic number and an egress interface card creating a sequential cyclic number and assigning it to the output packet.

Owner:FUJITSU LTD

SiCf/SiC ceramic-based composite material with composite interface and preparation method of SiCf/SiC ceramic-based composite material

The invention discloses a SiCf / SiC ceramic-based composite material with a composite interface. The SiCf / SiC ceramic-based composite material with the composite interface has the characteristic of comprising a CVD-SiC coating, a PIP-SiC matrix, the composite interface and SiC fiber, wherein the CVD-SiC coating is a silicon carbide coating which is prepared by using a chemical vapor deposition method and has a thickness of 100-500 [mu]m, the composite interface is formed through alternate cyclic overlapping of arbitrary two or three of a BN interface, a ZrO2 interface, a LaPO4 interface and a SiC interface, and the cyclic number is 3-5 times; and the PIP-SiC matrix is silicon carbide formed through in-situ pyrolysis of polycarbosilane, the volume of the SiC fiber accounts for 40-60% of thevolume of the composite material, and a pyrolytic carbon layer of 5-20 nm thick is formed on the surface. The preparation method comprises the steps: preparing the multi-layer composite interface on the surface of the silicon carbide fiber by using different preparation processes, then filling a SiC matrix by using a PIP method, and finally preparing a surface SiC coating by using a CVD method. The prepared SiCf / SiC ceramic-based composite material has high toughness, high oxidation resistance and a simple preparation process.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

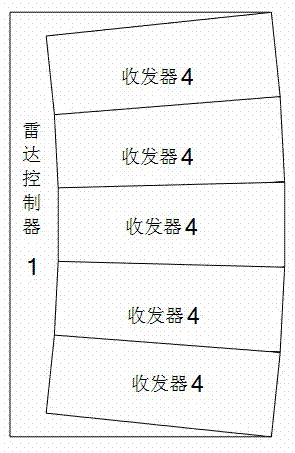

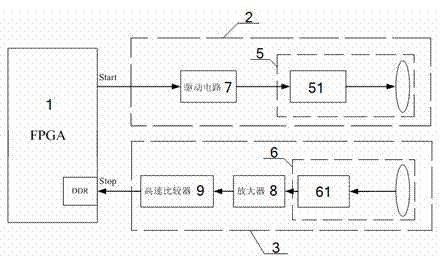

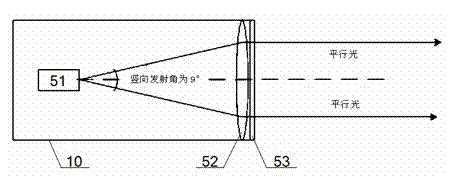

Five-path laser radar for vehicle and control method thereof

ActiveCN102540195AEasy to dodgeEasy to controlElectromagnetic wave reradiationPosition/course control in two dimensionsTransceiverArray data structure

The invention relates to a five-path laser radar for a vehicle and a control method of the five-path laser radar. The five-path laser radar comprises a radar controller, and five paths of transceivers in fan-shaped arrangement, wherein each path of transceiver respectively comprises a laser emitting lens tube and a laser receiving lens tube, the center axes of the five paths of transceivers are all crossed at the same point on the same plane, and in addition, the included angle between the adjacent laser emitting lens tubes is identical. When the five-path laser radar is used, the five paths of transceivers are firstly controlled for sequentially emitting and receiving laser pulses, the interval time is identical, then, the passing time t between the emitting and the receiving of each path of laser pulses is calculated, next, the t is subjected to twice screening through a formula that t is greater than or equal to t<min> and smaller than or equal to 1mus and the variance, the threshold and the circulation number group, then, the qualified t average value in the cyclic number group is calculated, and finally, the region of obstacles, the distance between the obstacles and the vehicle and the relative speed are determined according to the average value, so obstacles are avoided. The design has the advantages that the scanning period is short, the structure is simple, in addition, the cost is lower, the anti-shock performance is higher, and the detection distance, the range and the precision can meet the vehicle requirements.

Owner:DONGFENG MOTOR CORP HUBEI

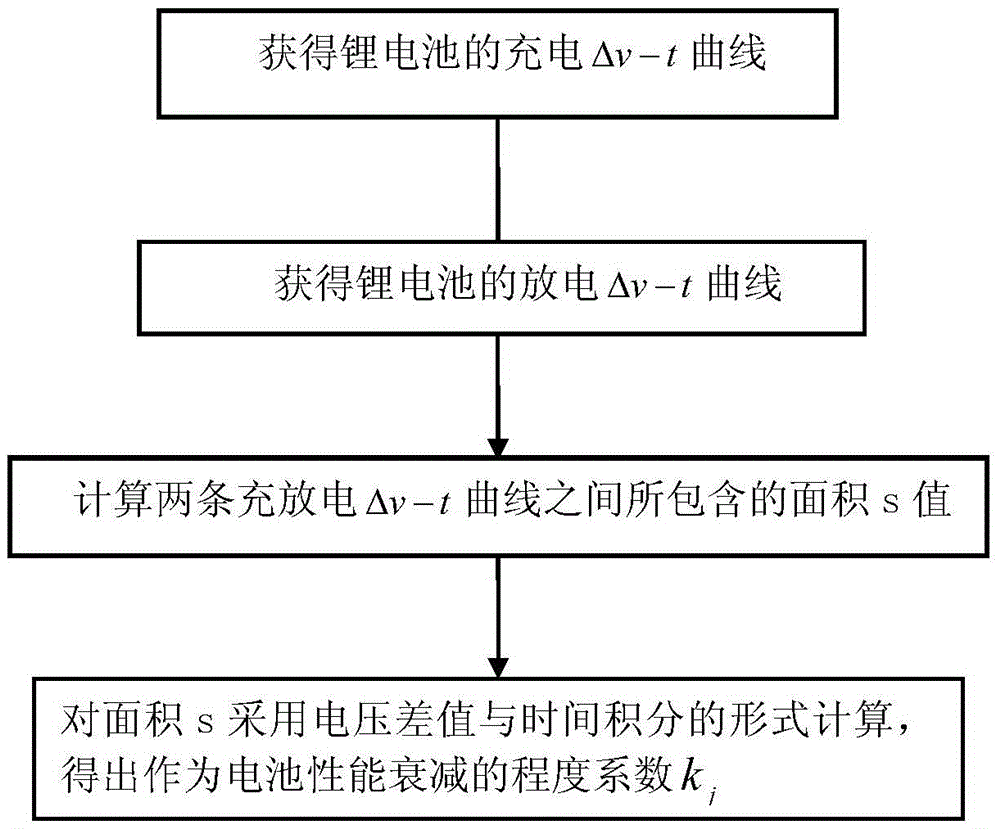

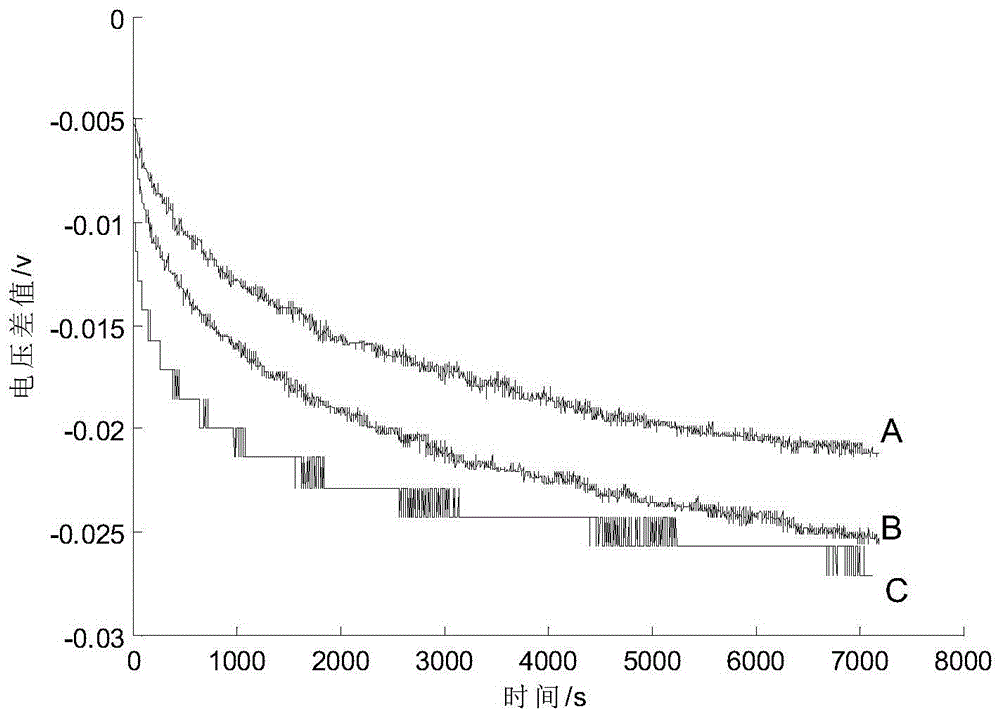

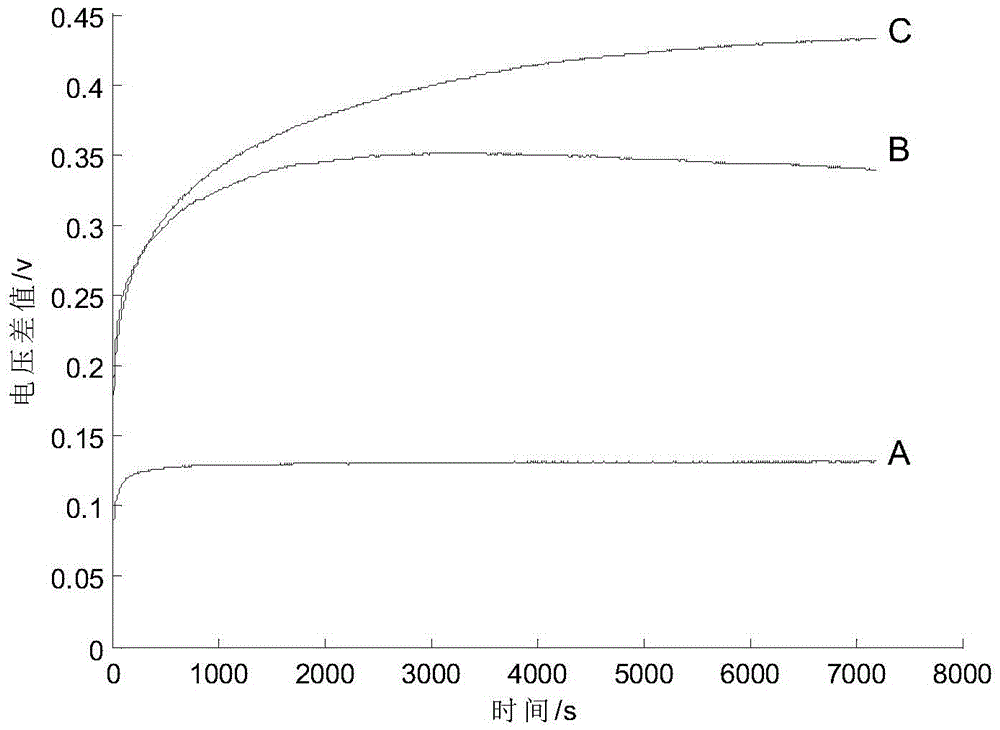

Judgment method for the reason of lithium battery performance degradation

The invention provides a judgment method for the reason of lithium battery performance degradation, and relates to judgment of battery electrical performance. The steps are that a charge deltav-t curve of a lithium battery is acquired and a discharge deltav-t curve of the lithium battery is acquired; the value of area s included between the charge and discharge deltav-t curves is calculated; and the area s is calculated by using the form of voltage difference and time integration so that the coefficient ki acting as the degree of battery performance degradation is obtained. The reason of lithium battery performance degradation is judged through comparison of the charge deltav-t curves and the discharge deltav-t curves respectively corresponding to different cyclic number of times of charge and discharge of the lithium battery so that the defects in the prior art that the reason of lithium battery performance degradation cannot be judged in the daily use process of the lithium battery can be overcome.

Owner:HEBEI UNIV OF TECH

On-demand printing of coding patterns

InactiveUS20060133877A1Input/output for user-computer interactionCharacter printing data arrangement from carrierCoding blockPhase difference

A computer-implemented method is designed for on-demand printing on digital printers of a coding pattern to code data on a surface. The coding pattern comprises a plurality of parallel number sequences which represent different rotations of a cyclic number sequence. The method could involve retrieving a digital representation of the coding pattern, and identifying the rotations therein to derive shift information which designates a phase difference between each rotation and the cyclic number sequence. In the printing operation, all the different rotations may be represented by the cyclic number sequence embodied as at least one code block image. This code block image is repeated in accordance with the shift information to form a printable image in the printer.

Owner:ANOTO AB

Position determination II - calculation

InactiveUS20050104861A9Input/output for user-computer interactionDigitally marking record carriersNumber seriesComputer science

