Patents

Literature

34results about How to "Realize positioning control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

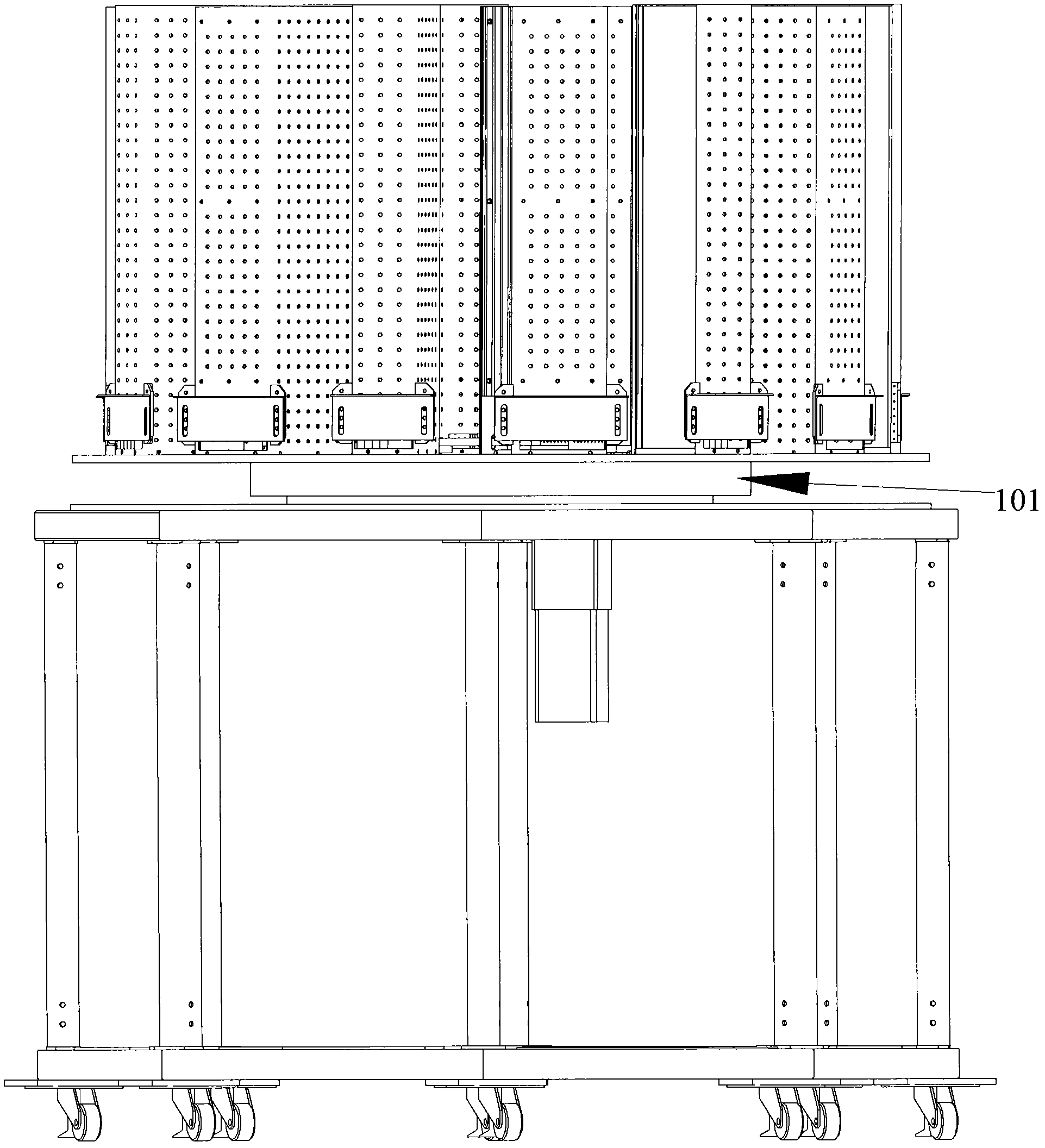

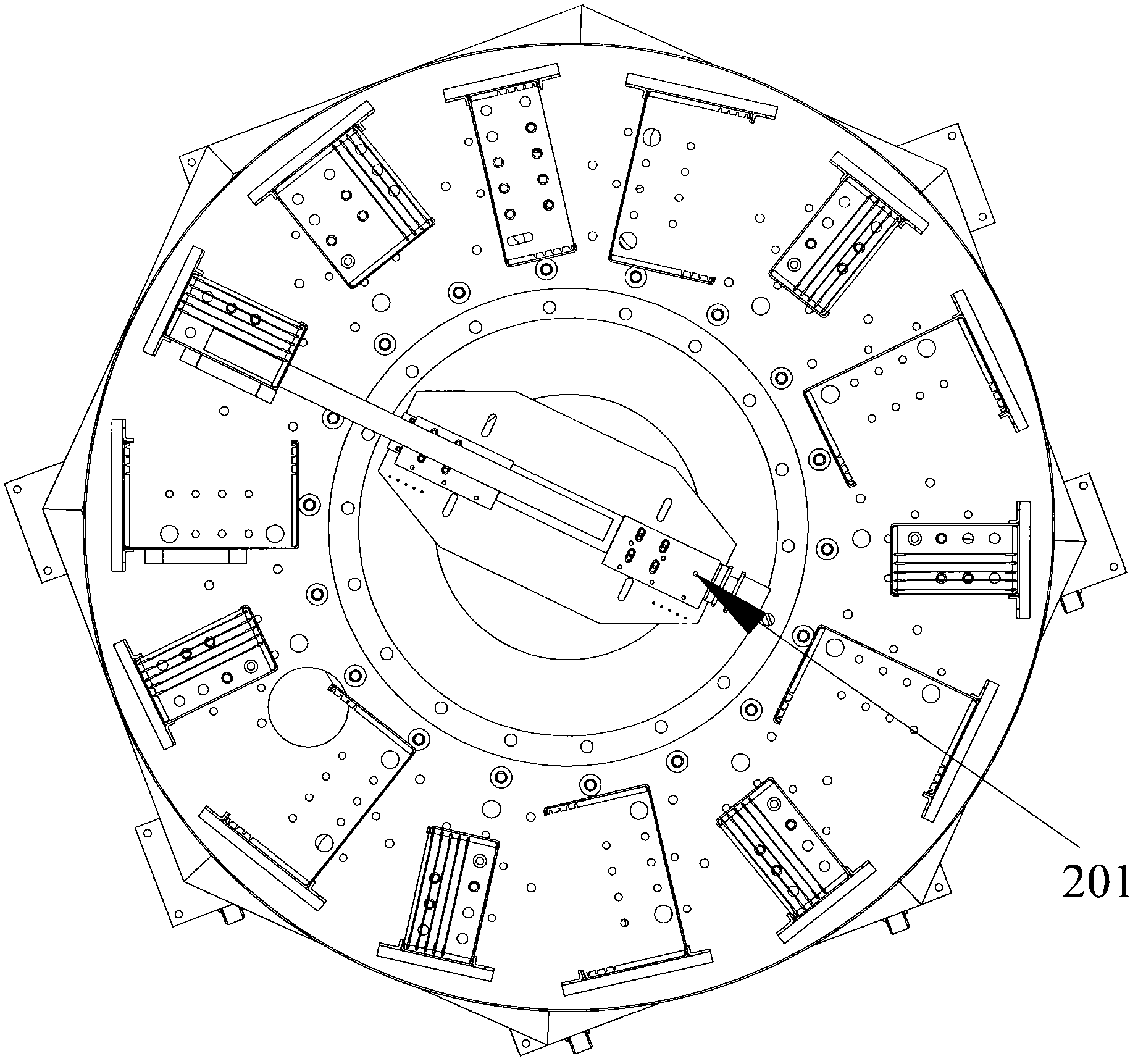

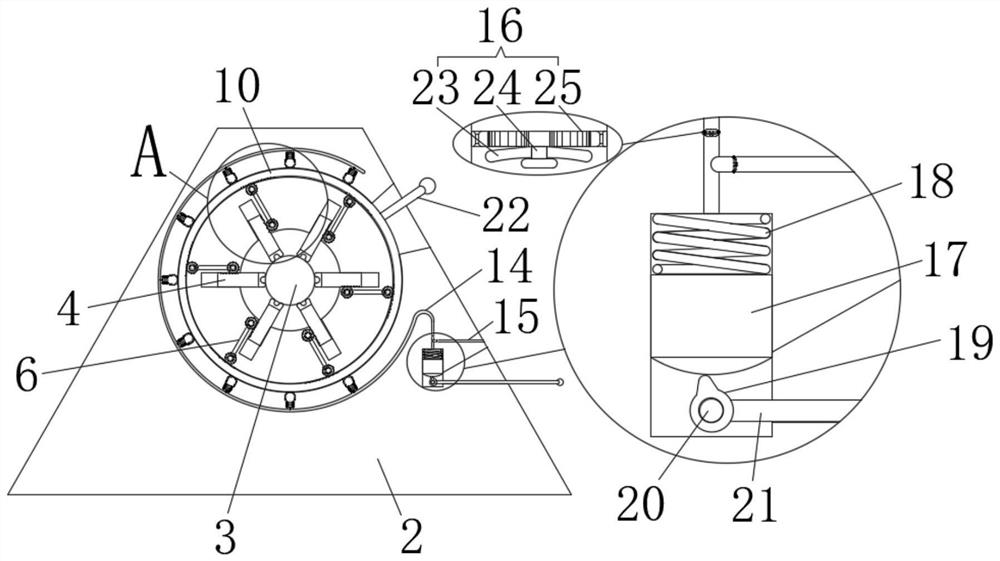

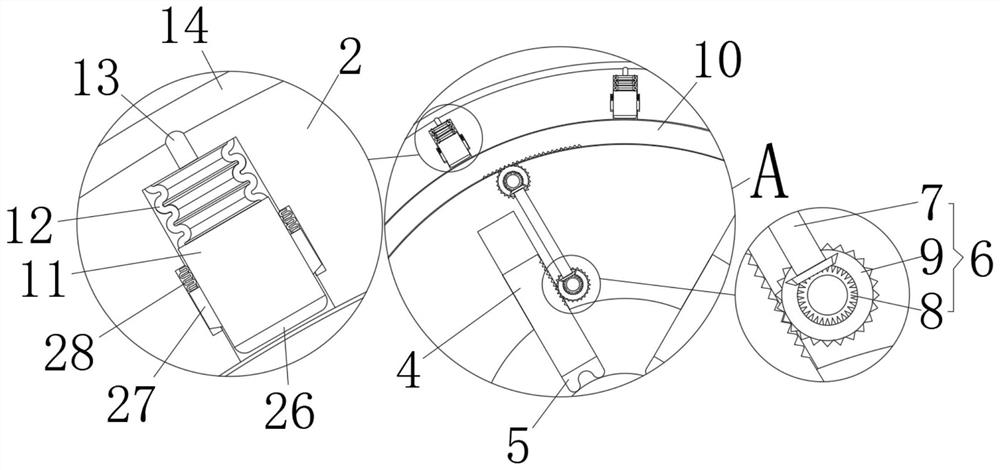

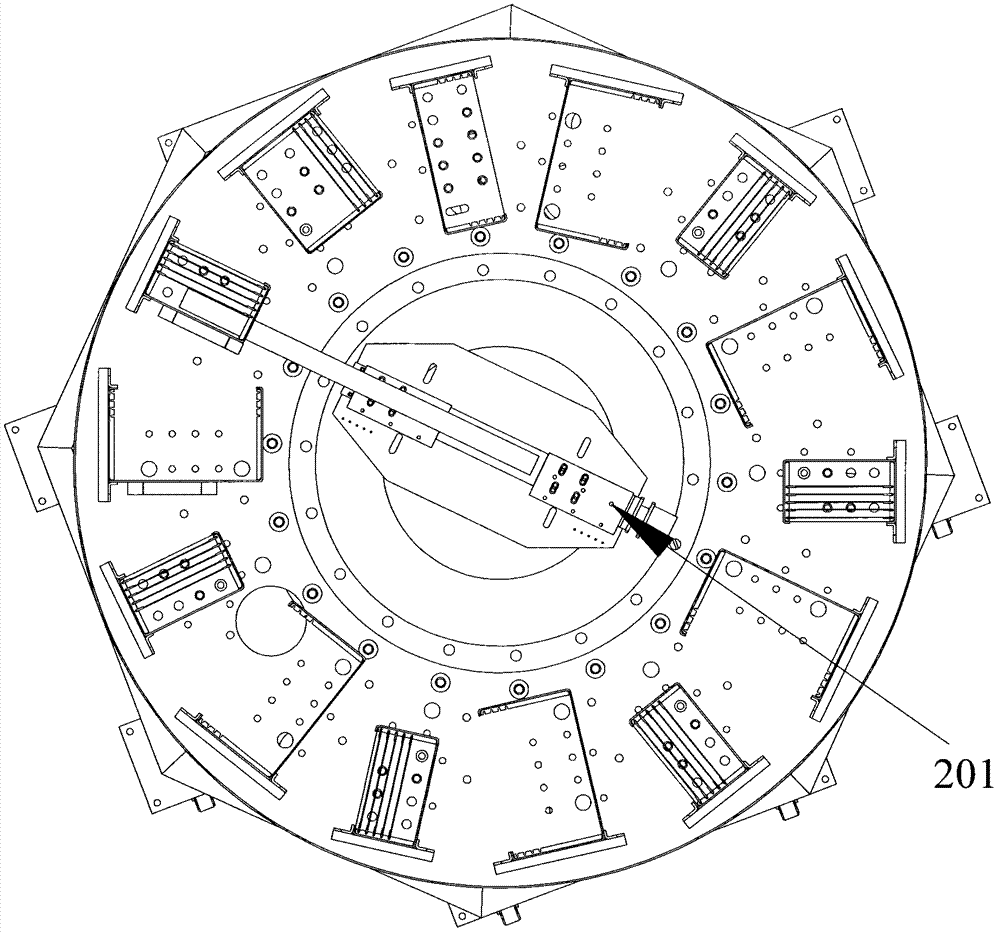

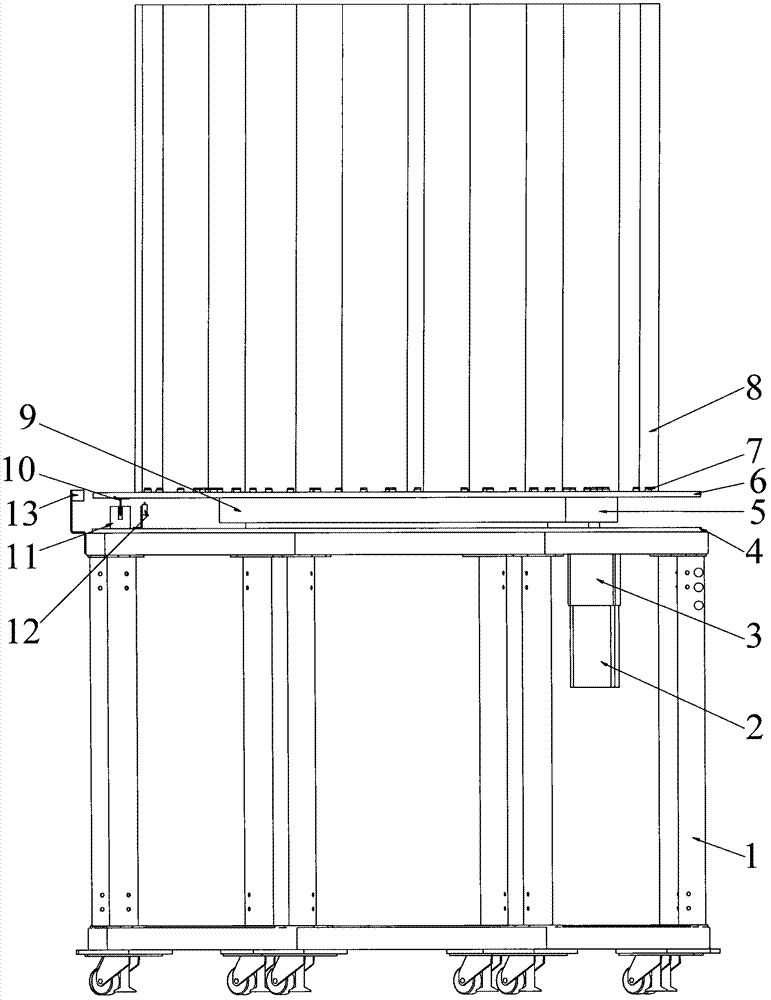

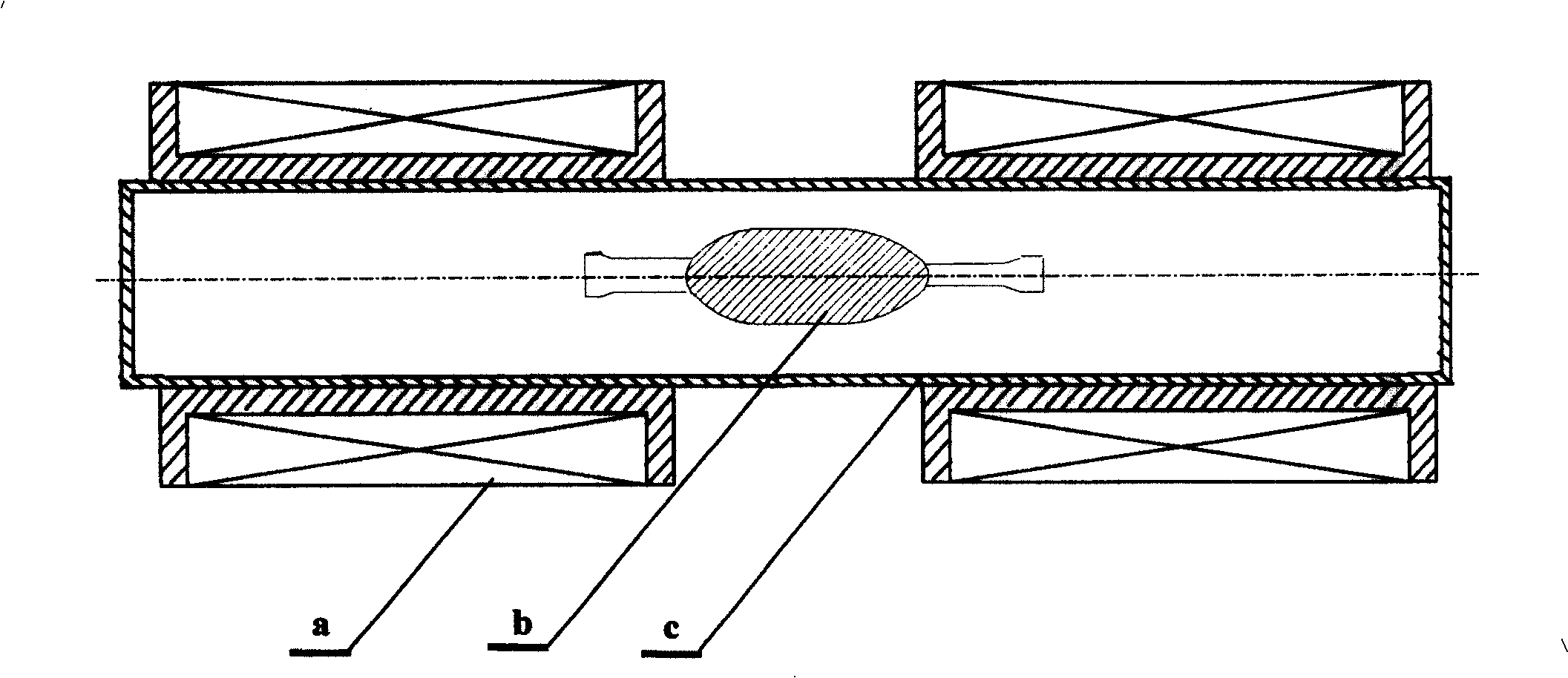

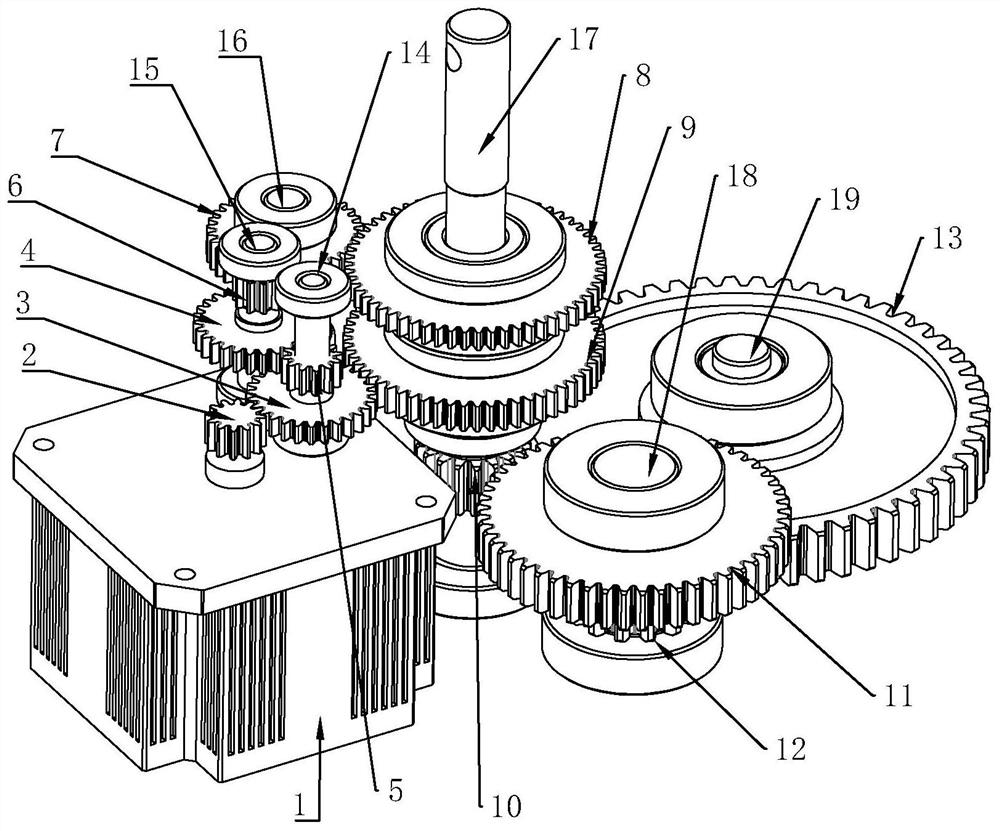

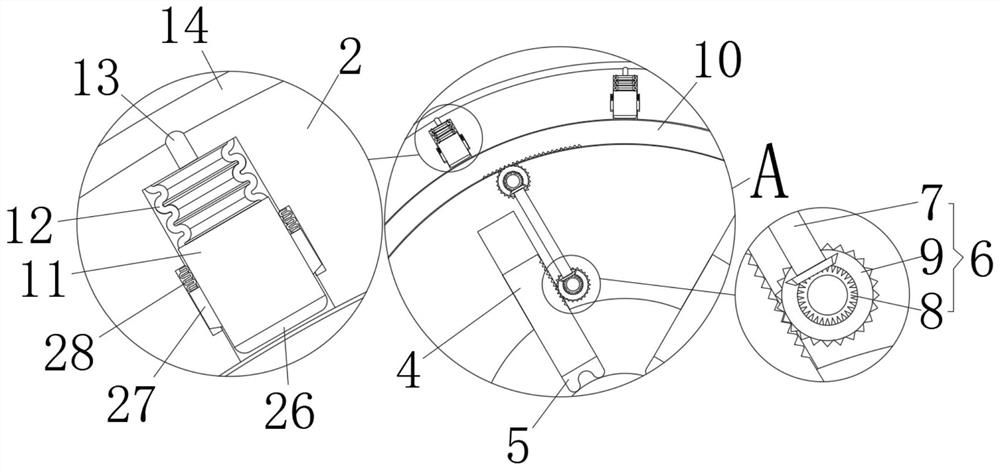

Rotary automatic medicine delivery machine

ActiveCN102114961AUnique designRealize positioning controlStorage devicesSynchronous motorReduction drive

The invention relates to a rotary automatic medicine delivery machine which comprises a slewing device and a pushing device. The slewing device comprises a lower slewing support connecting plate, a slewing support and an upper slewing support connecting plate, wherein, the slewing support is arranged on the lower slewing support connecting plate and is circumferentially equipped with teeth; the upper slewing support connecting plate is arranged on the slewing support; a speed reducer is fixed on the bottom surface of the lower slewing support connecting plate; and the output shaft of the speed reducer passes through the lower slewing support connecting plate and is equipped with a small gear, and the small gear is meshed with the teeth of the slewing support. The pushing device comprises a lower backing plate, an upper backing plate and an actuator, wherein, the lower backing plate is fixed on the upper slewing support connecting plate of the slewing device; the upper backing plate isarranged on the lower backing plate; the actuator is arranged on the upper backing plate; a connecting plate is fixed on the actuator; a push rod is arranged on the connecting plate; and the actuatoris connected with a synchronous motor in a transmission manner through a coupling. By utilizing the medicine delivery machine, a certain quantity of medicine boxes can be conveyed.

Owner:SUZHOU IRON TECH

Increment type photoelectric encoder

InactiveCN102226702AHigh resolutionHigh precisionConverting sensor output opticallyMachine pressImage resolution

Provided is an increment type photoelectric encoder. The invention relates to the field of photoelectric coding technology. The encoder comprises a housing and a positioning body fixed in the housing and is characterized in that O type sealing rings are provided at the connecting place of the housing and the positioning body. The positioning body is connected to a main shaft through a bearing. One end of the main shaft in the housing is provided with two PCB circuit boards. A code disc is provided between the two PCB circuit boards. The PCB circuit board at the left side of the code disc is provided with a light-sensitive element and the PCB circuit board at the right side of the code disc is provided with a light source. The upper part of the housing is connected to a connector. The invention has advantages such as high resolution, high precision, simple structure, small volume, reliable use, easy maintenance and the like. A solid and beautiful aluminium alloy and a stainless steel rotating shaft are adopted, the rotating shaft is designed with double bearings, and therefore the encoder can be used in a harsh working environment. The encoder is characterized by no screw and disposable machine pressed rubber so as to prevent dusts and splashing and ensure normal work in a scurvy environment.

