Method for testing reciprocating seal wear life of O-shaped rubber seal ring

A wear life and test method technology, applied in the direction of testing wear resistance, etc., can solve the problem of lack of reliable reference basis and standards for selection and correction, and achieve the effect of real and reliable environmental temperature and other conditions, accurate wear life, and effective prediction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings.

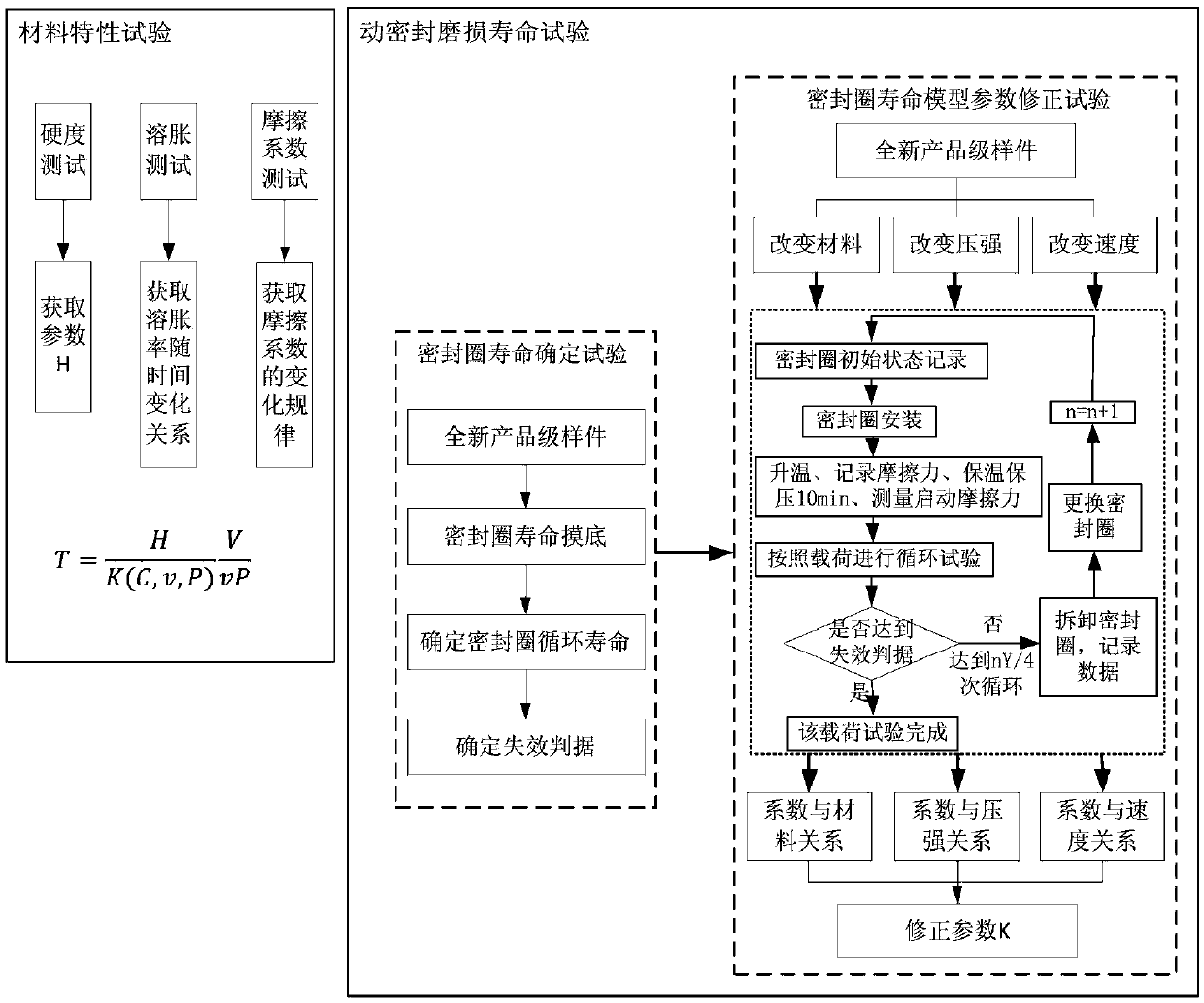