Owner:ANOTO IP LIC

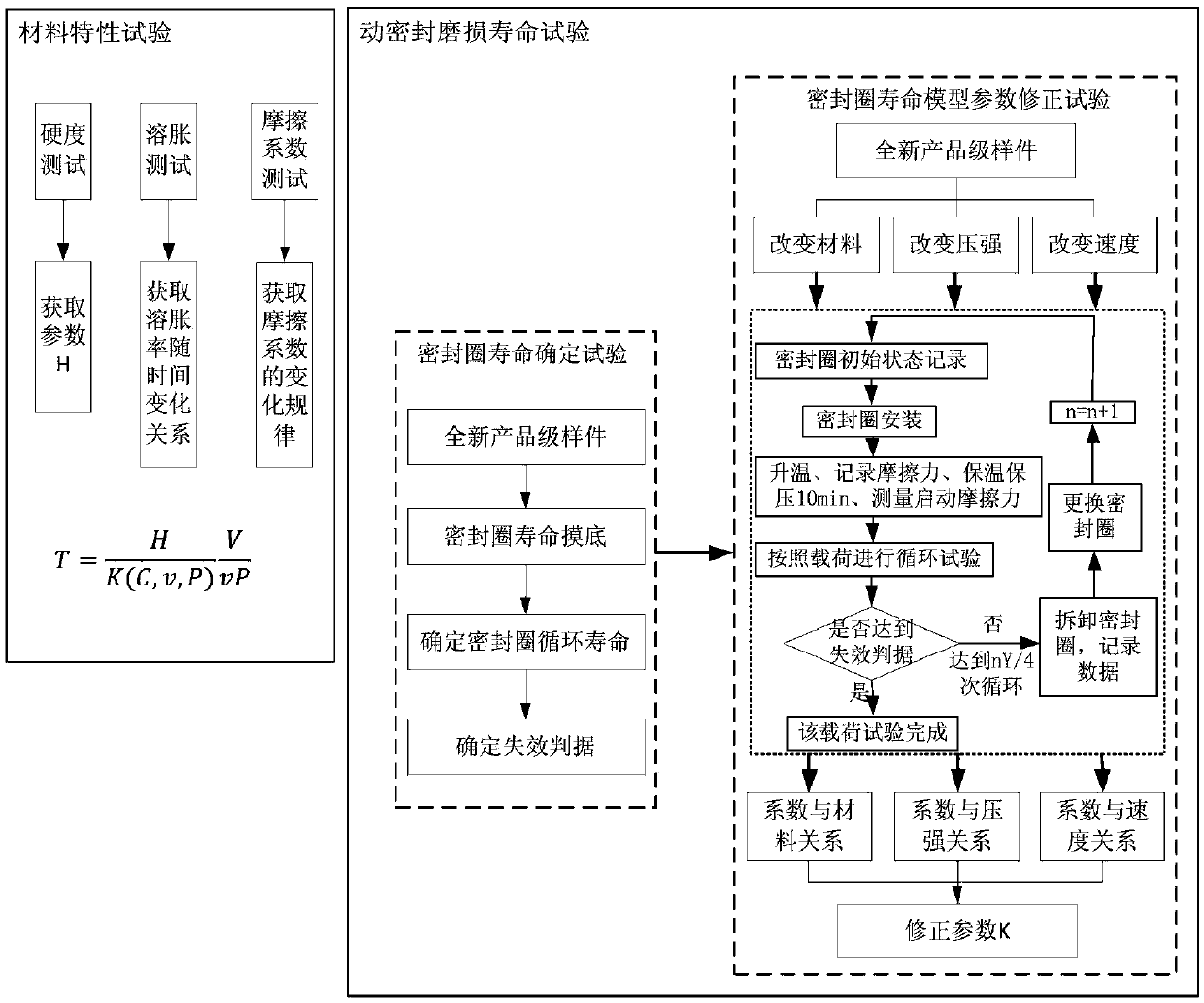

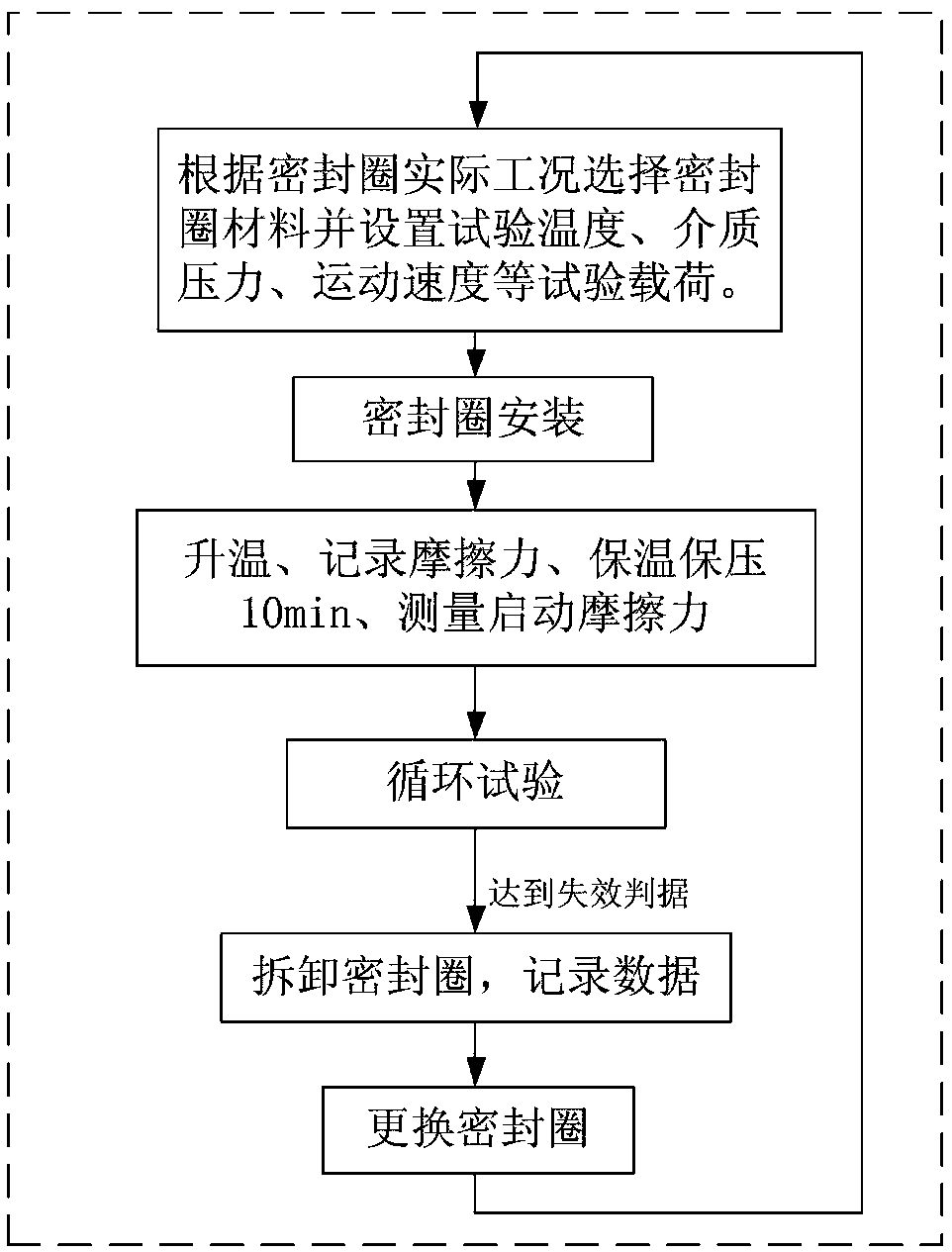

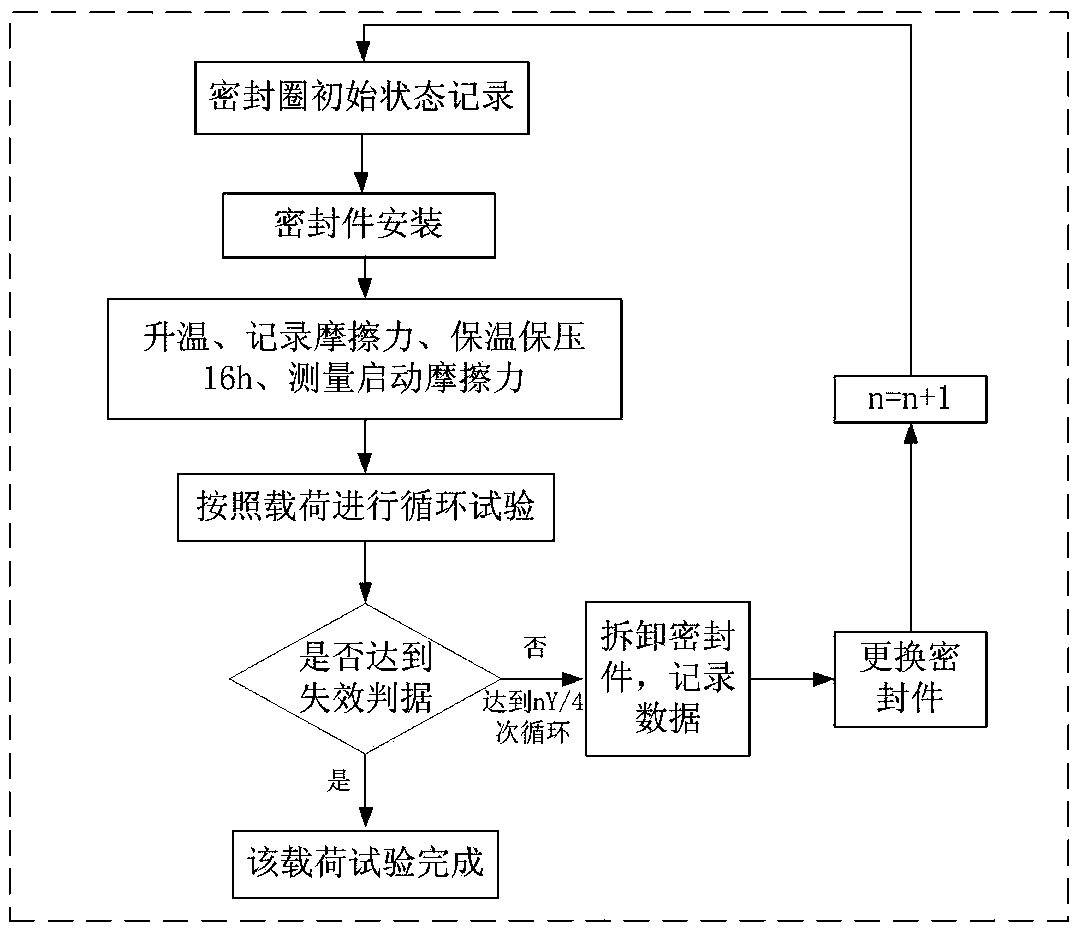

Method for testing reciprocating seal wear life of O-shaped rubber seal ring

ActiveCN109540719AAccurate and reliable wear volume resultsTest time is true and reliableInvestigating abrasion/wear resistanceEngineeringHardness

The invention discloses a method for testing reciprocating seal wear life of an O-shaped rubber seal ring, comprising the following steps of: step 1, testing material property of a seal element, wherein the material property test comprises a hardness test, a swelling test, and a friction coefficient test; step 2, performing a determination test on the life of the seal ring to obtain the cycle number when the seal ring fails, and determining the wear amount of the failed seal ring; and step 3, performing the parameter modification test of a sealing life model, obtaining the change law of the wear amount of the seal ring with time based on the dynamic seal wear life test, determining the detection step period of the parameter correction test based on failed cycle number, separately exploringthe speed and load to achieve the correction of the parameter K under different materials.

Owner:CHINA AERO POLYTECH ESTAB

On-demand printing of coding patterns

InactiveCN1806249AInput/output for user-computer interactionGraph readingCoding blockPhase difference

A computer-implemented method is designed for on-demand printing on digital printers of a coding pattern to code data on a surface. The coding pattern comprises a plurality of parallel number sequences which represent different rotations of a cyclic number sequence. The method could involve retrieving a digital representation of the coding pattern, and identifying the rotations therein to derive shift information which designates a phase difference between each rotation and the cyclic number sequence. In the printing operation, all the different rotations may be represented by the cyclic number sequence embodied as at least one code block image. This code block image is repeated in accordance with the shift information to form a printable image in the printer.

Owner:ANOTO AB

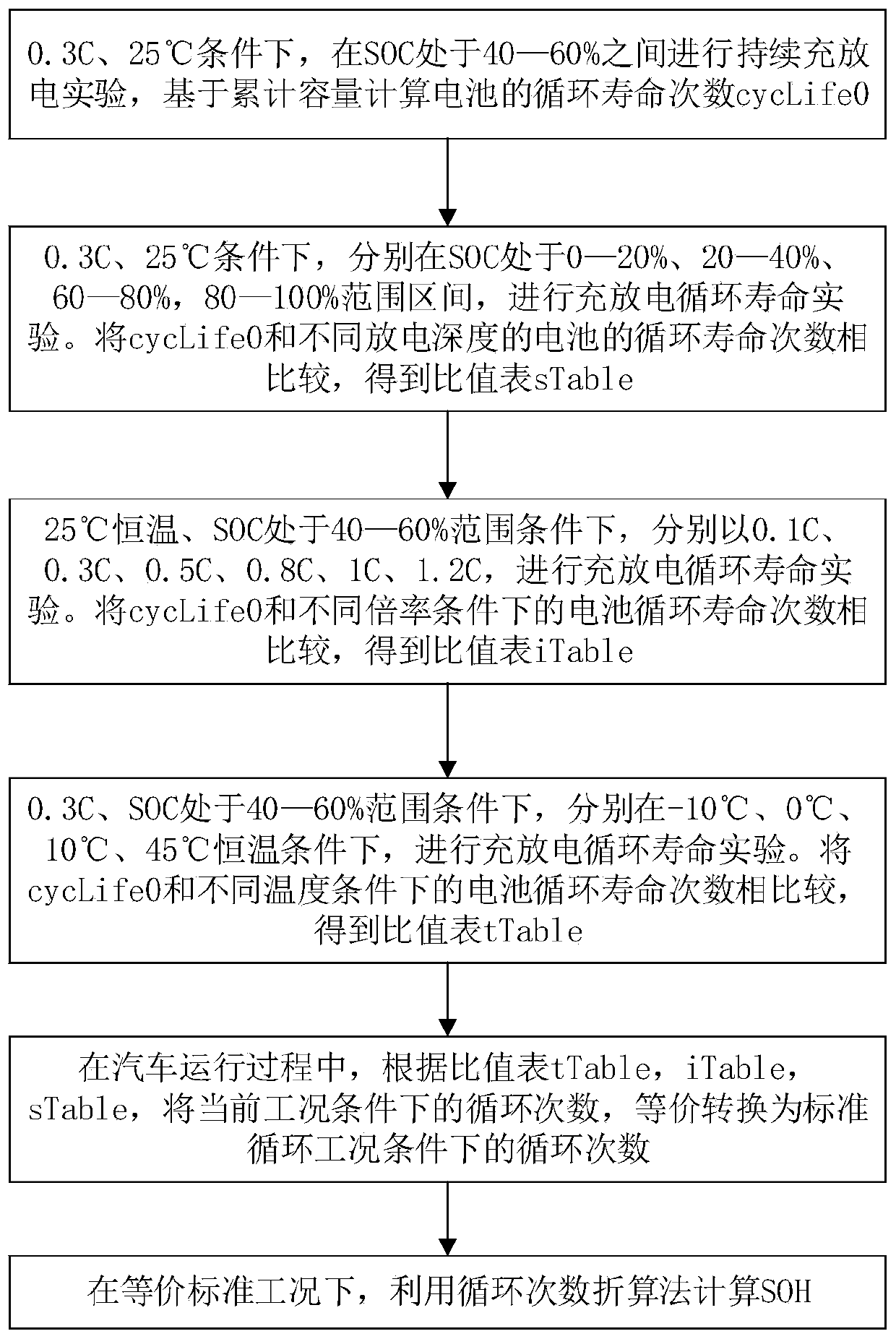

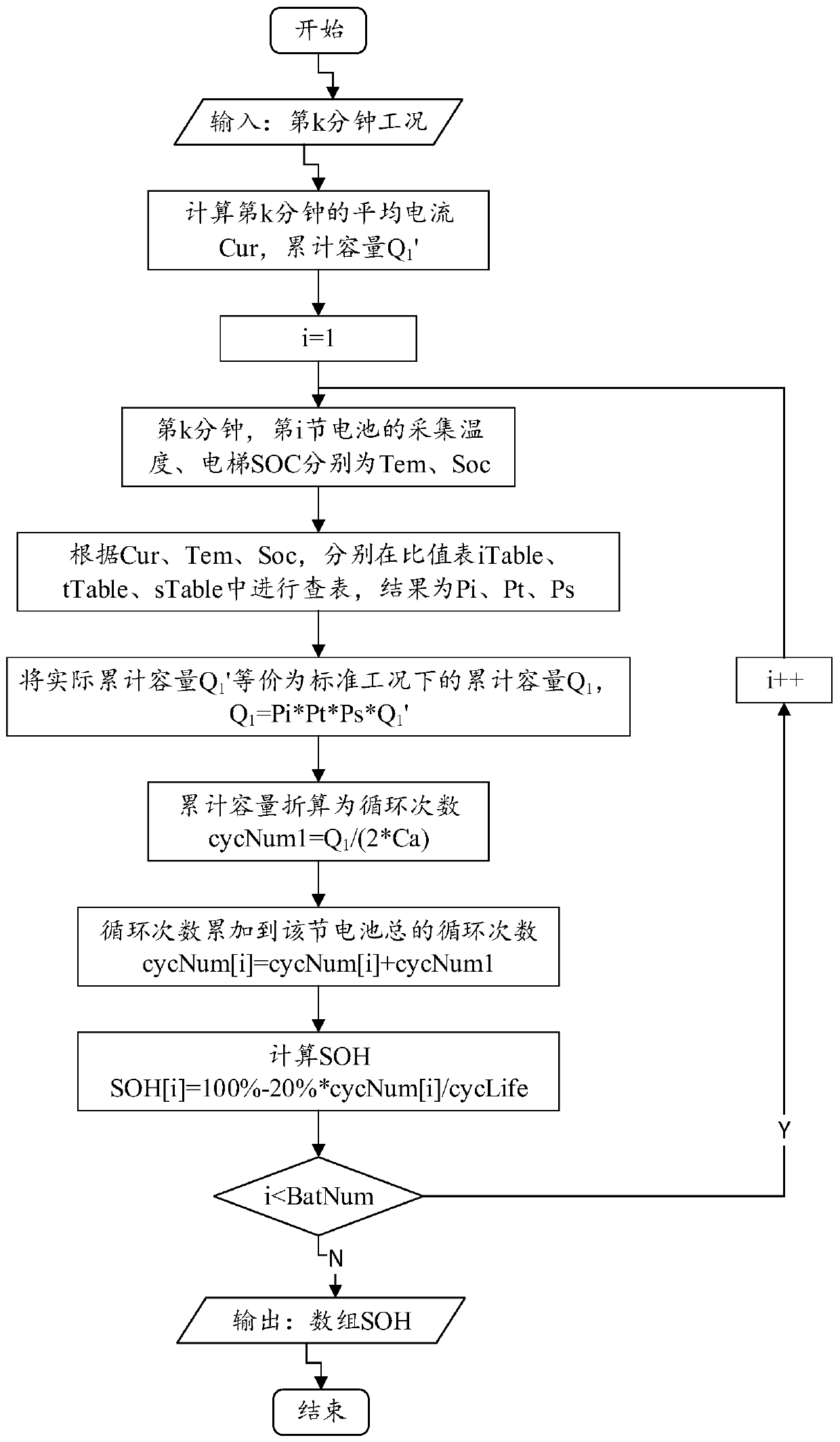

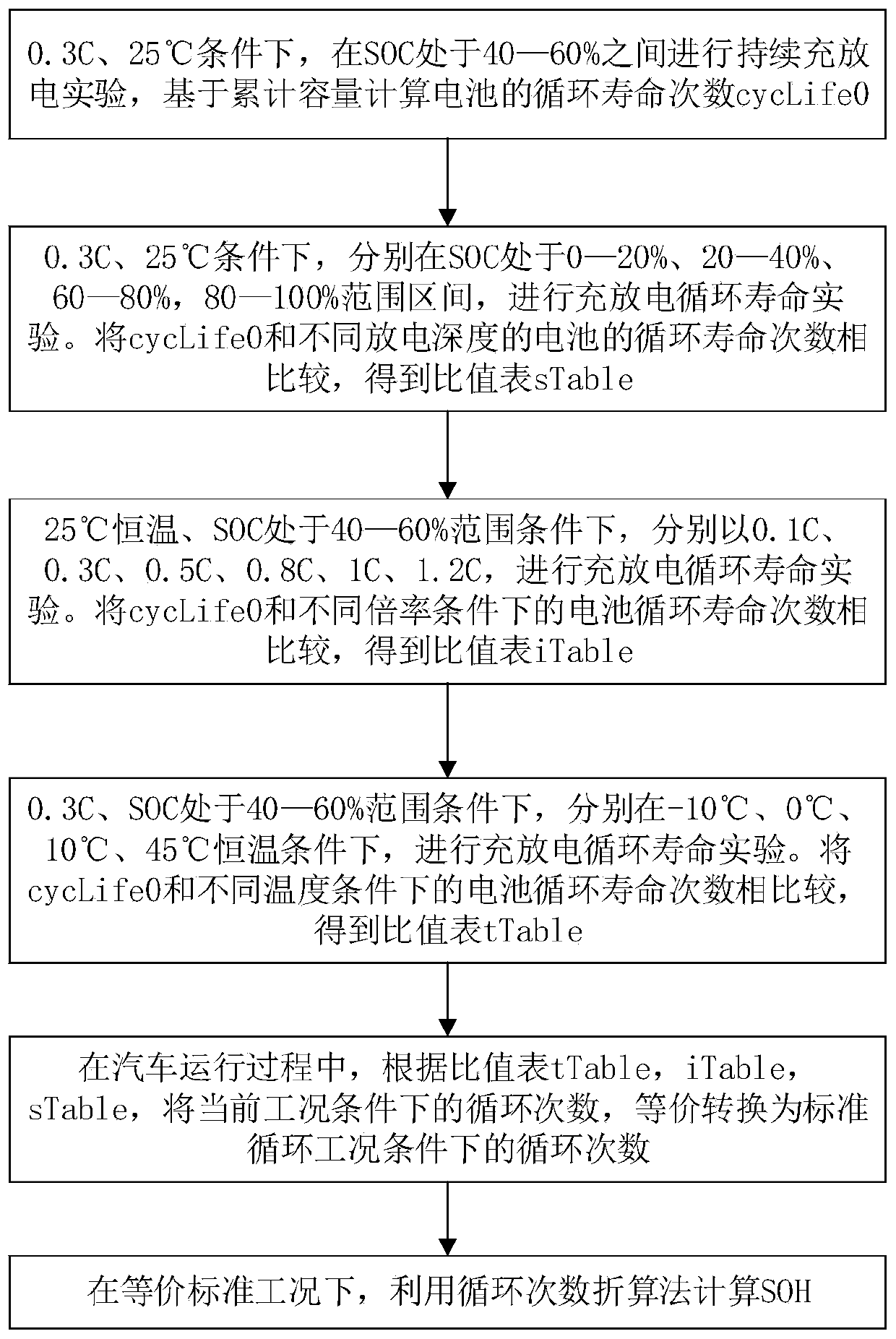

Power battery SOH estimation method considering multi-factor influence

ActiveCN109975713AEasy to manageImprove calculation accuracyElectrical testingPower batteryEstimation methods

The invention discloses a power battery SOH estimation method considering multi-factor influence. The method includes taking 25 DEG C, 0.3 C and SOC as standard working conditions at 40-60%, and performing a charging and discharging test under the working conditions so that the number of cycle life cycLife0 under the standard working conditions can be obtained; performing the charging and discharging test under different SOC ranges, different temperatures and different magnification conditions so that the number of the cycle life under different working condition environments can be obtained,and comparing the cycLife0 with the number of the cycle life under different SOC ranges, different temperatures and different magnification conditions so that ratio tables (sTable, tTable and iTable)can be obtained; during the running of an automobile, equivalently converting the number of the cycles under current temperatures, magnification and SOC into the number of the cycles under the standard working conditions according to the ratio tables (sTable, tTable and iTable); and utilizing a cyclic number conversion algorithm to calculate SOH under the equivalent standard working conditions. The method is simple in algorithm and high in calculating precision, and can calculate the SOH of all single cells, and therefore, management on the cells can be realized.

Owner:苏州正力新能源科技有限公司

Process for preparing modified natural graphite nodule

A process for preparing the modified natural graphite balls used to prepared the negative electrode of Li ion battery includes such steps as proportionally mixing a special solvent with treated asphalt, adding the solution along with natural graphite balls into reactor, constant-temp heating to obtain coated natural graphite balls, separating, baking, breaking, carbonizing, and high-temp graphitizing. It has high reversible capacity (330 mAh / g) and cyclic numbers (360).