Owner:王天甜

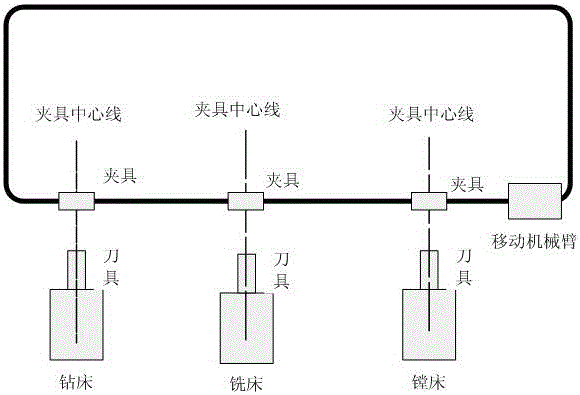

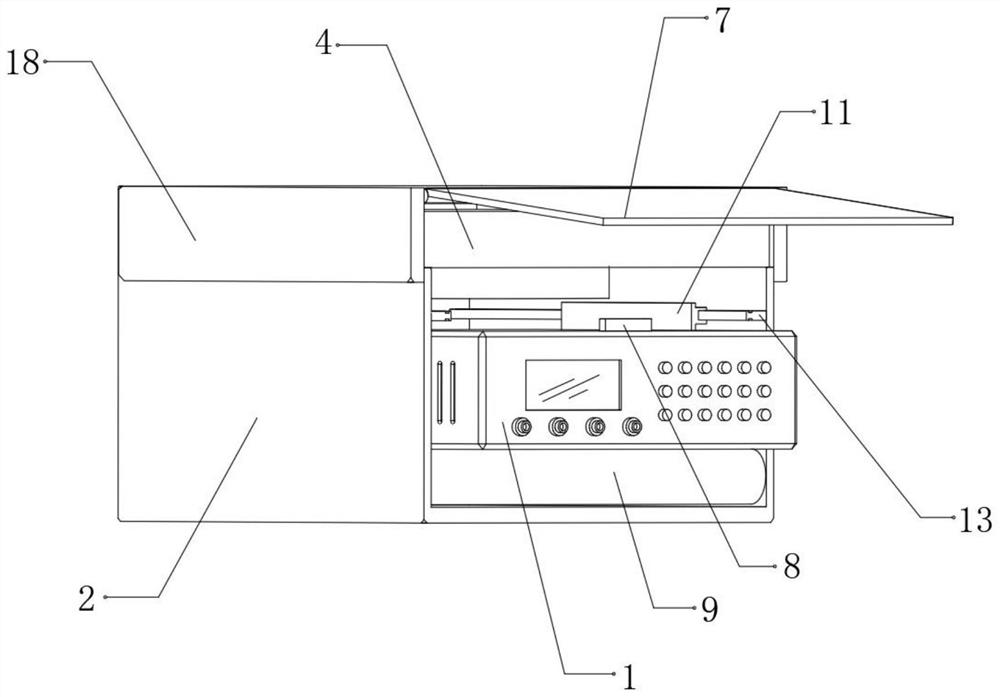

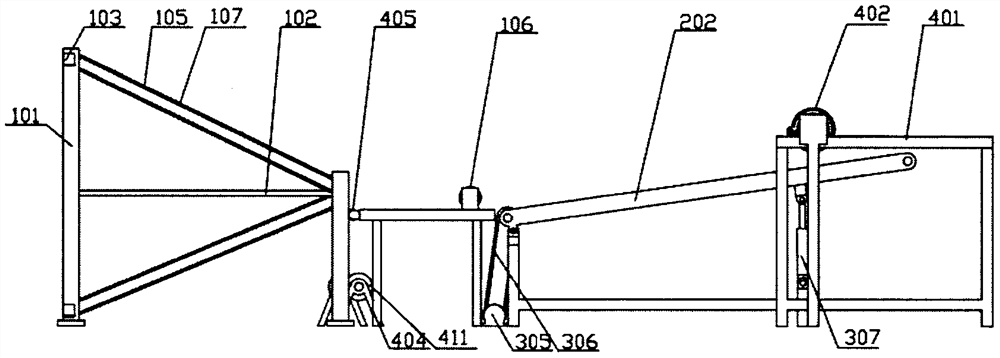

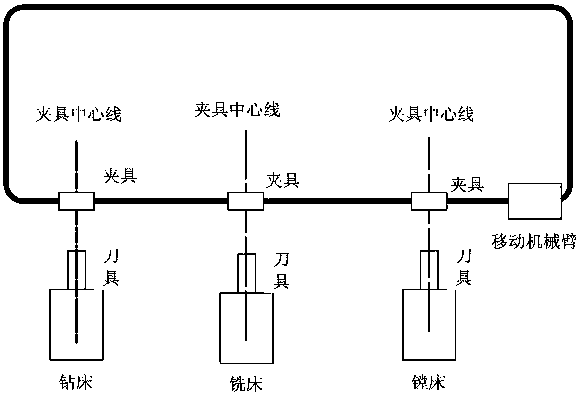

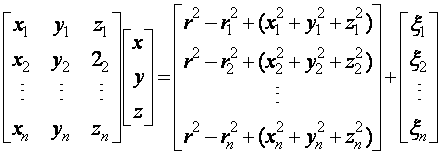

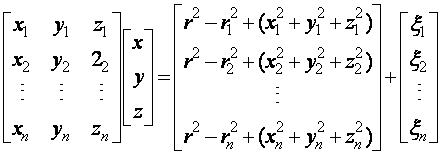

Multi-coordinate machining center combination method based on vision and movable mechanical arm

ActiveCN105058168ARealize online correctionRealize positioning controlMeasurement/indication equipmentsLaser rangingEngineering

The invention provides a multi-coordinate machining center combination method based on vision and a movable mechanical arm, and aims to overcome the large technical defect that a movable robot, a boring machine, a milling machine, a drilling machine and the like cannot be directly combined into a multi-coordinate machining center. The method comprises the steps that machining tasks and procedures are set on the movable mechanical arm, the boring machine, the milling machine and the drilling machine; a movable mechanical arm rail and clamps are arranged, a CCD and a laser ranging device or a connect camera is arranged on the movable mechanical arm, and a plurality of light mark points are arranged on the boring machine, the milling machine and the drilling machine towards the movable mechanical arm rail; then a workpiece to be machined is moved to a preset position by the movable mechanical arm through multi-joint control of the movable mechanical arm; and meanwhile, online locating monitoring and error correction are carried out in the machining process, fault alarms are given to a machining system, and multi-coordinate machining center combination is achieved. The great technical aim of directly combining the mobile robot, the boring machine, the milling machine, the drilling machine and the like into the multi-coordinate machining center is achieved.

Owner:XIAN FEISIDA AUTOMATION ENG

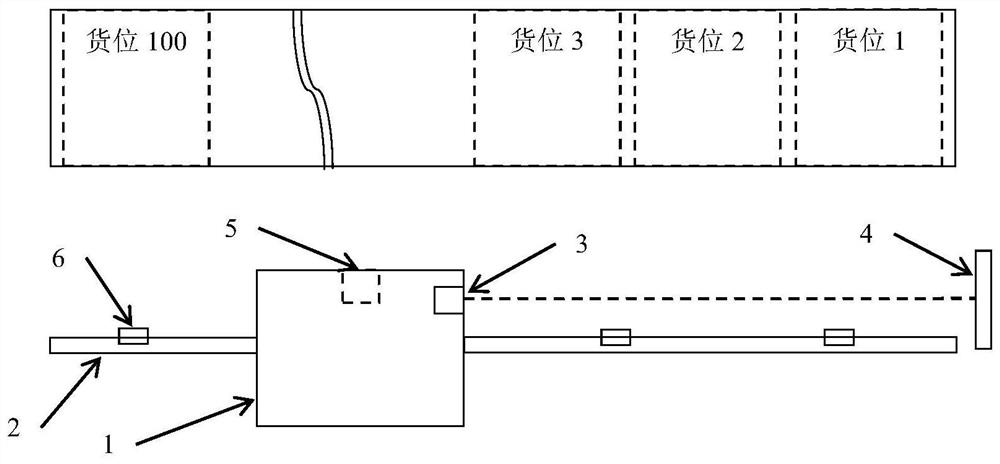

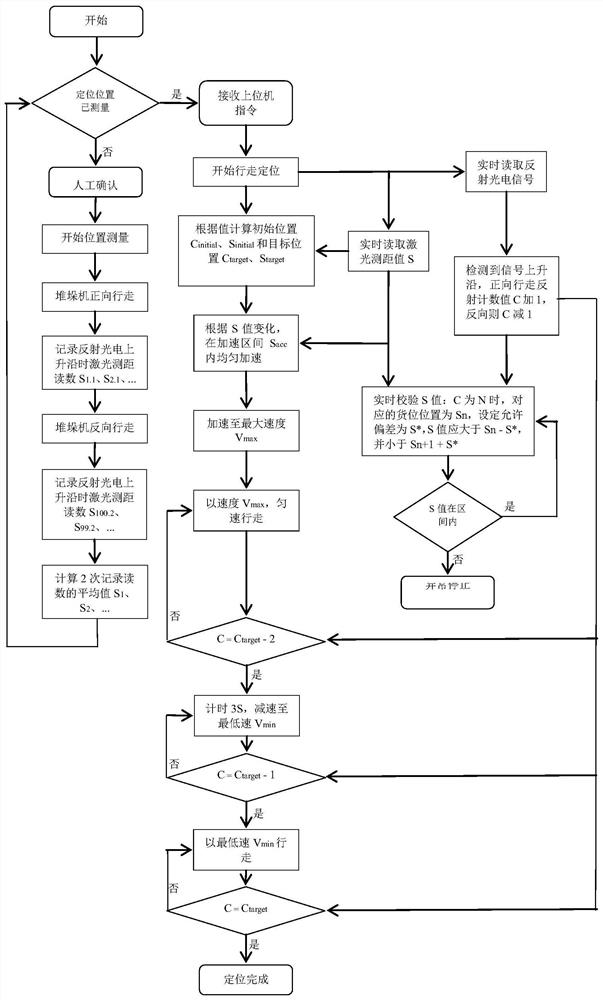

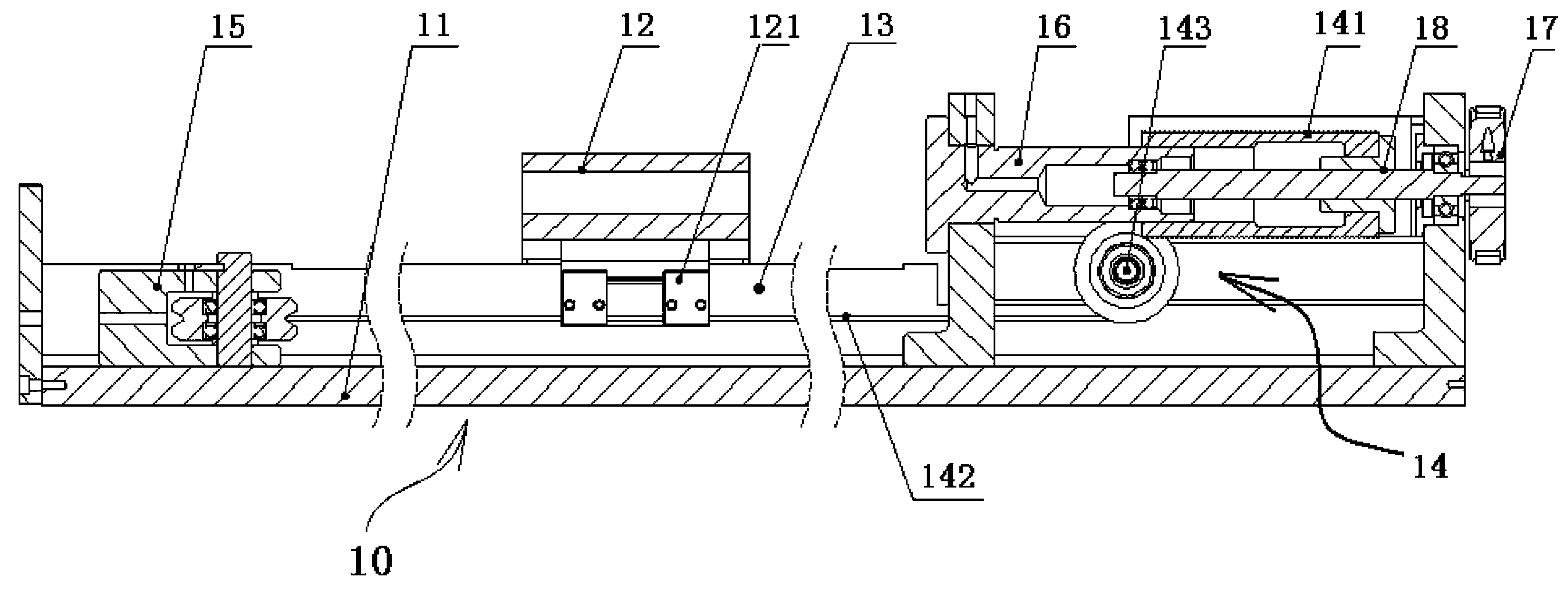

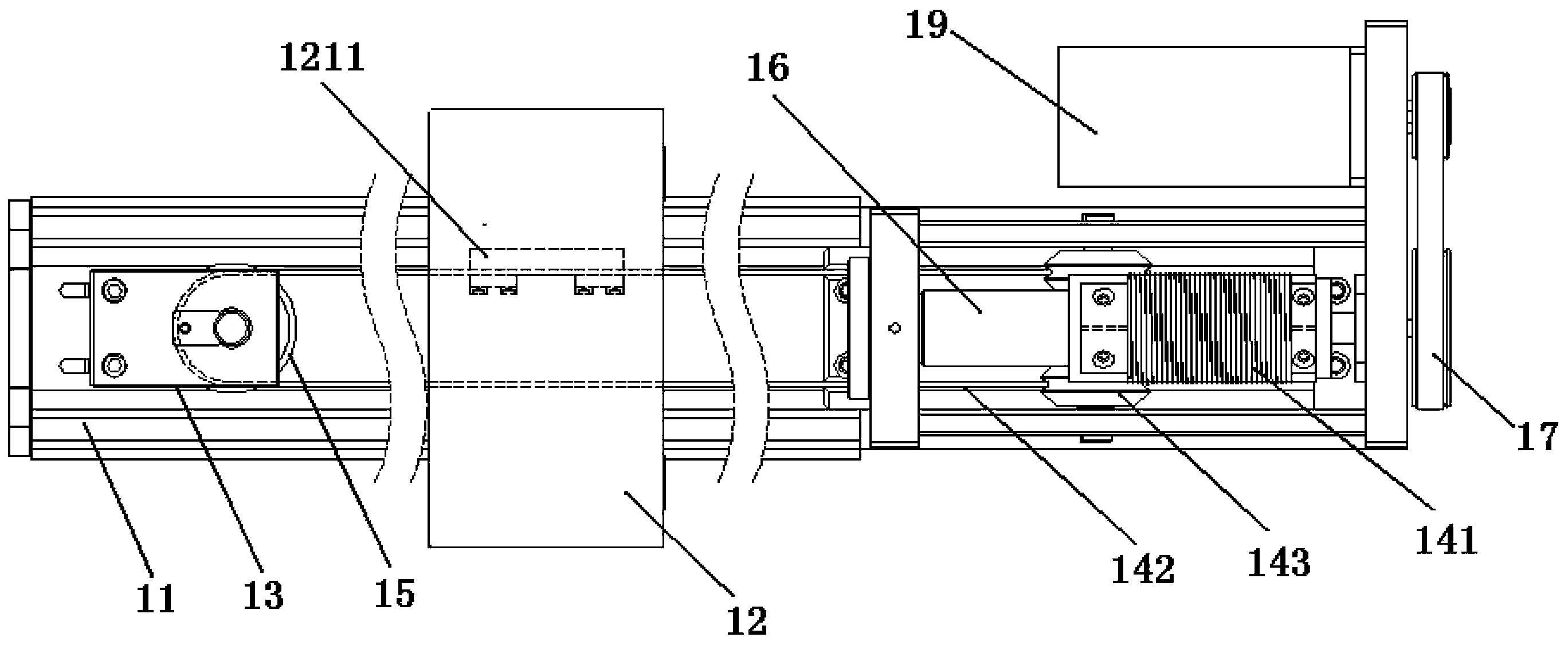

Positioning system, positioning method and control method of heavy-load stacking machine

PendingCN112327314AHigh positioning accuracyAchieve positioningElectromagnetic wave reradiationStorage devicesLaser rangingControl engineering

The invention discloses a positioning system, a positioning method and a control method of a heavy-load stacking machine. The positioning system comprises a stacking machine ground rail, a reflector plate, a laser range finder, a reflector plate, a reflective photoelectric sensor and a controller. The stacking machine ground rail is parallel to the extending direction of a plurality of stacking stations, and the stacking machine is installed on the stacking machine ground rail in a sliding mode. The reflector is fixed on one side of a ground rail of the stacking machine; the laser range finderis installed on the stacking machine, and the laser emitting direction of the laser range finder faces the reflector. The reflector plates are sequentially arranged in the length direction of the stacking machine ground rail corresponding to the stacking stations. The reflection type photoelectric sensor is installed on the stacking machine, wherein the signal receiving and sending end of the reflection type photoelectric sensor faces the stacking machine ground rail. The signal output ends of the laser range finder and the reflective photoelectric sensor are respectively connected with the controller. By means of the system and method, positioning control over the stacking machine with the alternating-current motor without the position feedback function can be achieved, the principle structure is simple, and accuracy and reliability are high.

Owner:江苏智库智能科技有限公司

High-speed mechanical arm with precise positioning function

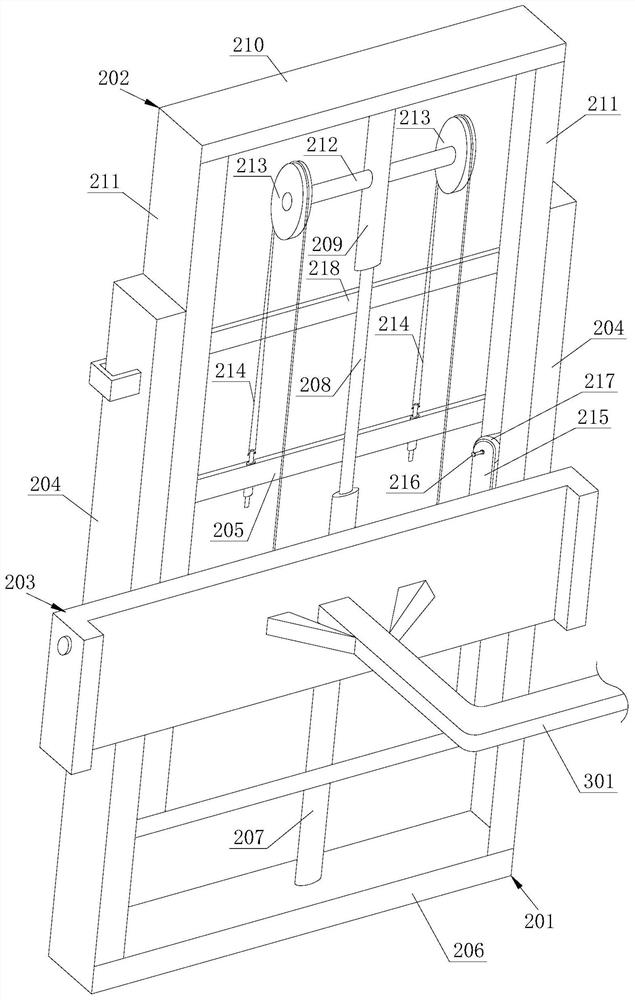

A high-speed mechanical arm with a precise positioning function comprises a motor, a driving part, a rack and a sliding block, wherein a sliding slot is arranged on the rack, the sliding block is arranged in the sliding slot and is driven by the driving part to move along the sliding slot. The mechanical arm is characterized in that the driving part comprises a winding drum and a steel wire rope wound on the winding drum, a threaded groove is arranged on the winding drum, the steel wire rope is coiled in the threaded groove and is arranged between the winding drum and the sliding slot to form a revolving loop, and a section, which is arranged in the sliding slot, of the steel wire rope is fastened with the bottom of the sliding block. The winding drum with the threaded slot is driven by utilizing a servo motor, the steel wire rope is precisely wound and unwound from the winding drum, namely, when the winding drum rotates for a turn, the linear distance that the steel wire rope moves is converted from the perimeter of the winding drum, under the same rotating speed, the speed of the steel wire rope is much higher than the speed of a screw nut pair, which is characterized in that the linear distance converted from the screw pitch, and the positioning and control on the sliding block are realized through controlling the rotating speed and the start and stop of the rotation precisely by the servo motor.