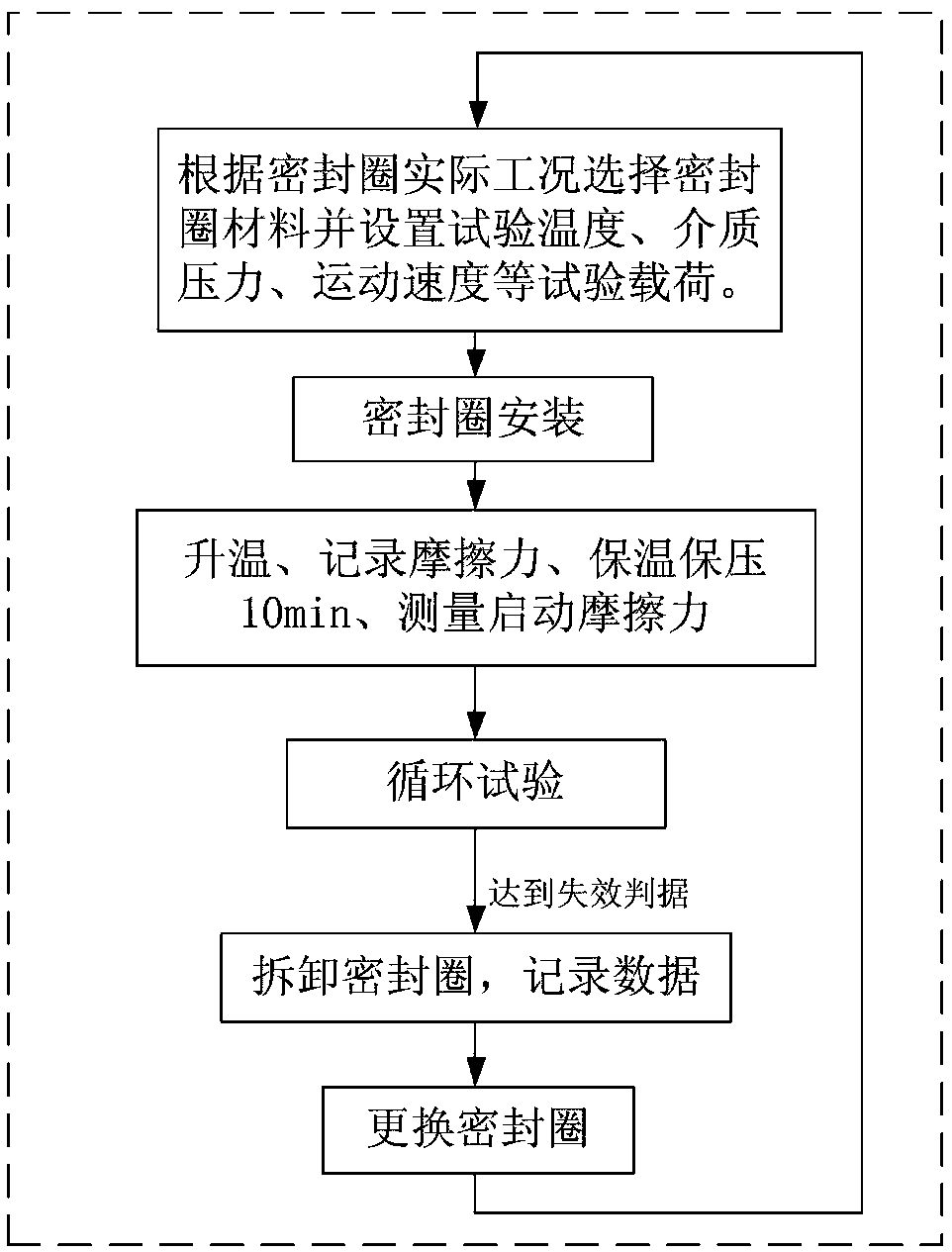

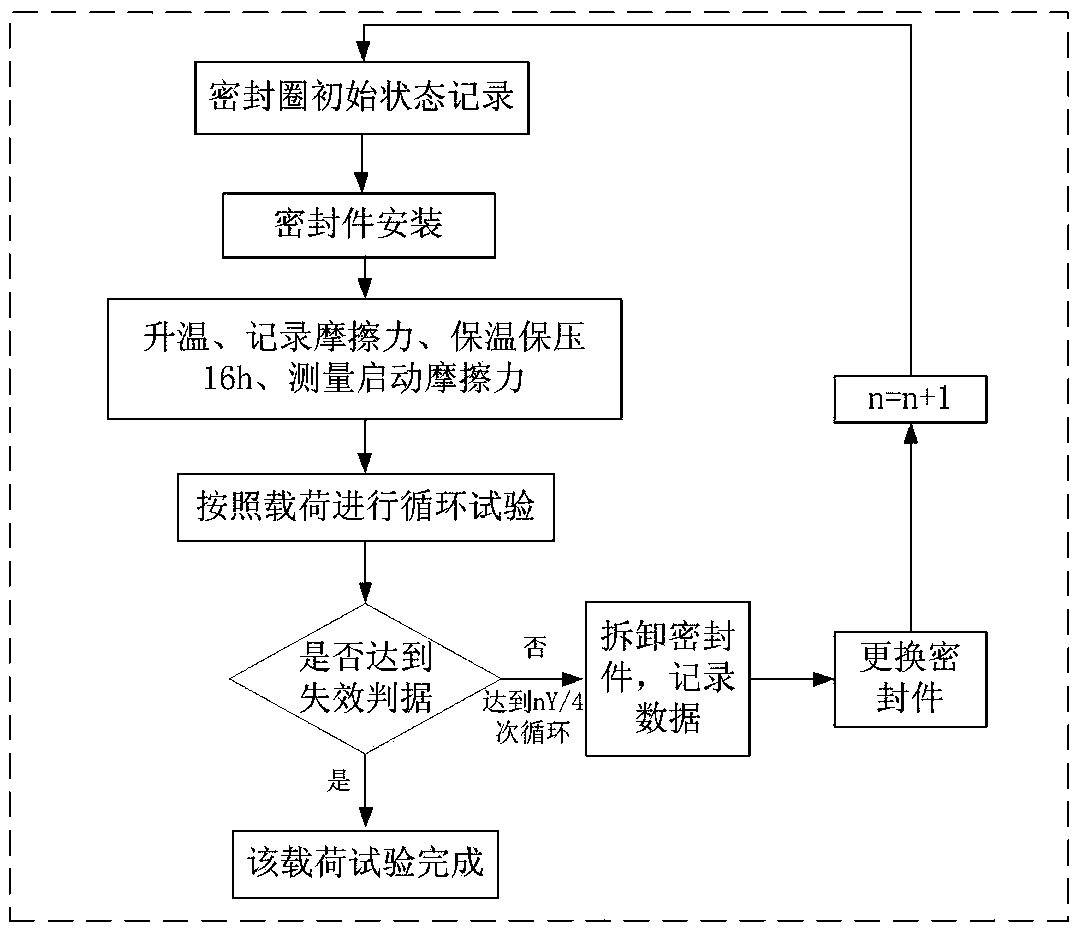

[0050] According to the rubber O-shaped seal ring reciprocating seal wear life test method of the present invention, it comprehensively considers the influence of material level factors, and carries out parameter correction to the O-type seal ring wear life model, such as Figure 1 to Figure 3 As shown, the specific steps are as follows:

[0051] Step 1: Carry out the material characteristic test of the sealing member, respectively carry out the hardness test, the swelling test and the friction coefficient test;

[0052] Step 2: Carry out a test to determine the life of the sealing ring to obtain the number of cycles when the sealing ring fails;

[0053] Step 3: Carry out the life model parameter correction test of the sealing ring, carry out the wear life test according to the load spectrum, and obtain the change law of the wear amount of the sealing ring with time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com