Patents

Literature

38results about How to "Realize online correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

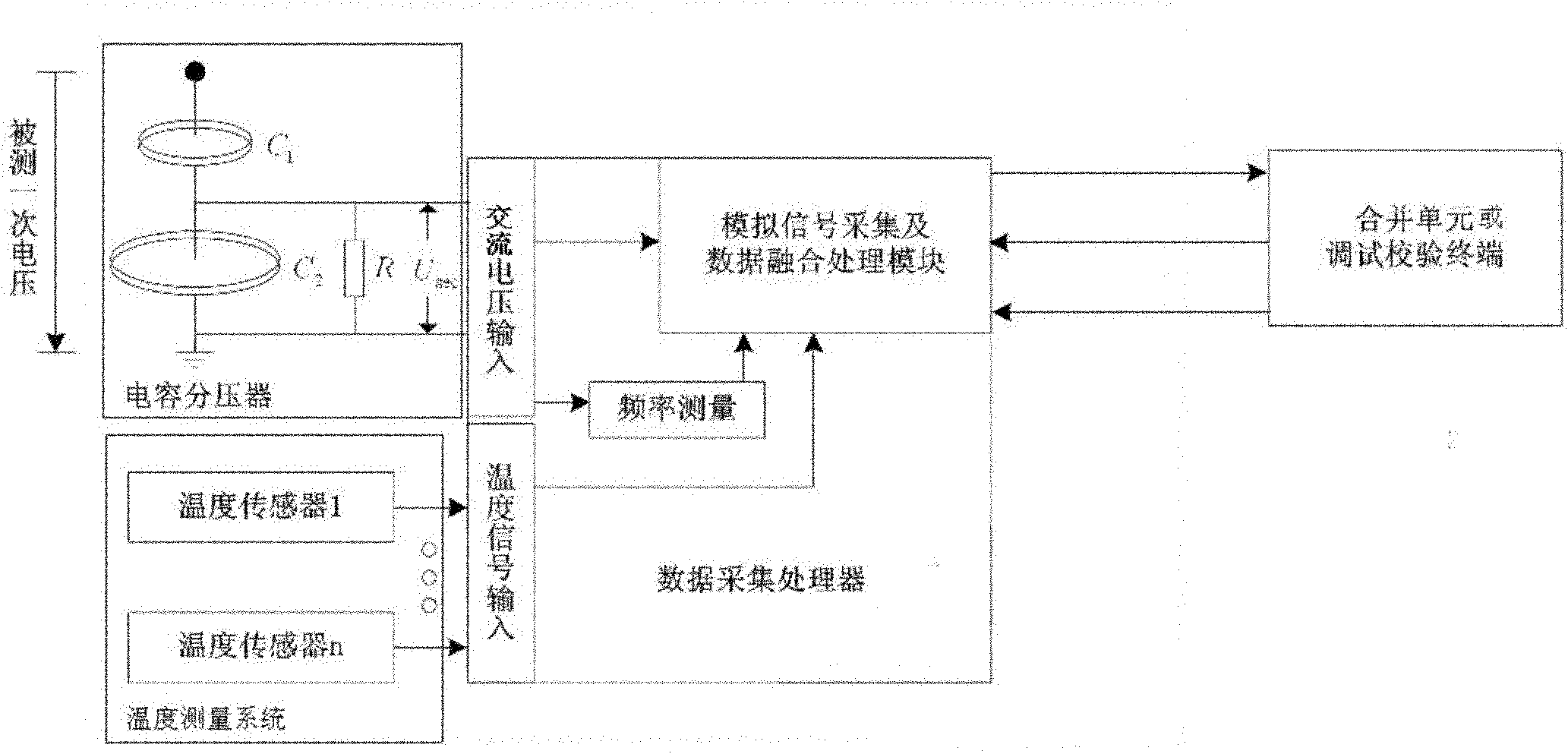

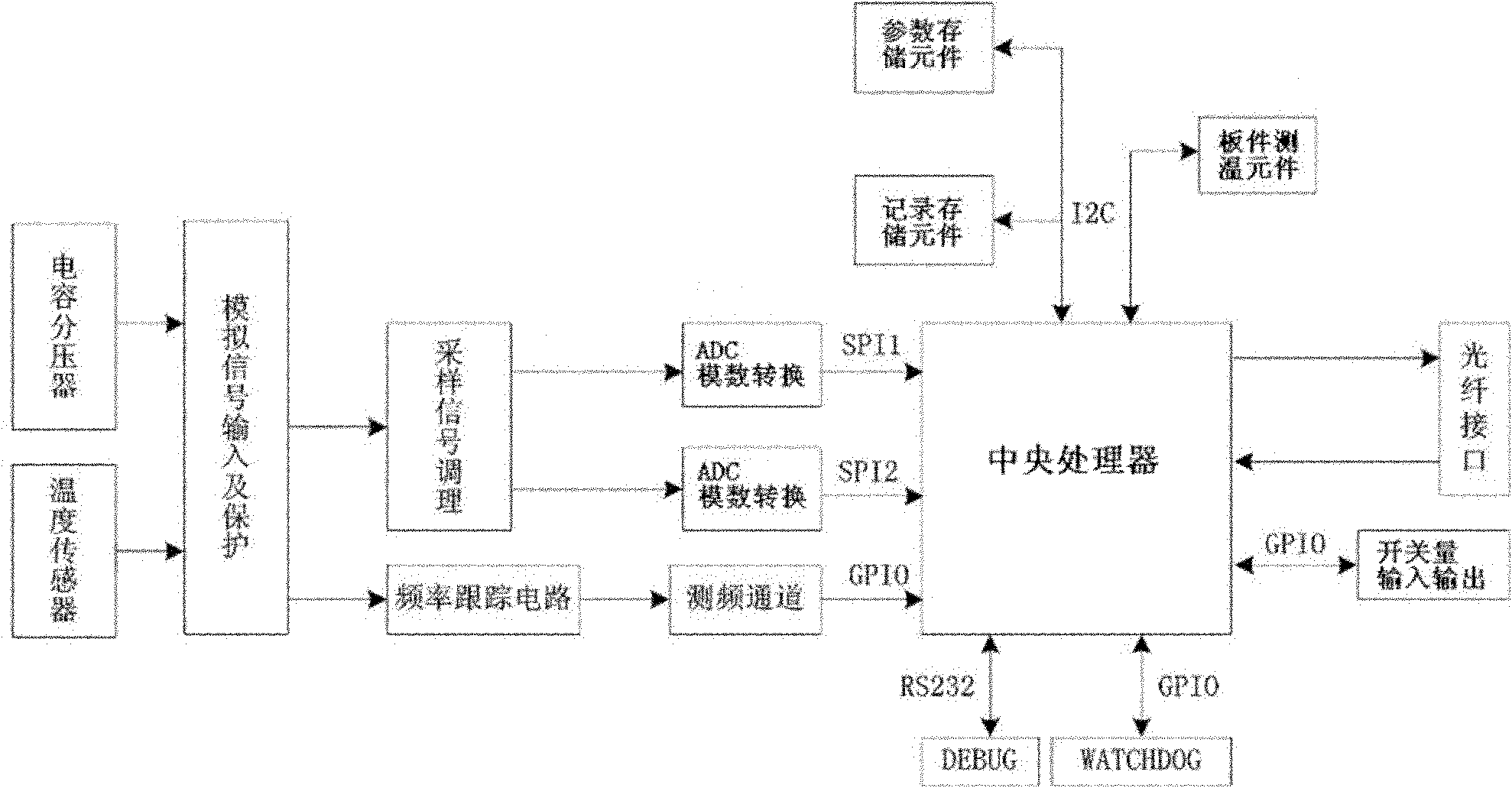