Owner:FUJISAN IND TECH CO LTD OF SHENZHEN CITY

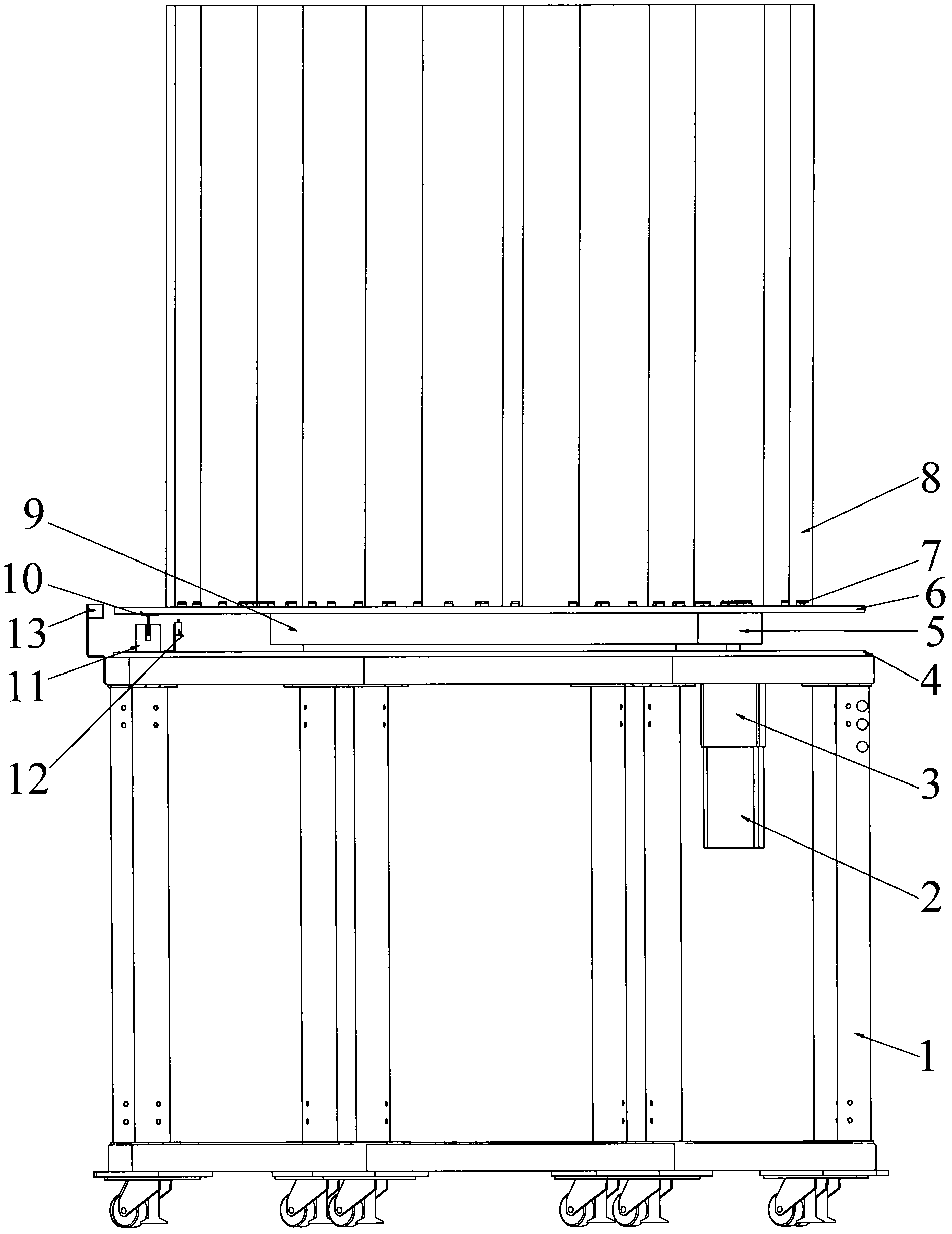

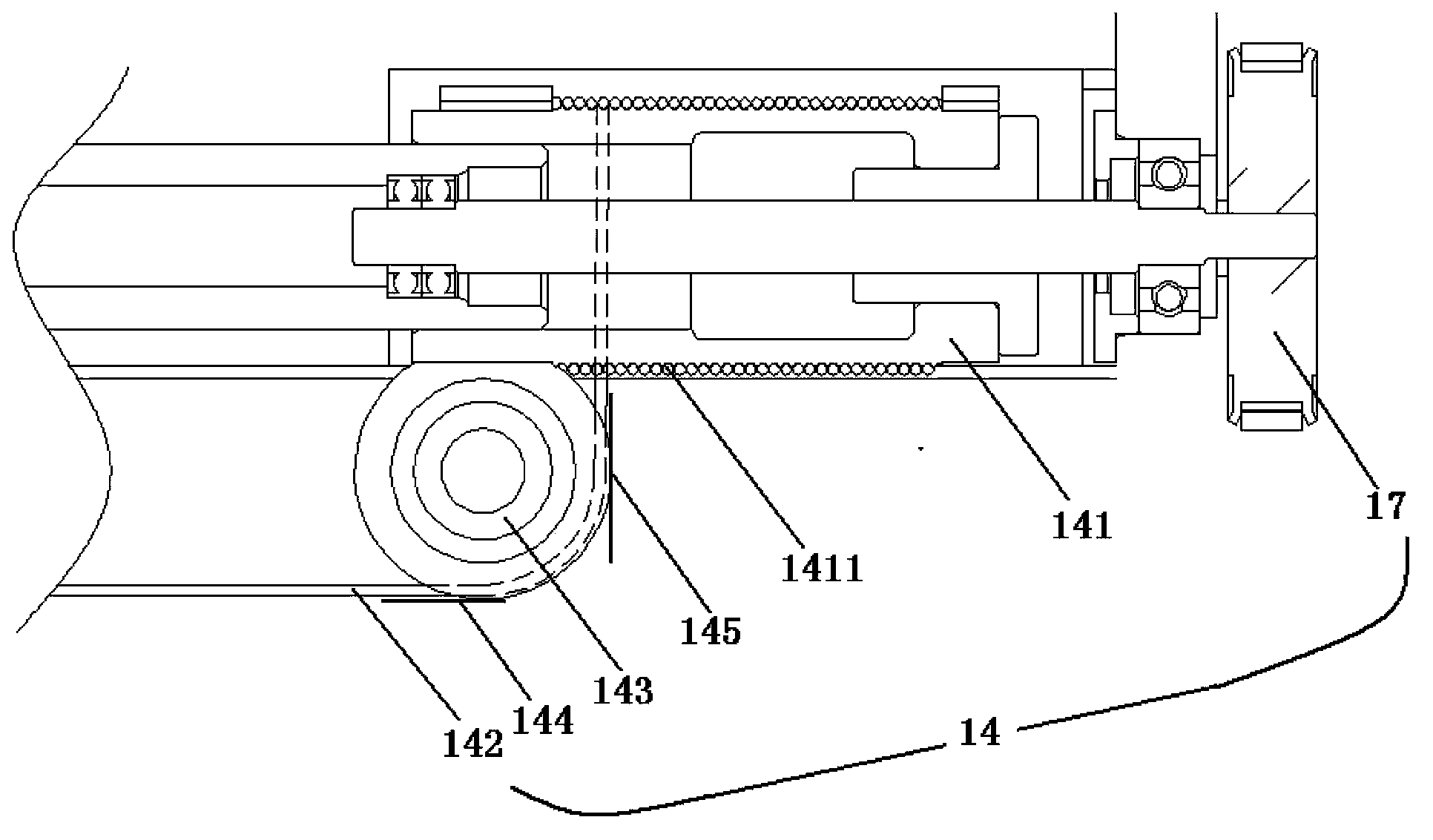

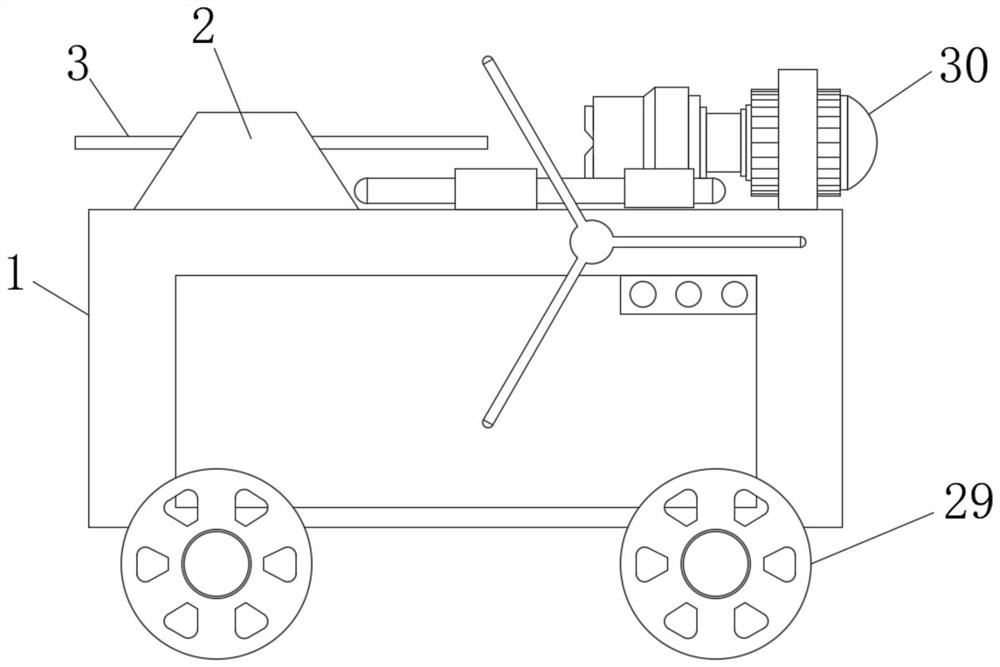

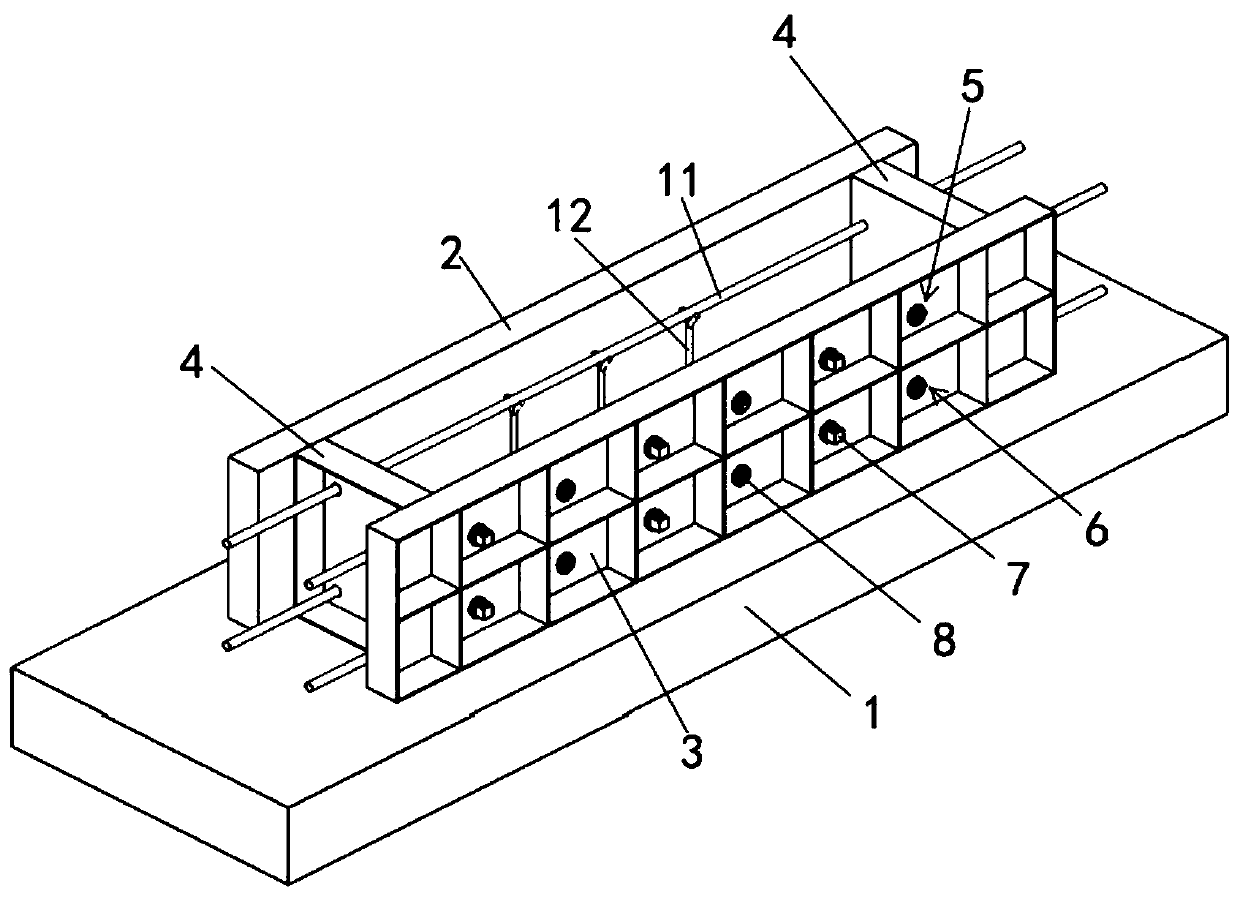

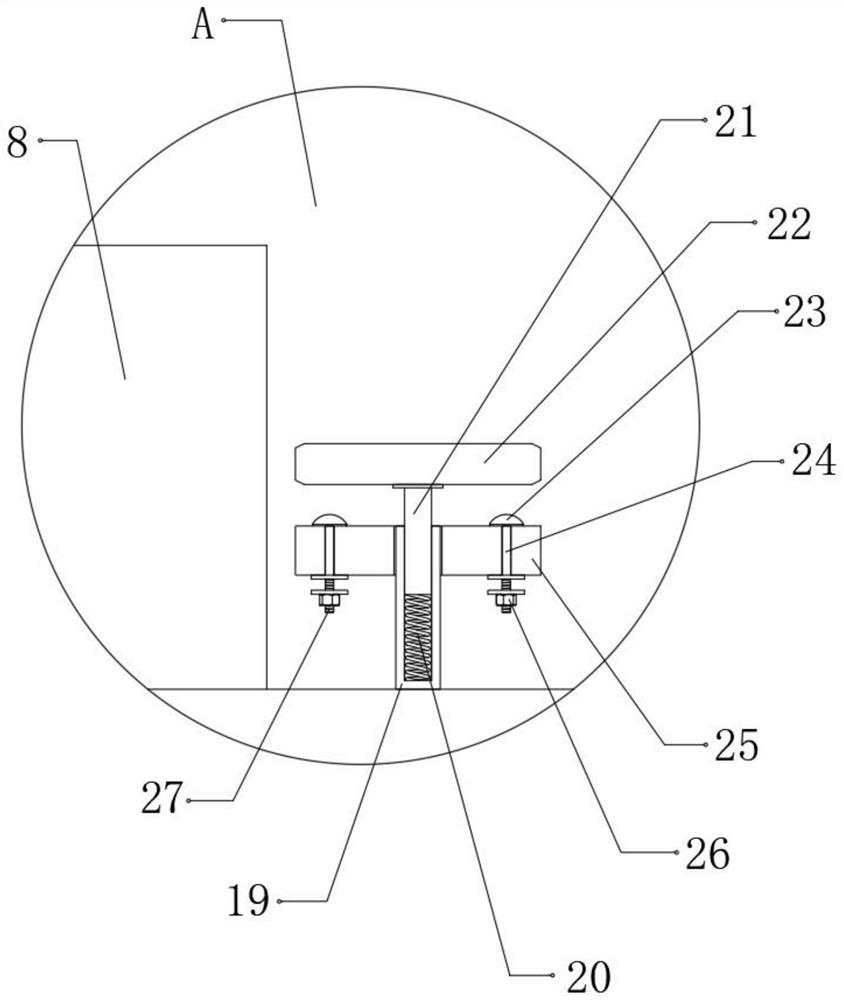

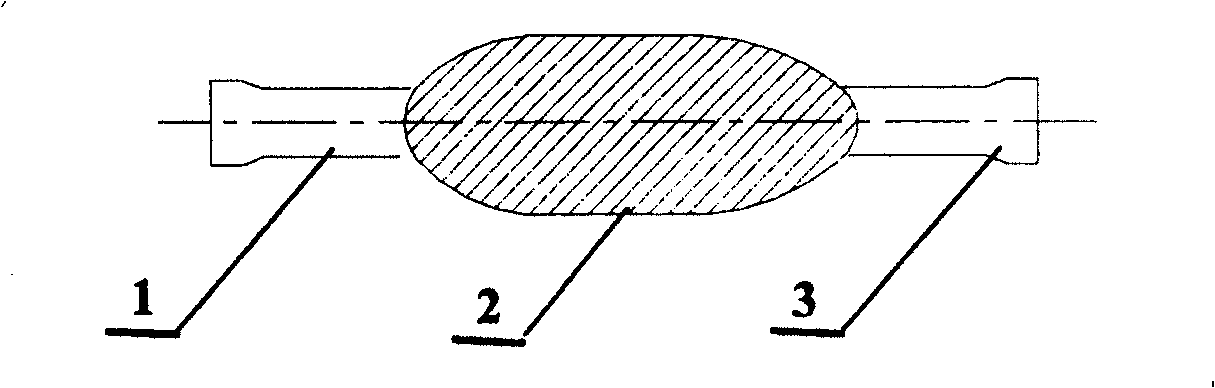

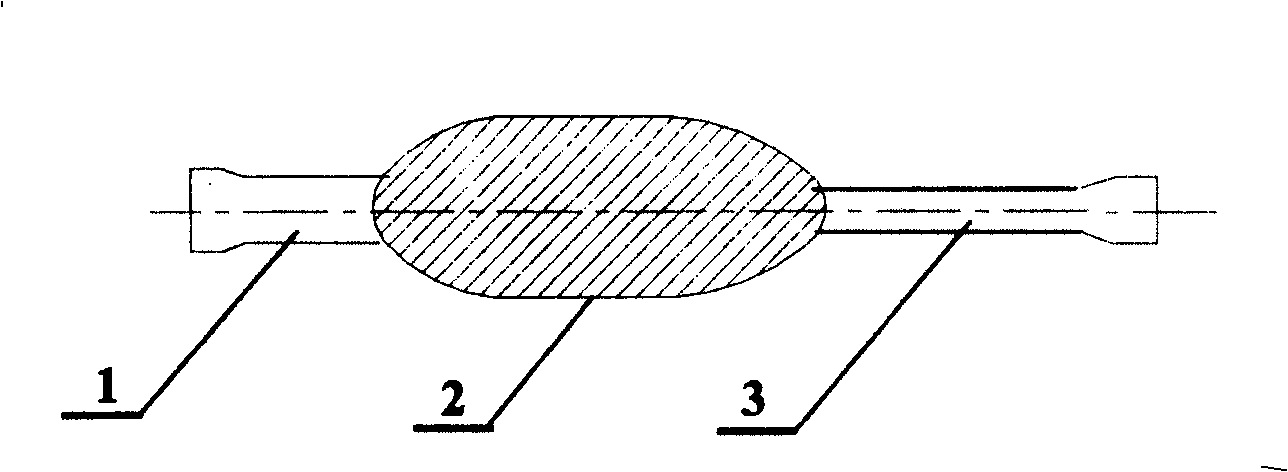

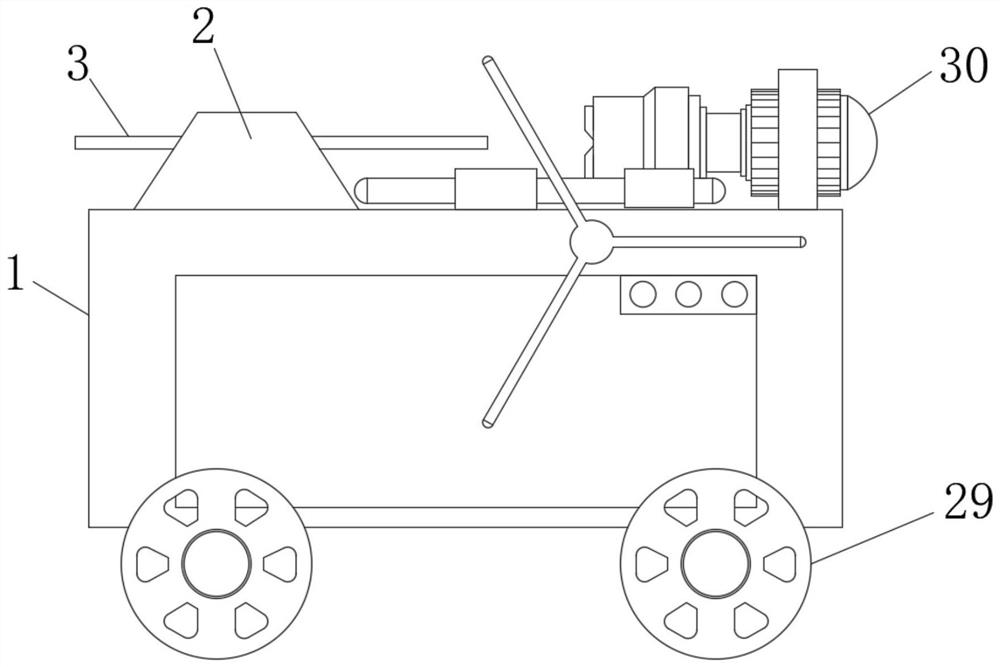

Steel bar thread rolling machine for construction steel bar machining

ActiveCN112045122AMeet the needs of processing efficiencyQuick job locationScrew-threads articlesMachineRebar

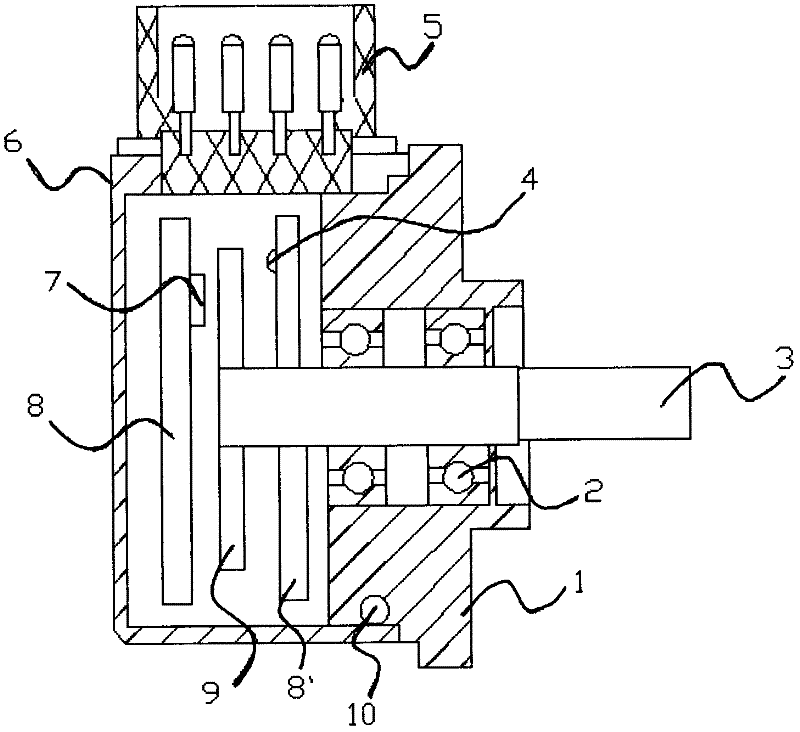

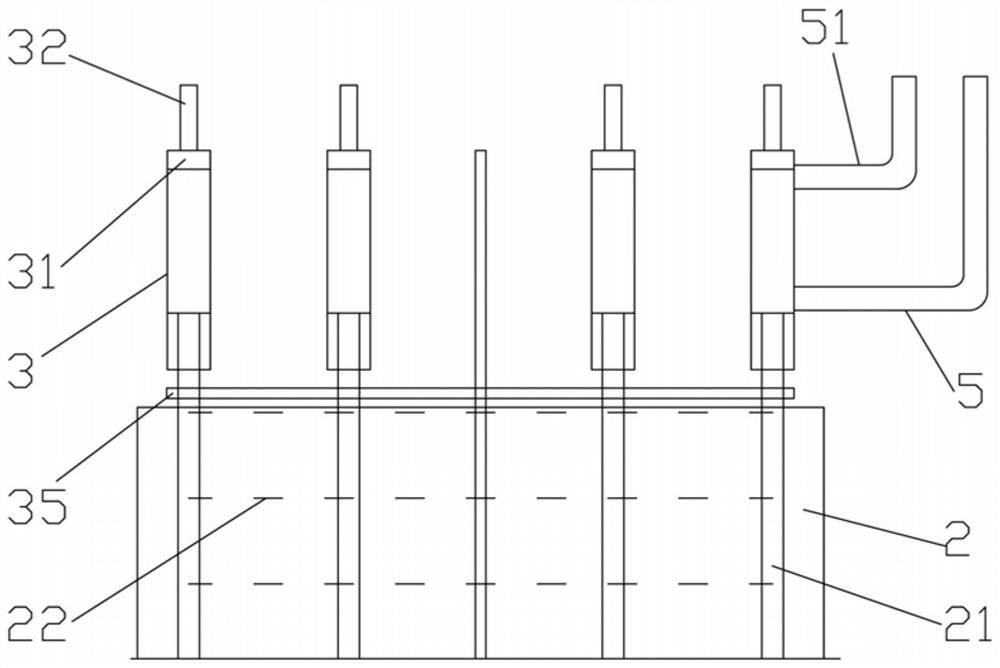

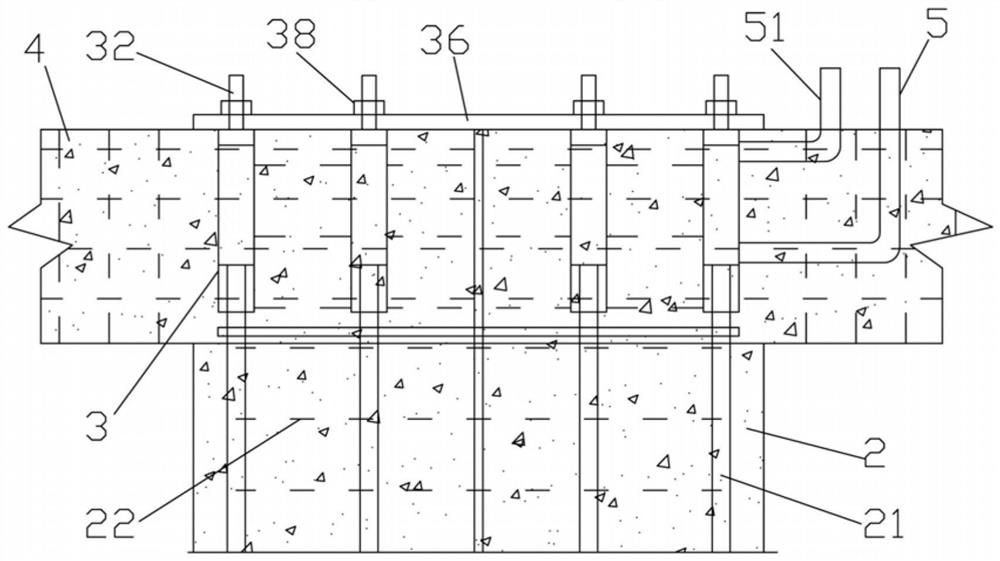

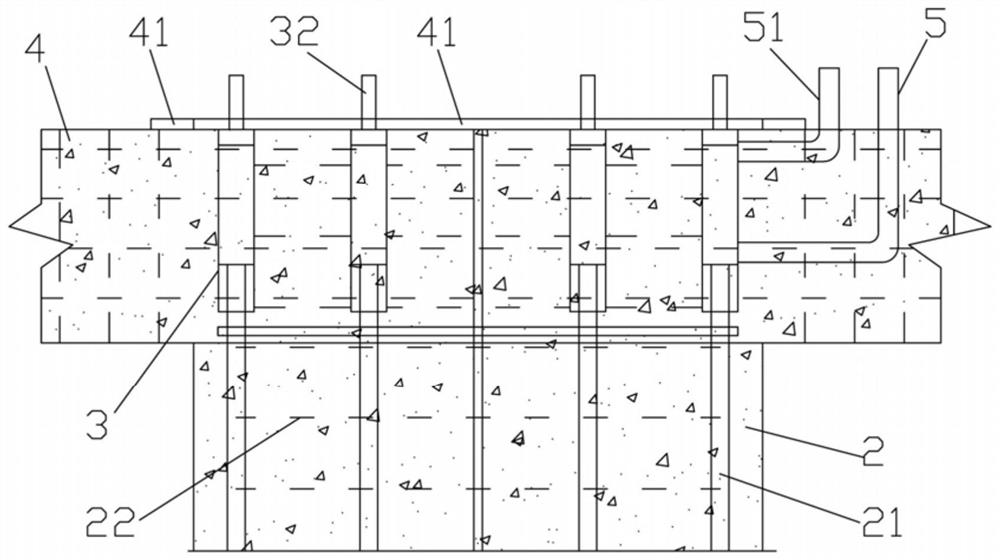

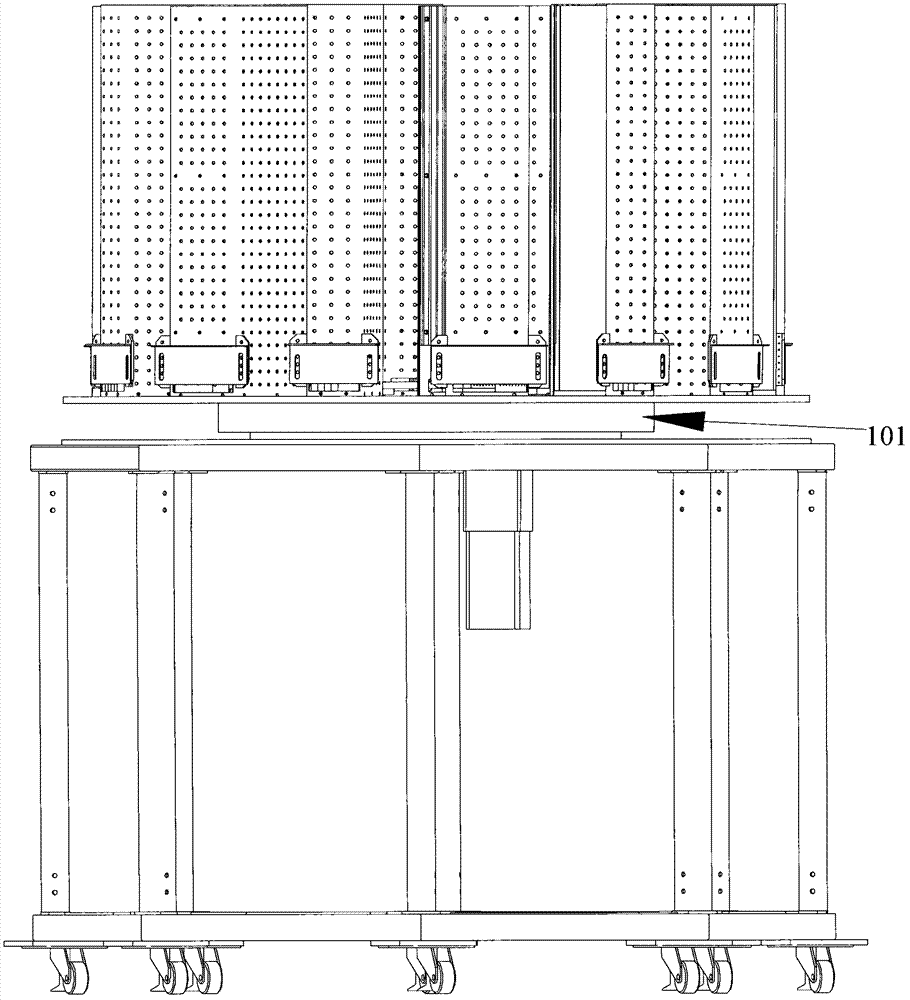

The invention relates to the technical field of steel bar thread rolling machines, in particular to a steel bar thread rolling machine for construction steel bar machining. The machine comprises a boxbody 1, a base 2 and a steel bar 3, wherein the base 2 is fixedly connected to the upper end of the box body 1, the steel bar 3 penetrates through the base 2, the base 2 is in a frustum shape and isprovided with a cylindrical hole, the steel bar 3 is arranged in the cylindrical hole of the base 2, a plurality of uniformly-distributed pushing plates 4 are arranged surrounding the steel bar 3, a rubber block 5 is fixedly connected to one end of each pushing plate 4, and the rubber blocks 5 are in contact with the steel bar 3. According to the structural design, the demand for locating steel bars 3 with different outer diameters by the base 2 is met, rapid locating work can be realized just by controlling a first handle 21 and a second handle 22, the efficient machining demand on the wholesteel bar thread rolling machine is met, and functions are stable and powerful.