Owner:冷亮

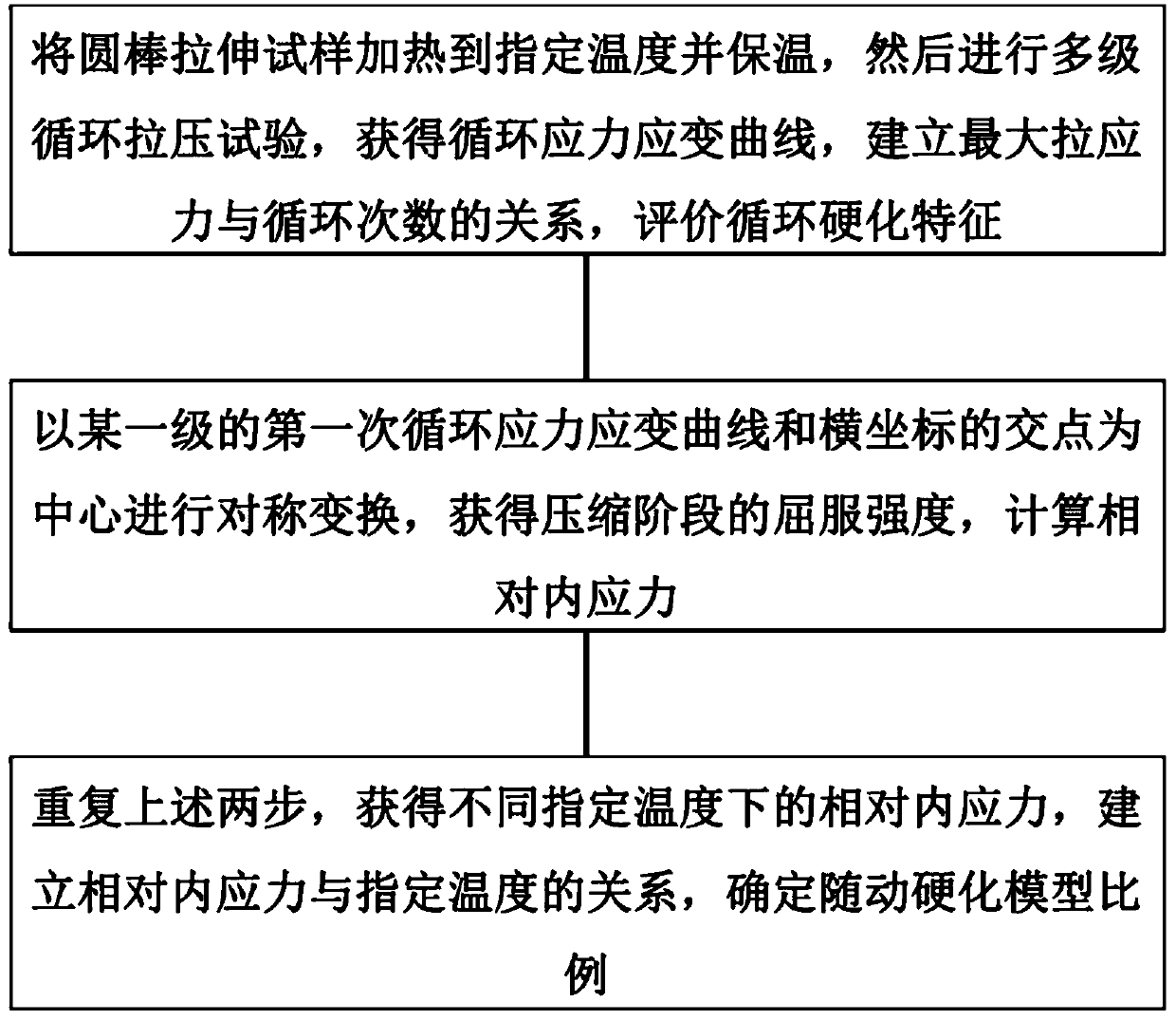

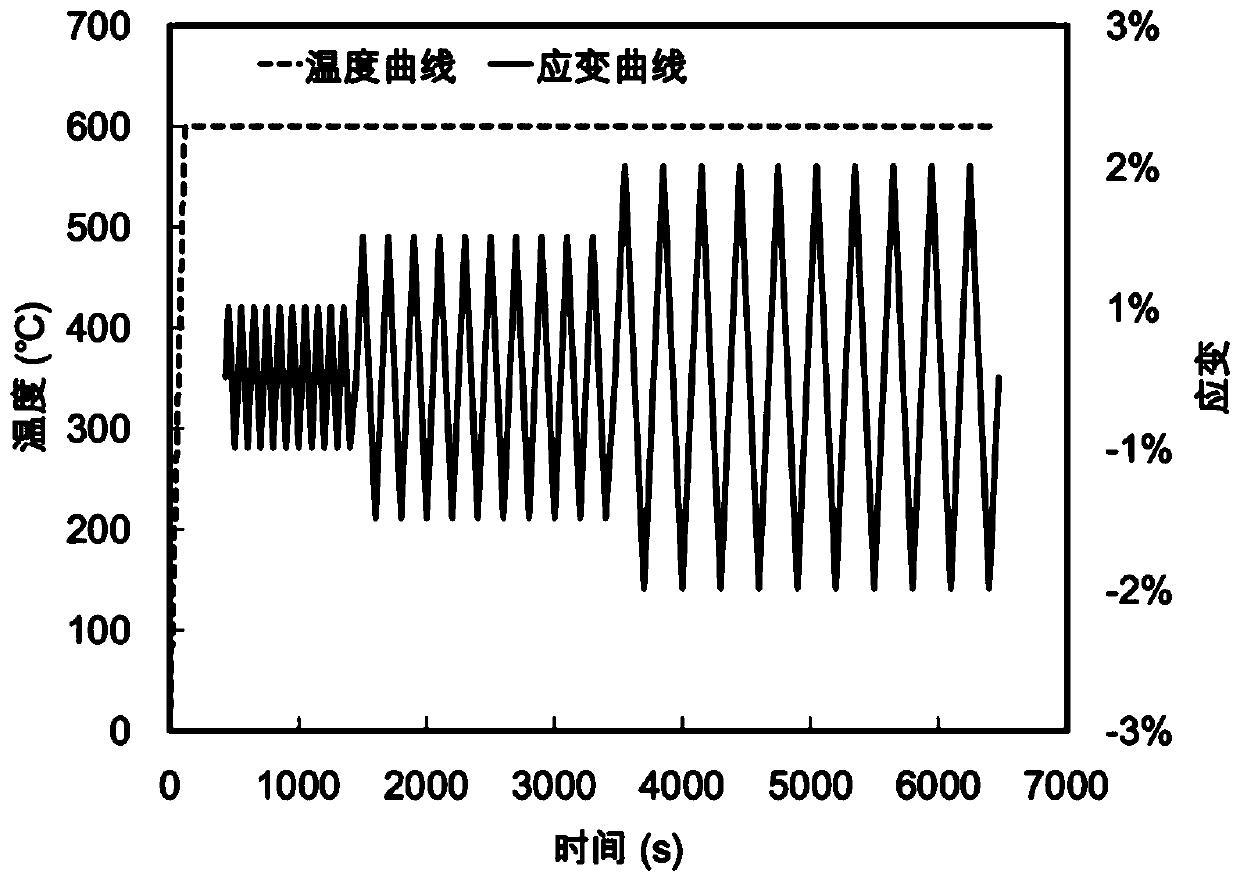

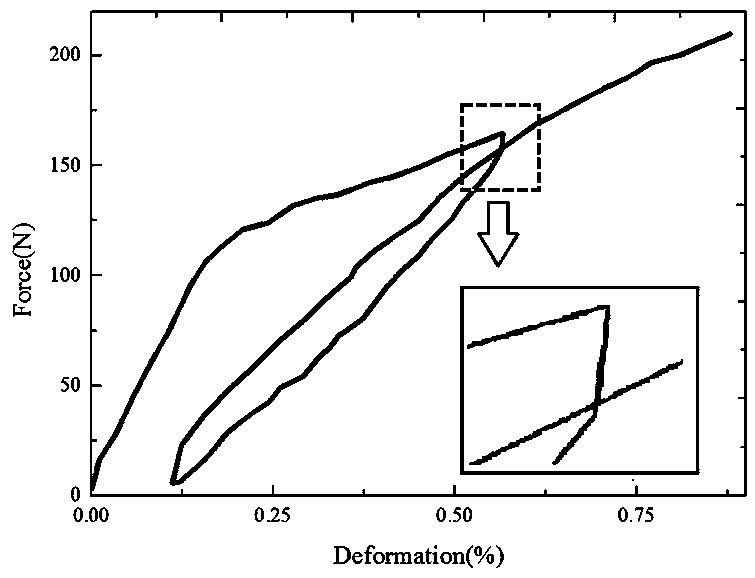

Material cyclic hardening behavior testing method in welding process

InactiveCN110308059AImprove accuracyMaterial strength using repeated/pulsating forcesStress–strain curveFatigue testing

The invention relates to a material cyclic hardening behavior testing method in welding process. The testing method comprises the following steps: 1) mounting a test sample on a high-temperature fatigue testing machine, heating the test sample to set temperature in a certain heating speed by using an annular infrared heating furnace, and preserving the heat of the test sample; 2) performing multi-stage load cyclic tensile-compression test by adopting strain control; 3) drawing a stress-strain curve graph of the cyclic tensile-compressive test, establishing a relation of the maximum tensile stress and cyclic number under the set temperature, and determining a strain hardening characteristic based on the maximum tensile stress change tendency; 4) computing the relative internal stress according to the cyclic stress-strain curve of the cyclic tensile-compressive test; and 5) taking a relative internal stress mean of the temperature under a test sample material mechanics melting point as the proportion of the test sample material follow-up hardening model according to the relation curve of the relative internal stress and the test temperature. Compared with the prior art, the testing method disclosed by the invention has the advantages of qualitatively evaluating the cyclic hardening characteristic and quantitatively determining the proportion of the follow-up hardening model.

Owner:SHANGHAI JIAO TONG UNIV

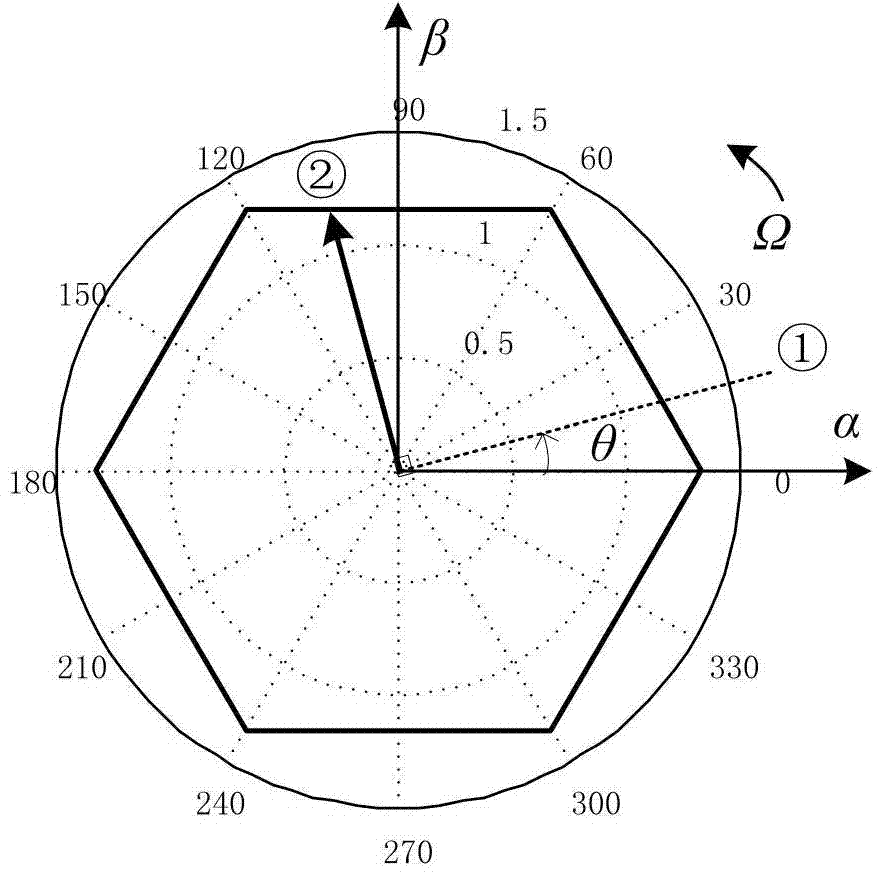

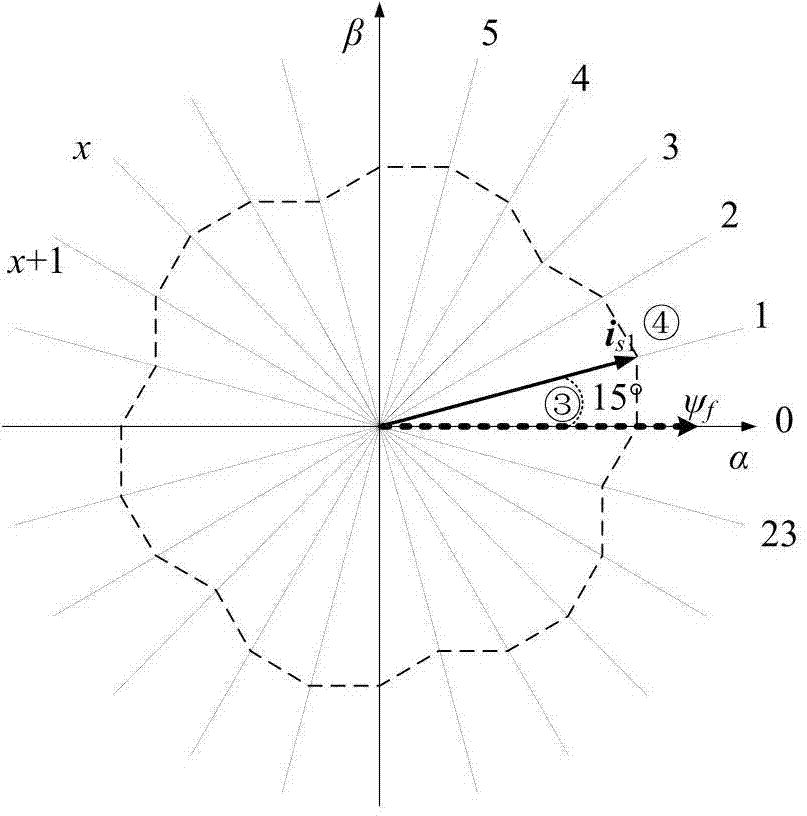

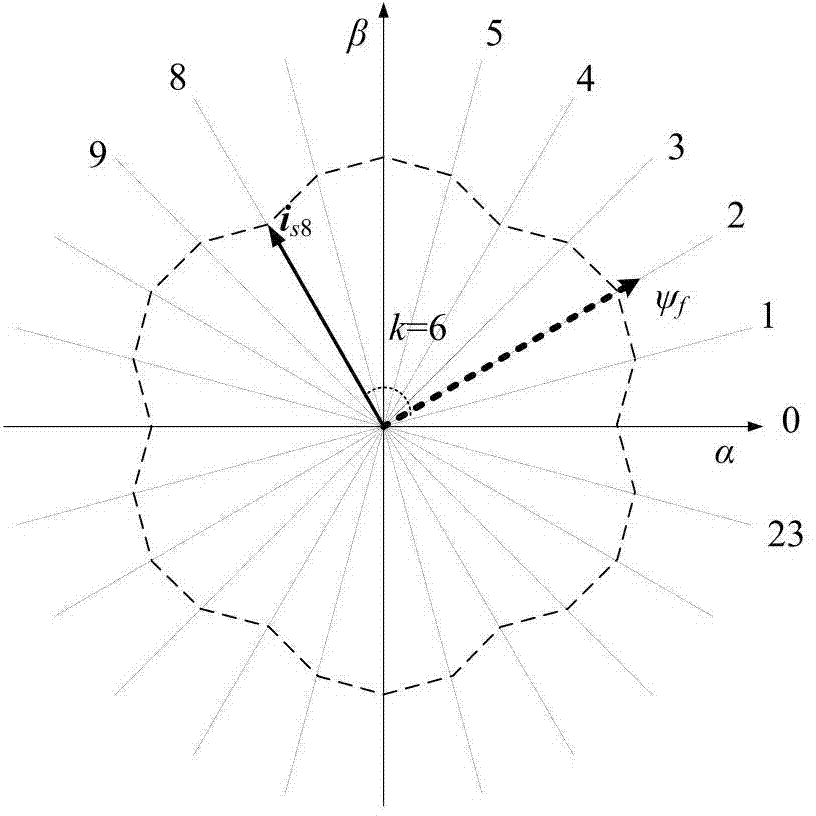

Operation method for stepping constant torque control on permanent magnet brushless direct current motor

ActiveCN104506101AHighlight substantive featuresRealize constant torque step controlElectronic commutation motor controlVector control systemsDigital signal processingBrushless motors

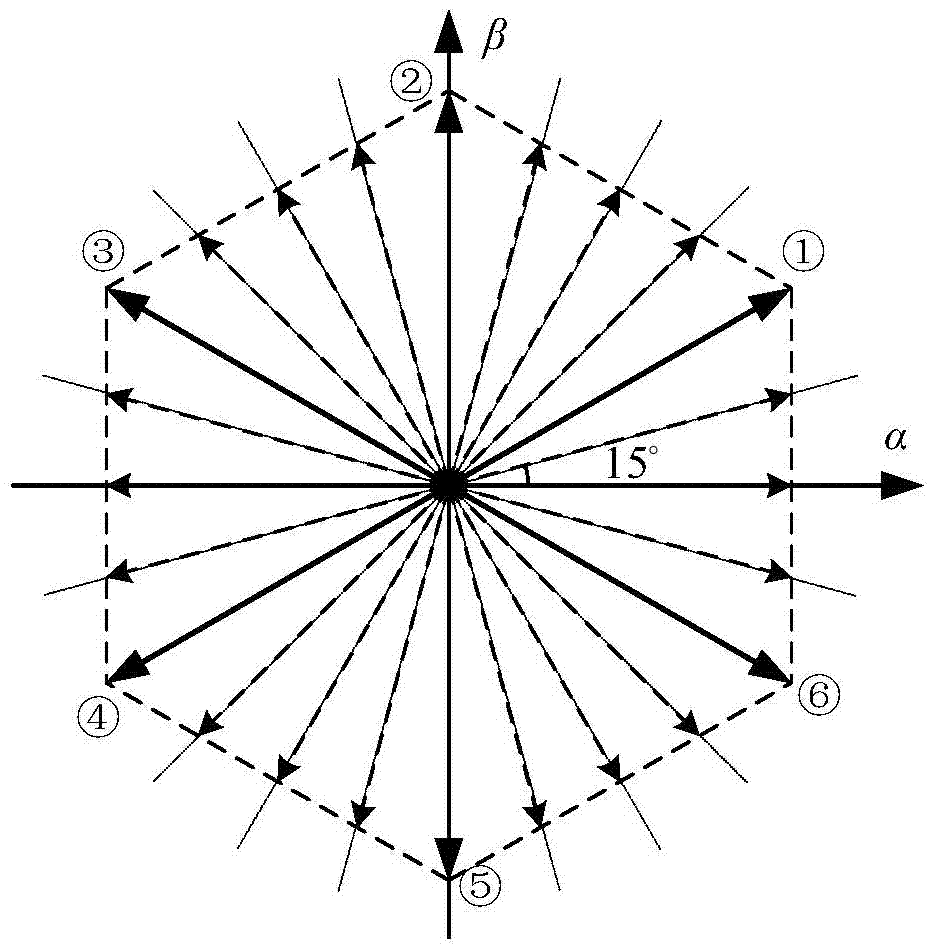

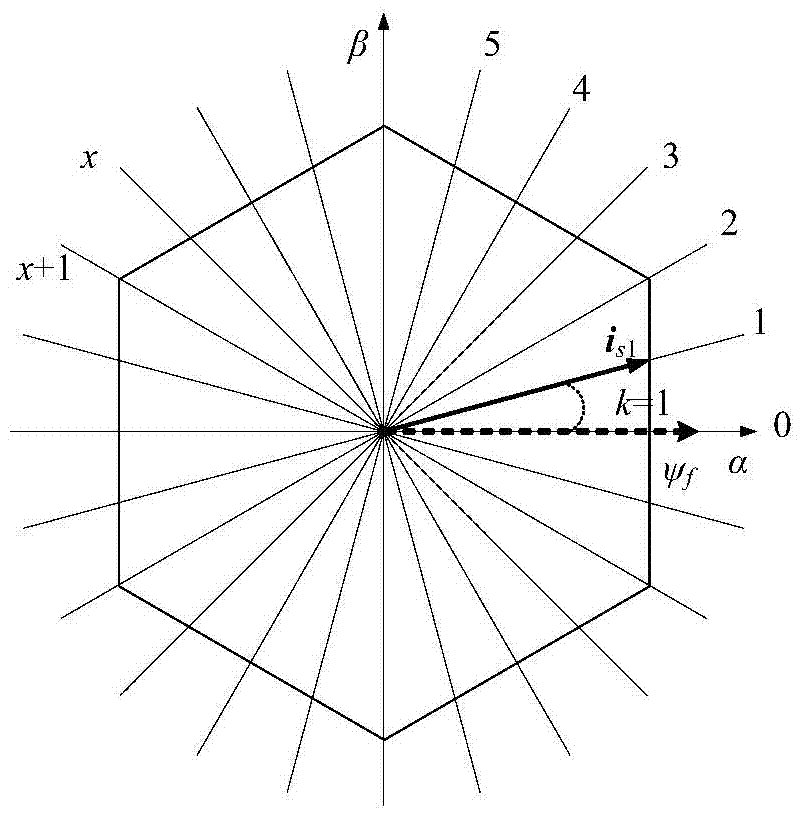

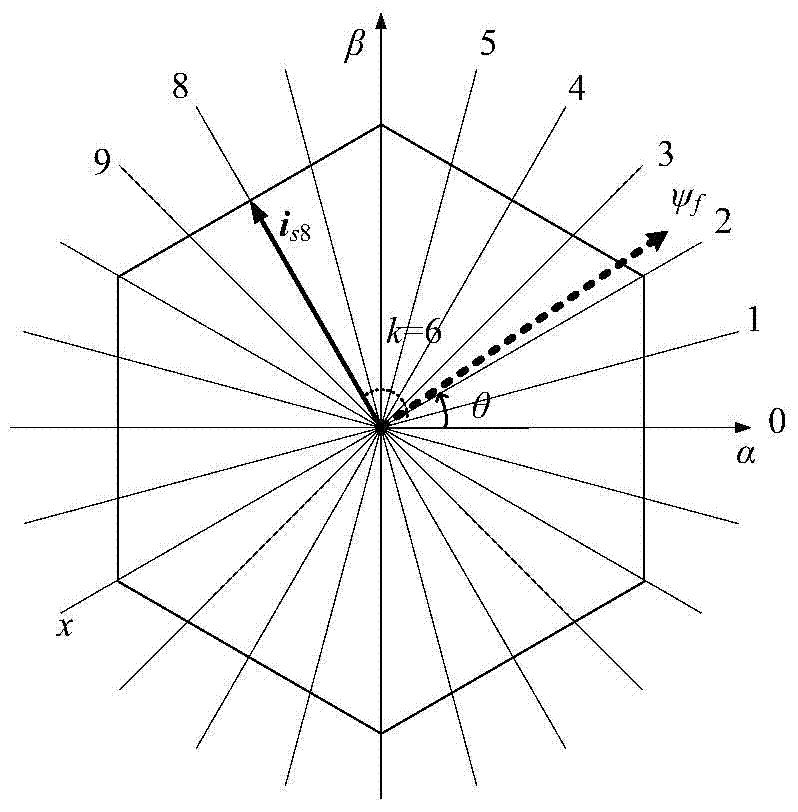

The invention discloses an operation method for stepping constant torque control on a permanent magnet brushless direct current motor, and relates to a motor control technology. A DSP (digital signal processing) control module in a device used in the method calculates a current vector required by control according to a set cyclic number of beats bH, a number of advancing steps k, a given electromagnetic torque T* and an amplitude value of a current vector (is) corresponding to different space positions and converts the current vector required by control into a logic level pulse width modulation signal by a current control method so as to control on and off of a switching tube of a three-phase bridge type inversion circuit in a power circuit, so that stepping constant-torque control on the permanent magnet brushless direct current motor is realized. According to the method, a stator current vector synthesized by three-phase current is dispersed at an electric angle space position according to a certain cyclic number of beats so as to obtain a dispersed current vector for controlling operation of the motor; by increase of the cyclic number of beats, a smaller stepping angle can be obtained, and the position resolution is improved; therefore, the positioning precision of the permanent magnet brushless direct current motor can be improved under the condition of guaranteeing the loading capacity.