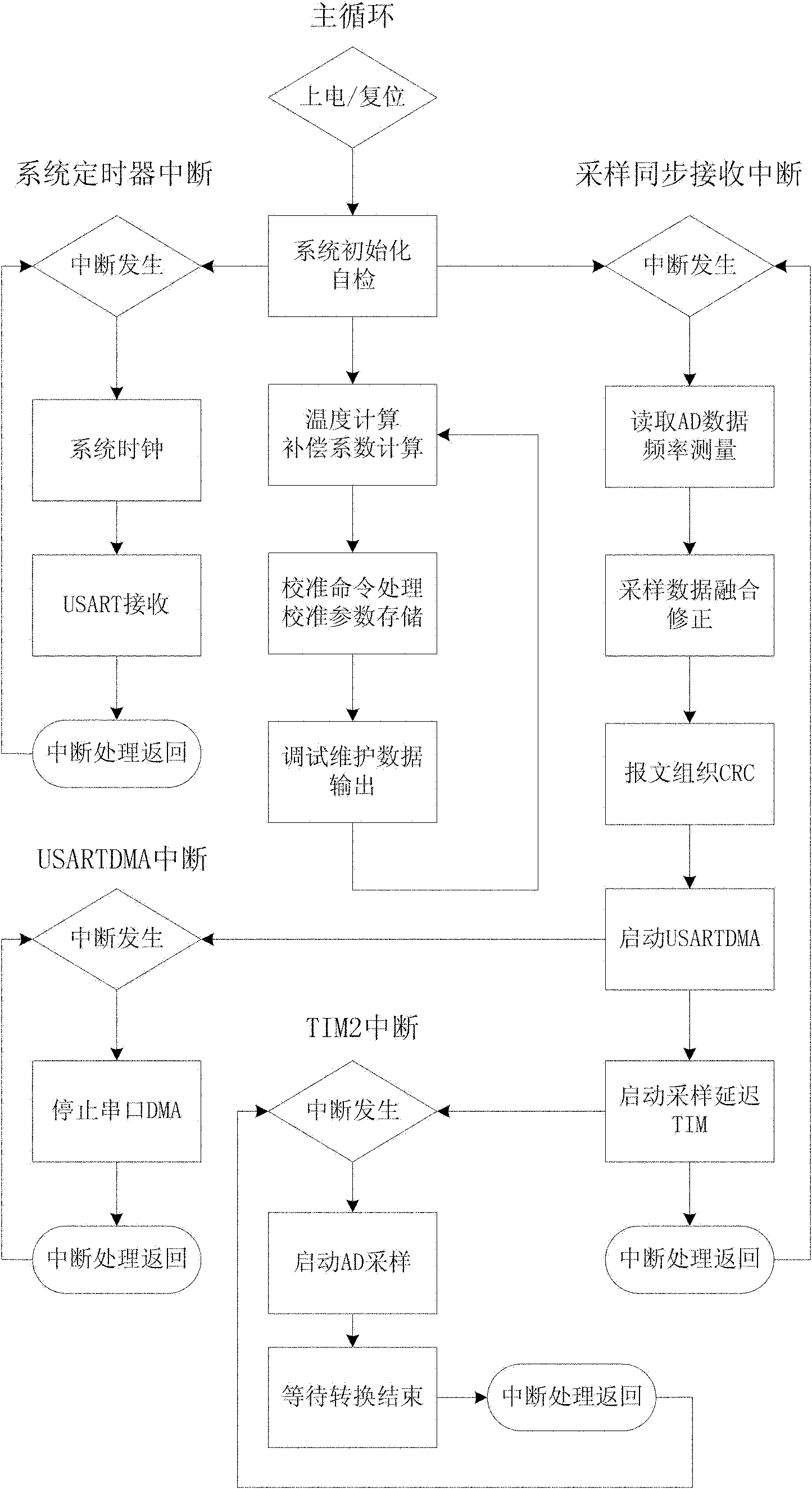

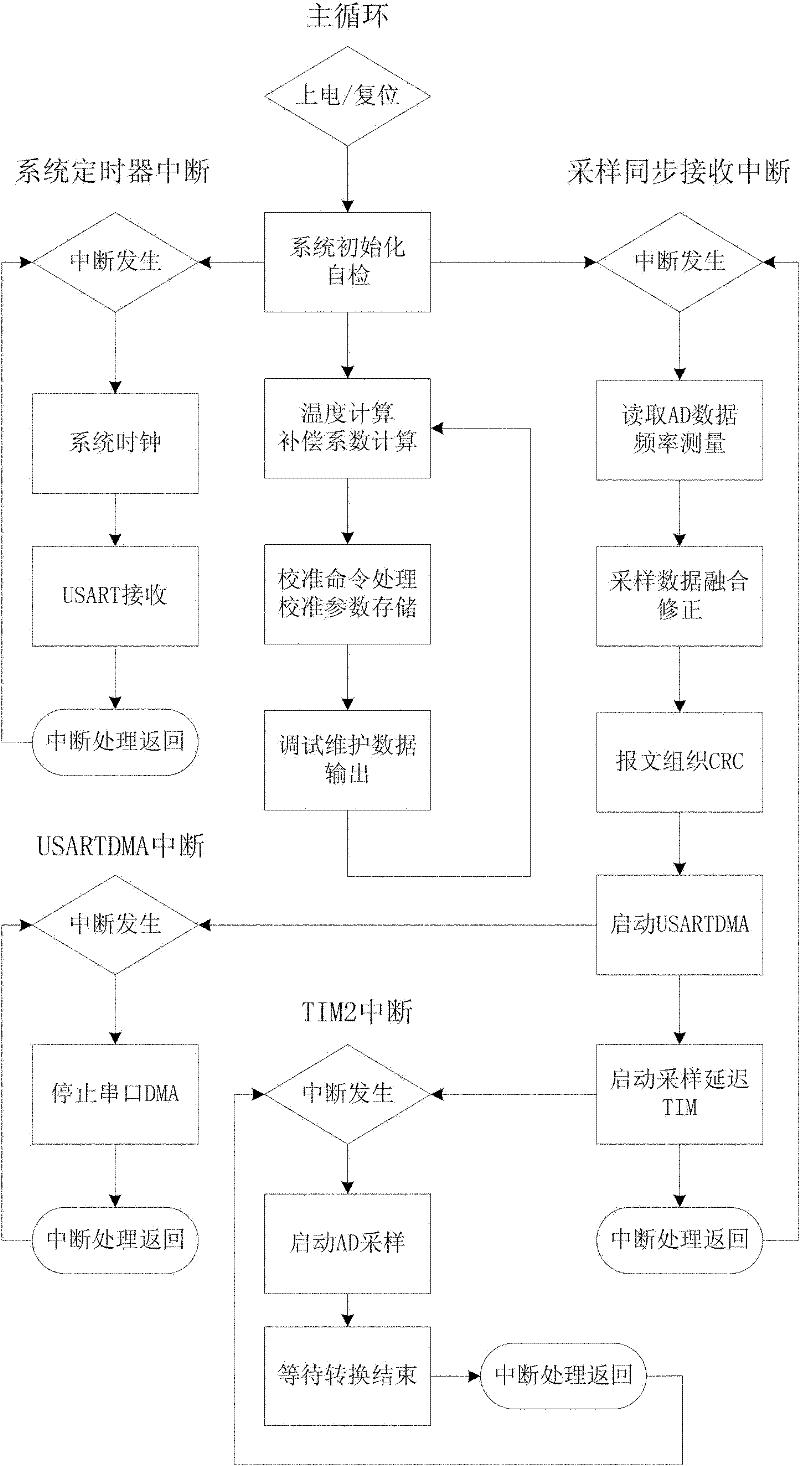

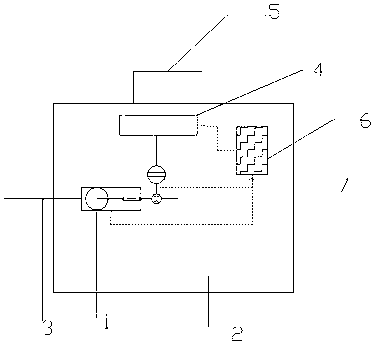

Electronic voltage transformer using data fusion technology and error calibration method thereof