Owner:广东新拓展建筑工程有限公司

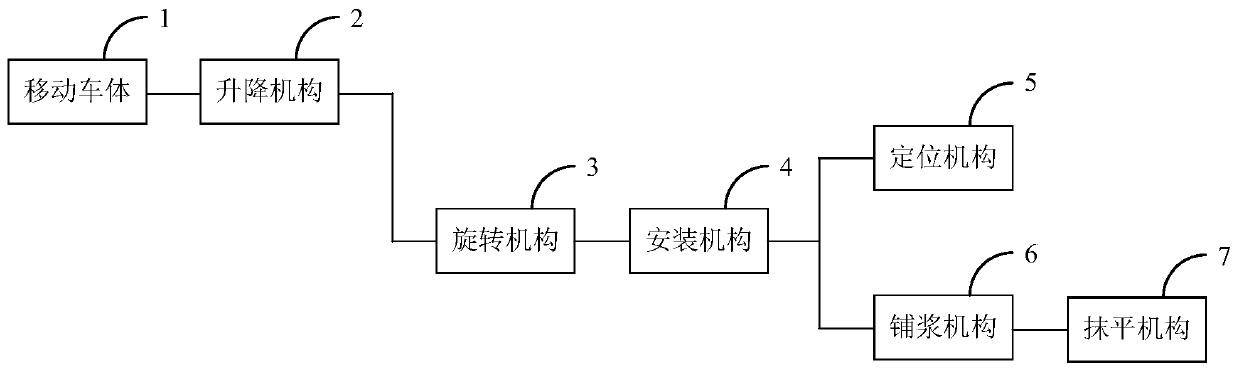

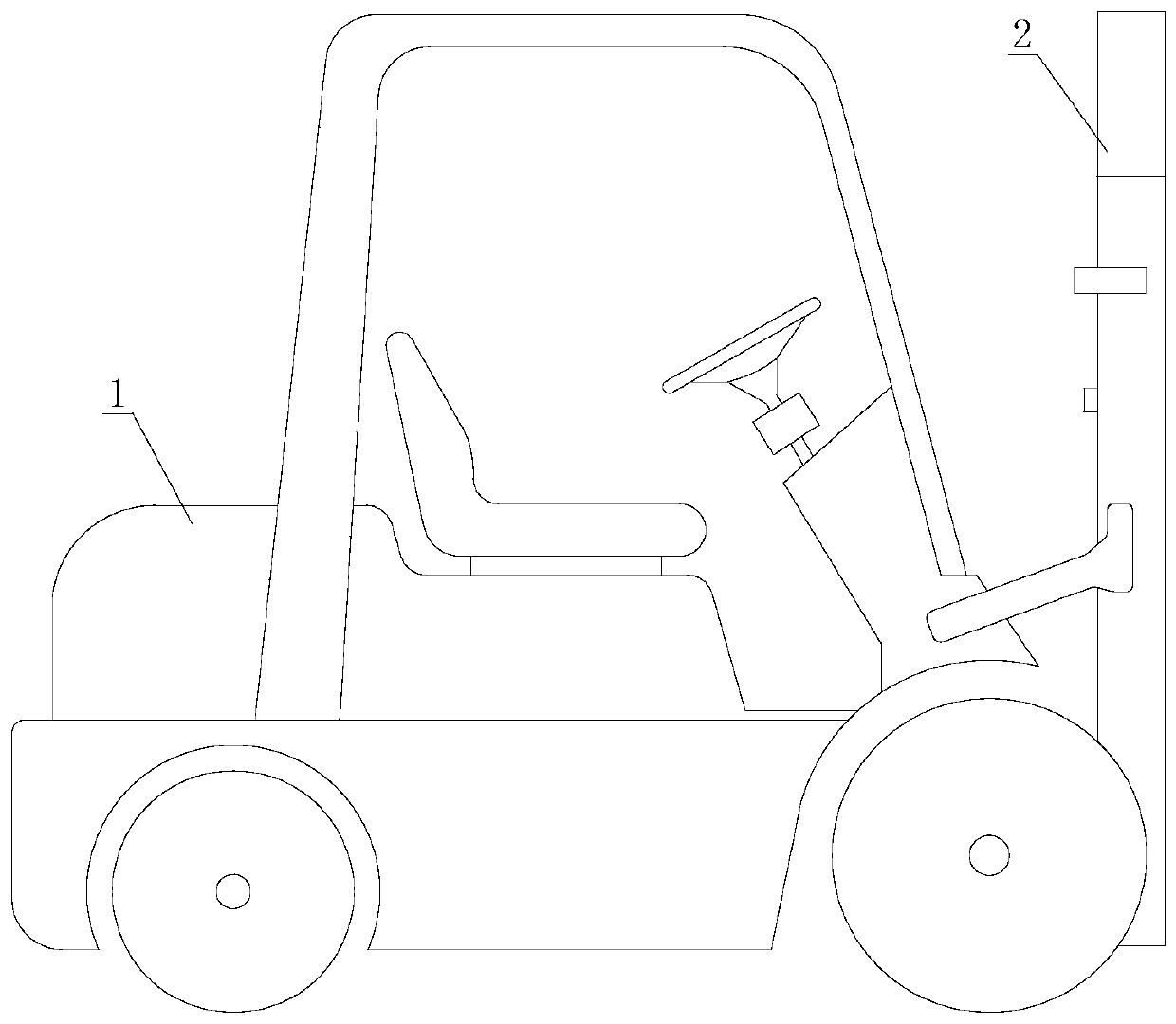

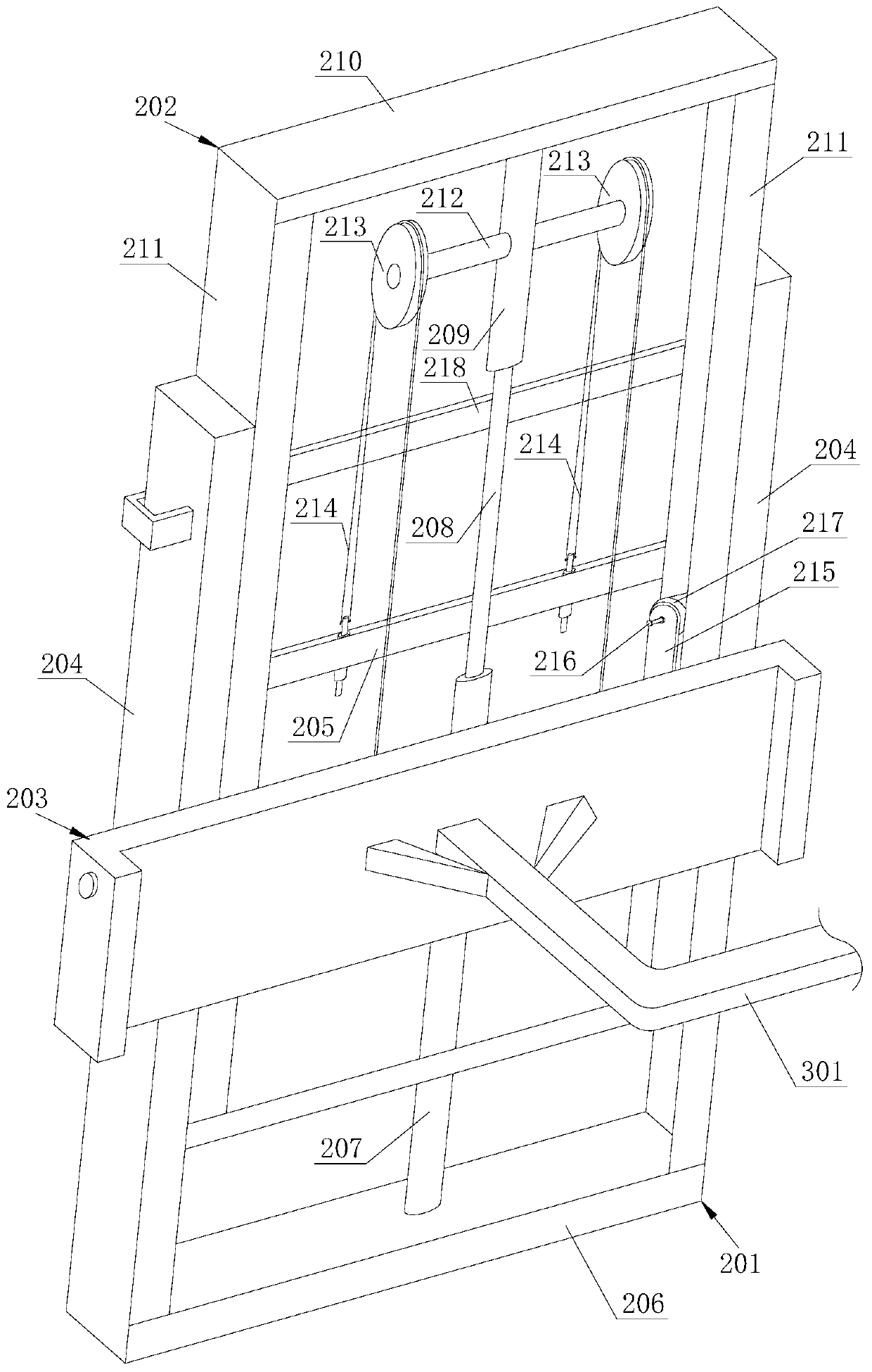

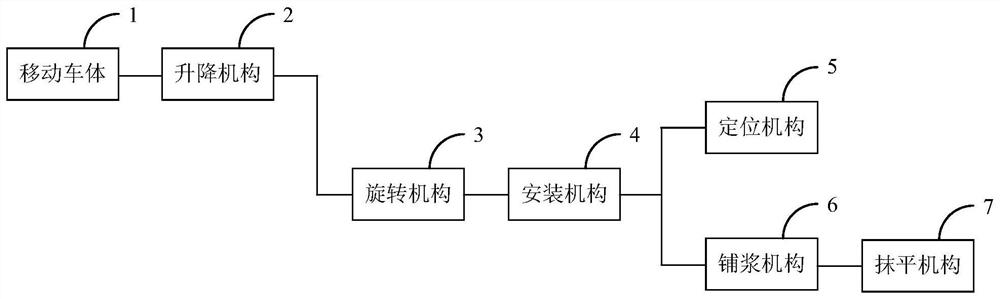

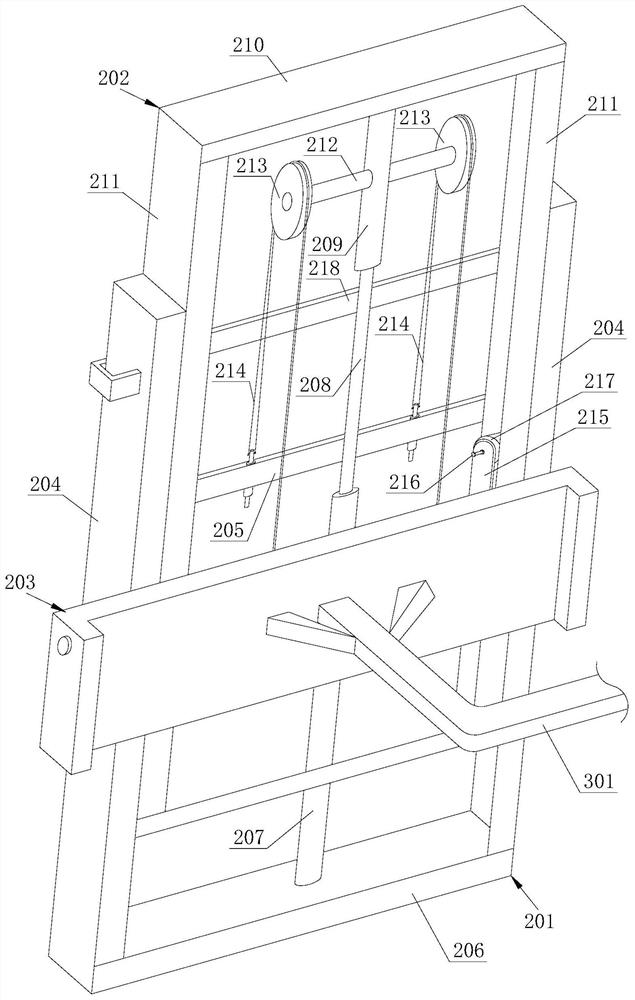

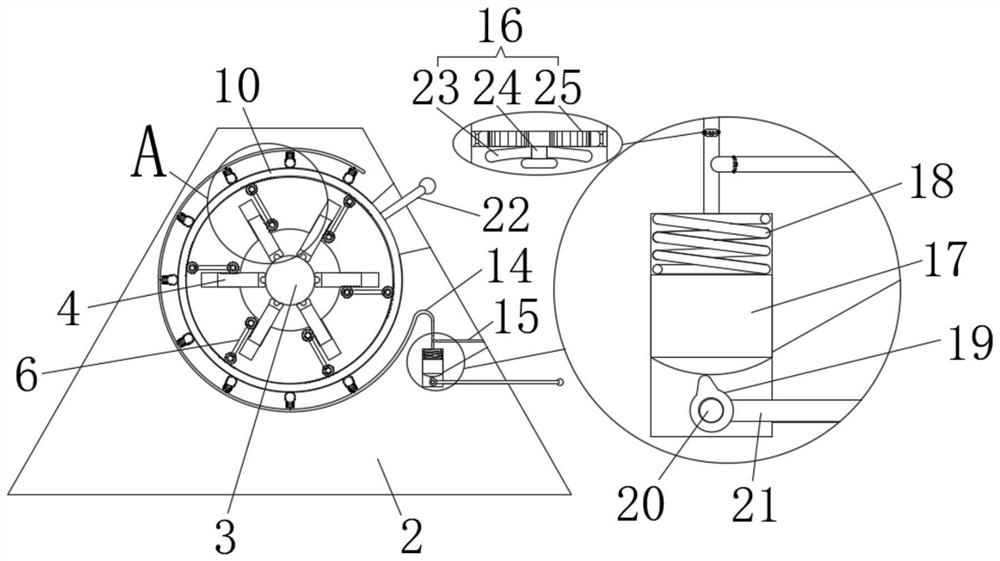

Movable type wall building mortar paving method

ActiveCN110836020AEasy to control pouring thicknessRealize positioning controlBuilding material handlingArchitectural engineeringElectric machinery

The invention provides a movable type wall building mortar paving method. The movable type wall building mortar paving method includes the following steps of lifting adjustment: horizontal pressing plates are adjusted to the height position of a to-be-built wall through lifting of a lifting cylinder; rotation adjustment: the horizontal pressing plates are rotated to be parallel to the length direction of the to-be-built wall through rotation of a servo motor; positioning adjustment: the inner sides of the bottom surfaces of the horizontal pressing plates are pressed on the surface of the to-be-built wall through expansion and contraction of an adjustment cylinder, and the inner side surface of a positioning flitch is clamped on the two side surfaces of the to-be-built wall; motor paving: amounting plate connected with a stirring barrel is driven by a driving motor to slide on a first supporting shaft and a second supporting shaft along with the driving motor, mortar in the stirring barrel is poured onto the surface of the to-be-built wall positioned by the two horizontal pressing plates in the positioning mechanism through a slurry discharge valve; and mortar trowelling: a trowelling plate is driven by a telescopic cylinder to move on the upper side of the mortar so as to smoothen the poured mortar. According to the movable type wall building mortar paving method, the mortar paving width and thickness can be positioned, and the mortar is automatically poured and trowelled, mortar pouring is controllable, and the building quality is guaranteed.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

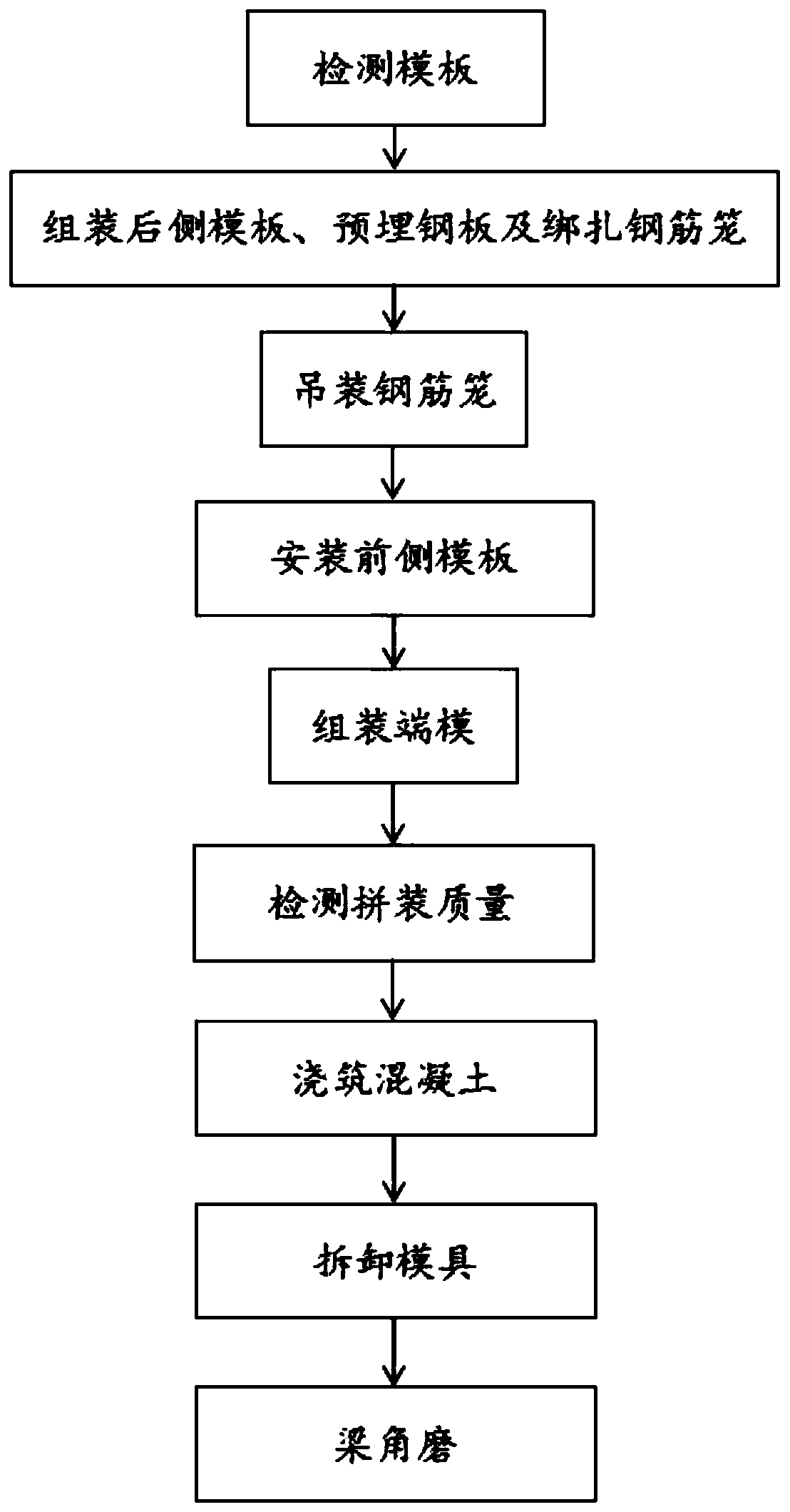

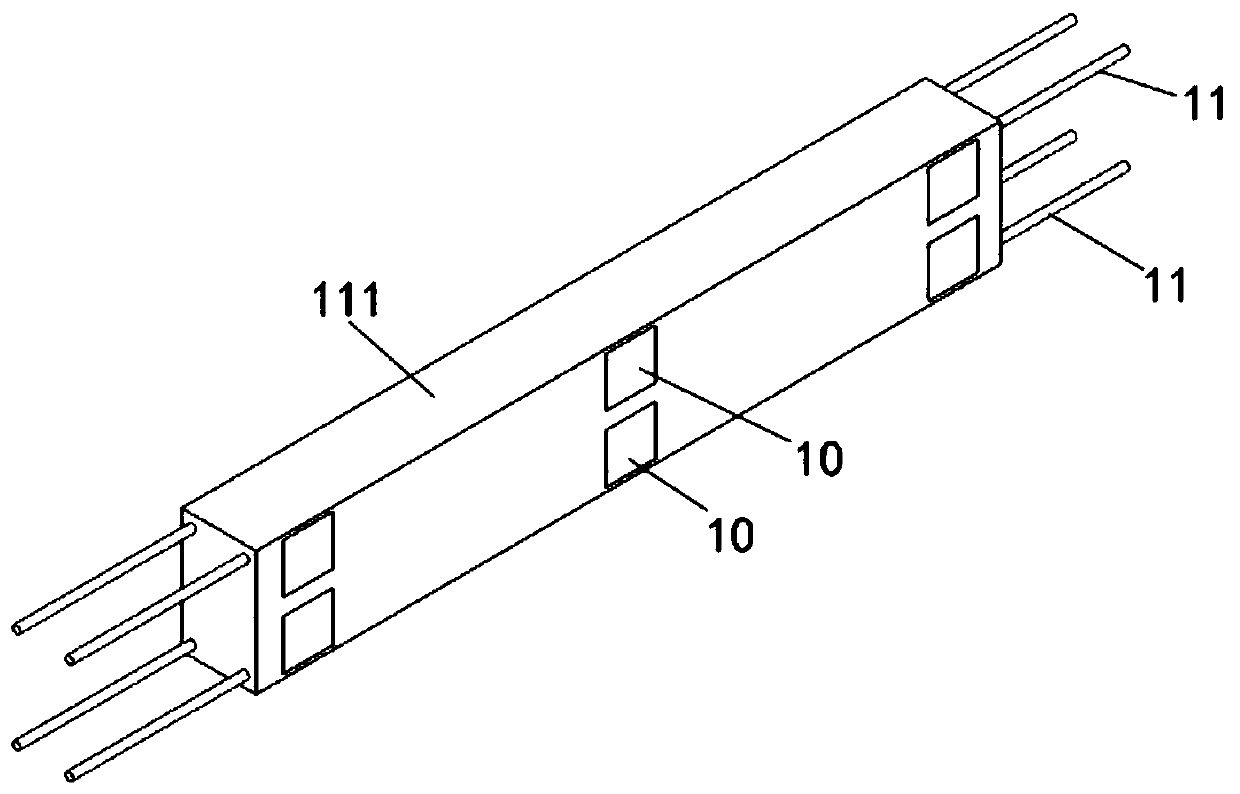

High-quality precast beam production method of embedded steel plate for precise positioning curtain wall installation

ActiveCN111452210AQuick adjustment loading and unloadingReduce the difficulty of operationCeramic shaping apparatusSteel platesRebar

The invention discloses a high-quality precast beam production method of an embedded steel plate for precise positioning curtain wall installation. The high-quality precast beam production method of the embedded steel plate for precise positioning curtain wall installation comprises a mould table for building a mould, a rear-side mould plate, a front-side mould plate and two end mould plates, wherein multiple upper rows of through holes and multiple lower rows of through holes are formed in the front-side mould plate; a fixator is arranged on the front-side mould plate; and after the fixator is installed, the end face of a magnetic drawing end of a magnetic base and the end face of an end cover are parallel and level to the inner surface of the front-side mould plate. A preparation processcomprises the following steps of (1) detecting the mould plates; (2) assembling the rear-side mould plate, assembling the embedded steel plate, binding a reinforcement cage, and arranging a support fork in the reinforcement cage; (3) hoisting the reinforcement cage; (4) installing the front-side template plate; (5) assembling the end mould plates; (6) inspecting the assembling quality; (7) concreting; (8) disassembling the mould; and (9) polishing beam corners. According to the high-quality precast beam production method of the embedded steel plate for precise positioning curtain wall installation provided by the invention, the position of the embedded steel plate can be precisely positioned, and the thickness of an upper-row reinforcement protection layer is effectively controlled.