Owner:HEBEI UNIV OF TECH

Operation method for stepping dispersion control on permanent magnet brushless direct current motor

ActiveCN104506107AHighlight substantive featuresMany positioning pointsElectronic commutation motor controlVector control systemsDigital signal processingBrushless motors

The invention discloses an operation method for stepping dispersion control on a permanent magnet brushless direct current motor, and relates to a motor control technology. A device used in the method comprises a DSP (digital signal processing) control module, a power circuit, the permanent magnet brushless direct current motor, an encoder position detection module and an input power module. For the common three-phase permanent magnet brushless direct current motor, a stator current vector synthesized by three-phase current is dispersed and subdivided, and a dispersion positioning position in a space is obtained according to a certain cyclic number of beats, so that positioning control on the motor can be realized by controlling the space position of a stator magnetic field, and the positioning precision of the motor is improved; furthermore, the stator current vector synthesized by the three-phase current is dispersed at an electric angle space position according to a certain cyclic number of beats so as to obtain a dispersed current vector for controlling operation of the motor; by increase of the cyclic number of beats, a smaller stepping angle can be obtained, and the position resolution is improved; therefore, the positioning precision of the permanent magnet brushless direct current motor can be improved under the condition of guaranteeing the loading capacity.

Owner:HEBEI UNIV OF TECH

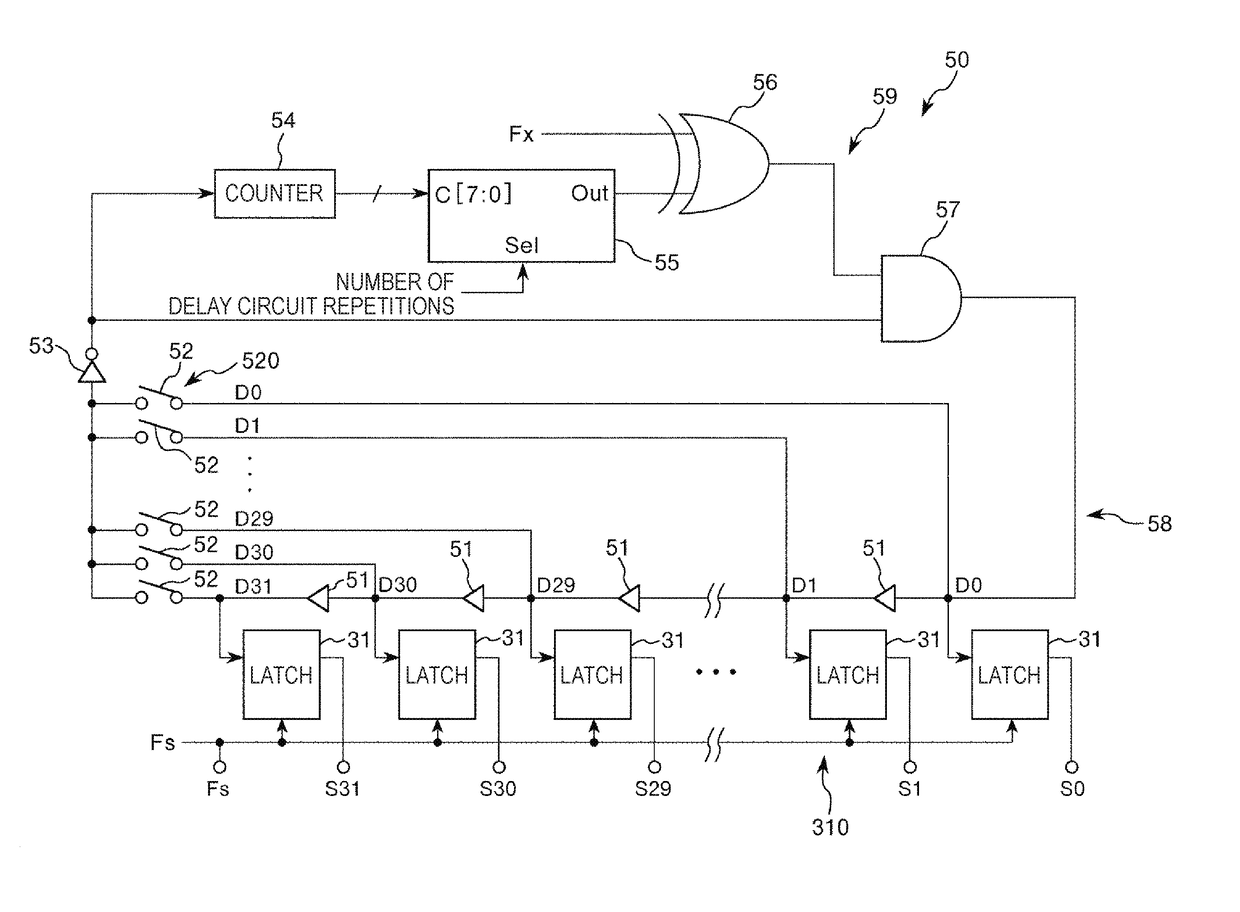

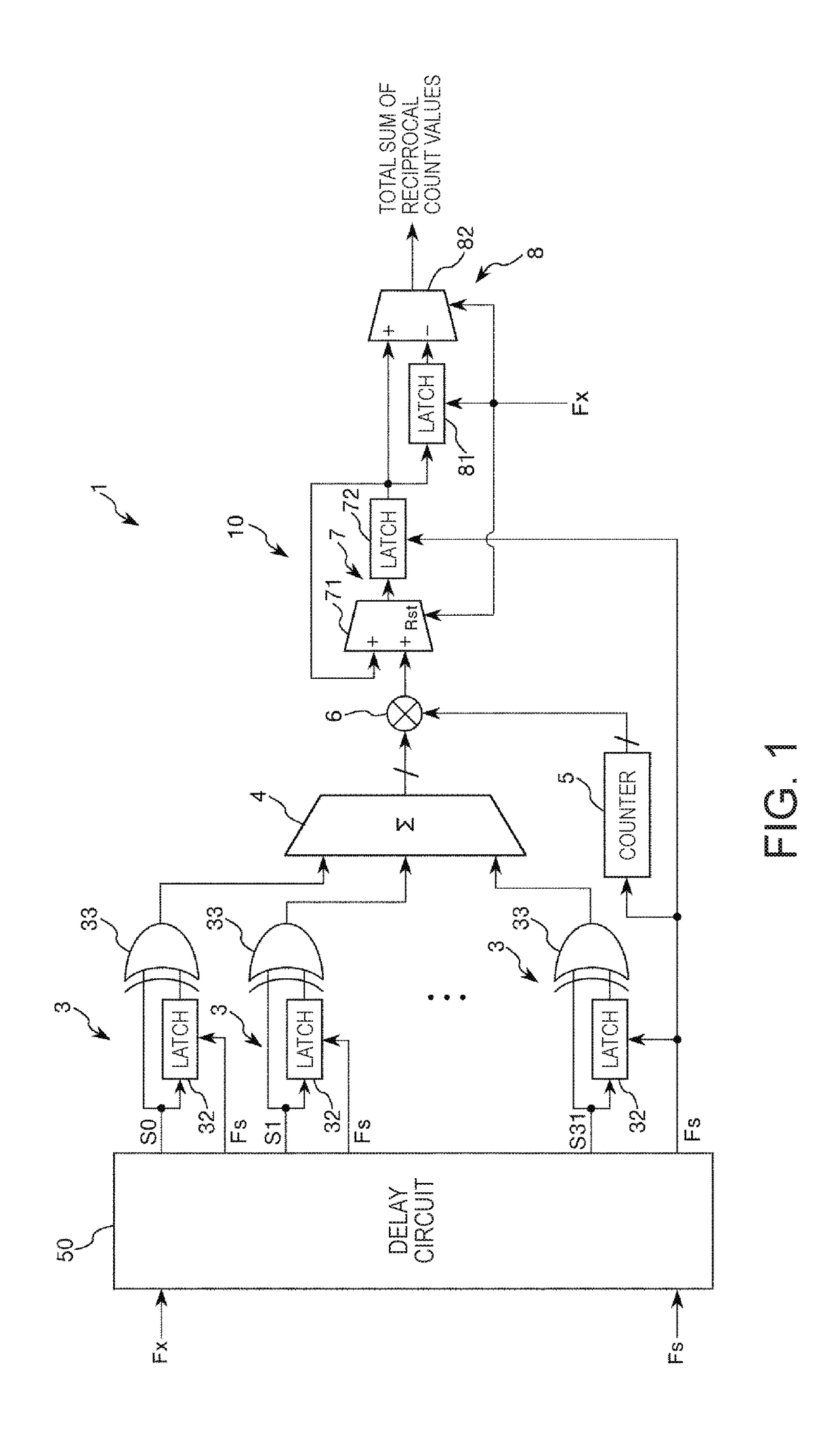

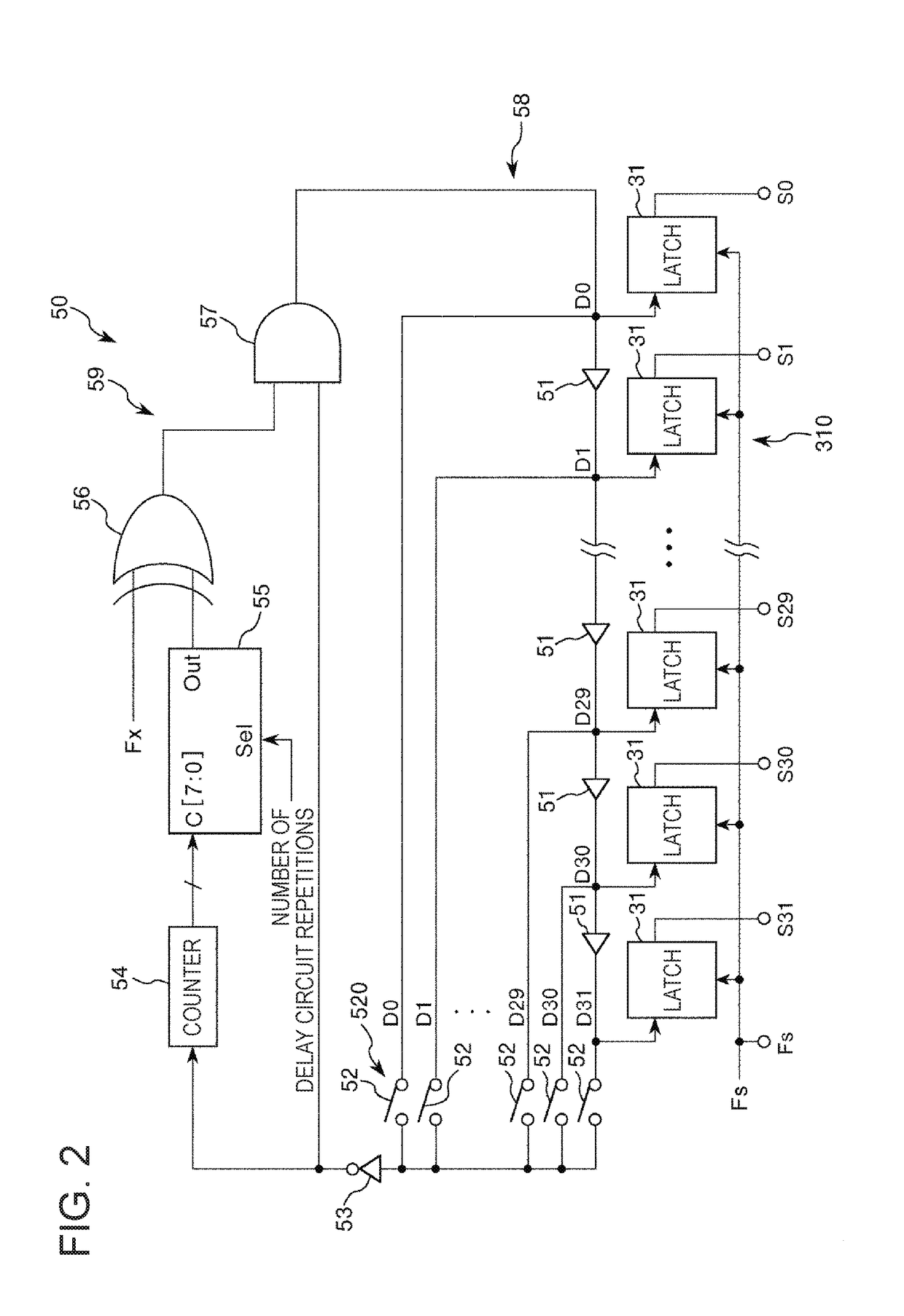

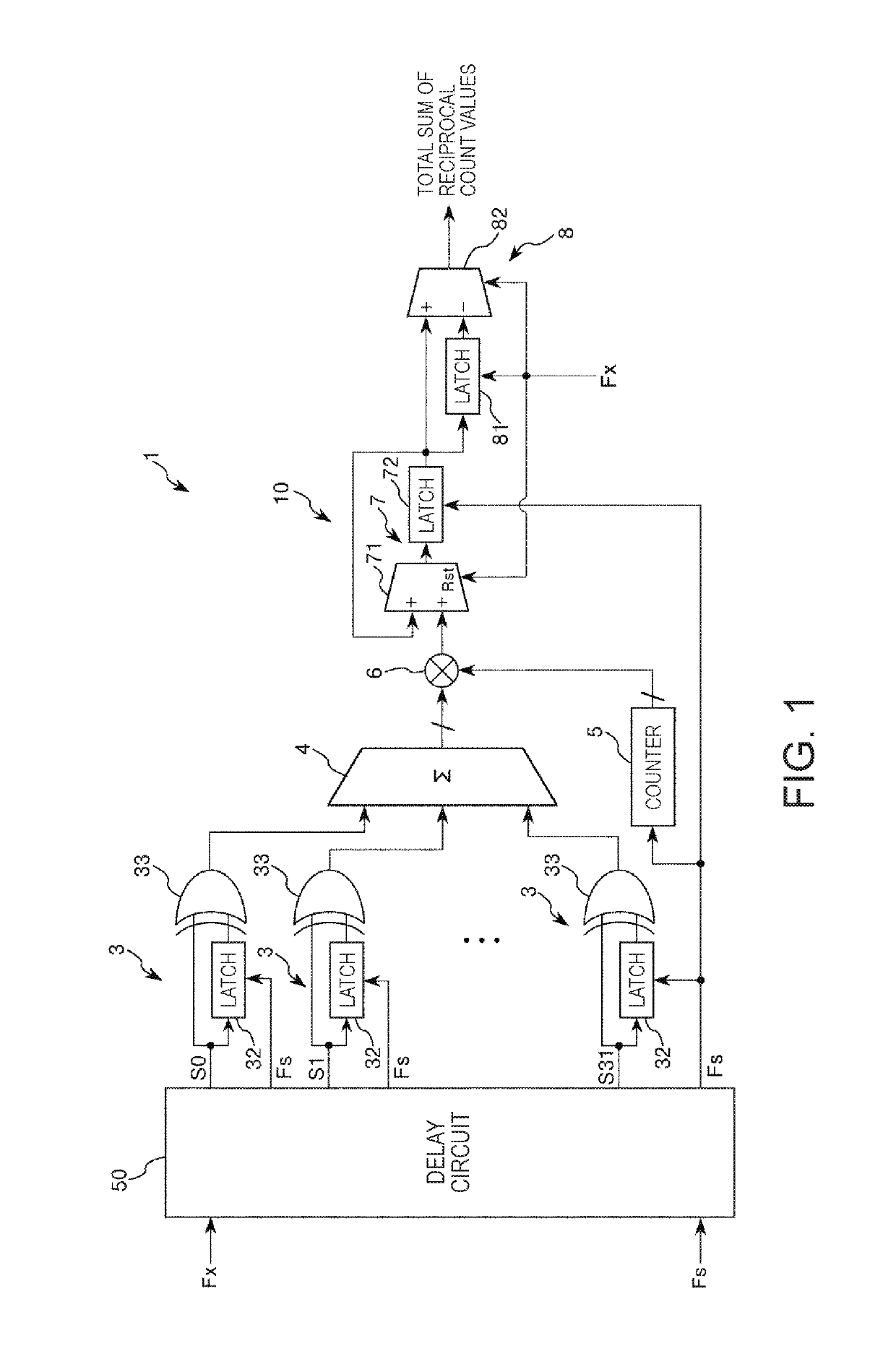

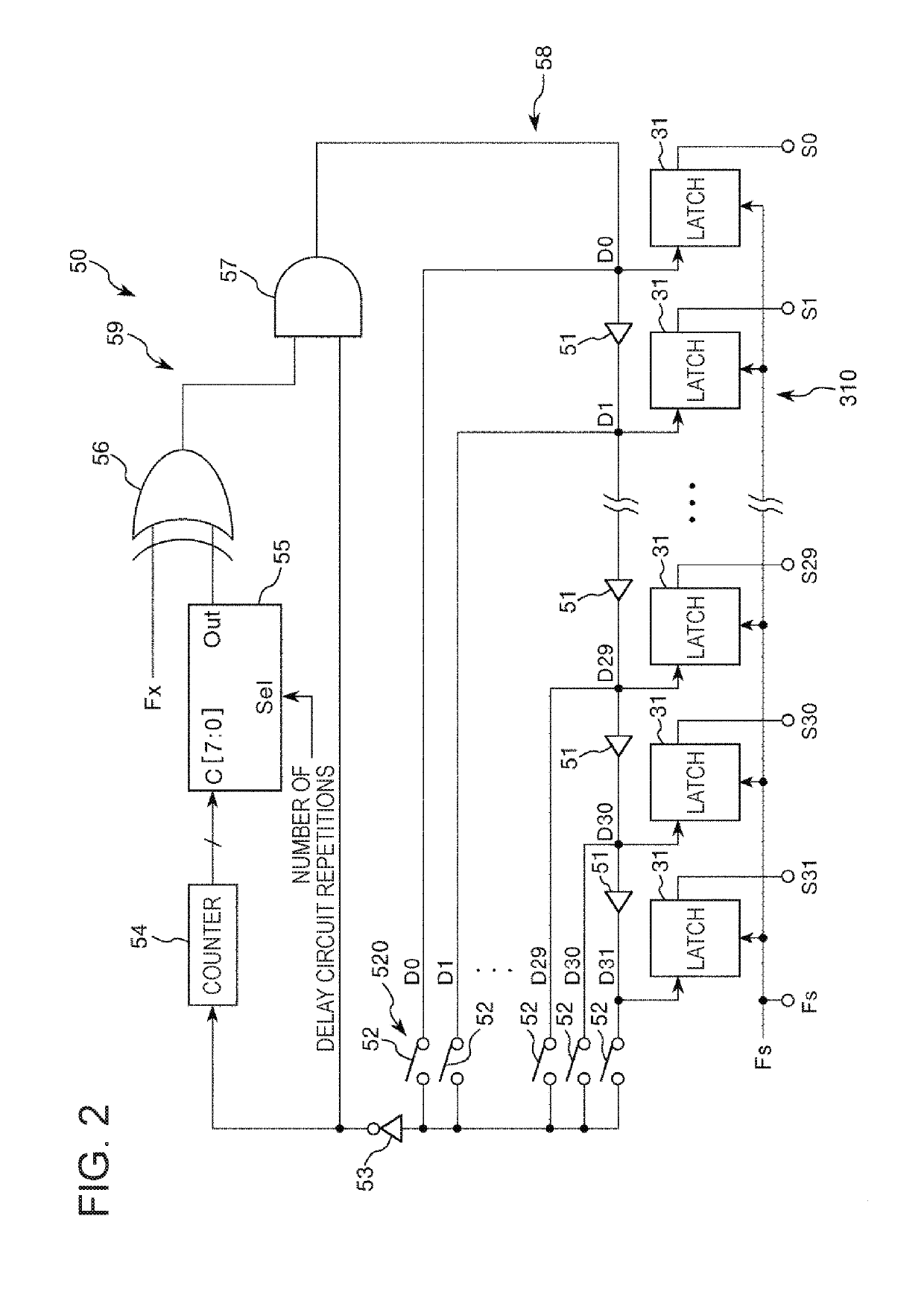

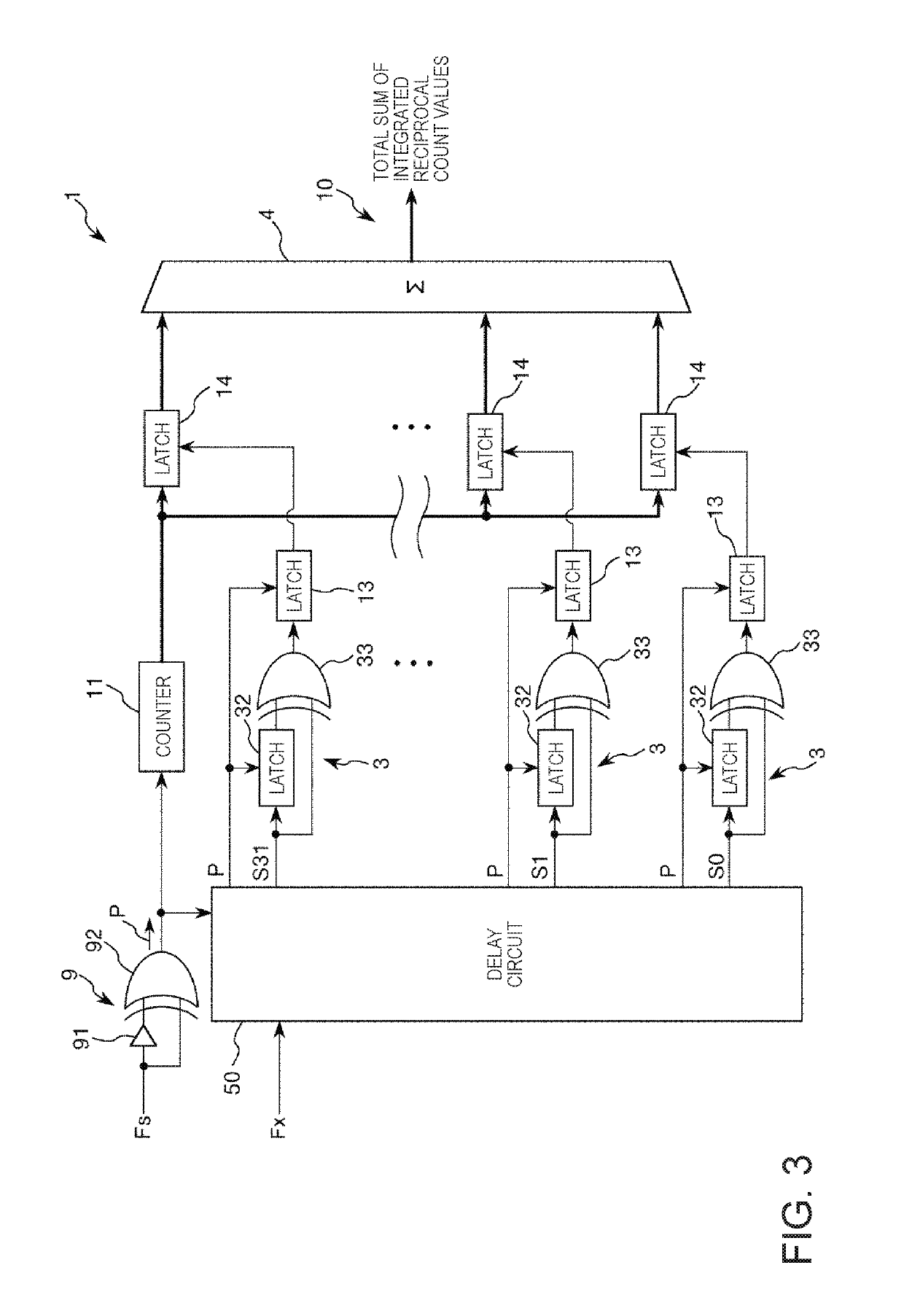

Delay circuit, count value generation circuit, and physical quantity sensor

ActiveUS20180175840A1Improve accuracyHigh-precision detectionExclusive-OR circuitsCounting chain synchronous pulse countersElectricityControl circuit

A delay circuit includes: a cyclic number control circuit that generates a third signal based on first and second signals generated based on a trigger signal; a loop circuit in which a plurality of delay elements are electrically connected in series, one output of outputs of the plurality of delay elements is fed back to form a loop, and the third signal is input to the delay element at an initial stage; and a latch circuit that latches output values of the plurality of delay elements as latch signals. The second signal is one output among the outputs of the plurality of delay elements. The loop circuit stops the feedback when a cyclic number of loops reaches a prescribed cyclic number.

Owner:SEIKO EPSON CORP

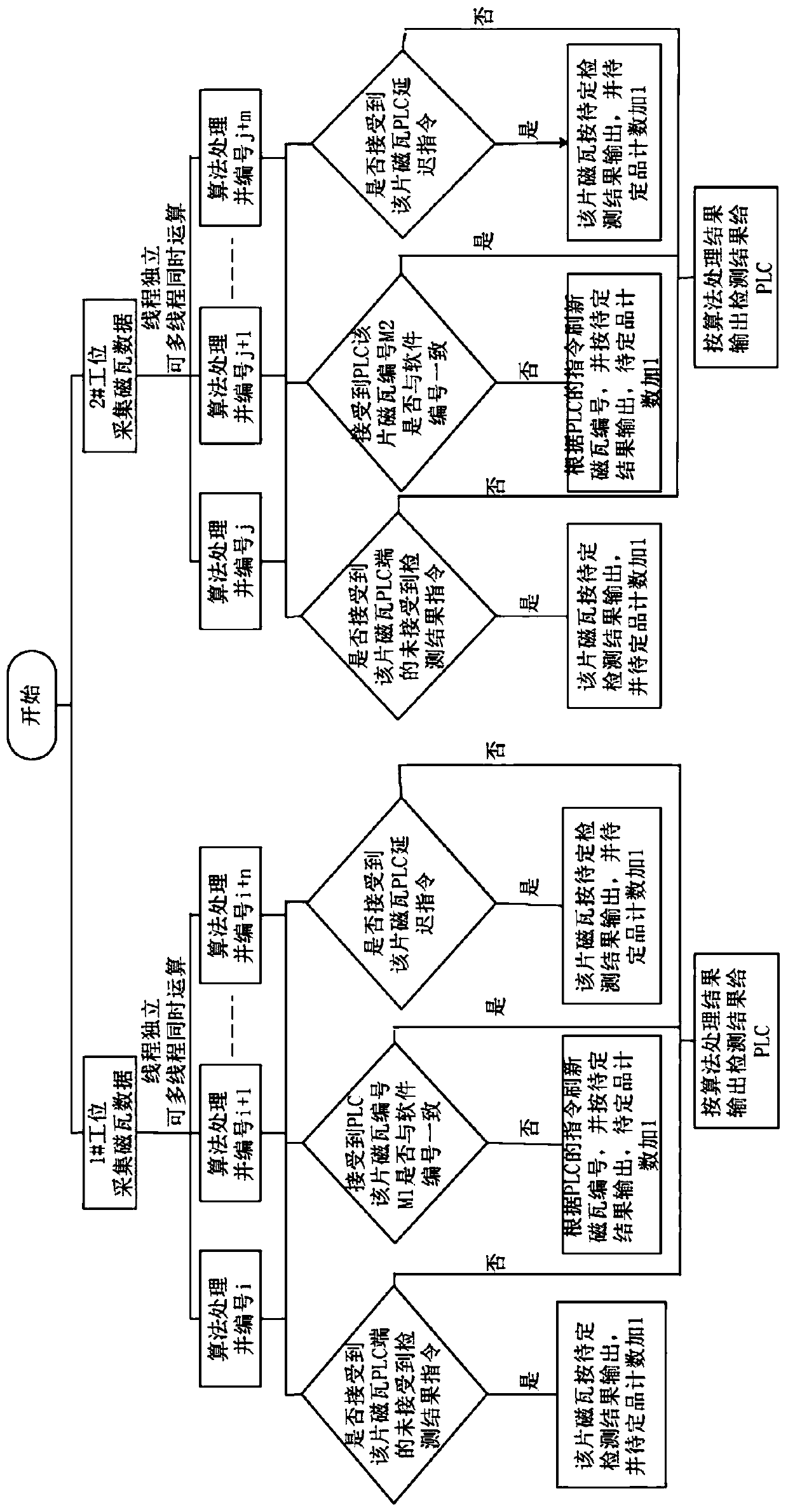

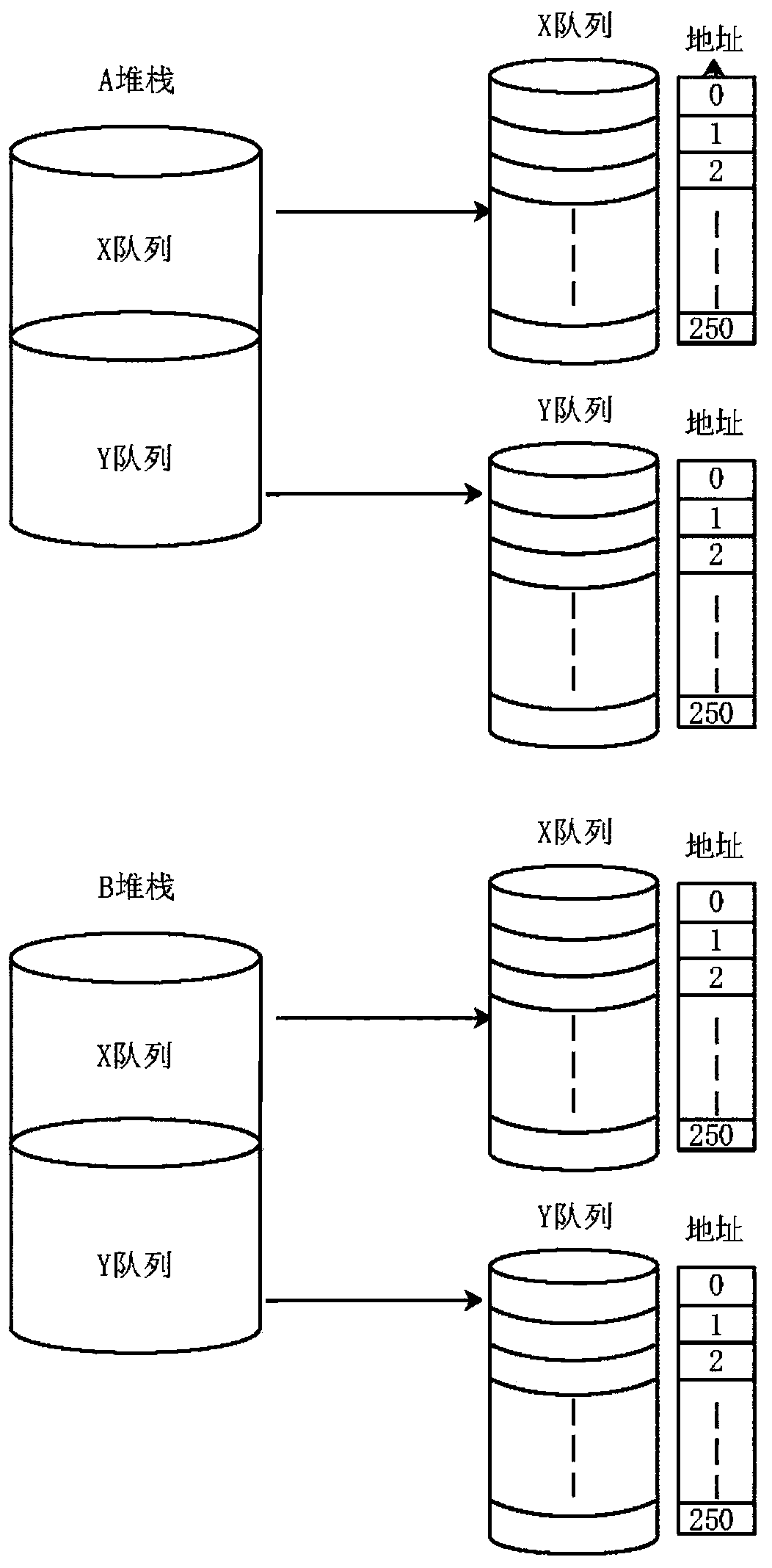

Machine vision equipment communication verification method based on PLC serial communication

InactiveCN108196524ASolve the problem of communication out of syncAccurate sortingProgramme controlElectric testing/monitoringMachine visionVisual perception

