Material cyclic hardening behavior testing method in welding process

A technology of welding process and testing method, which is applied in the direction of analyzing materials, testing material strength by applying repetitive force/pulsation force, measuring devices, etc. It can solve problems such as multi-level fatigue load stress-strain relationship prediction, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

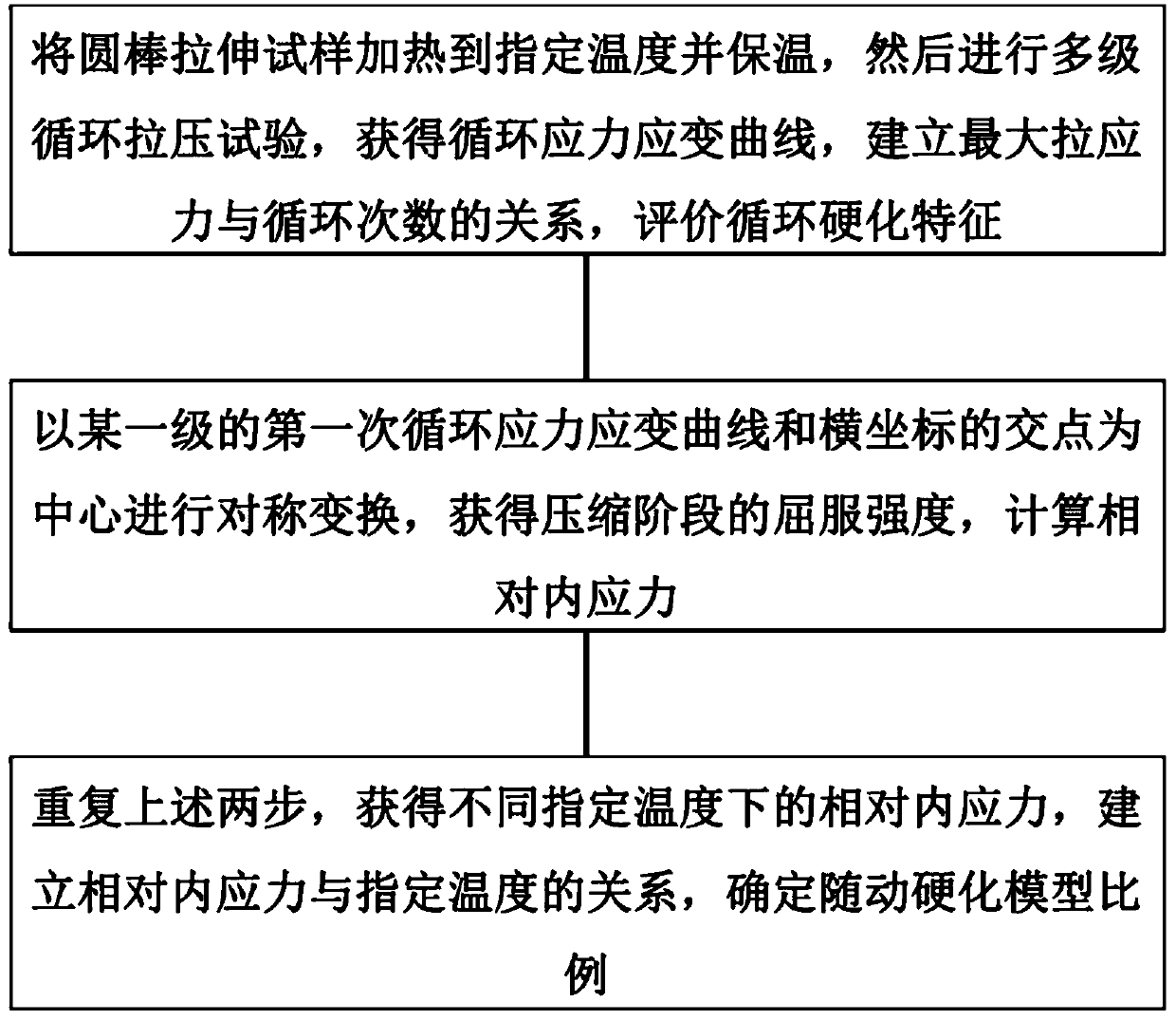

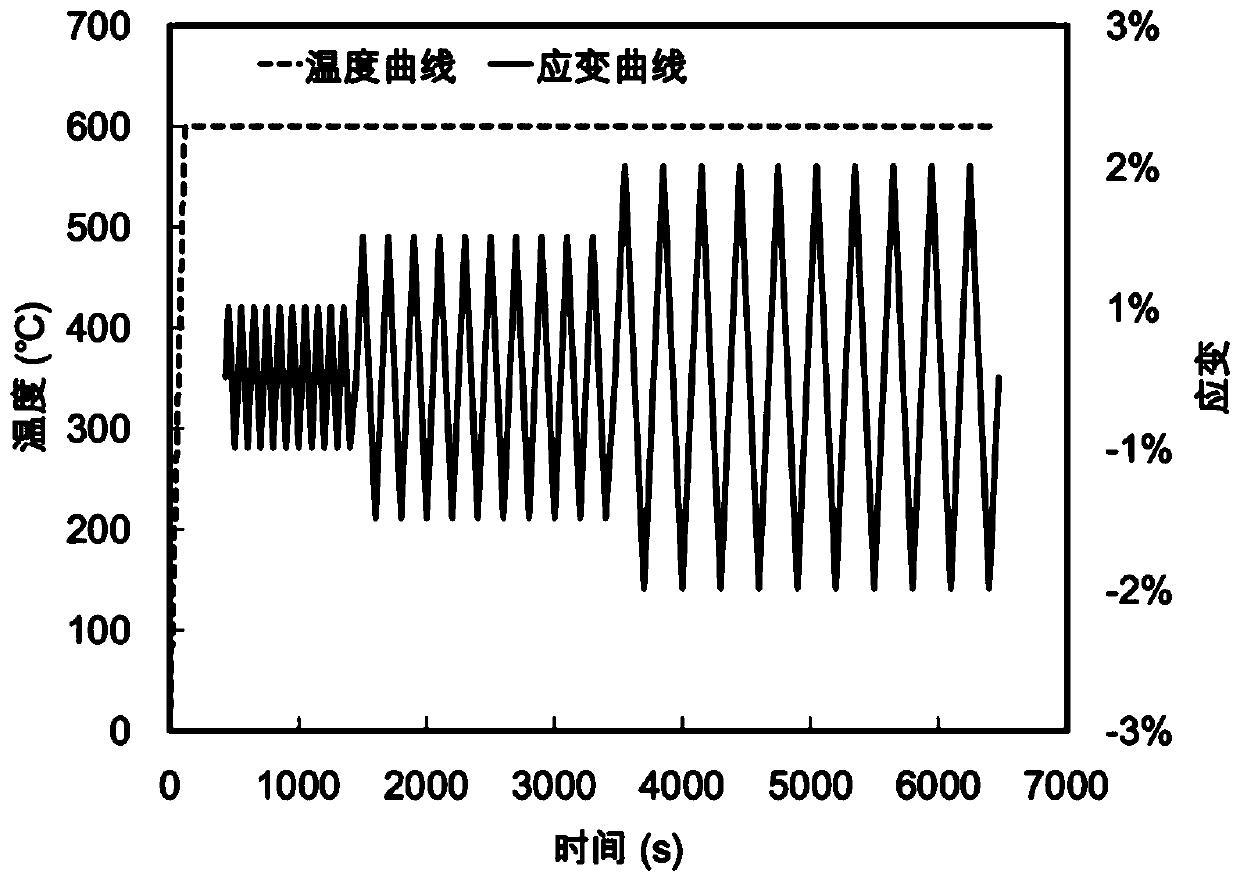

[0036] The invention provides a method for testing the cyclic hardening behavior of materials in the welding process. The method obtains cyclic stress-strain curves through isothermal multi-stage strain cyclic tension and compression tests, evaluates the cyclic hardening characteristics of materials in the welding process with the change trend of the maximum tensile stress, and proposes a relative The internal stress method determines the kinematic hardening model scale in nonlinear mixed hardening models.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com