Owner:苏州杰通建筑工业有限公司

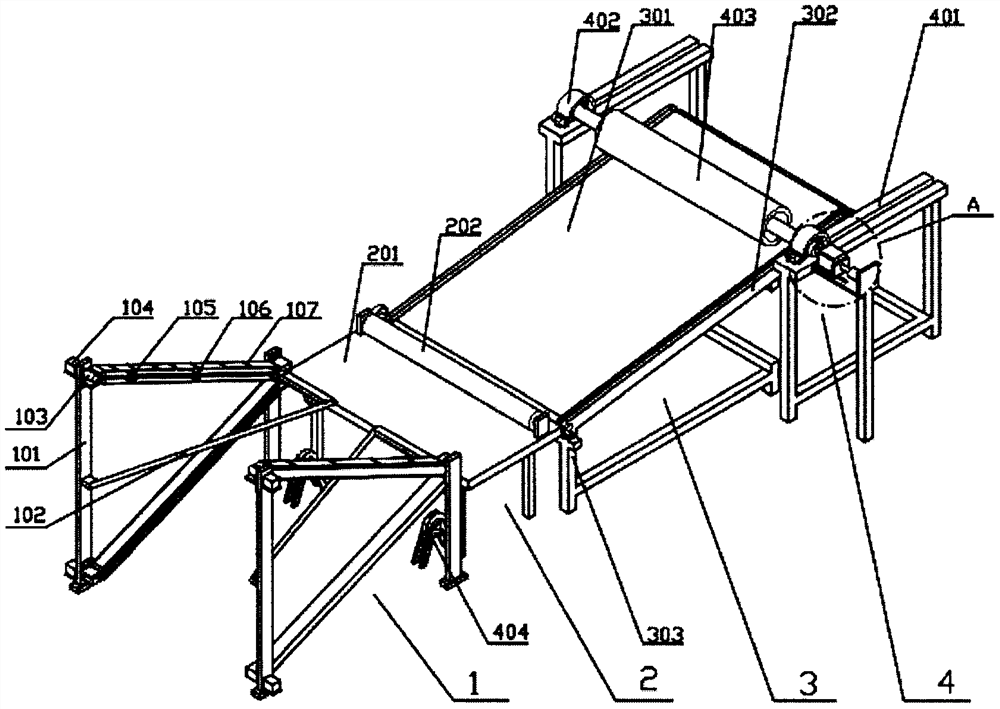

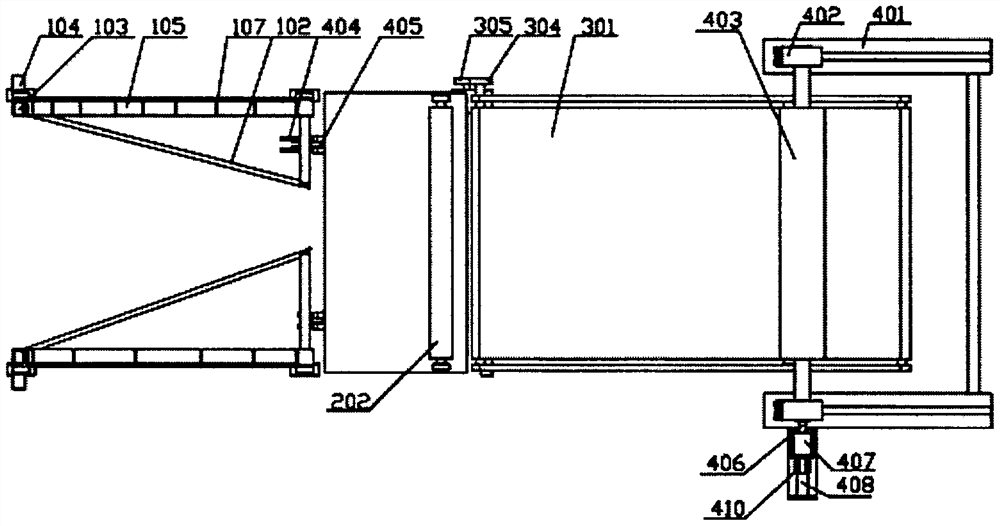

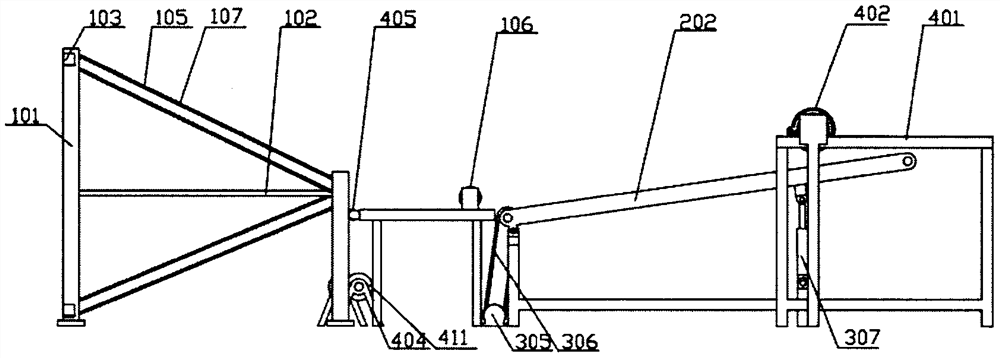

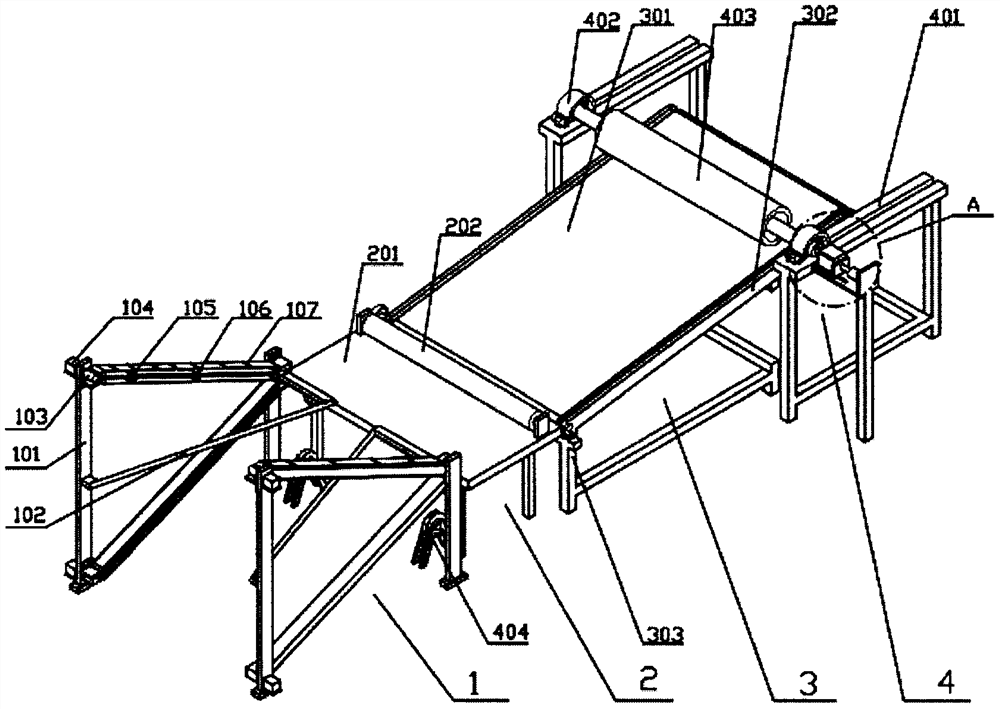

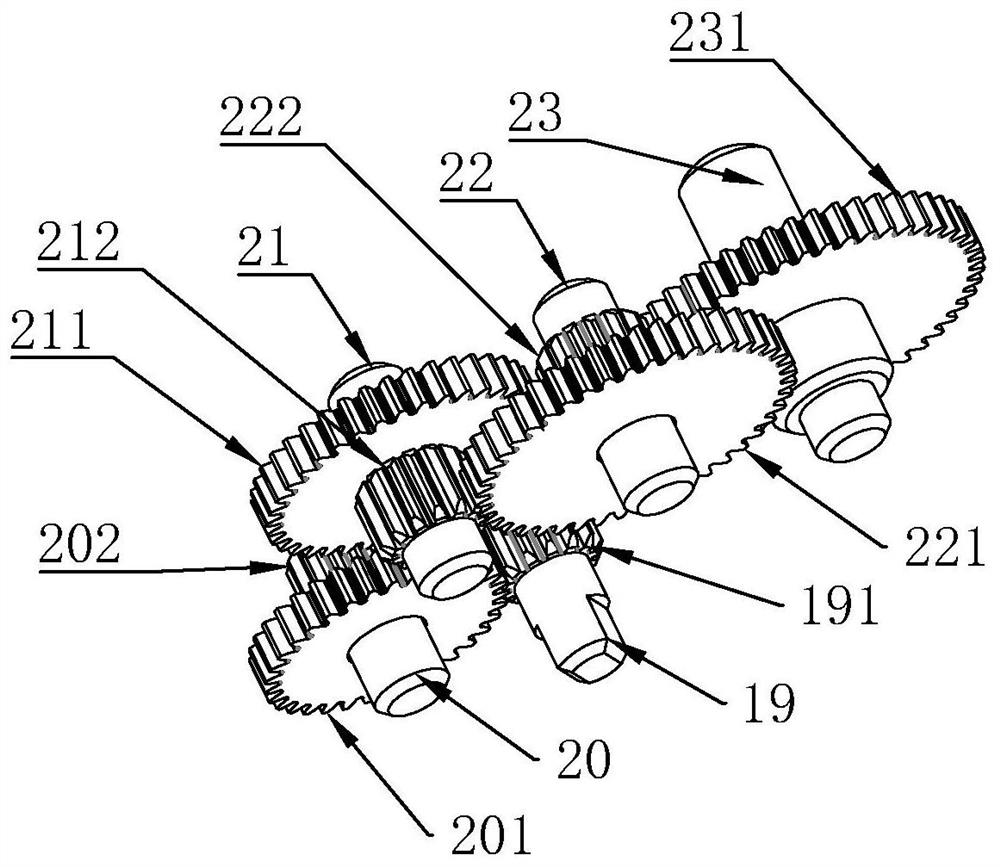

Automatic ton bag rolling machine

ActiveCN112141464AQuick loading and unloadingEasy to installBundling machine detailsGear wheelElectric machinery

The invention relates to an automatic ton bag rolling machine. The automatic ton bag rolling machine is characterized by comprising a folding mechanism, a flattening mechanism, a ton bag conveying mechanism and a rolling mechanism, all of which are sequentially arranged from left to right. The folding mechanism comprises a transmission mechanism, a bag collecting mechanism and a guiding and limiting mechanism and is used for folding ton bags into regular rectangles. The flattening mechanism is composed of a flattening roller and a flattening plate and used for thoroughly exhausting air in thefolded ton bags and flattening and pressing the ton bags. The ton bag conveying mechanism comprises a conveying belt, a supporting frame, a conveying gear, a conveying chain, a conveying motor and anair cylinder and is mainly used for conveying the ton bags to the rolling mechanism from the flattening mechanism. The rolling mechanism comprises a bundling tape mechanism, a rolling shaft, a positioning groove, positioning clamping jaws and a rolling shaft driving device, and the rolling shaft can be conveniently disassembled and driven after rolling. According to the automatic ton bag rolling machine, continuous rolling of the ton bags is achieved, preconditions are provided for full-automatic packaging of the ton bags, the labor intensity is reduced, and the production efficiency is improved.

Owner:HEBEI UNIV OF TECH

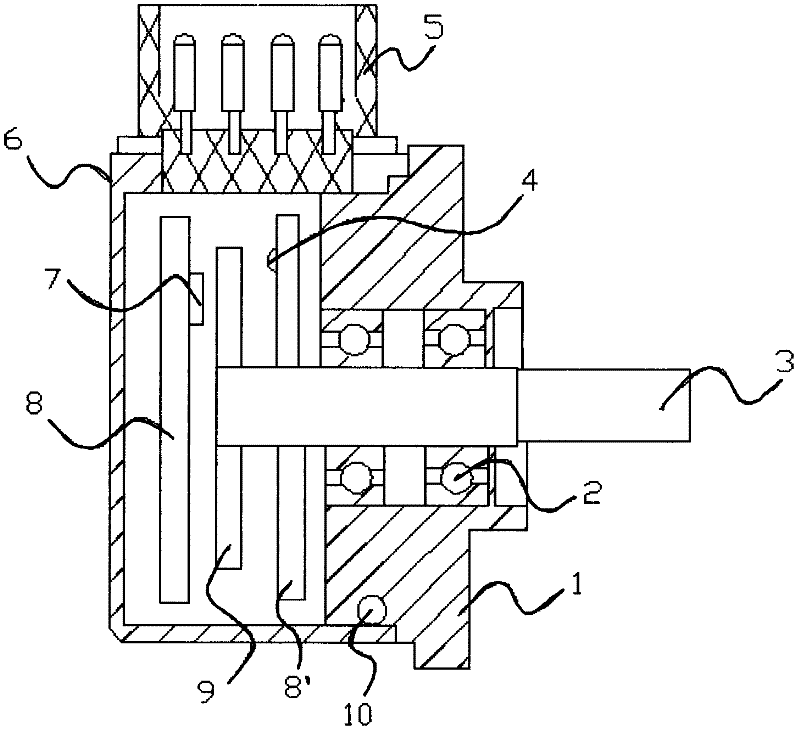

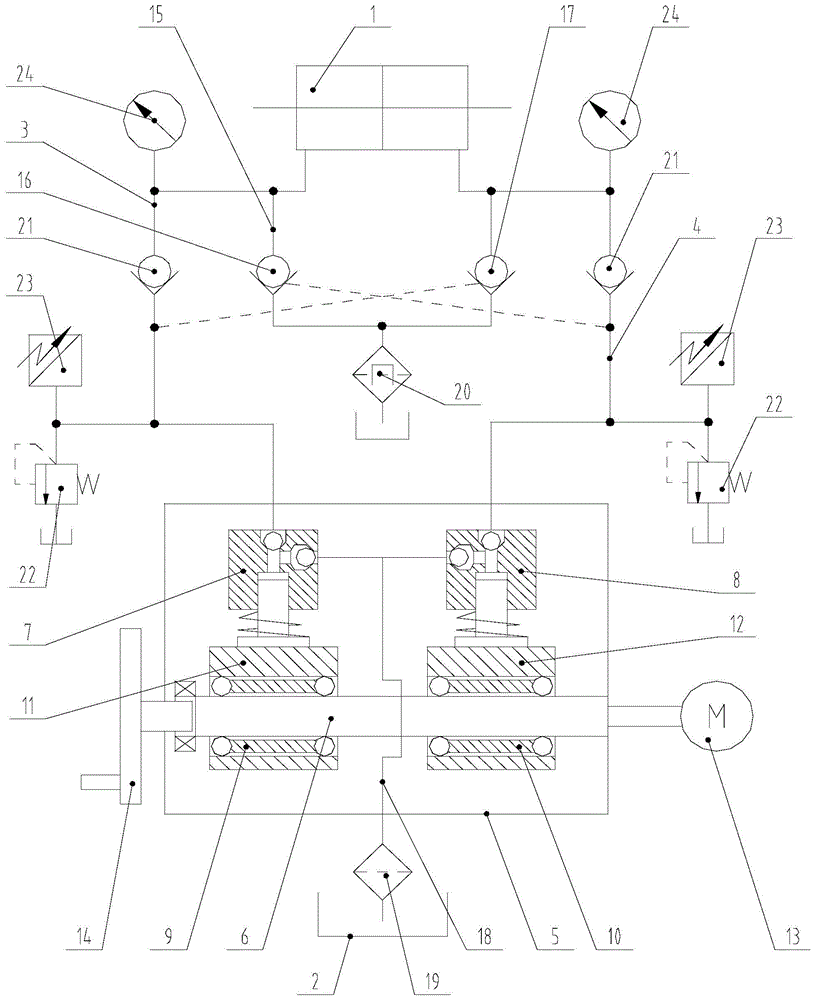

Double-channel plunger flow assignment electro-hydraulic actuator

InactiveCN104564864AThe system is stable and reliableHigh oil volumetric efficiencyServomotor componentsServomotorsOil supplyFuel tank

The invention discloses a double-channel plunger flow assignment electro-hydraulic actuator. The actuator comprises a two-way pump, a two-way oil cylinder, an oil tank and an oil channel system. A forwarding oil supplying first oil outlet and a reversing oil supplying second oil outlet are formed in the two-way pump. The oil channel system comprises a first oil channel communicated with the first oil outlet and a left chamber of the two-way oil cylinder and a second oil channel communicated with the second oil outlet and a right chamber of the two-way oil cylinder. By means of the actuator, two pressure oil is produced through forward and reverse rotation of the two-way pump to be output independently through two channels, and accordingly, the oil cylinder reciprocating is achieved, a traditional solenoid directional valve is not needed, the actuator is simple and reliable, the two-way oil cylinder volume efficiency is high, 'packeted oil' is prevented, oil can be pumped in the low rotation speed, and high-accuracy location control of the pump control system is achieved.

Owner:CHONGQING CHUANYI AUTOMATION

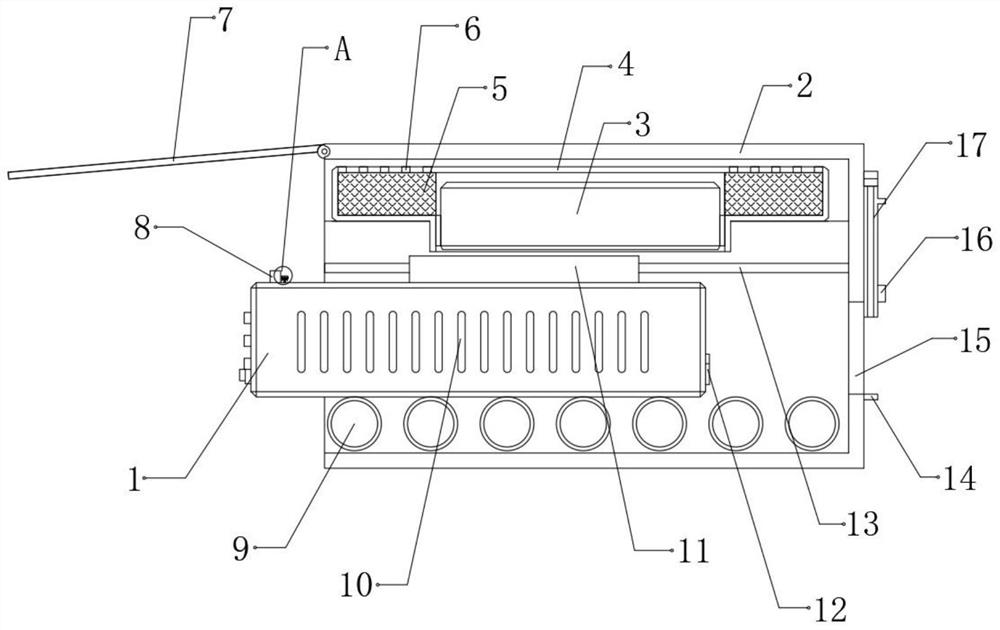

Pulse signal generator for testing integrated circuit

PendingCN113543544ARealize positioning controlAct as an electrostatic shieldCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsControl signalHemt circuits

The invention discloses a pulse signal generator for testing an integrated circuit. The pulse signal generator comprises a signal generator body, a heat dissipation window and a power interface. When the signal generator is used and the signal generating body needs to be used, the signal generating body is controlled to slide towards the turning plate from the interior of the box shell, the hinged turning plate is automatically ejected open after being stressed, the bottom edge of the turning plate reaches the outer wall of the top of the signal generator body, then the signal generator body continues to slide, and the bottom edge of the turning plate is lifted by the supporting plate; when the turning plate falls down from the top of the supporting plate, the switch triggering assembly is pressed downwards, the driving circuit for controlling the signal generator body to move is disconnected, the signal generator body can stop moving, the turning plate and the box shell jointly form a closed metal shell, the electrostatic shielding effect is achieved, idle time protection is conducted on the signal generator body, and the signal generator body is protected. When the signal generator body needs to be used, the turning plate can be matched with the switch triggering assembly through the weight of the turning plate to achieve positioning control over the signal generator body.

Owner:王嘉豪

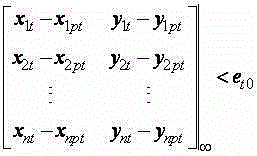

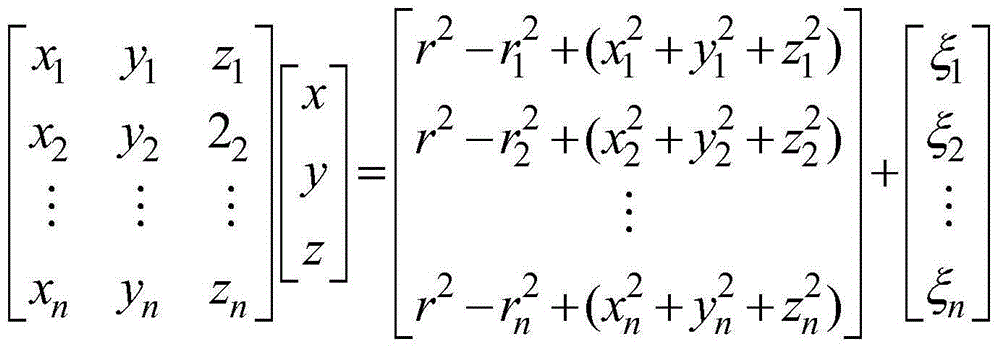

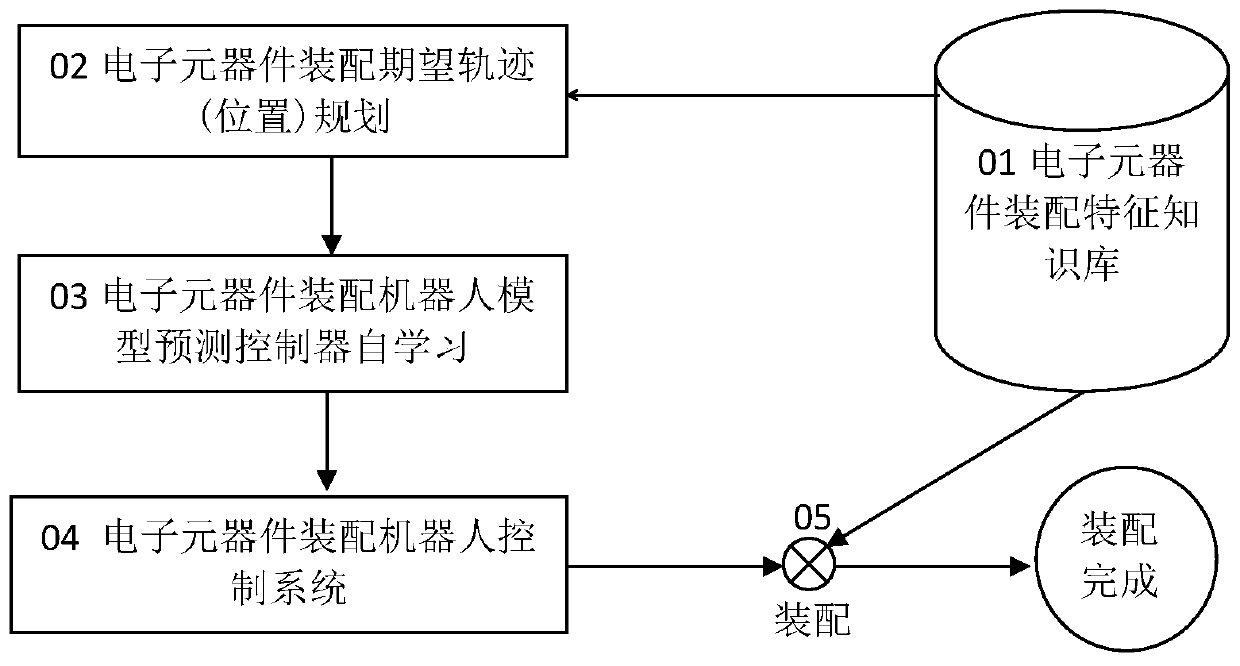

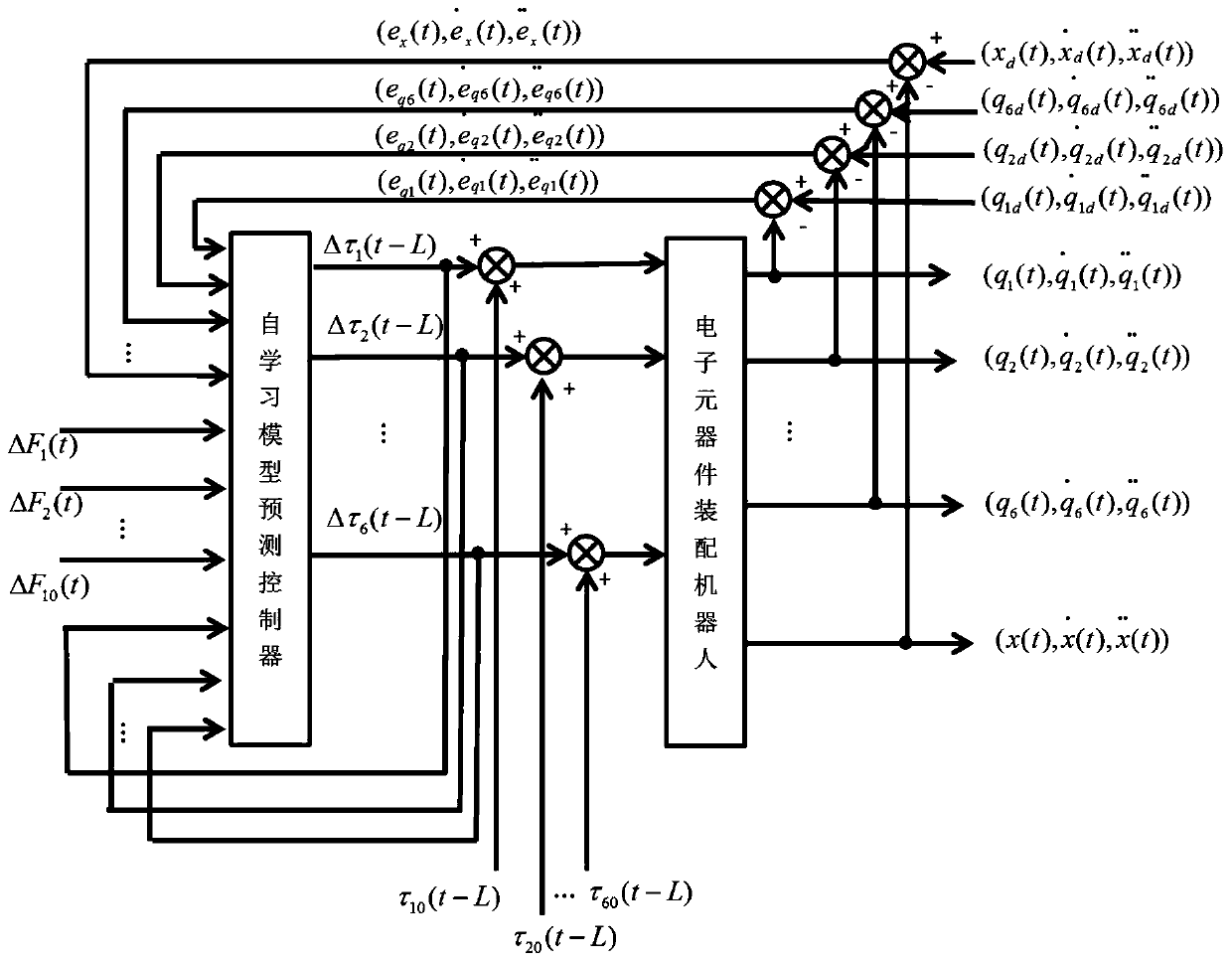

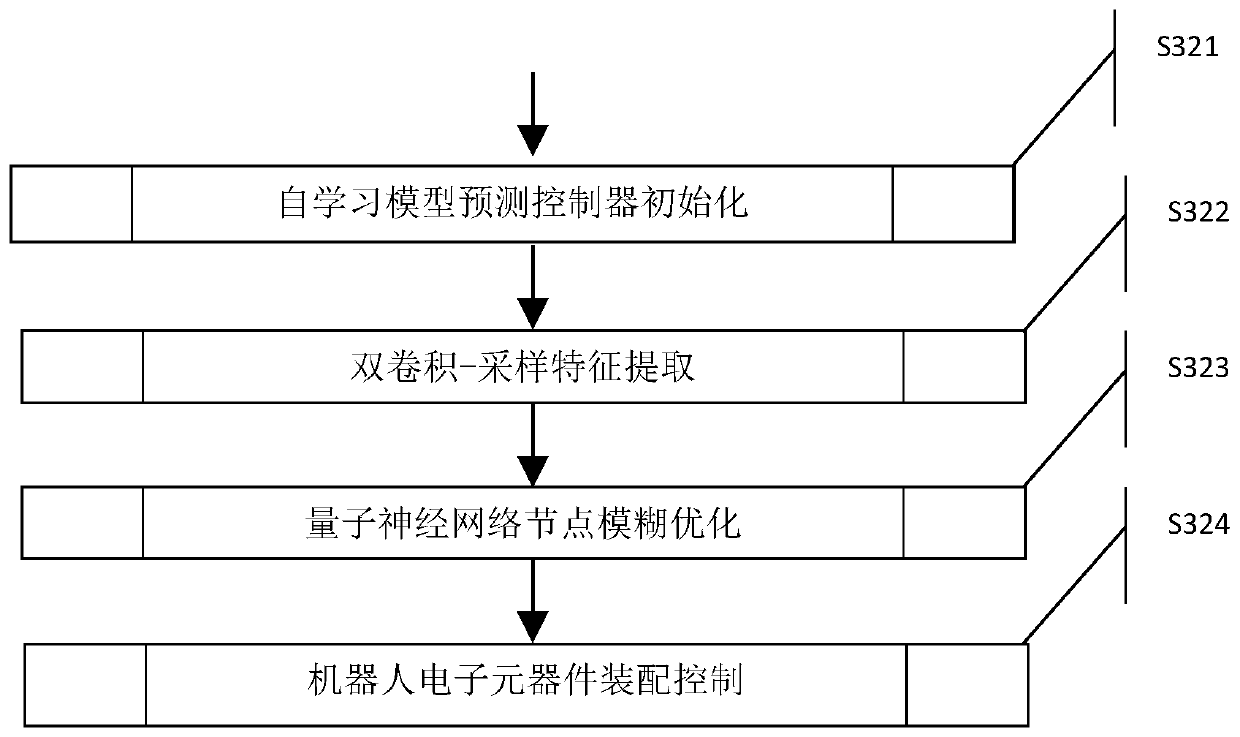

Self-learning model predictive control method for assembly of robot electronic components

ActiveCN111203883AMeet the needs of high-precision online assemblyHigh speedProgramme-controlled manipulatorPredictive controllerEngineering

The invention discloses a self-learning model predictive control method for assembly of robot electronic components. The self-learning model predictive control method includes the steps that the difference between the position, speed and acceleration output of an end effector and a joint and an expected value is input in real time; a model predictive controller is obtained through self-learning training, and the controlling torque delay difference is output; delta[tau] is further used as feedback and as the input of the assembly robot of the electronic components so as to output the actualtarget position, speed and acceleration of the robot joint and the robot end effector in the assembly process of the electronic components; the difference between the above and the expected value is fed back to a model predictive controller to realize the self-learning of the predictive controller; compared with an existing robot assembly control method, according to the self-learning model predictive control method, the self-learning model predictive controller with the difference as input and output has the characteristics of high speed and high precision, and the needs of high precision on-line assembly of the electronic components under various interference factors can be met.