The invention relates to a machine vision equipment communication verification method based on PLC serial communication. The method includes the following aspects: 1) a PC side which performs cyclic numbering on each picture of an object to be detected which is obtained by a camera, encodes a detection result of each picture and the encoded detection results are pressed into a detection result stack from a rear end according to a time sequence, a detection result sending thread being developed; and 2) a PLC side which performs cyclic numbering on each photographing signal, and establishes a removal moment stack.

Owner:TIANJIN PUDA SOFTWARE TECH

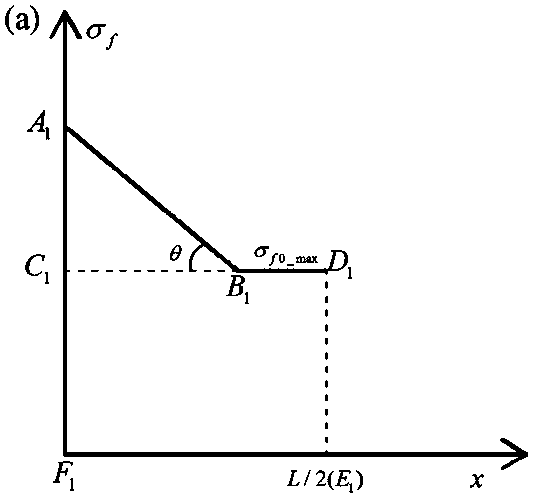

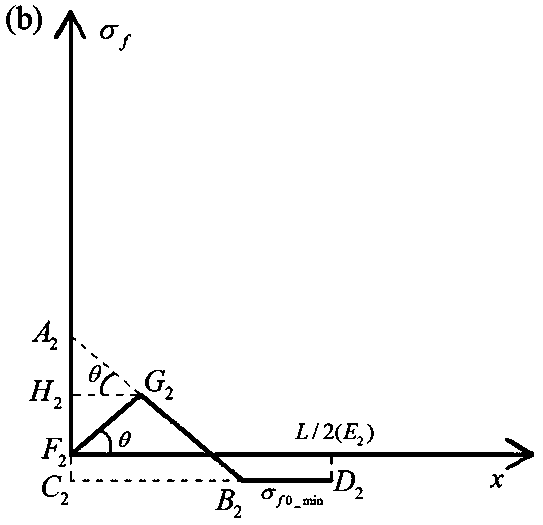

A Method for Identifying Interface Parameters of Ceramic Matrix Composites

ActiveCN109632537BSimple methodShort timeUsing mechanical meansDesign optimisation/simulationFatigue loadingSecant modulus

The invention provides a ceramic matrix composite interface parameter identifying method. The method comprises the steps that a unidirectional ceramic matrix composite fatigue test is carried out to acquire a material loading and unloading stress-strain curve; stress and strain corresponding to the highest point and the lowest point of the loading and unloading stress-strain curve under differentcycle numbers are extracted, and the slope thereof is calculated, wherein the calculated values are the experimental values of hysteresis loop secant modulus under different cycle numbers; a crack observation technology is used to measure the average crack spacing of the material under the maximum fatigue loading stress; based on a shear lag model, a symbolic-graphic combination method is used todetermine the theoretical expression of the hysteresis loop secant modulus under different interface debonding and slip states; and the experimental values of the hysteresis loop secant modulus underdifferent cycle numbers are brought into the theoretical expression of the hysteresis loop secant modulus to identify the numerical values of the interface friction force under different cycle numbers. The method provided by the invention can identify the numerical values of the interface friction force under different cycle numbers based on the fatigue loading and unloading stress-strain curve, is simple and easy to implement, and consumes less time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

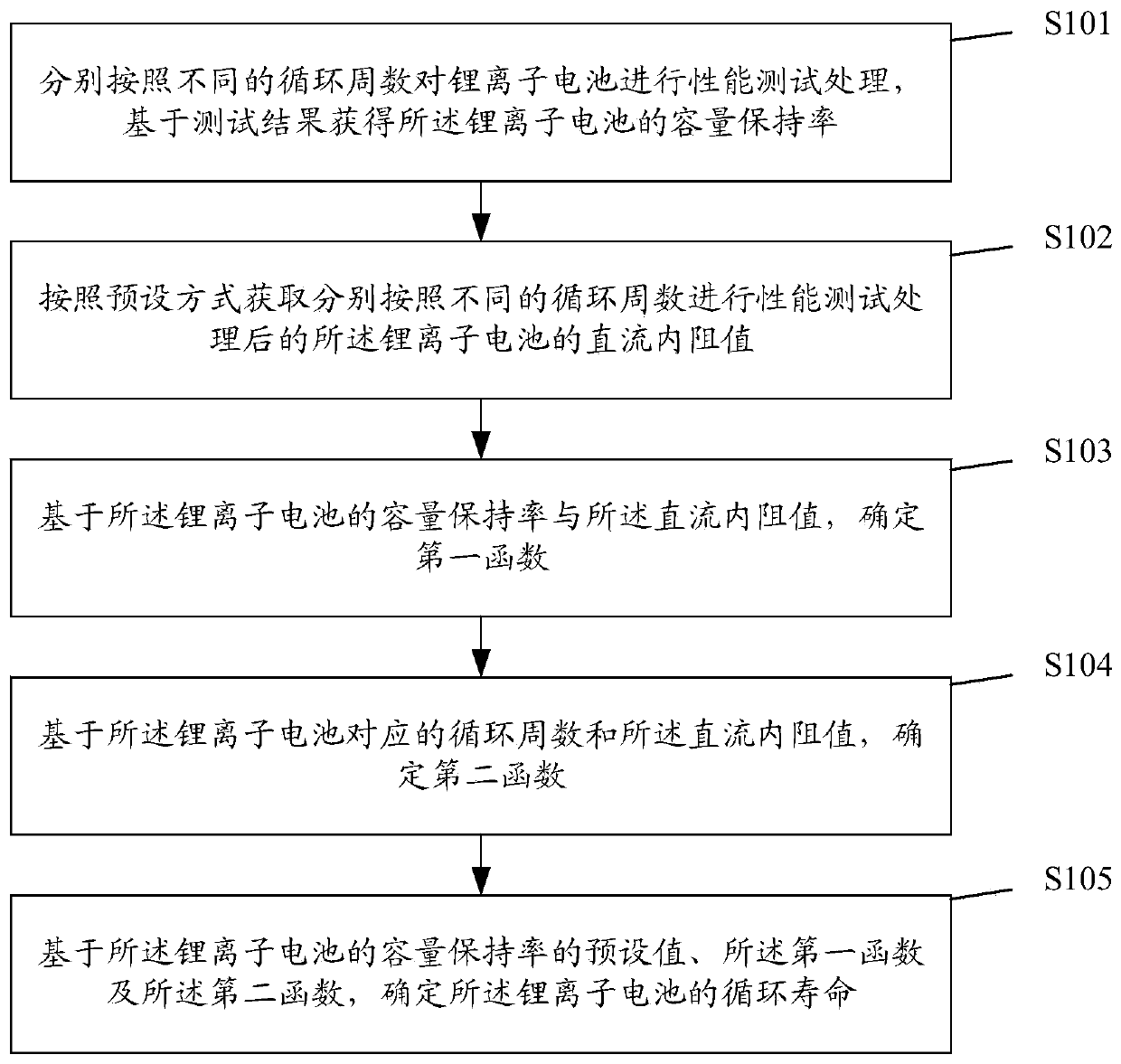

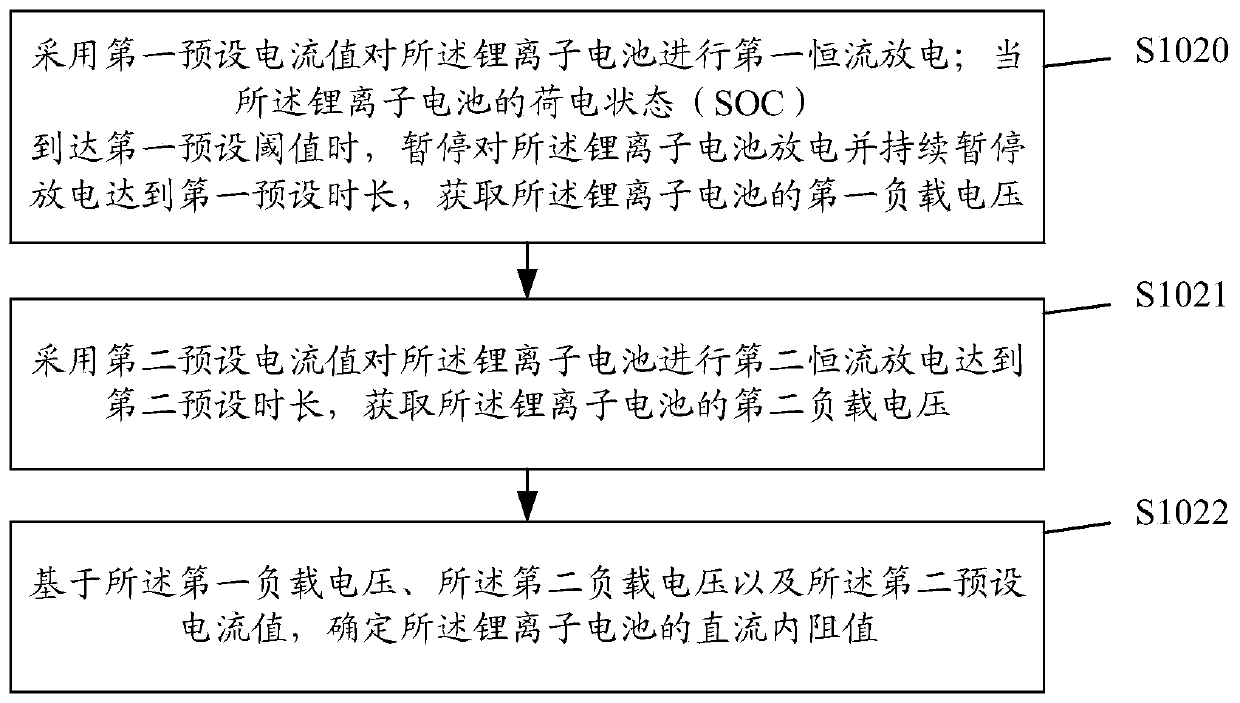

Battery cycle life prediction method, battery cycle life prediction device and storage medium

The embodiment of the invention provides a battery cycle life prediction method, a battery cycle life prediction device and a storage medium. The method comprises the steps of: performing performancetest processing on a lithium ion battery according to different cyclic numbers respectively, and obtaining the capacity retention ratio of the lithium ion battery based on a test result; according toa pre-set manner, obtaining the direct-current internal resistance value of the lithium ion battery subjected to performance test processing according to different cyclic numbers respectively; on thebasis of the capacity retention ratio and the direct-current internal resistance value of the lithium ion battery, determining a first function; on the basis of the corresponding cyclic number and thedirect-current internal resistance value of the lithium ion battery, determining a second function; and, on the basis of the pre-set value of the capacity retention ratio of the lithium ion battery,the first function and the second function, determining the cycle life of the lithium ion battery.

