Method for determining minimum number of times of rapid fatigue test

A technology of fatigue test and number of times, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, measuring devices, instruments, etc., which can solve problems such as unsafety and poor precision, and achieve the effect of saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

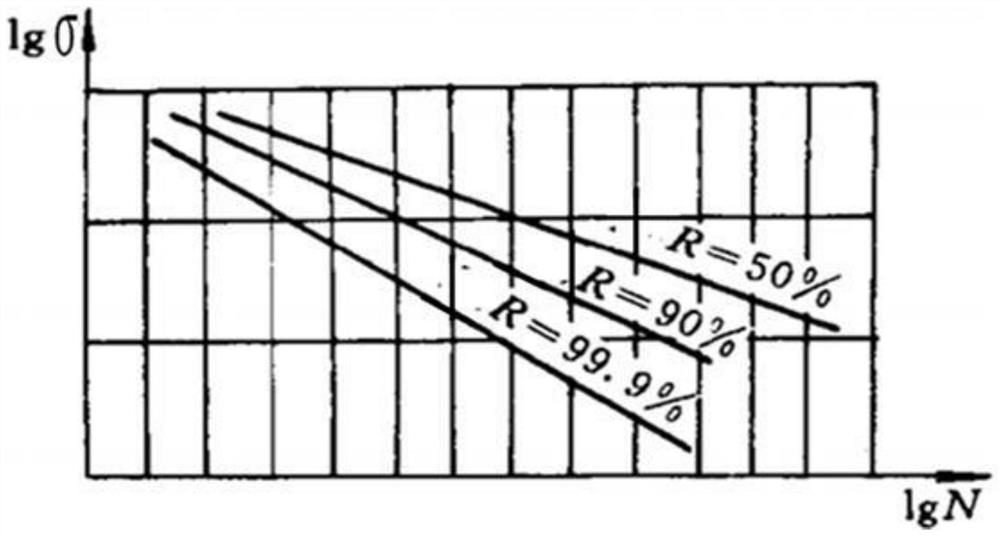

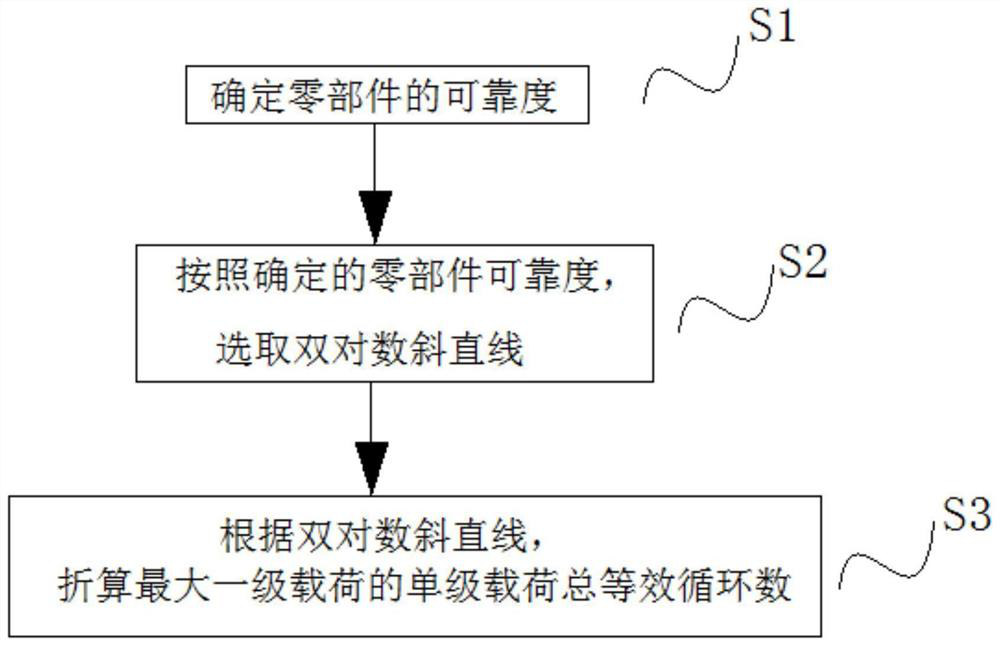

[0030] This example discloses a method for determining the minimum number of rapid fatigue tests, such as figure 1 , figure 2 As shown, the specific process of the method for determining the minimum number of rapid fatigue tests is as follows:

[0031] S1: Determine the reliability target R (R≥50%) of the component under the specified life;

[0032] In this step S1, the reliability target R of the component is determined during the component product design stage. The calculated minimum number of rapid fatigue tests is to ensure that: after passing the number of bench tests, if the product reliability verification result R1≥R, then the corresponding reliability R2≥R at the specified life of the product.

[0033] In this example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com