Owner:YANCHENG TEACHERS UNIV

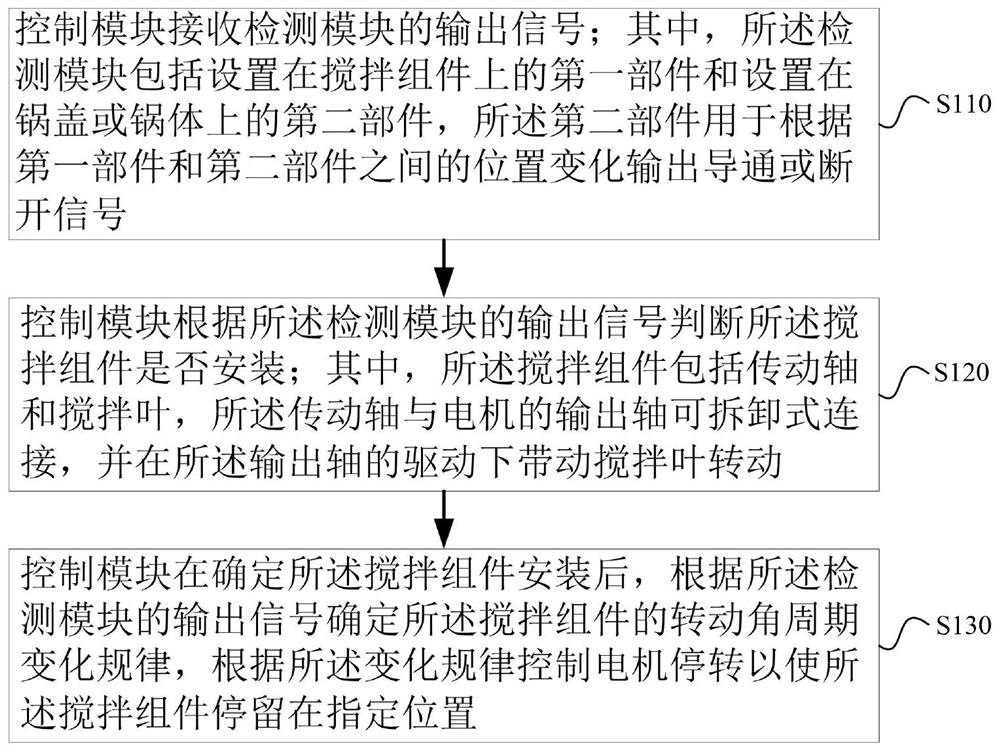

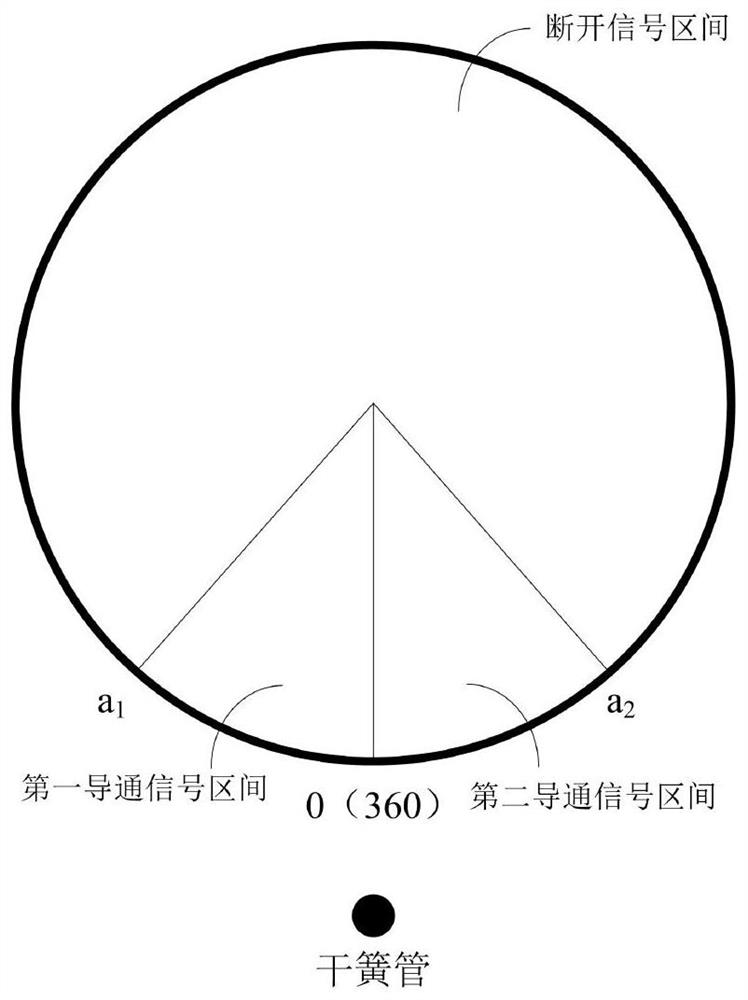

Stirring and positioning method for cooking machine and cooking machine

ActiveCN109480607BRealize positioning controlImprove experienceCooking vessel constructionsDrive shaftControl engineering

The invention discloses an automatic cooker stirring positioning method and an automatic cooker. The automatic cooker stirring positioning method comprises that a control module receives an output signal of a detecting module; the detecting module comprises a first component disposed on a stirring assembly and a second component disposed on a lid or a body, and the second component is used for outputting a connection or disconnection signal according to the position change between the first component and the second component; the control module determines whether the stirring assembly is installed according to the output signal of the detecting module; the stirring assembly includes a transmission shaft and stirring blades, and the transmission shaft is detachably connected with an outputshaft of a motor and drives the stirring blades to rotate under driving of the output shaft; the control module determines the rotation angle periodical change rule of the stirring assembly accordingto the output signal of the detecting module after determining that the stirring assembly is installed and controls the motor to stop according to the change rule to enable the stirring assembly to stop at the specified position. By means of the technical scheme, the precise positioning control of the stirring assembly of the automatic cooker can be achieved.

Owner:JOYOUNG CO LTD

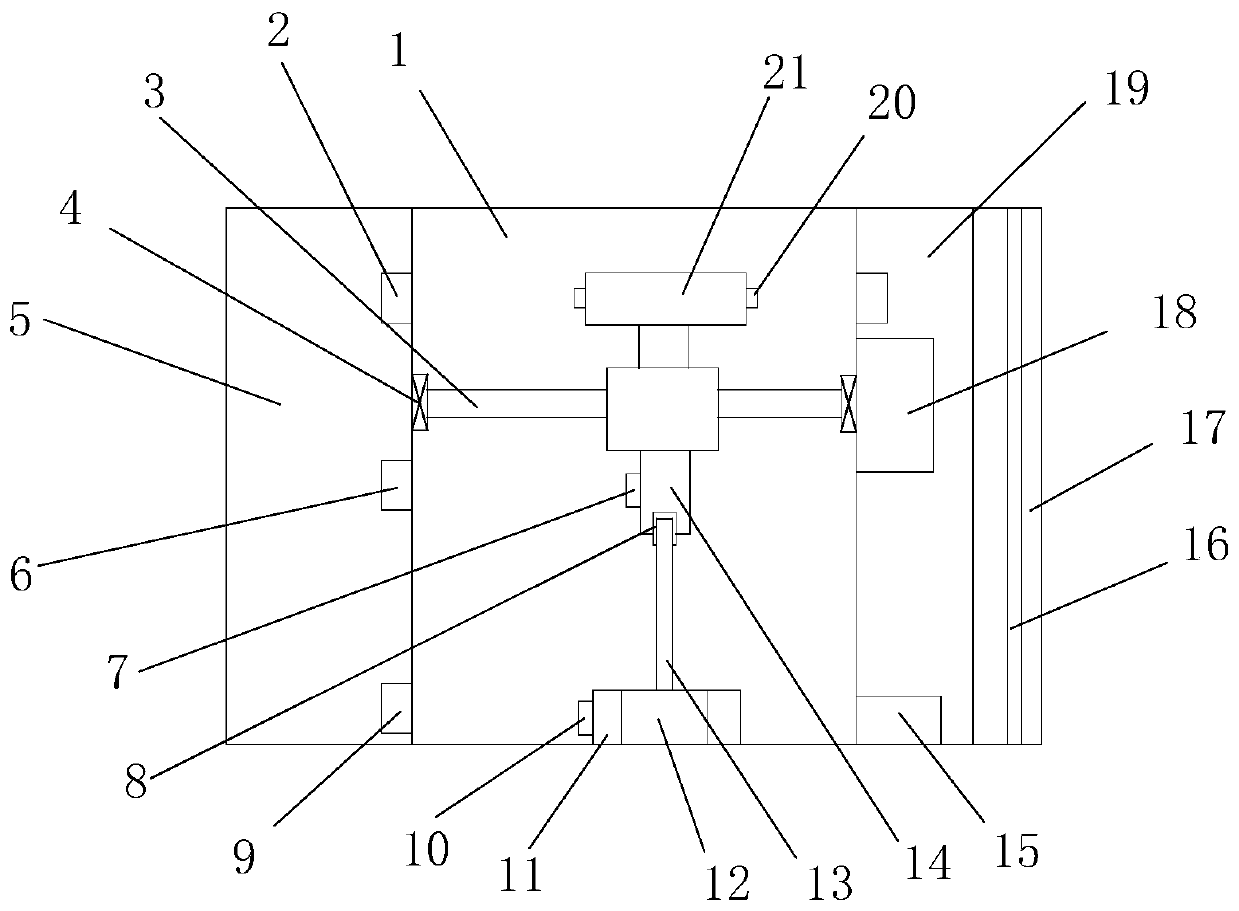

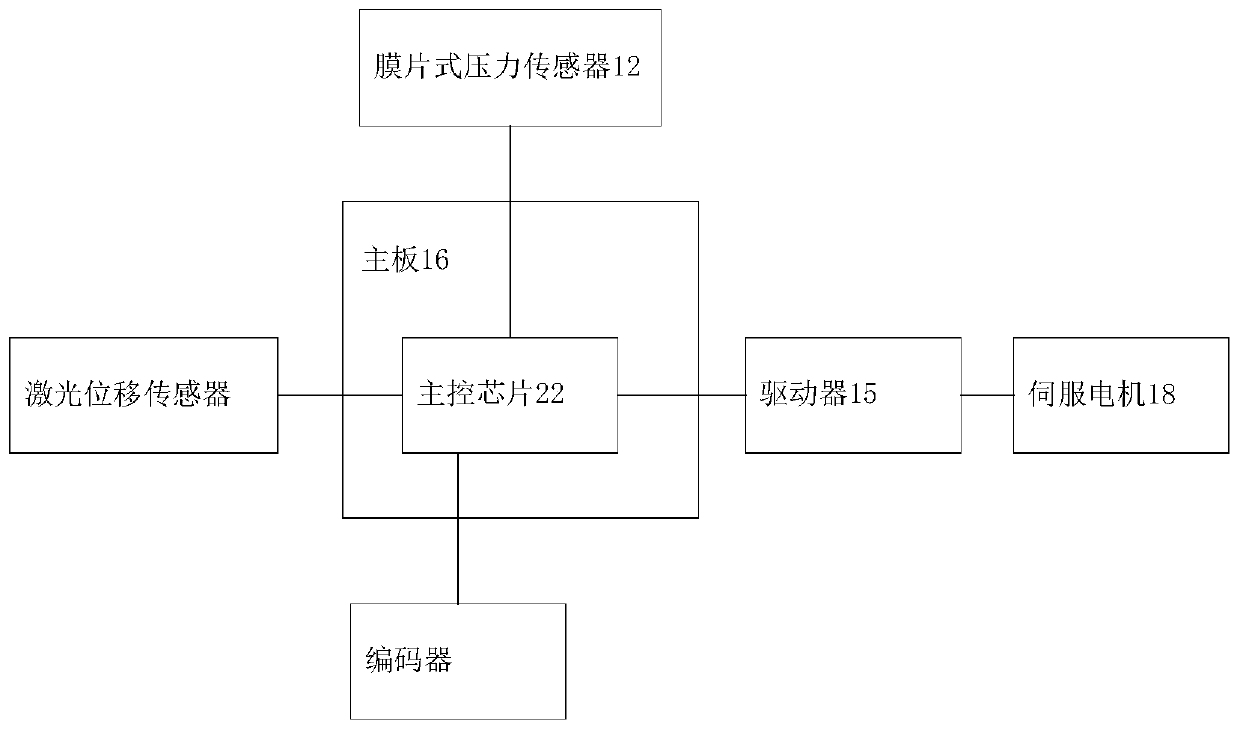

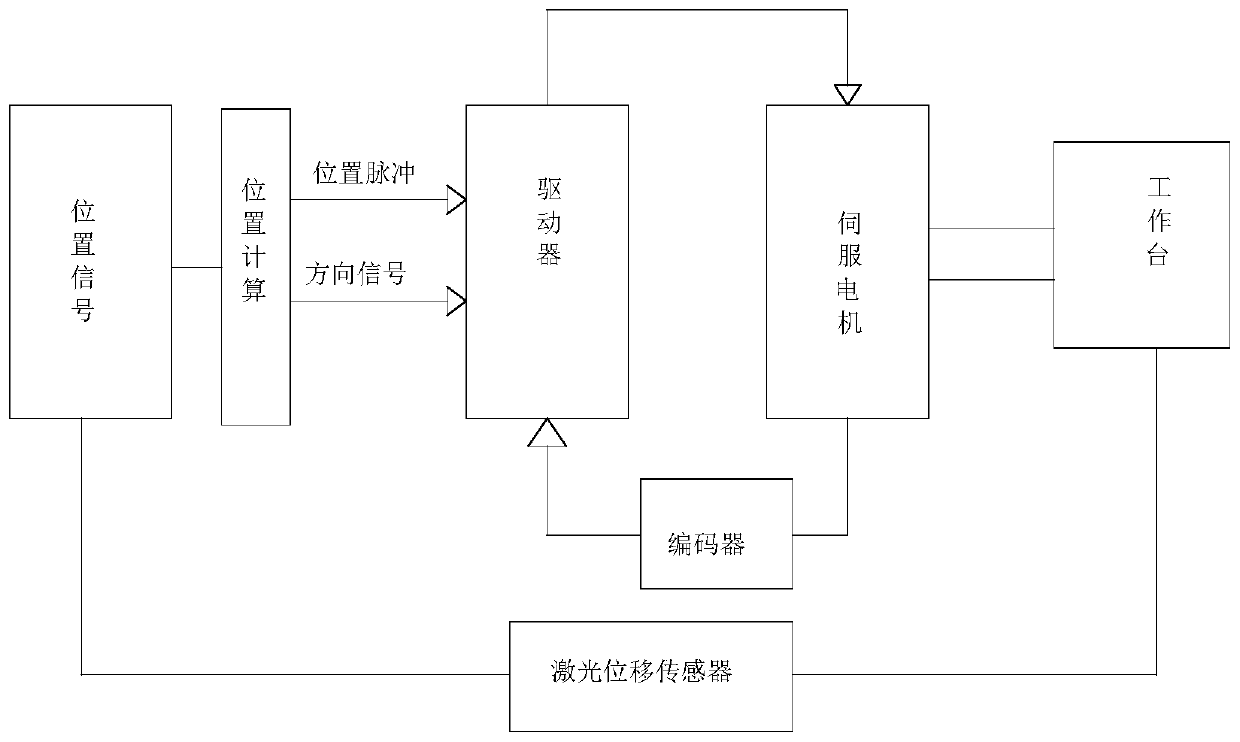

Automatic equipment positioning control mechanism

InactiveCN111158408ARealize positioning controlRealize open-loop positioning controlSpeed/accelaration control using electric meansLaser transmitterEngineering

The invention discloses an automatic equipment positioning control mechanism including a positioning bin; a moving mechanism is arranged in the positioning bin; the moving mechanism is connected witha workbench. A second fixed seat is arranged at the bottom of the workbench. A clamping seat is arranged below the second fixed seat; a first fixed seat is arranged at the bottom of the positioning bin corresponding to the lower part of the clamping seat; a diaphragm type pressure sensor is arranged on the first fixed seat; a metal diaphragm is arranged on the diaphragm pressure sensor; the top ofthe metal diaphragm is fixedly connected with the clamping seat, the left side and the right side of the fixed outer bin are provided with a supporting bin and a driving bin correspondingly, the diaphragm is creatively driven to deform in the moving positioning process, the pressure sensor is used for converting the diaphragm into an electric signal, the displacement of the workbench is obtainedthrough calculation, and positioning control is achieved. A laser emitter is further arranged, and a laser receiver is correspondingly arranged on the left side in the positioning bin. Displacement ismeasured through laser, open-loop positioning control is achieved, and measurement and positioning are achieved in cooperation with a diaphragm type pressure sensor.

Owner:南京亚克电子有限公司

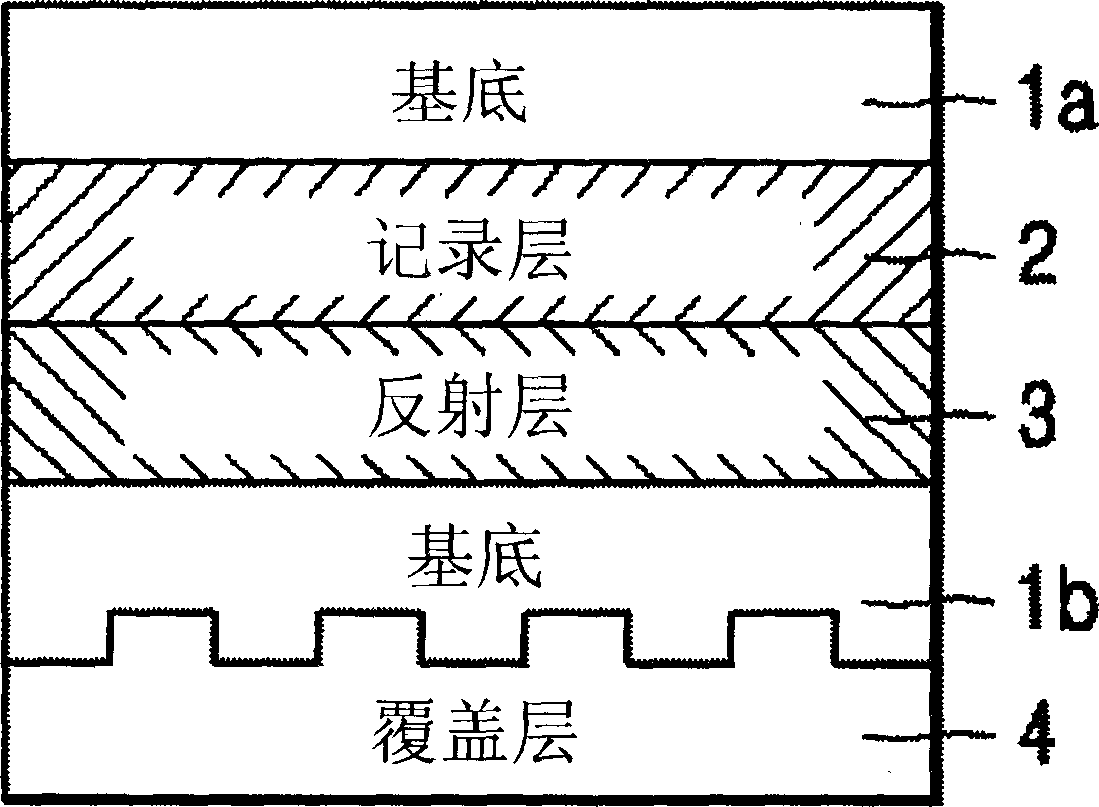

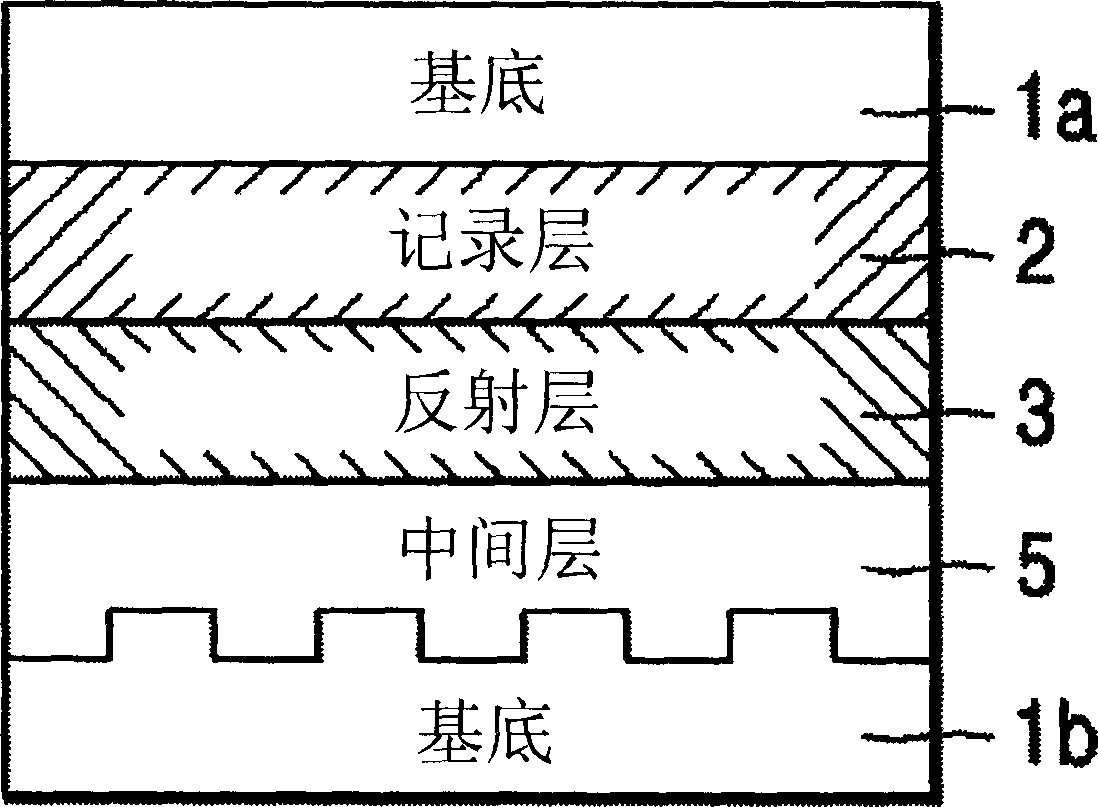

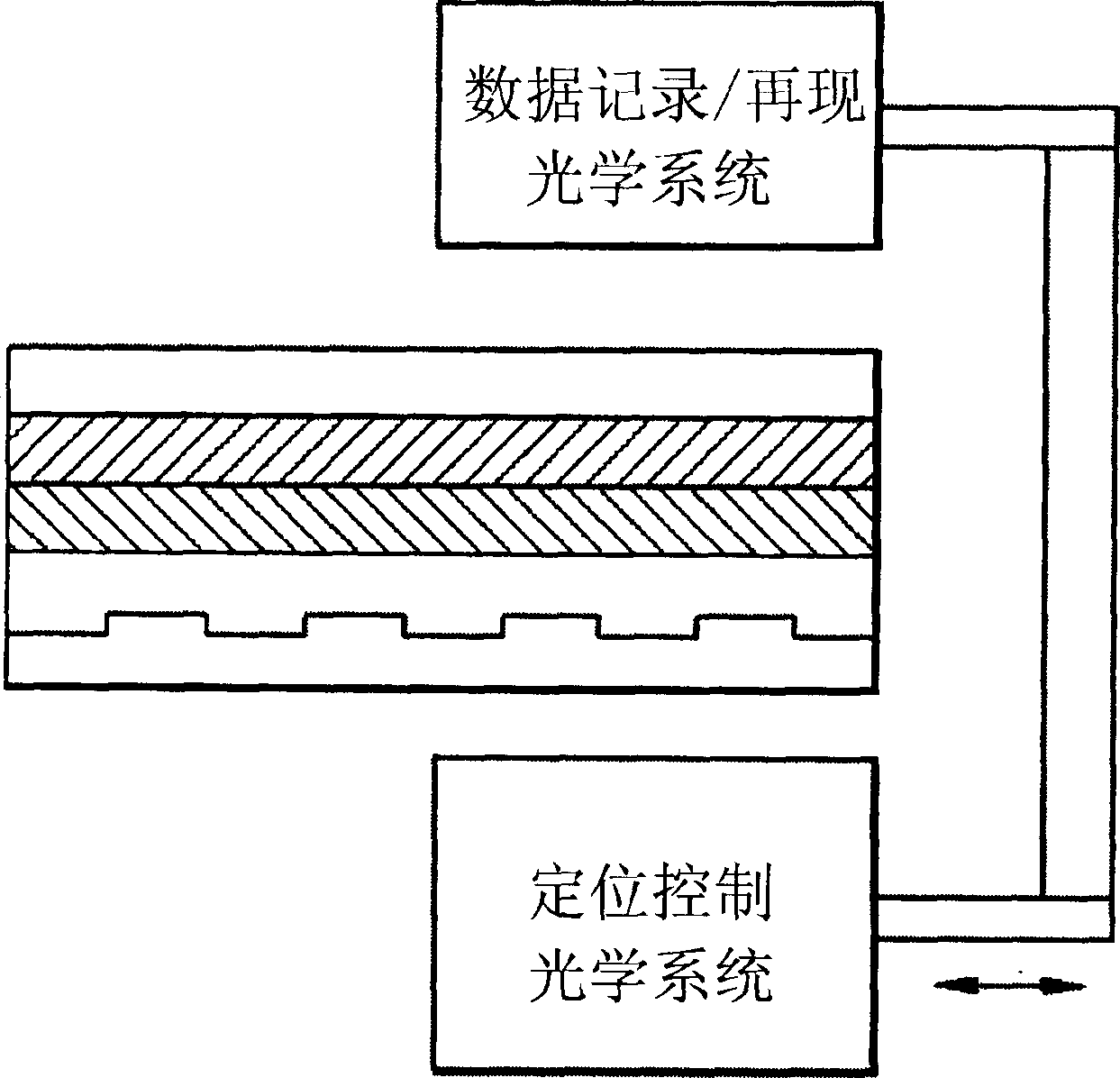

Hologram recording medium

InactiveCN1771544ARealize positioning controlRecord information storageRecording/reproducing/erasing using optical interference patternsMultiplexingLight beam

PROBLEM TO BE SOLVED: To provide a hologram memory medium in which positioning of a beam spot for recording information is accurately controlled with respect to a recording medium by simple configuration and in which shift multiplexing recording is performed while performing two-dimensional positioning control in tangential and radial directions of the recording medium. SOLUTION: The hologram memory medium in which positioning of a beam spot for recording information is accurately controlled with respect to a recording medium and in which shift multiplexing recording is performed while performing two-dimensional positioning control in tangential and radial directions of the recording medium is provided by forming a recording layer and a reflective layer between at least two substrates, continuously or intermittently arranging protrusions or recesses for optical positioning control on the substrate adjacent to the reflective layer, and making the reflective layer side shape of the substrate nearly flat.