Owner:蜂巢能源(武汉)有限公司

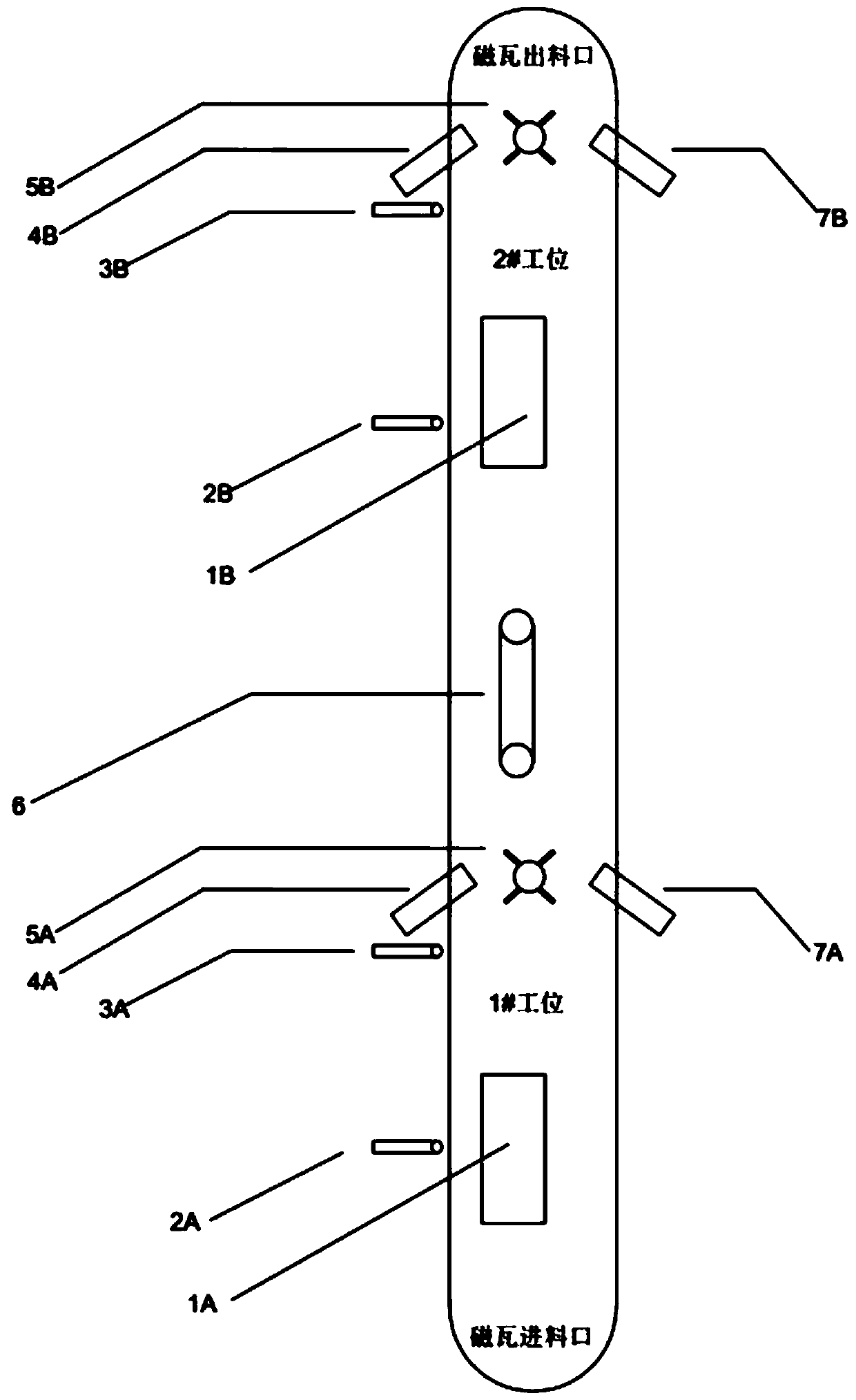

Control system and method of online detection device for magnetic shoes

ActiveCN110369322AMeet the requirements for processing 3D dataDoes not reduce detection efficiencyUsing optical meansSortingControl systemOpto electronic

The invention discloses a control system and method of an online detection device for magnetic shoes. A PC in the control system comprises a first numbering unit used for cyclic numbering when a firstphotoelectric sensor senses the magnetic shoes, an analysis unit used for acquiring a judgment result according to magnetic shoe information acquired by a 3D contourgraph, a first sending unit used for sending serial numbers of the magnetic shoes and the judgment result to a PLC, and a first receiving unit used for receiving the serial numbers, sent from the PLC, of the magnetic shoes; and the PLC comprises a second numbering unit used for numbering when the first photoelectric sensor senses the magnetic shoes, a second sending unit used for sending serial numbers, numbered by the second numbering unit, of the magnetic shoes to the PC, a second receiving unit used for receiving the serial numbers of the magnetic shoes and the judgment result sent from the PC, and an output unit used for controlling a sorting device to work according to the received serial numbers of the magnetic shoes and the judgment result when a second photoelectric sensor senses the magnetic shoes. According to the control system and method, sequential control is conducted on the online detection device for the magnetic shoes, equipment which operates abnormally is diagnosed and corrected, configuration requirements are lowered, and qualified products and unqualified products are accurately sorted.

Owner:湖南航天天麓新材料检测有限责任公司

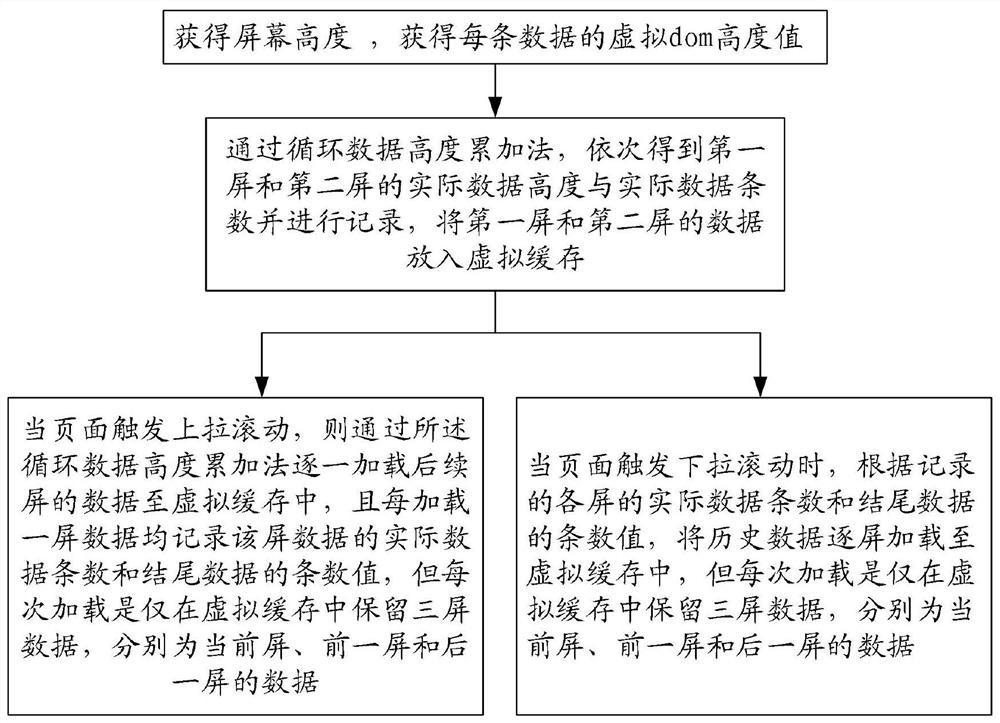

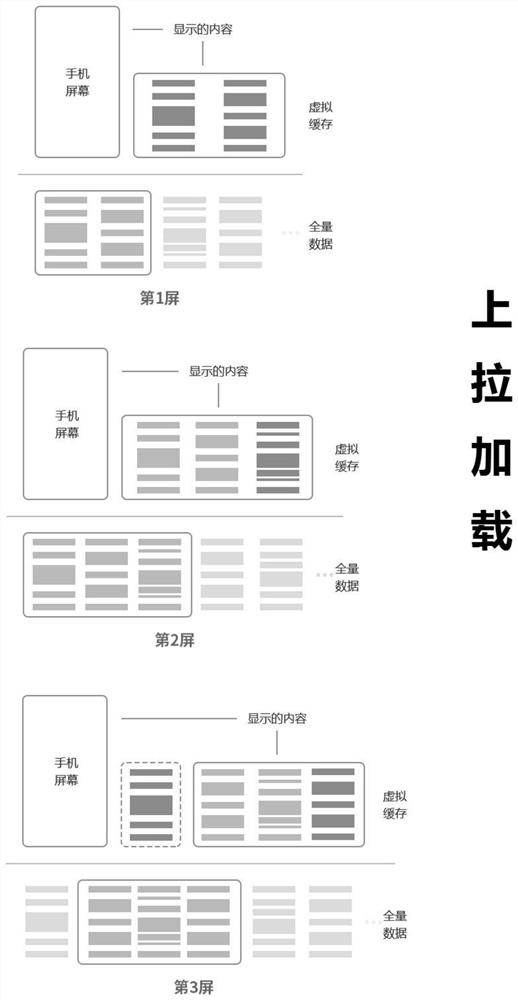

Rendering acceleration method and device for H5 list, equipment and medium

PendingCN113535294ANo lag issueSolve the scrolling is not smoothSoftware engineeringProgram loading/initiatingComputer hardwareParallel computing

The invention provides a rendering acceleration method and device for an H5 list, equipment and a medium. The method comprises the steps of obtaining the screen height and the virtual dom height value of each piece of data; sequentially obtaining the actual data height and the actual data number of the first screen and the second screen through a cyclic data height accumulation method, recording the actual data height and the actual data number, and putting the data of the first screen and the second screen into a virtual cache; when the page triggers pull-up scrolling, loading data of a subsequent screen to the virtual cache one by one through the cyclic data height accumulation method; or when the page triggers pull-down scrolling, loading the historical data to the virtual cache screen by screen, however, the data of the three screens, namely the data of the current screen, the data of the previous screen and the data of the next screen, are only reserved in the virtual cache in each time of loading. According to the invention, the number of virtual caches of the screen is obtained by accumulating the data heights one by one, and rendering is optimized, so that the problems of unsmooth screen rolling and screen jamming caused by the problem of the data content height are solved.