Owner:SAMSUNG ELECTRONICS CO LTD

Prefabricated column and cast-in-place concrete structure sleeve inverted insertion type one-time grouting construction method

PendingCN113187100AEffective spacing controlRealize positioning controlBuilding reinforcementsBuilding material handlingFloor slabGrout

The invention provides a prefabricated column and cast-in-place concrete structure sleeve inverted insertion type one-time grouting construction method. The method comprises the steps that 1, a cast-in-place concrete structure is constructed, the cast-in-place concrete structure is provided with cast-in-place piles and a cast-in-place floor, sleeves are arranged at the upper ends of cast-in-place pile column ribs, cup openings of the sleeves are flush with the top end of the cast-in-place floor, the sleeves are provided with upper-end slurry openings and lower-end slurry openings, the cast-in-place piles are sequentially constructed, the sleeves are mounted, positioning plates at the upper ends of the sleeves are mounted and the cast-in-place floor is constructed; 2, the positioning plates are dismounted; 3, the limiting plates are constructed; 4, a prefabricated column is hoisted, a joint grout outlet pipe is arranged in the prefabricated column, connecting ribs are arranged at the lower ends of prefabricated column ribs and are inserted into the sleeves one by one; 5, the prefabricated column is supported; 6, grouting construction is conducted in the sleeves one by one, so that grouting materials overflow from a grout outlet pipe, and grouting is conducted on the last sleeve till the grouting materials are discharged from the joint grout outlet pipe; and 7, construction is completed. According to the construction method, air in the sleeves and a joint in assembly type construction can be discharged easily, grouting fullness is guaranteed, and the method has the advantages of being high in construction quality, good in effect and easy to operate.

Owner:GUANGDONG IND EQUIP INSTALLATION

Rotary automatic medicine delivery machine

The invention relates to a rotary automatic medicine delivery machine which comprises a slewing device and a pushing device. The slewing device comprises a lower slewing support connecting plate, a slewing support and an upper slewing support connecting plate, wherein, the slewing support is arranged on the lower slewing support connecting plate and is circumferentially equipped with teeth; the upper slewing support connecting plate is arranged on the slewing support; a speed reducer is fixed on the bottom surface of the lower slewing support connecting plate; and the output shaft of the speed reducer passes through the lower slewing support connecting plate and is equipped with a small gear, and the small gear is meshed with the teeth of the slewing support. The pushing device comprises a lower backing plate, an upper backing plate and an actuator, wherein, the lower backing plate is fixed on the upper slewing support connecting plate of the slewing device; the upper backing plate isarranged on the lower backing plate; the actuator is arranged on the upper backing plate; a connecting plate is fixed on the actuator; a push rod is arranged on the connecting plate; and the actuatoris connected with a synchronous motor in a transmission manner through a coupling. By utilizing the medicine delivery machine, a certain quantity of medicine boxes can be conveyed.

Owner:SUZHOU IRON TECH

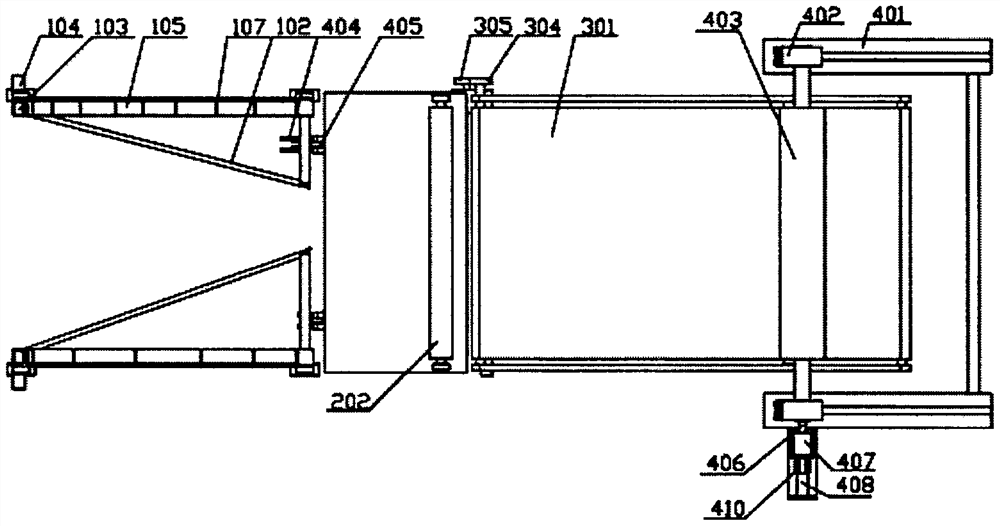

Precise positioning of high-speed robotic arm

A high-speed mechanical arm with a precise positioning function comprises a motor, a driving part, a rack and a sliding block, wherein a sliding slot is arranged on the rack, the sliding block is arranged in the sliding slot and is driven by the driving part to move along the sliding slot. The mechanical arm is characterized in that the driving part comprises a winding drum and a steel wire rope wound on the winding drum, a threaded groove is arranged on the winding drum, the steel wire rope is coiled in the threaded groove and is arranged between the winding drum and the sliding slot to form a revolving loop, and a section, which is arranged in the sliding slot, of the steel wire rope is fastened with the bottom of the sliding block. The winding drum with the threaded slot is driven by utilizing a servo motor, the steel wire rope is precisely wound and unwound from the winding drum, namely, when the winding drum rotates for a turn, the linear distance that the steel wire rope moves is converted from the perimeter of the winding drum, under the same rotating speed, the speed of the steel wire rope is much higher than the speed of a screw nut pair, which is characterized in that the linear distance converted from the screw pitch, and the positioning and control on the sliding block are realized through controlling the rotating speed and the start and stop of the rotation precisely by the servo motor.

Owner:FUJISAN IND TECH CO LTD OF SHENZHEN CITY

A mobile laying wall grouting positioning method

ActiveCN110878639BEasy to control pouring thicknessImprove construction efficiencyBuilding material handlingChain linkPiston rod

The invention provides a mobile grouting and positioning method for laying walls, including lifting adjustment: the lifting frame is driven up and down through the expansion and contraction of the piston rod of the lifting cylinder, and the lifting frame is driven by the chain, the connecting base plate, the rotating mechanism and the main and auxiliary vertical plates, and the first pressing plate And the horizontal pressing plate in the second pressing plate is adjusted to the height position of the wall to be built; rotation adjustment: the rotation of the servo motor drives the rotating column to rotate, and the rotating column drives the first pressing plate and the second pressing plate to rotate through the lower base plate and the main and auxiliary vertical plates. Rotate the horizontal pressing plate between the first pressing plate and the second pressing plate to be parallel to the length direction of the wall to be built; positioning width adjustment: adjust the positioning width between the first pressing plate and the second pressing plate by adjusting the expansion and contraction of the cylinder, so that the first pressing plate and the second pressing plate The inner side of the bottom surface of the horizontal pressing plate in the second pressing plate is pressed on the surface of the wall to be built, and the inner side of the positioning sticker is stuck on the two sides of the wall to be built. The method can position the thickness and width of the mortar pouring, control the pouring mortar, and ensure the quality of the masonry.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of movable wall laying mortar method

ActiveCN110836020BEasy to control pouring thicknessRealize positioning controlBuilding material handlingElectric machineArchitectural engineering

The invention provides a mobile brick-laying mortar method, including lifting adjustment: adjusting the horizontal pressing plate to the height position of the wall to be built by lifting and lowering the lifting cylinder, and rotating adjustment: rotating the horizontal pressing plate to the height position of the wall to be built by rotating the servo motor The length direction of the building wall is parallel, positioning adjustment: by adjusting the expansion and contraction of the cylinder, the inner side of the bottom surface of the horizontal pressing plate is pressed against the surface of the wall to be built, and the inner side of the positioning plate is stuck on the two sides of the wall to be built, and the mortar is laid: The mounting plate connected with the mixing drum is driven by the drive motor to slide on the first support shaft and the second support shaft together with the drive motor, and the mortar in the mixing drum is poured into the positioning mechanism through the discharge valve. Lay the surface of the wall and smooth the mortar: the telescopic cylinder drives the trowel board to move on the upper side of the mortar to smooth the pouring mortar. The application can position the width and thickness of the mortar paving, automatically pour and smooth the mortar, control the pouring mortar, and ensure the quality of the masonry.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

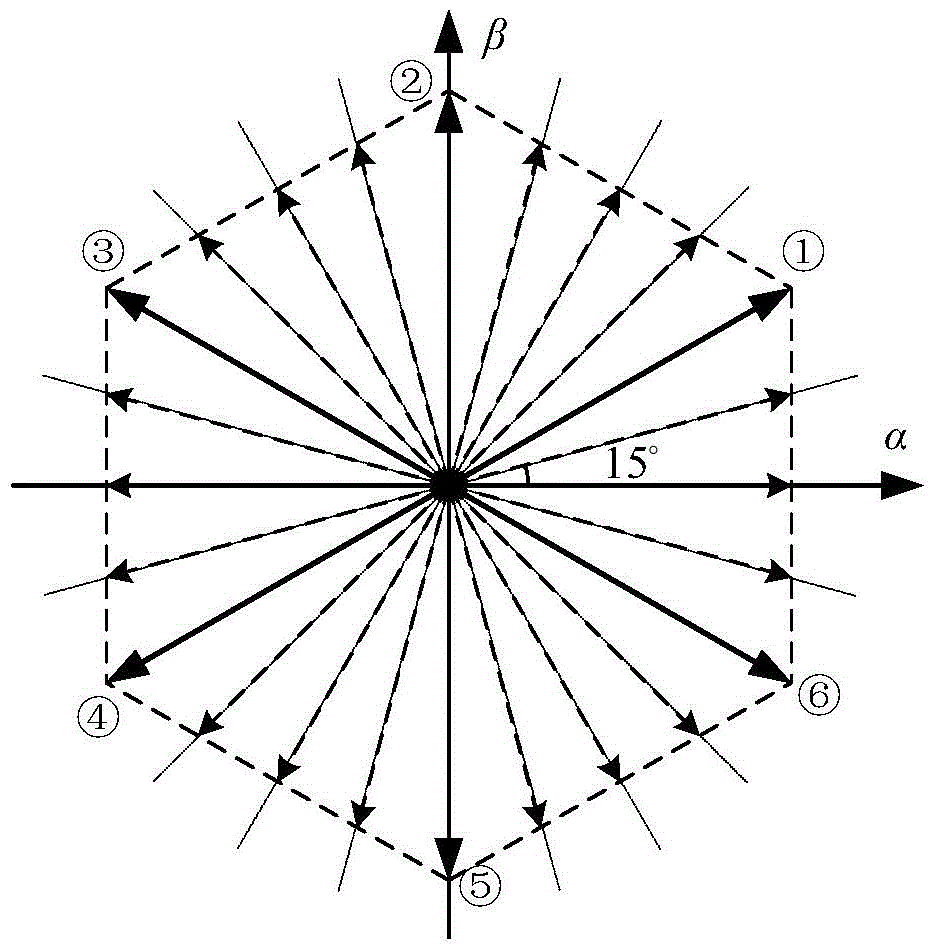

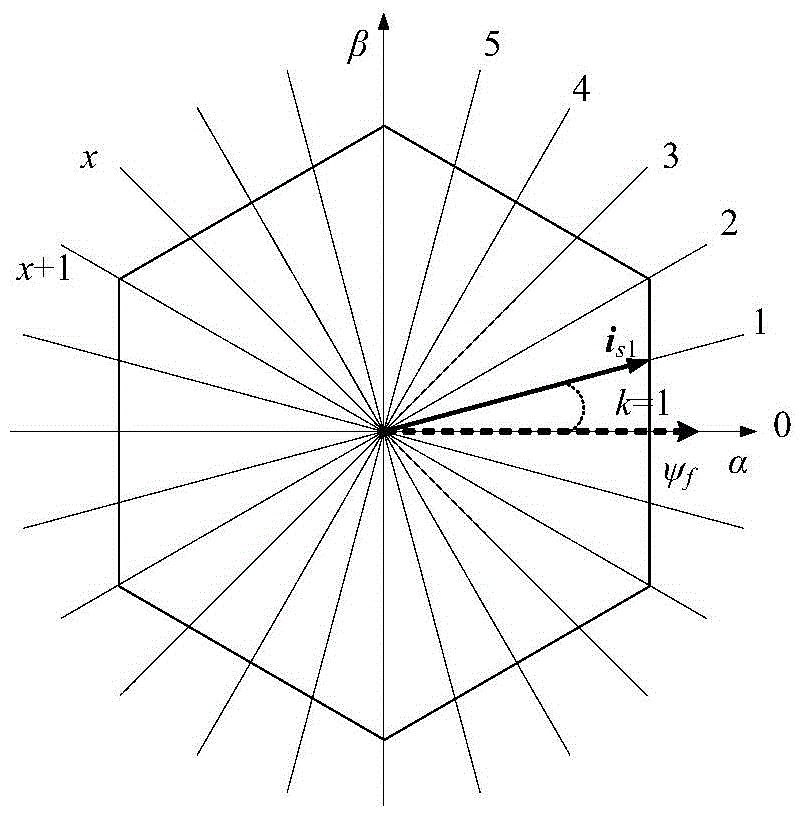

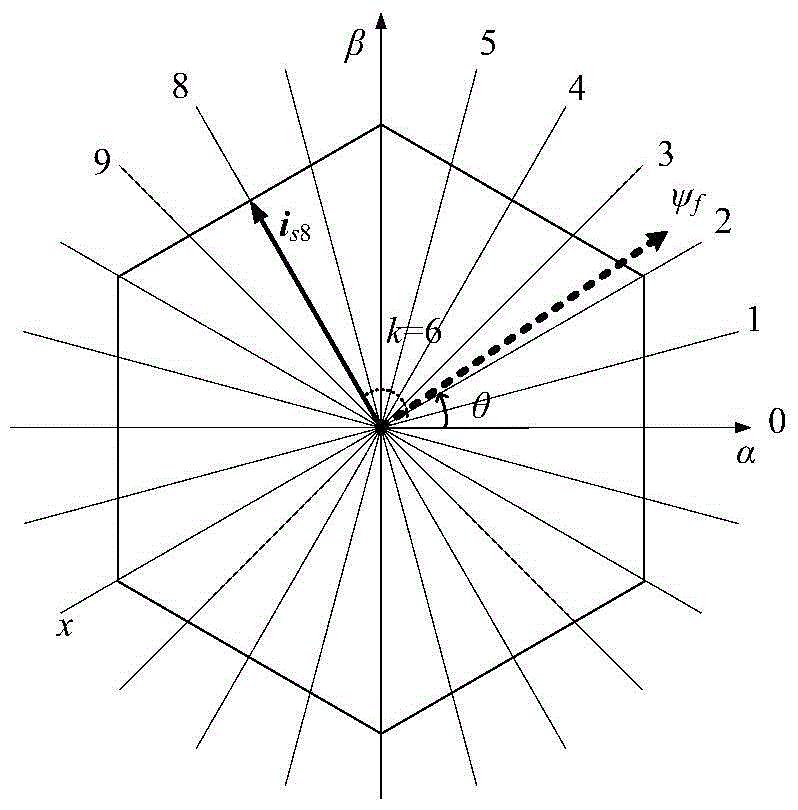

Operation Method of Discrete Stepping Control for Permanent Magnet Brushless DC Motor

ActiveCN104506107BHighlight substantive featuresMany positioning pointsElectronic commutation motor controlVector control systemsDigital signal processingEngineering

The invention discloses an operation method for stepping dispersion control on a permanent magnet brushless direct current motor, and relates to a motor control technology. A device used in the method comprises a DSP (digital signal processing) control module, a power circuit, the permanent magnet brushless direct current motor, an encoder position detection module and an input power module. For the common three-phase permanent magnet brushless direct current motor, a stator current vector synthesized by three-phase current is dispersed and subdivided, and a dispersion positioning position in a space is obtained according to a certain cyclic number of beats, so that positioning control on the motor can be realized by controlling the space position of a stator magnetic field, and the positioning precision of the motor is improved; furthermore, the stator current vector synthesized by the three-phase current is dispersed at an electric angle space position according to a certain cyclic number of beats so as to obtain a dispersed current vector for controlling operation of the motor; by increase of the cyclic number of beats, a smaller stepping angle can be obtained, and the position resolution is improved; therefore, the positioning precision of the permanent magnet brushless direct current motor can be improved under the condition of guaranteeing the loading capacity.

Owner:HEBEI UNIV OF TECH

Dual resonance frequency driving method of magnetic mini travel robot

InactiveCN100444510CRealize two-way swimming controlImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesSurgeryResonanceMicro robotics

This invention belongs to automatic engineering technique field and relates to a basic method to realize the double-direction swim of micro robot in sealed tube through magnetic field driving. It provides a double-direction driving model with robot head and tail which have two resonance frequency driver thin films according to push characteristics of vibration thin film and liquid couple and thin film each phase of resonance frequency relation characteristics. It generates drive magnetic field through Helmholtz double coil driving between two resonance frequency of the front and back thin film driver to realize the continuous adjusting and position control of the robot swimming speed. íí

Owner:DALIAN UNIV OF TECH

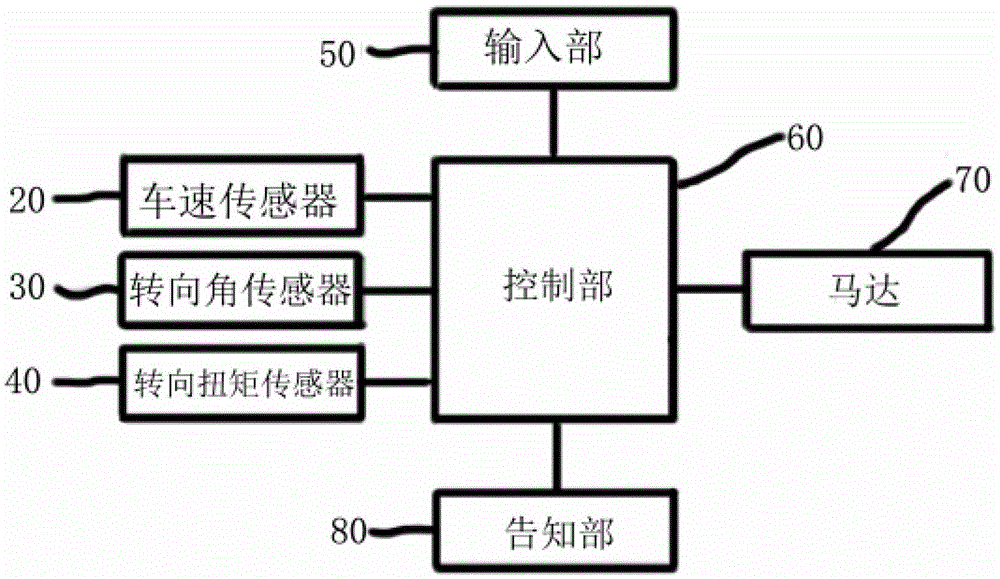

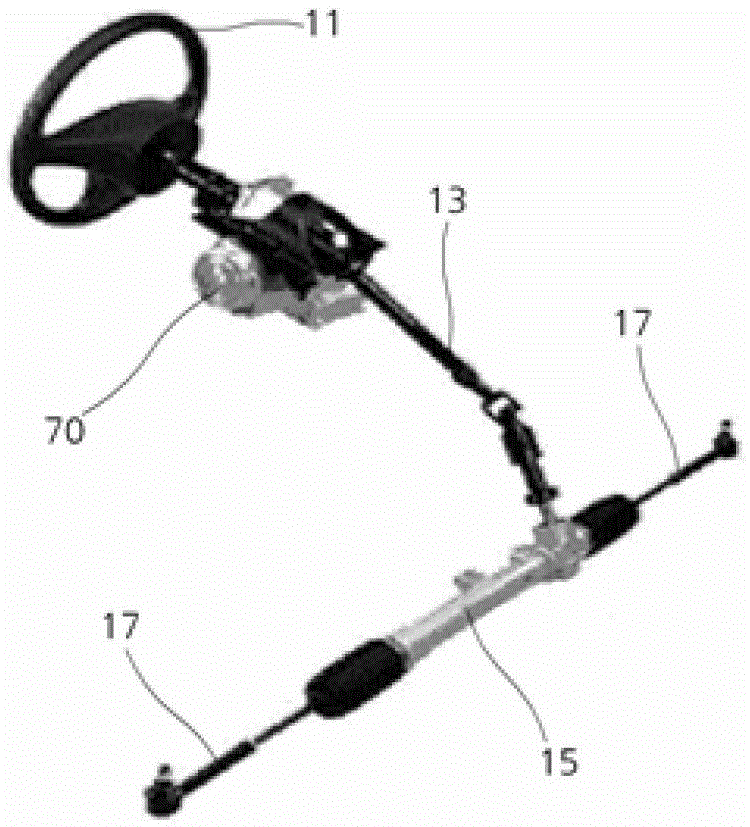

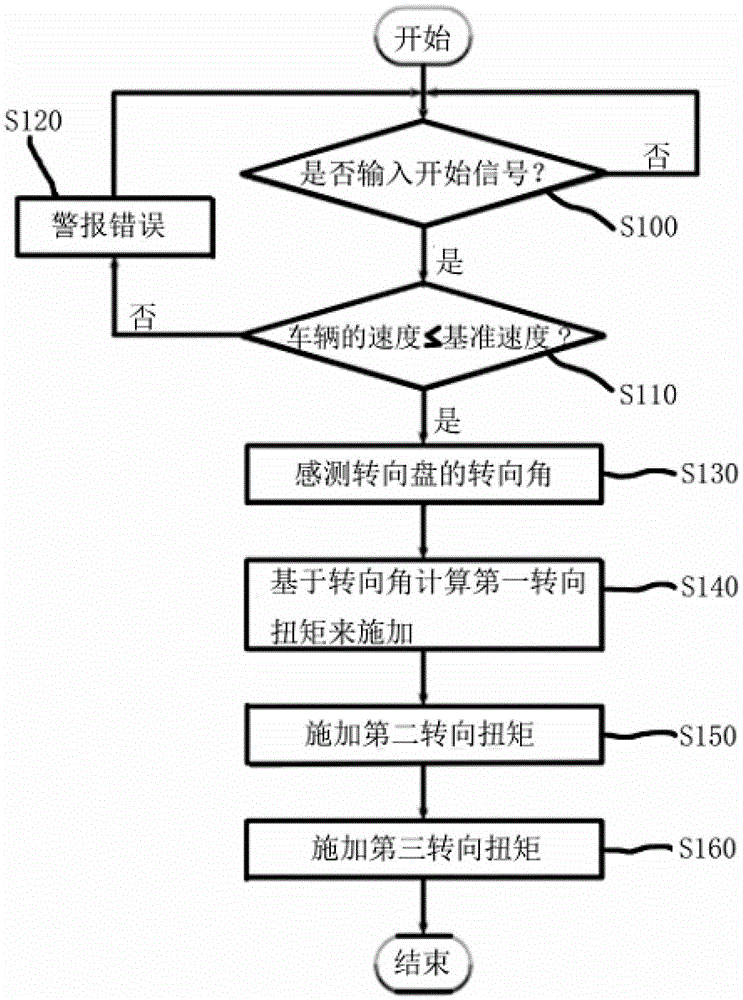

Vehicle wheel alignment control method

ActiveCN102897210BRemove detent torquePrecise positioningSteering linkagesAutomatic steering controlSteering wheelControl theory

The invention relates to a control method for wheel alignment of a vehicle. The control method comprises the following steps: if inputting a start signal and a steering wheel is recovered to be in themiddle, a control portion adding steering to the steering wheel toward a recovering direction; and after the steering wheel is added steering, the control portion steering the steering wheeltoward adirectionwhich is inverse to the recovering direction so as to recover the steering wheel to be in the middle. The control method is advantaged in that through removing locating torsion of a tyre, wheel alignment performance can be improved, without adding other devices, and the wheel alignment control can be realized just by logic alternation.