Owner:摩尔元数(福建)科技有限公司

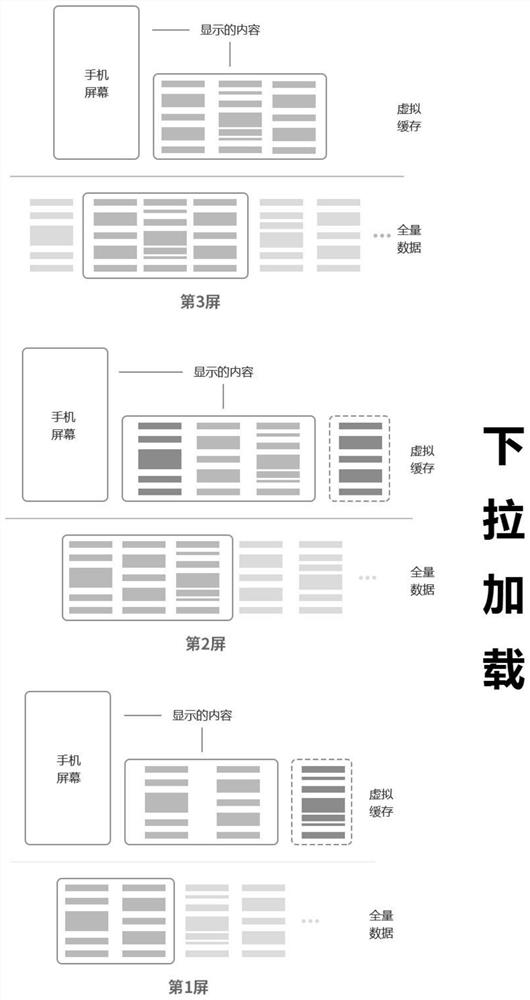

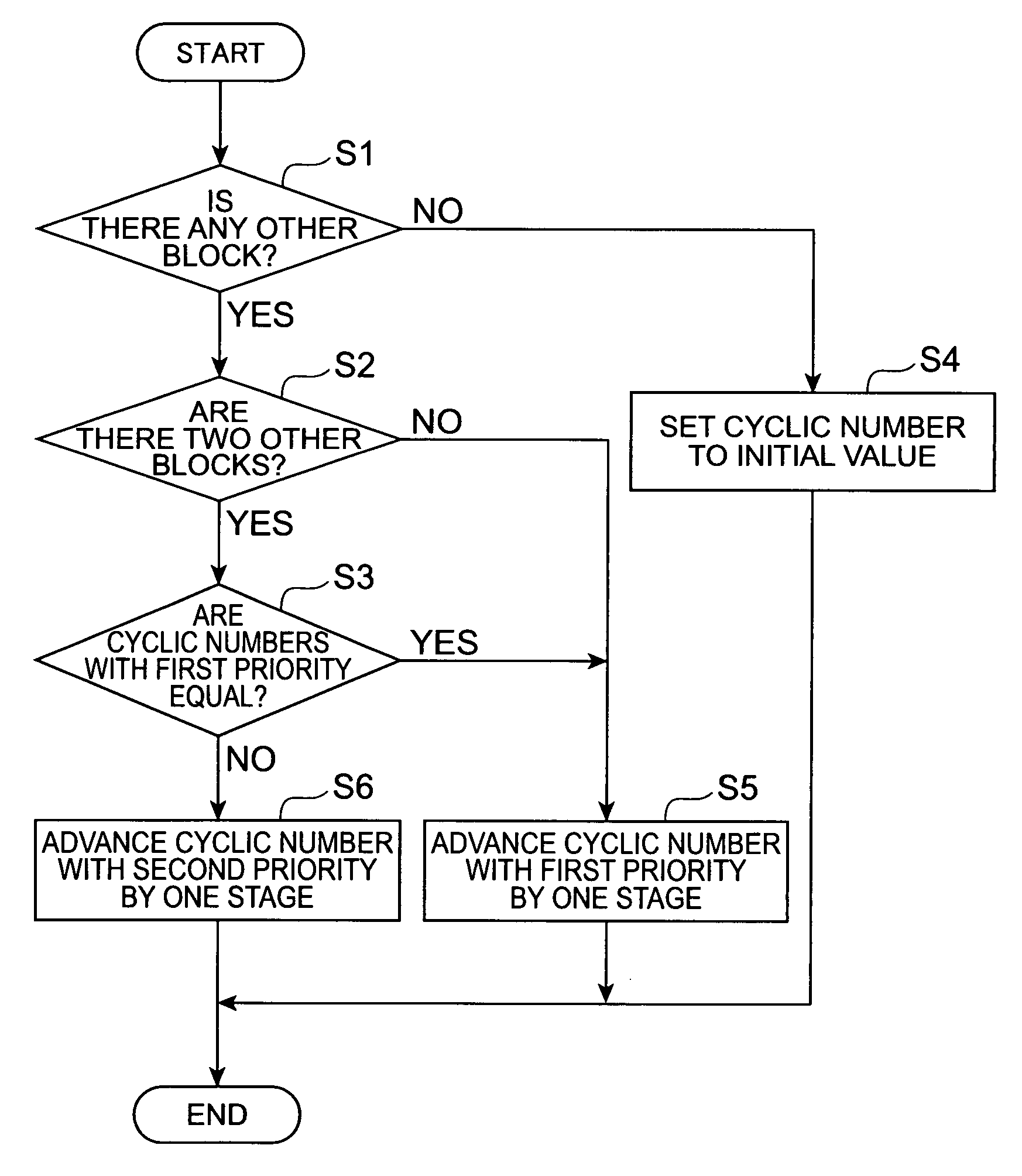

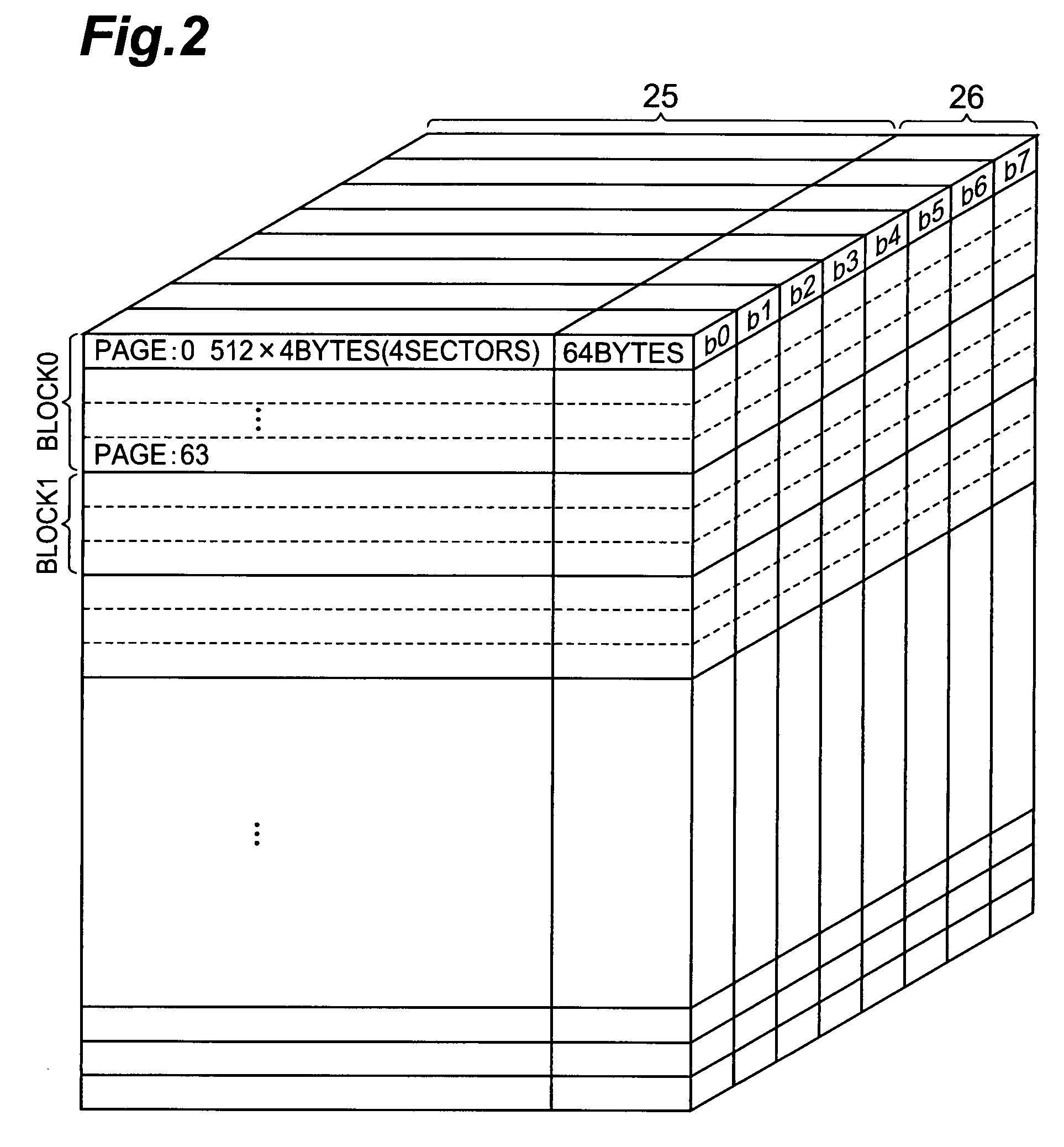

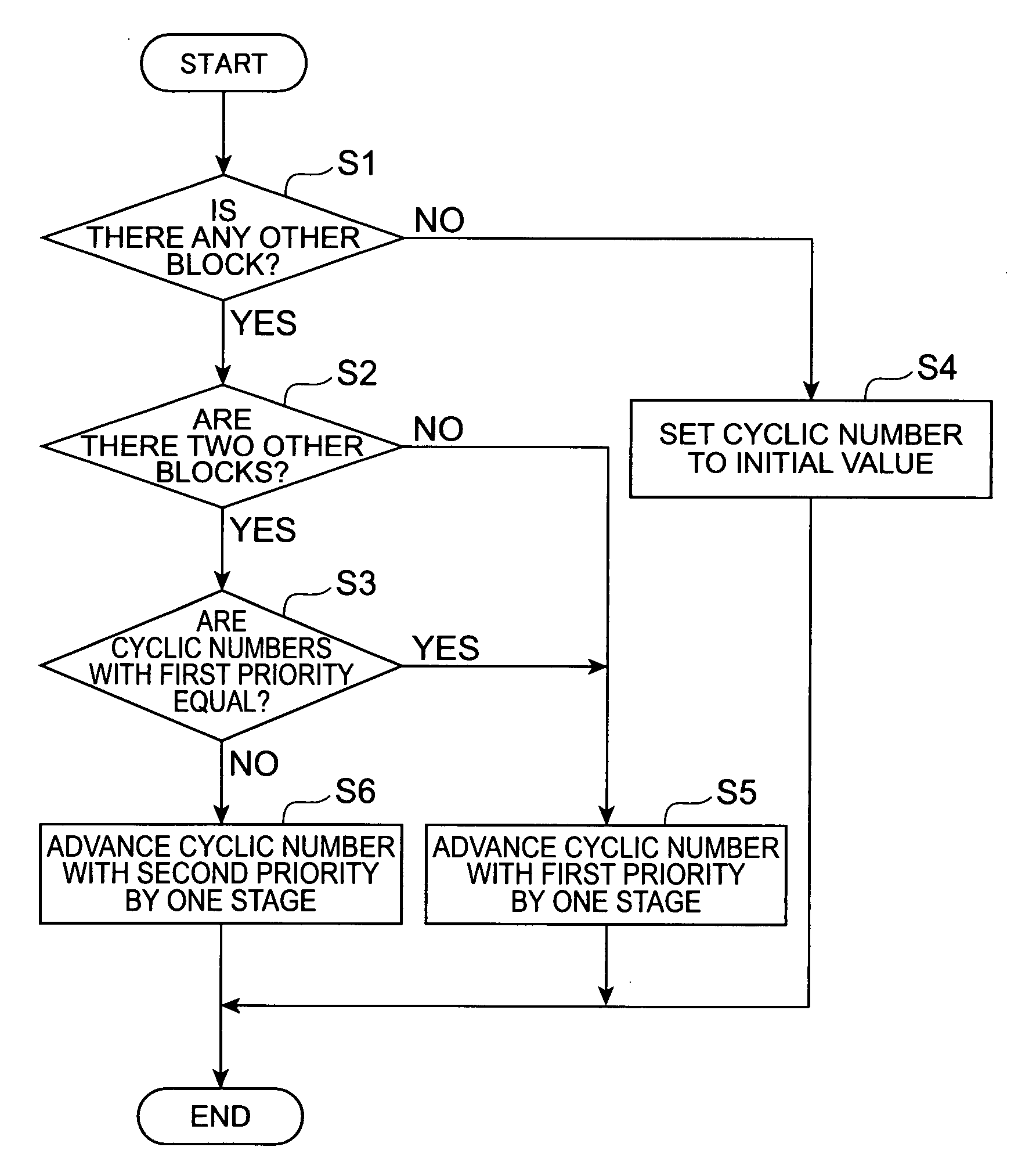

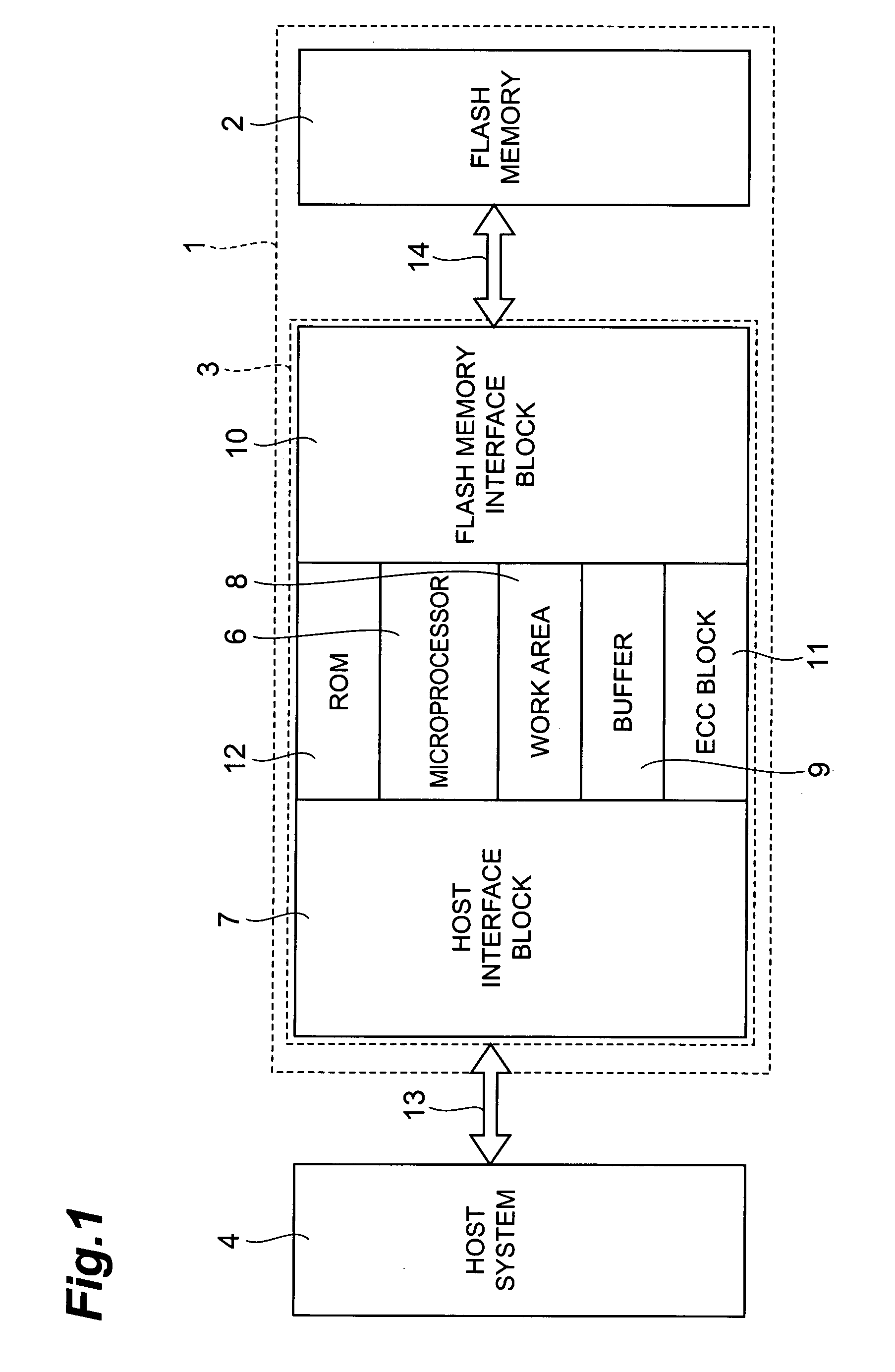

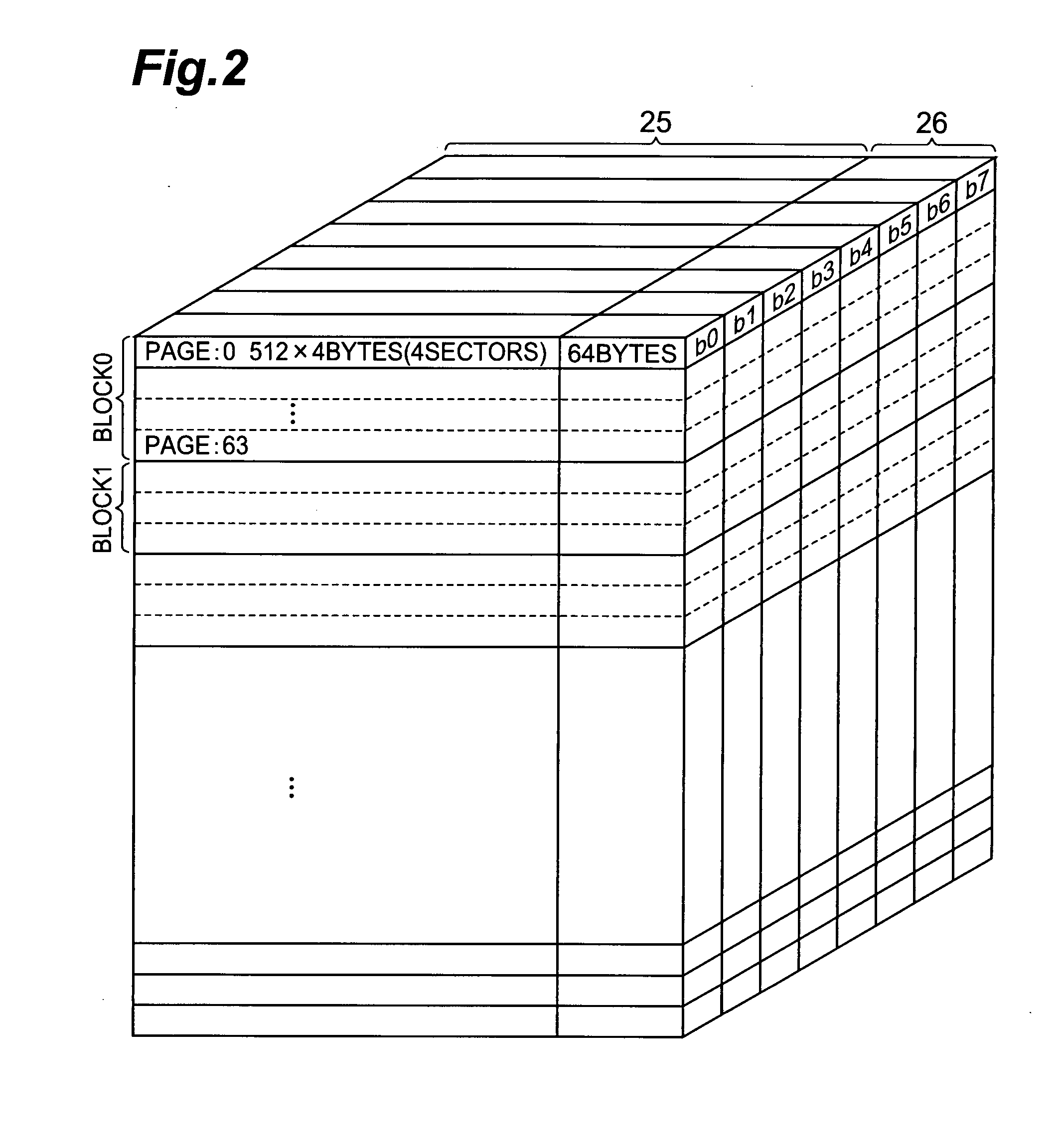

Chronological identification in flash memory using cyclic numbers

ActiveUS7685356B2Accurately determinedMemory architecture accessing/allocationDigital data processing detailsAlgorithmChronological time

Chronological identification information is composed of a plurality of cyclic numbers with priorities. For generating new chronological identification information, the chronological relation is compared in order from cyclic numbers with the highest priority to extract the newest chronological identification information in the chronological relation; when the newest chronological identification information in the chronological relation is extracted, a cyclic number with a priority as a comparison target in the extraction of the extracted chronological identification information is determined to be a cyclic number with the priority in the newly generated chronological identification information. When the cyclic numbers with a priority compared as comparison targets in the chronological identification information all are equal, no further extraction is carried out and the cyclic number subsequent to the cyclic numbers is determined to be a cyclic number with the priority in the newly generated chronological identification information.

Owner:TDK CORPARATION

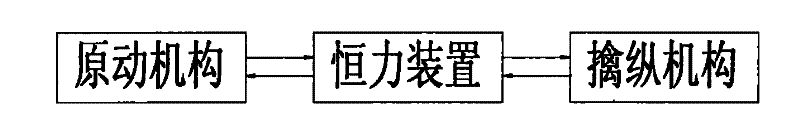

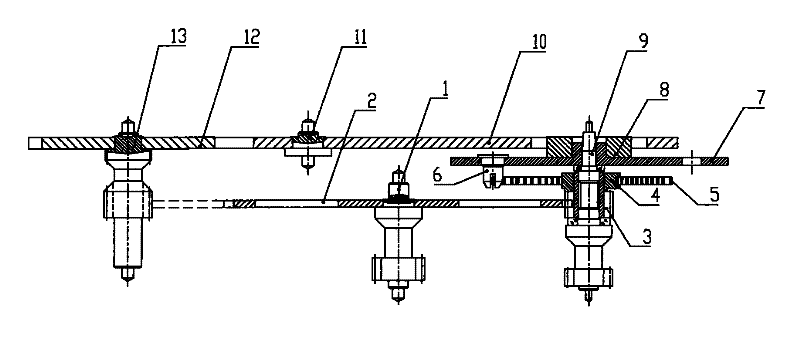

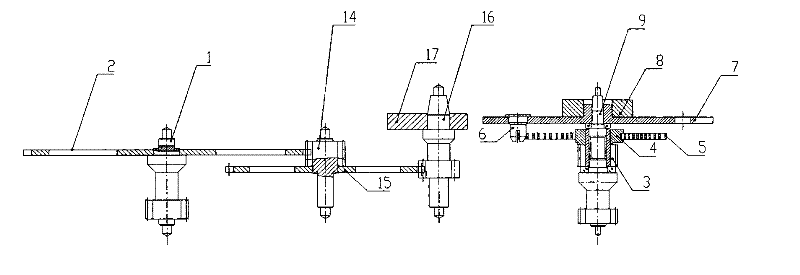

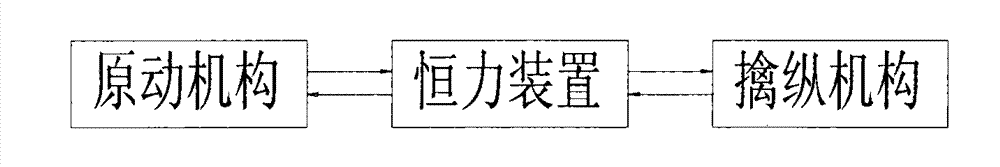

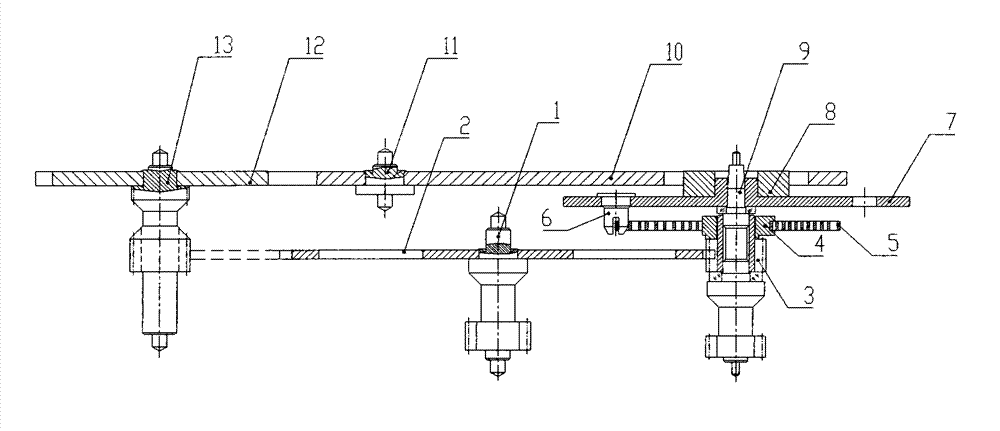

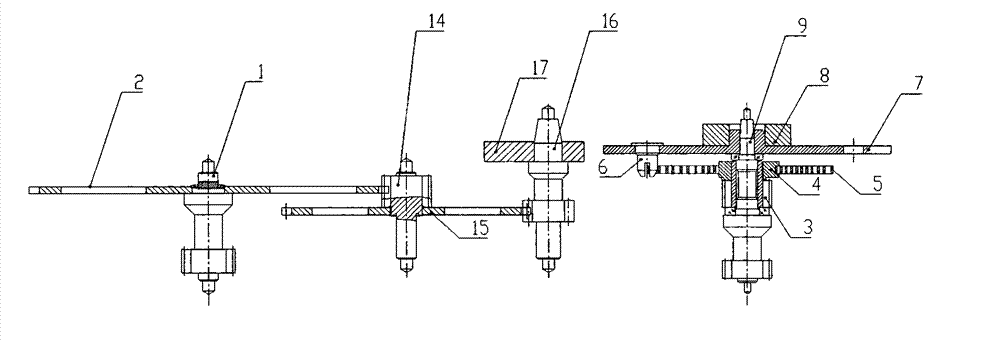

A constant force device for a watch

ActiveCN102269967AWork reliablyStable jobEscapementsClock driving mechanismsDrive wheelConstant power

The invention discloses a constant force device of a watch. The constant force device comprises a constant power part and an anti-sway part, wherein the constant power part is in engaged connection with an anti-sway gear shaft of the anti-sway part through a driving wheel sheet; and the anti-sway part is used for preventing a positioning wheel sheet of the constant power part from rotation when the torque required by a main spring is smaller than the torque required by a middle spring so as to stop the watch from swinging. The invention has the advantages that: an arresting device is added onthe constant force device, the watch can stop swinging as earlier as possible when a brake wheel is free from the control of a fork tile, namely the middle spring cannot reach the upper limit of preload, the unchanged preload cyclic number of the middle spring is ensured when the watch is wound up again, so relative constant torque corresponding to the elastic force of the middle spring can be ensured to be transmitted to an escape wheel. The structure is simple, the running is stable, and the technique is good, so the constant force device can stably and reliably work.