Owner:HYUNDAI MOBIS CO LTD

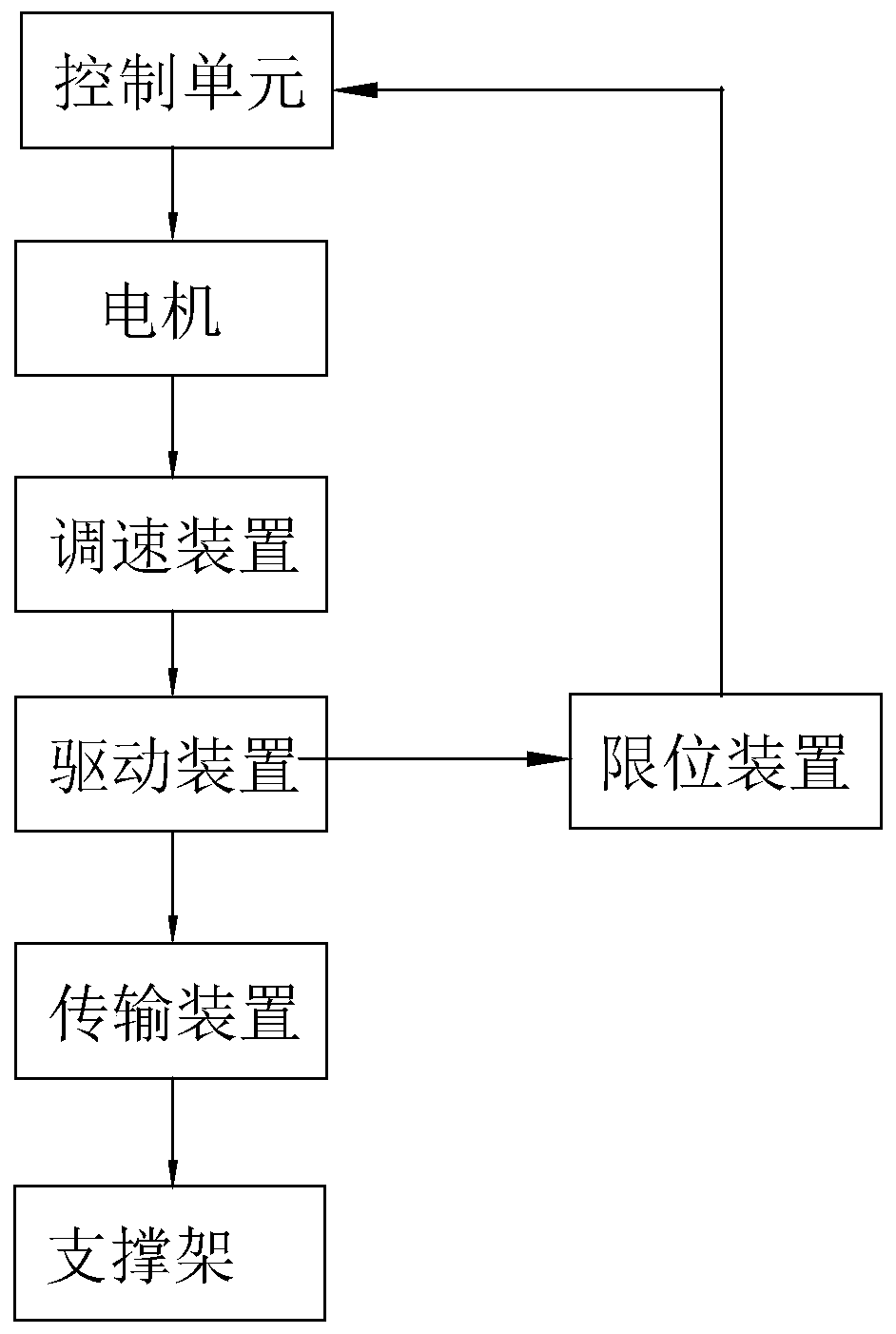

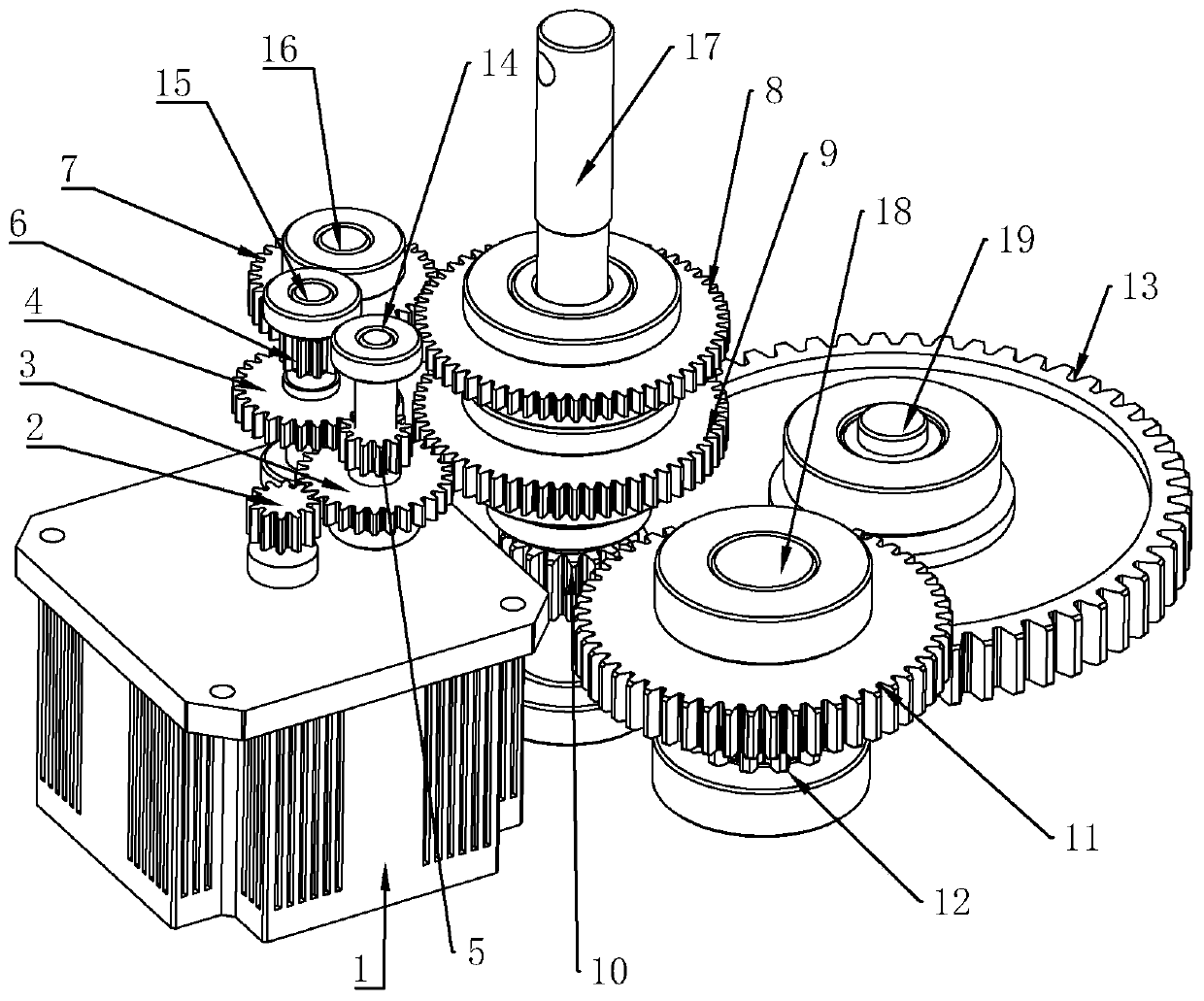

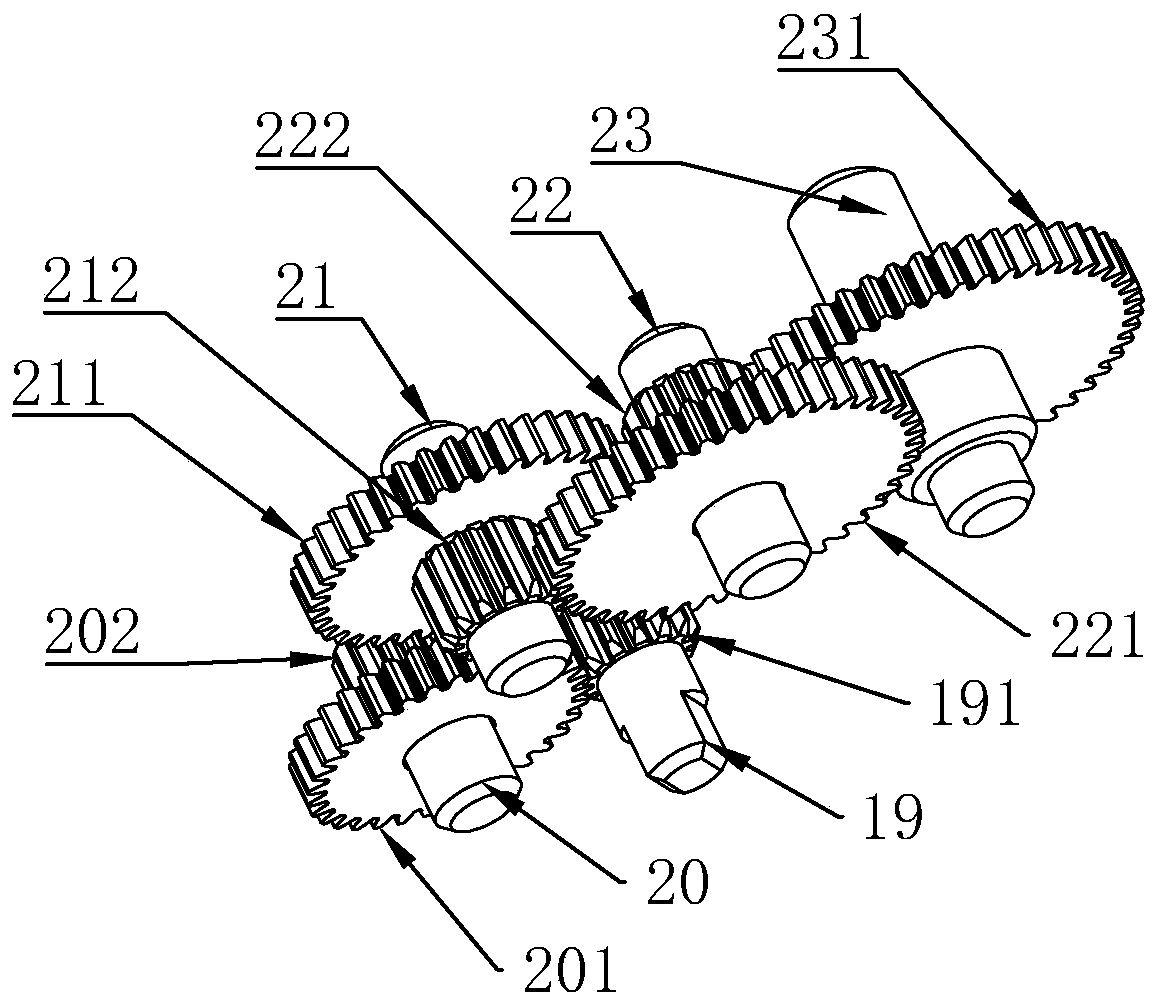

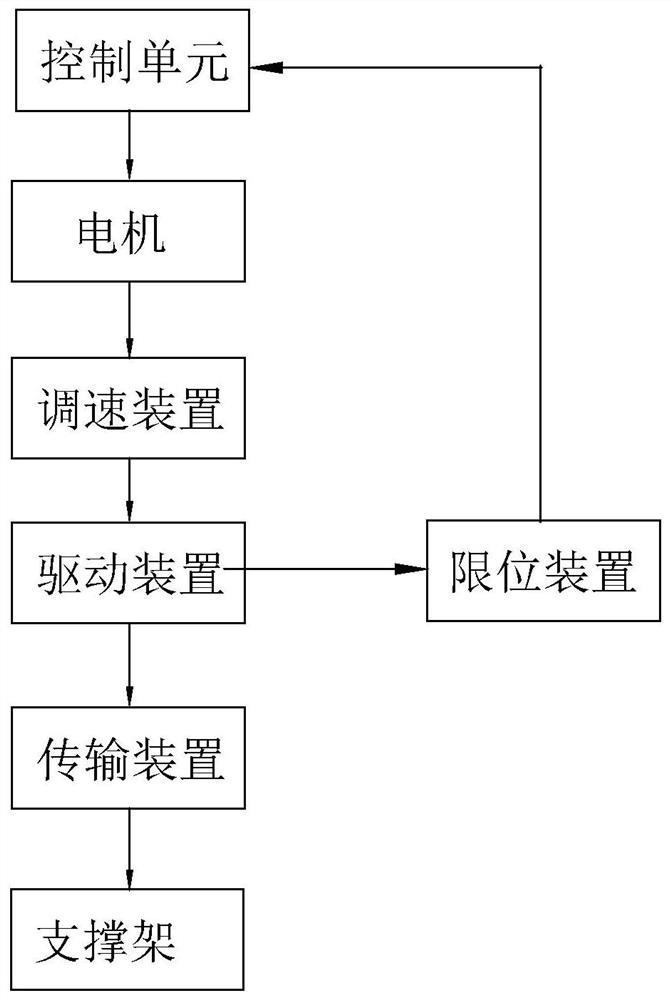

Method and device for controlling electric supporting frame for trailer

ActiveCN110745113AImprove reliabilityImprove securityVehicle fittings for liftingStart signalEngineering

The invention discloses a method and device for controlling an electric supporting frame for a trailer. The electric supporting frame comprises a motor, a speed adjusting device, a control unit, a limiting device, a driving device, a conveying device and a supporting frame body. The control unit receives an electric supporting frame ascending or descending starting signal, the motor is controlledto rotate forwards or backwards, and the limiting device gives an initial position signal and starts initial position recording. After the motor rotates and the speed is regulated through the speed regulating device, the driving device is driven to move, then the motion of the driving device drives the conveying device to move, and therefore the electric supporting frame is controlled to ascend ordescend. When the position record in the limiting device reaches the end point, a signal indicating reaching of the highest position or lowest position is sent, and after the control unit receives the position signal, the motor is controlled to be shut down. The speed regulating device, the driving device and the transmitting device operate in a gear engagement manner. The motor drives the supporting frame body to ascend or descend, all-day work of the supporting frame body is achieved, and the safety of supporting frame operation is guaranteed.

Owner:WENLING DONGLING MOTOR

A ton bag automatic rolling machine

ActiveCN112141464BEasy to installQuick loading and unloadingBundling machine detailsGear wheelElectric machinery

The invention relates to an automatic rolling machine for big bags, which is characterized in that it comprises a folding mechanism, a flattening mechanism, a conveying mechanism for big bags and a rolling mechanism, which are arranged in sequence from left to right. The folding mechanism includes a transmission mechanism, a bag-receiving mechanism, and a guiding and limiting mechanism, which folds the ton bag into a regular rectangle; Evacuate, flatten and compress; the big bag conveying mechanism includes a conveying belt, a support frame, a conveying gear, a conveying chain, a conveying motor, and a cylinder, and mainly conveys the big bag from the flattening mechanism to the rolling mechanism; the The reeling mechanism includes a strapping mechanism, a reel, a positioning groove, a positioning jaw, and a reel driving device, which can realize the convenient disassembly and driving of the reel after rolling. The invention realizes the continuous rolling of the big bag, provides the precondition for the automatic packaging of the big bag, reduces the labor intensity and improves the production efficiency.

Owner:HEBEI UNIV OF TECH

Combination method of multi-coordinate machining center based on vision and moving manipulator

ActiveCN105058168BRealize online correctionRealize positioning controlMeasurement/indication equipmentsLaser rangingEngineering

Owner:XIAN FEISIDA AUTOMATION ENG

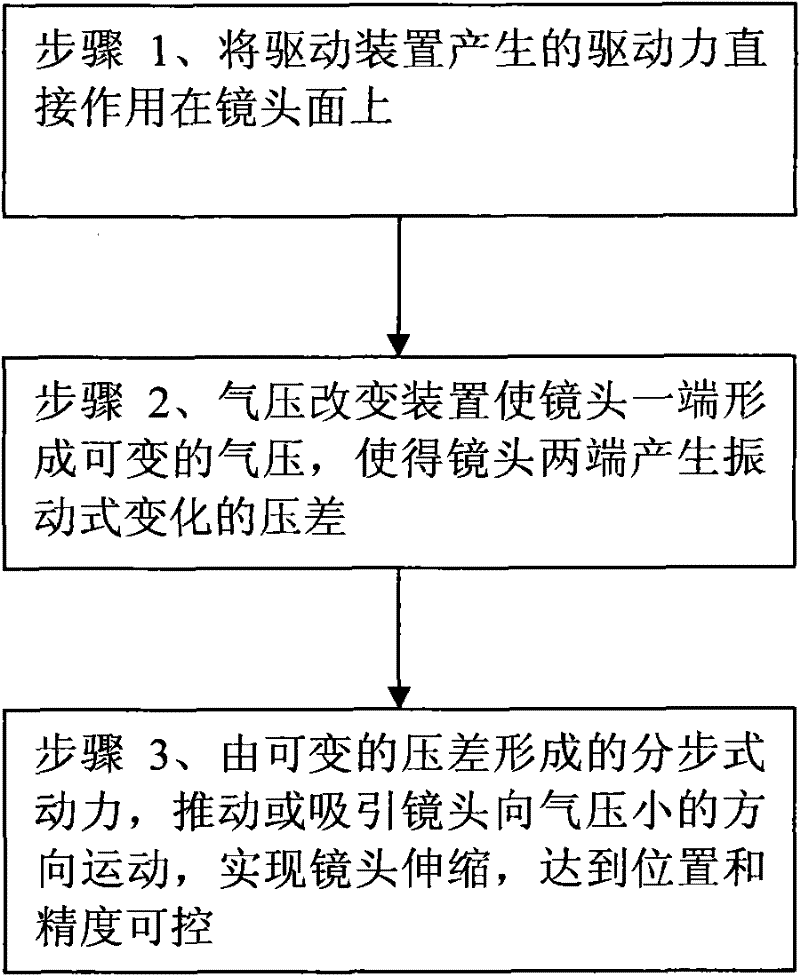

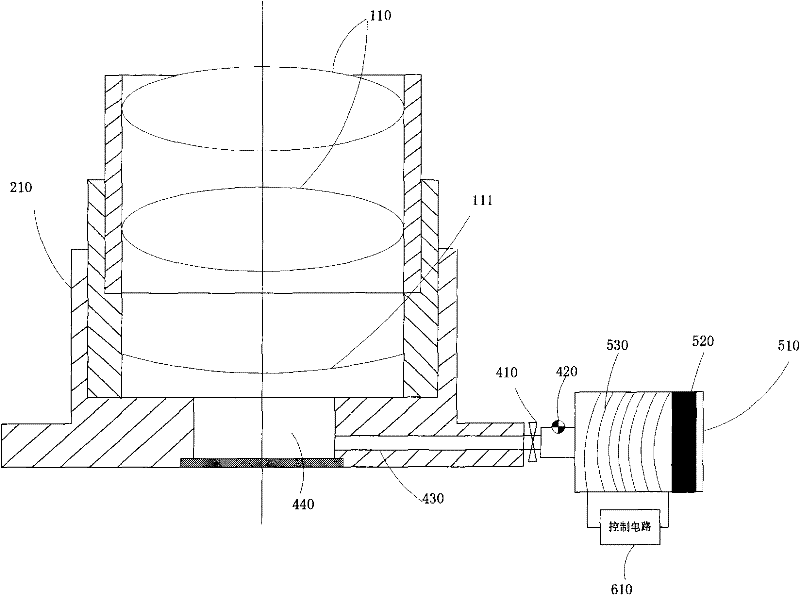

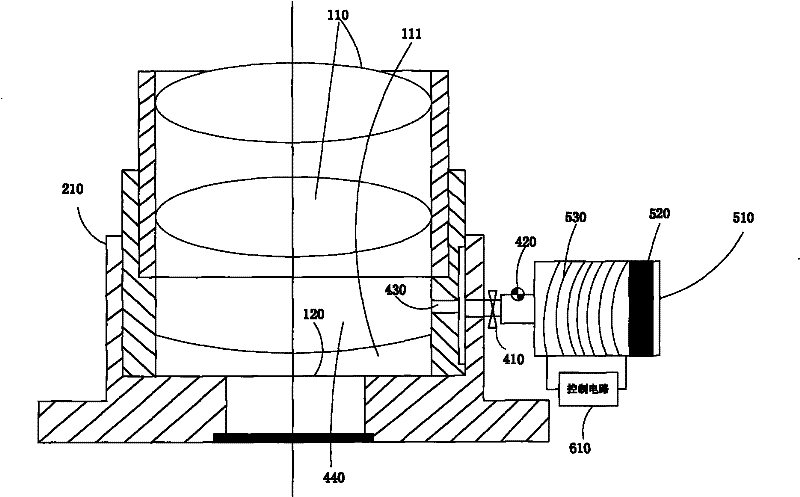

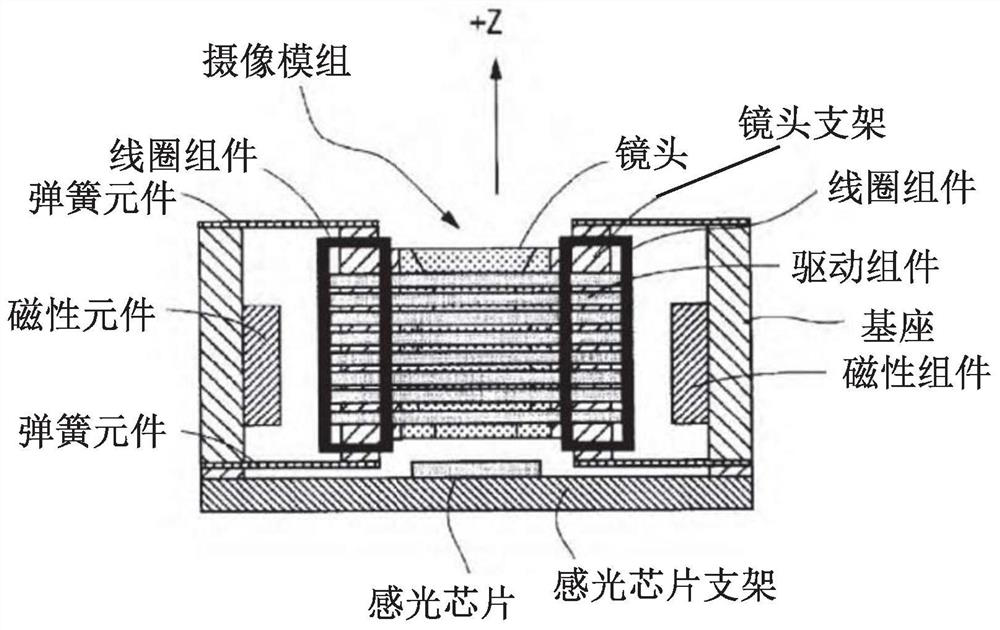

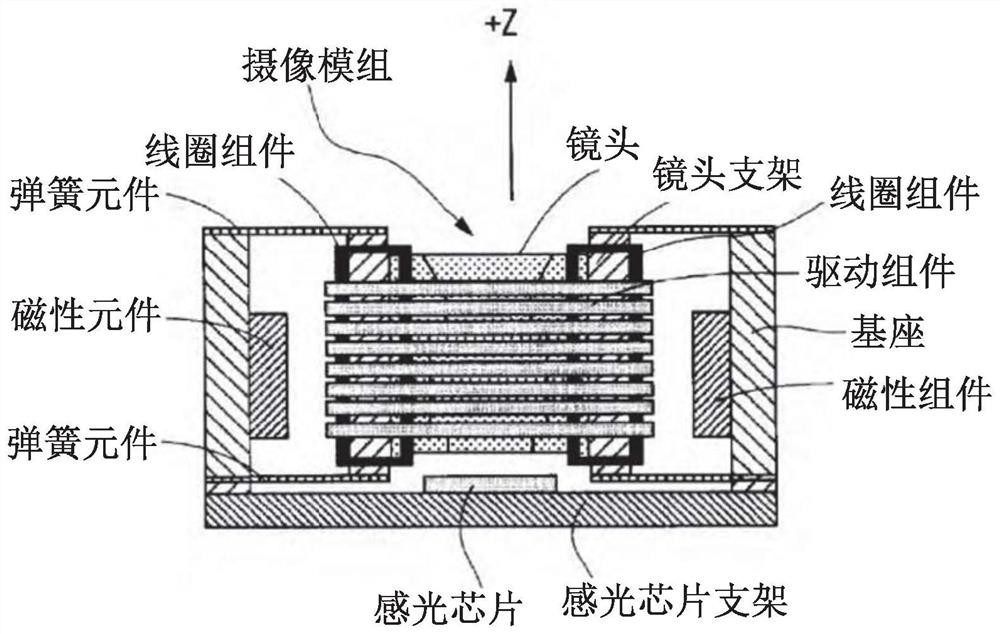

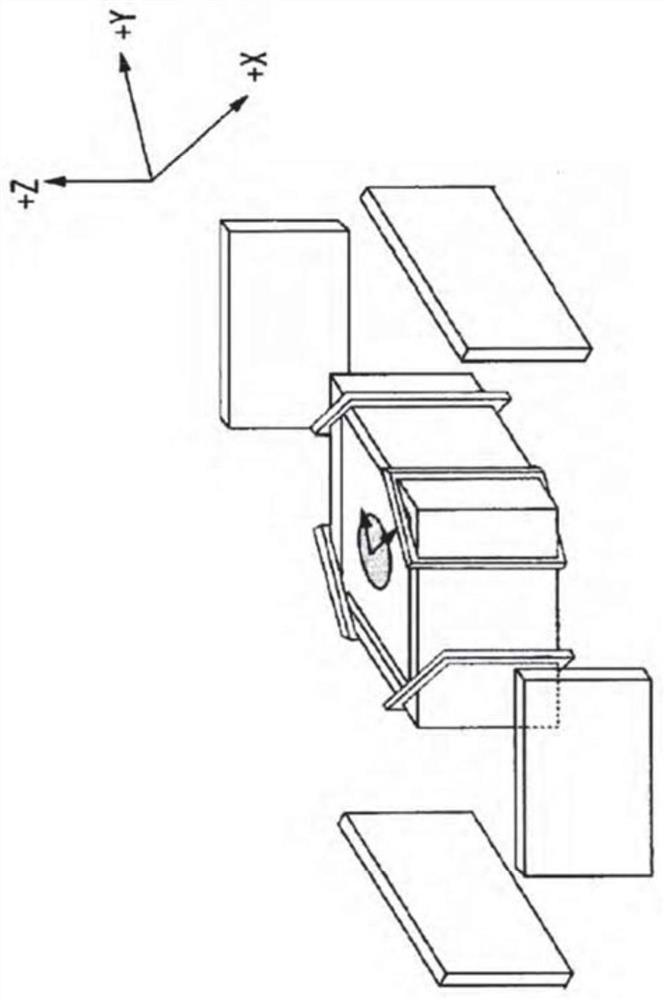

Driving method of zoomer lens device

The invention relates to a driving method of a zoomer lens. Variable acting force is directly applied to a lens surface, by changing the air pressure at one end of at least one lens group, the air pressure applied to two ends of the lens group produces variable pressure difference to form variable driving force, therefore, the lens group is driven to move towards lower air pressure, to realize the function that the lens can be telescopic within a large travel range, simultaneously high accuracy positioning during the telescoping process is realized, and the optical zoom and the automatic focusing of the lens are realized.

Owner:GALAXYCORE SHANGHAI

MEMS device for lens barrel positioning

ActiveCN108780206BQuality improvementAchieving autofocusProjector focusing arrangementCamera focusing arrangementMicroelectromechanical systemsCamera module

A micro-electromechanical system (MEMS), which uses a thermal micro-actuator (31) to position a lens barrel (20) on a smart device, such as a camera module of a mobile phone. The micro-driver extends radially relative to a lens barrel, and each micro-driver can be bent by heat. The control unit (32) includes a heating circuit (321) operatively connected to the micro-drives to controllably apply thermal energy to each of the micro-drives, wherein each micro-drive is correspondingly bent to face a base (10) The lens barrel is moved, thereby controlling the three-axis positioning of the lens barrel. The operation of the microdrive is not affected by changes in ambient temperature.

Owner:NINGBO SUNNY OPOTECH CO LTD +1

A control method and device for an electric support frame for a trailer

ActiveCN110745113BRealize positioning controlImprove reliabilityVehicle fittings for liftingElectric machineGear wheel

The invention discloses a method and device for controlling an electric support frame for a trailer. The electric support frame includes a motor, a speed regulating device, a control unit, a limit device, a driving device, a transmission device, and a support frame. Or drop the start signal to control the forward or reverse rotation of the motor. The limit device gives the initial position signal and starts position recording. After the motor rotates through the speed regulating device, it drives the driving device to move, and the movement of the driving device drives the transmission device. movement, thereby controlling the rise or fall of the electric support frame; when the position record in the limit device reaches the end point, a signal of reaching the highest position or the lowest position is sent, and the control unit controls the motor to stop running after receiving the position signal; the speed regulating device, The driving device and the transmission device are operated by gear meshing. The motor is used to drive the rising or falling of the supporting frame, which realizes the all-weather work of the supporting frame and ensures the safe operation of the supporting frame.

Owner:WENLING DONGLING MOTOR

A steel bar thread rolling machine for building steel bar processing

ActiveCN112045122BMeet the needs of processing efficiencyQuick job locationScrew-threads articlesClassical mechanicsMachine

The present invention relates to the technical field of steel bar rolling machine, in particular to a steel bar thread rolling machine for building steel bar processing, comprising a box body 1, a base 2 and a steel bar 3, the upper end of the box body 1 is fixedly connected with a base 2, on the base 2 The steel bar 3 runs through, the base 2 is prism-shaped and a cylindrical hole is opened on the base 2, the steel bar 3 is arranged in the cylindrical hole of the base 2, and a number of uniformly distributed pusher plates 4 are arranged around the steel bar 3, and the pusher plate 4 One end is fixedly connected with a rubber block 5, and the rubber block 5 is in contact with the steel bar 3. The structural design of the present invention realizes the requirement for the base 2 to locate the steel bar 3 with different outer diameter sizes, and by controlling the handle one 21 and the handle two 22, quick positioning can be realized Work, to meet the high-efficiency processing requirements of the entire steel bar rolling machine, with stable and powerful functions.

Owner:广东新拓展建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com