Owner:TIANJIN SEAGULL WATCH CO LTD

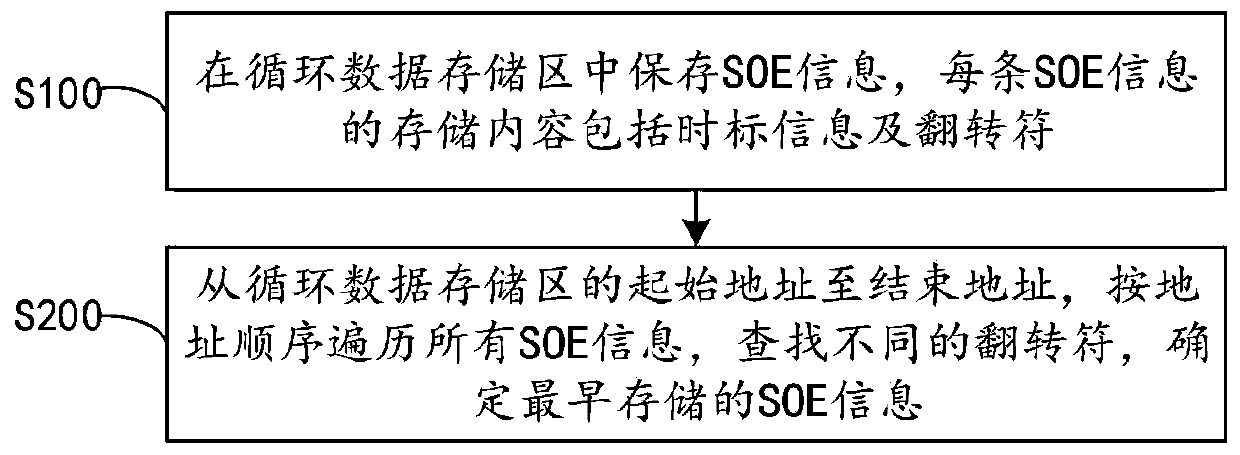

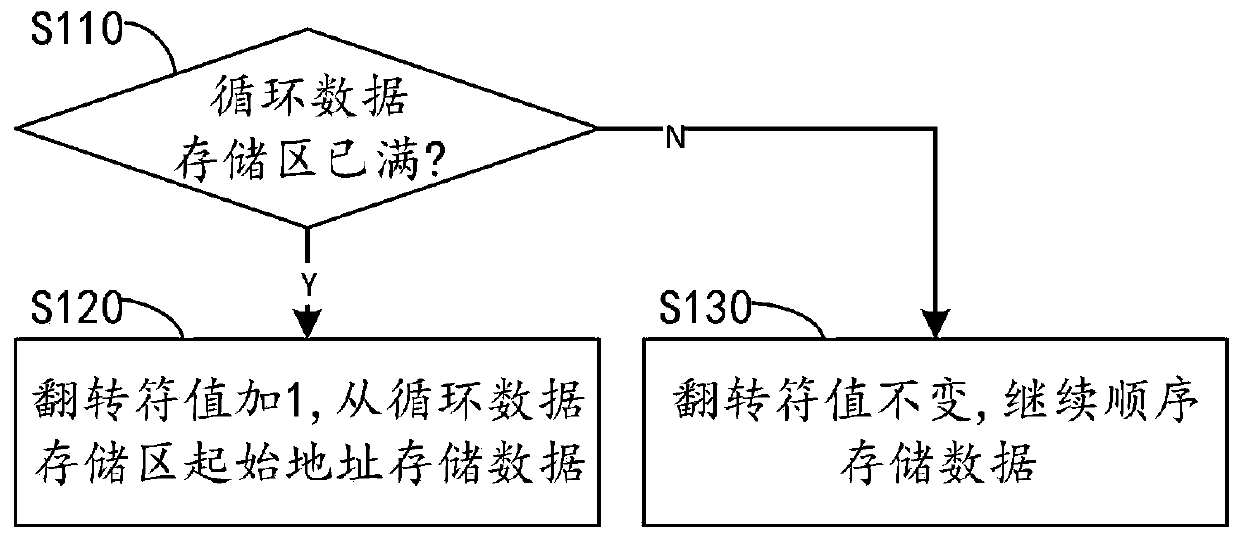

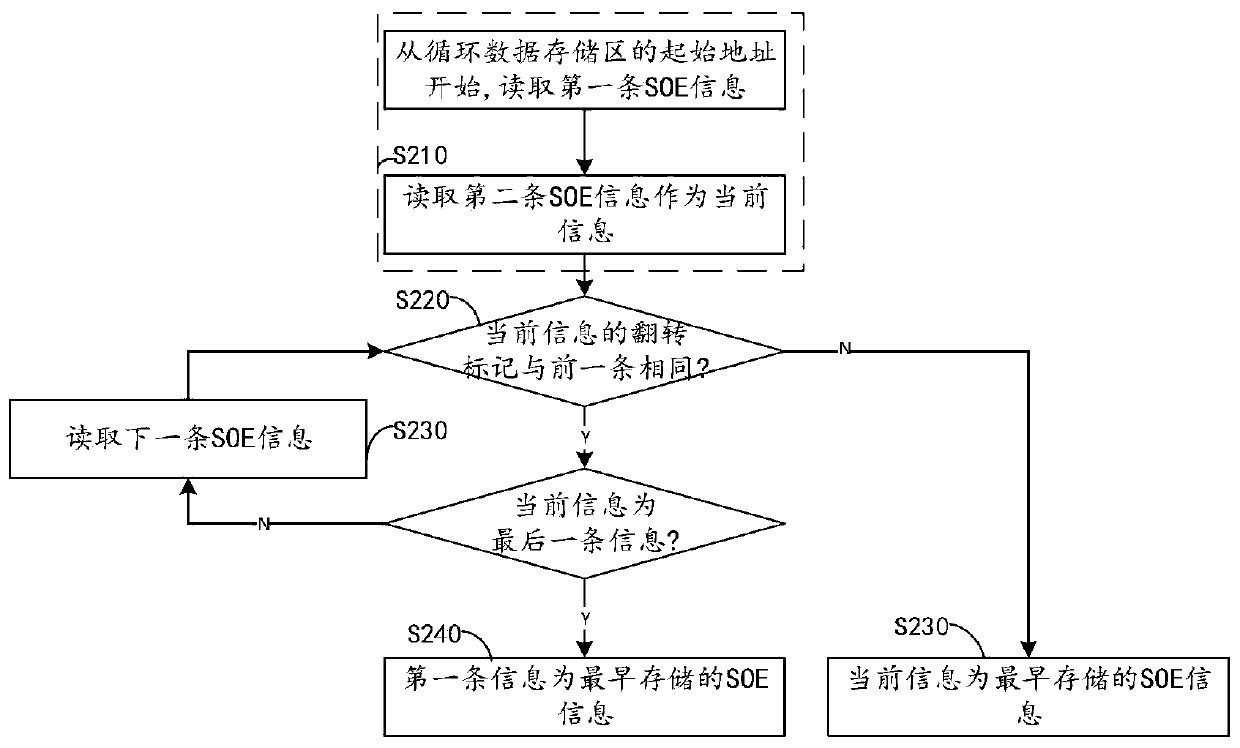

SOE information management method and storage device thereof

ActiveCN111061650AReduce processing timeGuaranteed safe operationMemory adressing/allocation/relocationInformation findingComputer engineering

The invention discloses an SOE information management method and a storage device thereof. The method comprises the steps of storing SOE information in a cyclic data storage area, the storage contentof each piece of SOE information comprises time scale information and a flipping character, the flipping character represents the number of times that the cyclic data storage area is covered, and thelength of the space occupied by the flipping character is smaller than the length of the space occupied by the time scale information; and traversing the SOE information according to an address sequence from a starting address to an ending address of the cyclic data storage area, searching different flipping symbols, and determining the SOE information stored at the earliest time. The embodiment of the invention at least has the following beneficial effects: the calculation amount and the space occupation during comparison are reduced, the CPU processing time is reduced, and the processing efficiency is improved, so that the safe and effective operation of the low-performance power grid equipment is ensured.

Owner:ZHUHAI XJ ELECTRIC

Delay circuit, count value generation circuit, and physical quantity sensor

ActiveUS10491201B2Reduce circuit sizeExclusive-OR circuitsCounting chain synchronous pulse countersElectricityControl circuit

A delay circuit includes: a cyclic number control circuit that generates a third signal based on first and second signals generated based on a trigger signal; a loop circuit in which a plurality of delay elements are electrically connected in series, one output of outputs of the plurality of delay elements is fed back to form a loop, and the third signal is input to the delay element at an initial stage; and a latch circuit that latches output values of the plurality of delay elements as latch signals. The second signal is one output among the outputs of the plurality of delay elements. The loop circuit stops the feedback when a cyclic number of loops reaches a prescribed cyclic number.

Owner:SEIKO EPSON CORP

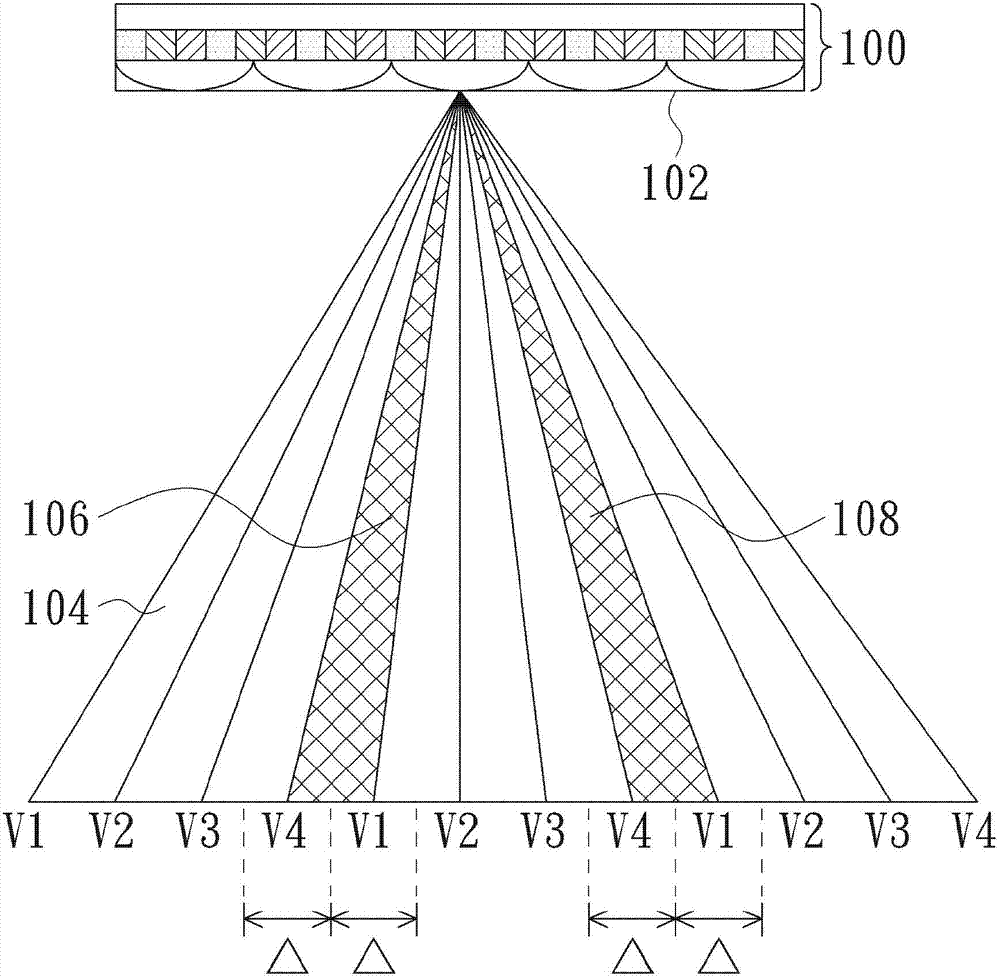

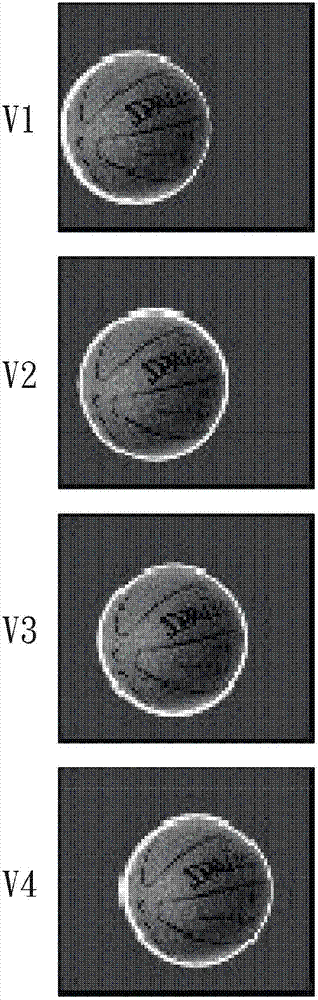

Display device and operation method

ActiveCN103200414ASlight jump effectImprove comfortStatic indicating devicesSteroscopic systemsComputer graphics (images)Display device

A display device and an operation method. The display device comprises a display panel and a display panel control module. The display panel control module ranks required two-dimensional images in sequence according to a cyclic number sequence formed by a preset number sequence, and each two adjacent numbers in the preset number sequence represent two adjacent angles of view. The display panel control module also replaces a two-dimensional image to which at least a number corresponds in the preset number sequence with a mixed image containing two-dimensional images of at least two different angles of view, synthesizes image data of a three-dimensional image accordingly, and controls a display panel to display the three-dimensional image on the basis of the image data of the three-dimensional image, wherein image data of each mixed image contains part of image data of the two-dimensional images of angles of view to which at least two numbers correspond in the preset number sequence.

Owner:AU OPTRONICS CORP

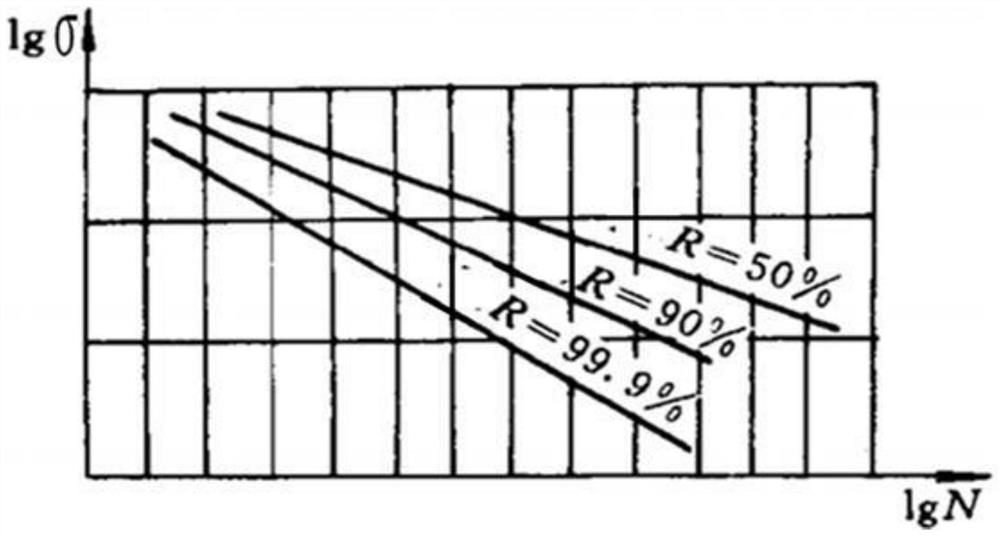

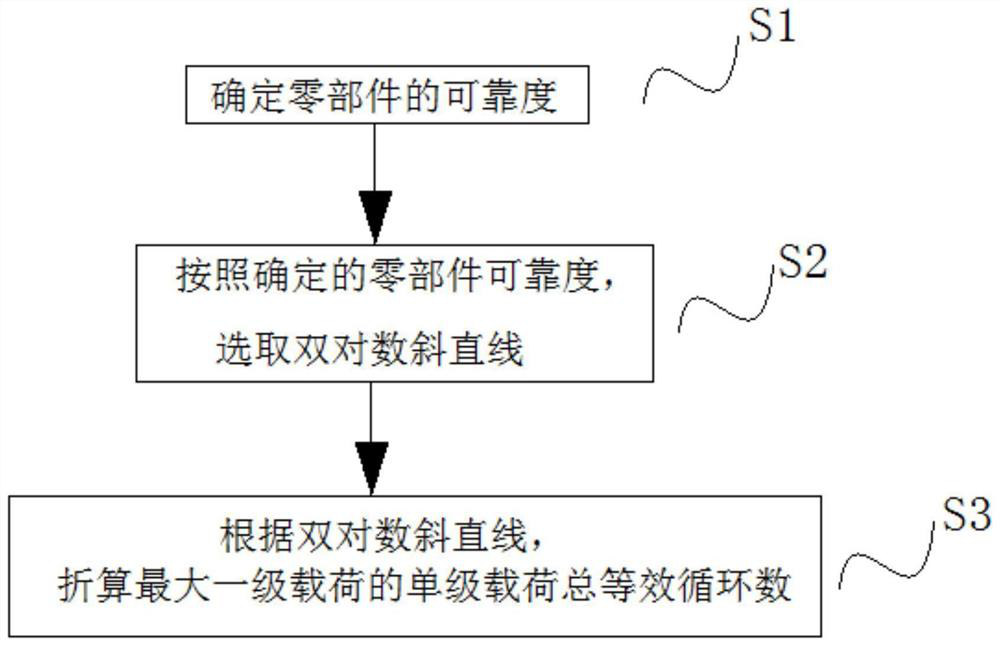

Method for determining minimum number of times of rapid fatigue test

PendingCN111693387ASave time and costMaterial strength using repeated/pulsating forcesAlgorithmIndustrial engineering

The invention provides a method for determining the minimum number of times of a rapid fatigue test. The method specifically comprises the steps of 1, determining the reliability R of a part under thespecified service life; selecting a logarithm value lg(sigma) of the load sigma and a logarithm value lg(NR) of the fatigue life NR with the corresponding reliability R, forming a double logarithm straight line between the logarithm value lg(sigma) of the load sigma and the logarithm value lg(NR) of the fatigue life NR, and converting the load spectrum into the total equivalent cycle number of the single-stage load of the maximum-stage load, namely, the minimum number of times of the rapid fatigue test. The minimum number of times of the rapid fatigue test obtained by the method does not needto be multiplied by a multiple t like the number of times of fatigue calculated according to the current theory, and t is an empirical value obtained by long-term exploration and can be used as the minimum number of times of the rapid fatigue test. Therefore, for parts made of novel materials, the time cost spent on long-term exploration for obtaining t is greatly saved.

Owner:FAW JIEFANG AUTOMOTIVE CO

Packet switching system

InactiveUS8621325B2Data switching by path configurationStatic storageComputer hardwarePacket-switching node

A packet switching system includes a forwarding processing unit determining a destination of an input packet by analyzing the input packet and outputting it as an output packet, the forwarding processing unit comprises an ingress interface card checking if the input packet has a sequential cyclic number and an egress interface card creating a sequential cyclic number and assigning it to the output packet.

Owner:FUJITSU LTD

Memory controller, flash memory system with memory controller, and control method of flash memory

ActiveUS20070283083A1Accurately determinedMemory architecture accessing/allocationDigital data processing detailsAlgorithmChronological time

Chronological identification information is composed of a plurality of cyclic numbers with priorities. For generating new chronological identification information, the chronological relation is compared in order from cyclic numbers with the highest priority to extract the newest chronological identification information in the chronological relation; when the newest chronological identification information in the chronological relation is extracted, a cyclic number with a priority as a comparison target in the extraction of the extracted chronological identification information is determined to be a cyclic number with the priority in the newly generated chronological identification information. When the cyclic numbers with a priority compared as comparison targets in the chronological identification information all are equal, no further extraction is carried out and the cyclic number subsequent to the cyclic numbers is determined to be a cyclic number with the priority in the newly generated chronological identification information.

Owner:TDK CORPARATION

Constant force device of watch

ActiveCN102269967BWork reliablyStable jobEscapementsClock driving mechanismsDrive wheelConstant power

The invention discloses a constant force device of a watch. The constant force device comprises a constant power part and an anti-sway part, wherein the constant power part is in engaged connection with an anti-sway gear shaft of the anti-sway part through a driving wheel sheet; and the anti-sway part is used for preventing a positioning wheel sheet of the constant power part from rotation when the torque required by a main spring is smaller than the torque required by a middle spring so as to stop the watch from swinging. The invention has the advantages that: an arresting device is added onthe constant force device, the watch can stop swinging as earlier as possible when a brake wheel is free from the control of a fork tile, namely the middle spring cannot reach the upper limit of preload, the unchanged preload cyclic number of the middle spring is ensured when the watch is wound up again, so relative constant torque corresponding to the elastic force of the middle spring can be ensured to be transmitted to an escape wheel. The structure is simple, the running is stable, and the technique is good, so the constant force device can stably and reliably work.

Owner:TIANJIN SEAGULL WATCH CO LTD

On-demand printing of coding patterns

Owner:ANOTO AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com