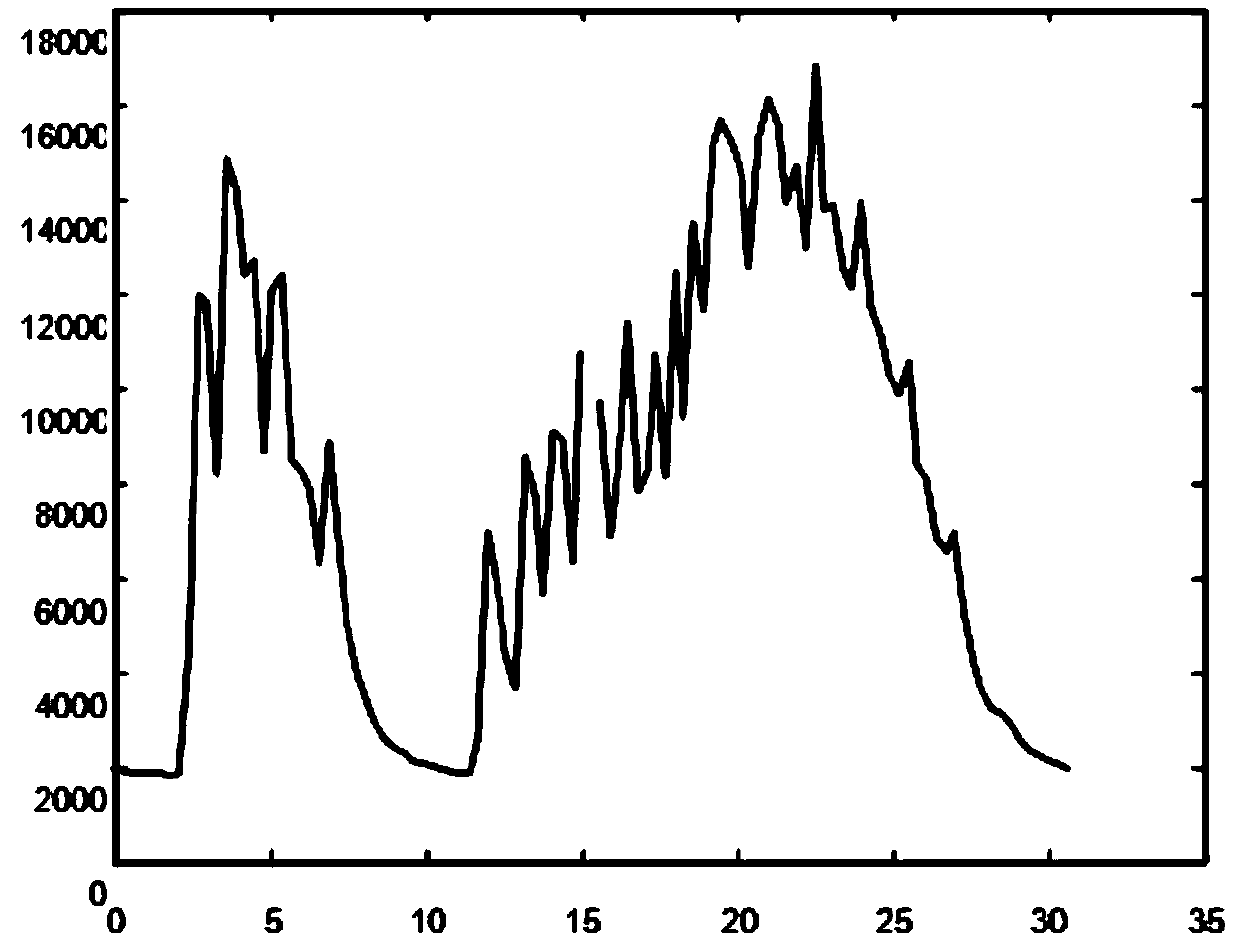

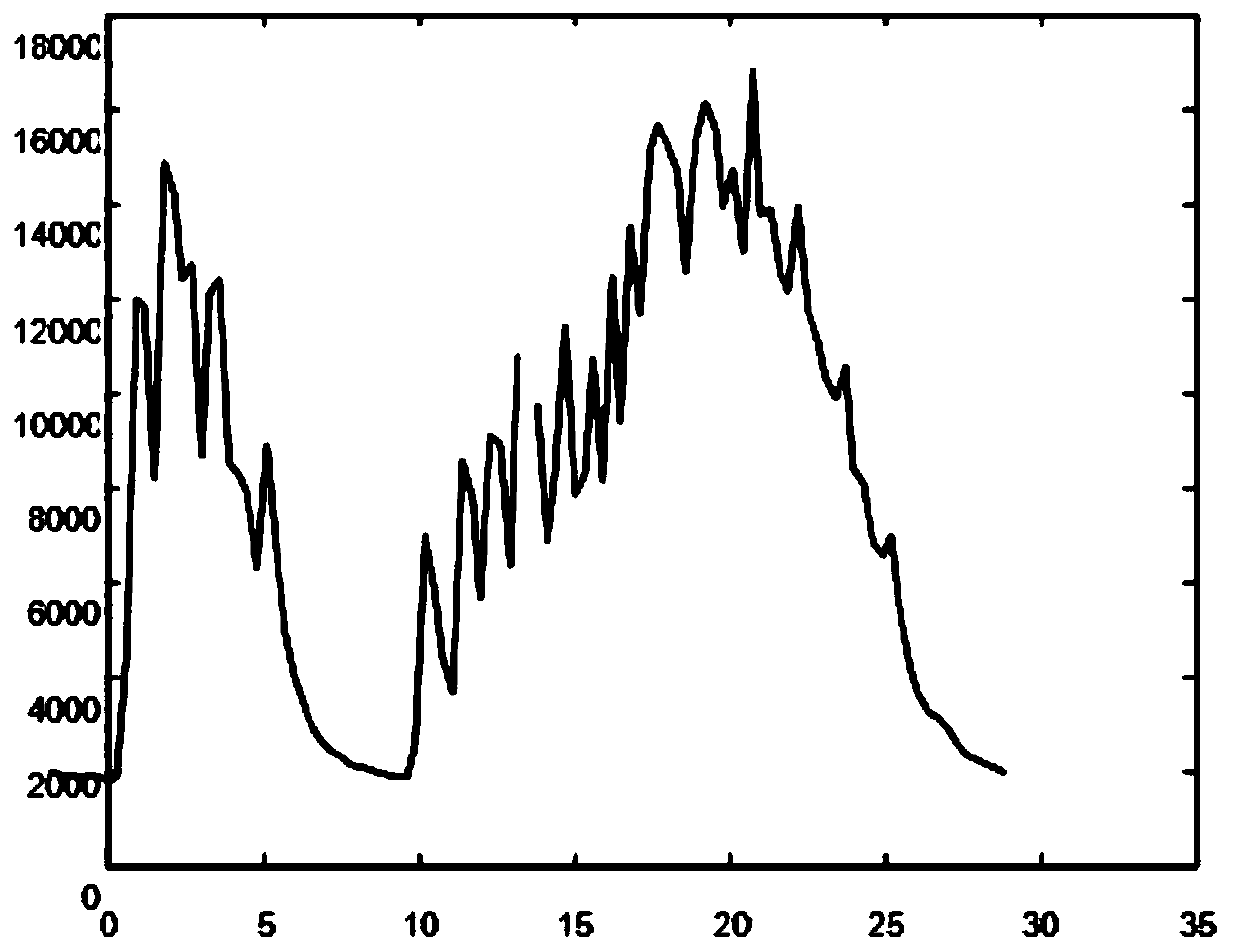

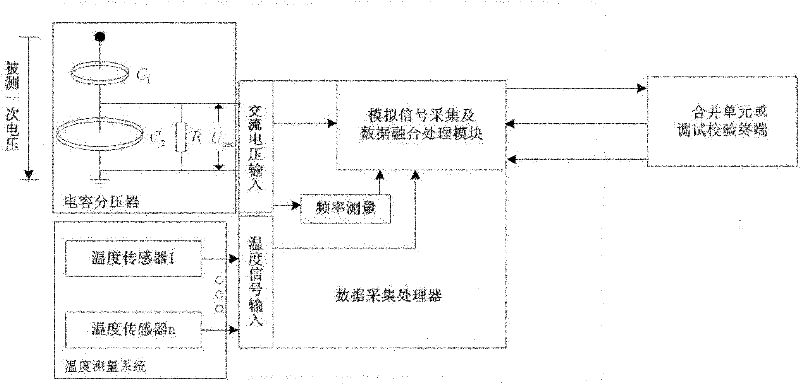

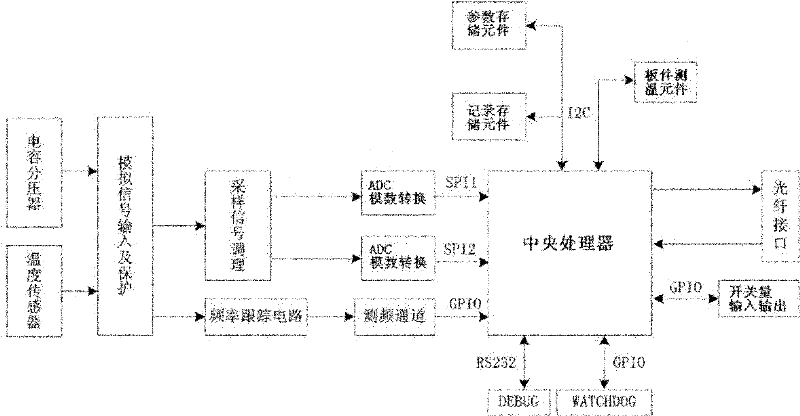

The invention discloses an electronic voltage transformer using data fusion technology and an error calibration method thereof. The error calibration method comprises the following steps of: acquiring a secondary measured voltage by using a capacitive voltage divider and a sampling resistor R, accessing the voltage to a data acquisition processor for sampling, and tracing the frequency of the voltage; accessing a signal of a temperature sensor to the data acquisition processor, and computing the temperatures of measuring points; dynamically computing a divided voltage ratio of the capacitive voltage divider according to the temperature variation of the measuring points by using data acquisition device processing software so as to modify a transformation ratio error of the transformer; dynamically computing phase deviation according to signal frequency variation by using the data acquisition device processing software so as to modify a phase error; and outputting a digital sampling value through an optical fiber interface. The device is simple in structure, safe and practical; errors caused by manufacturing factors, temperature and signal acquisition circuits and the like can be effectively modified and restrained; and the measuring accuracy, temperature stability and transient performance of the electronic voltage transformer according to a capacitive voltage division principle are improved.

Owner:NARI TECH CO LTD +1

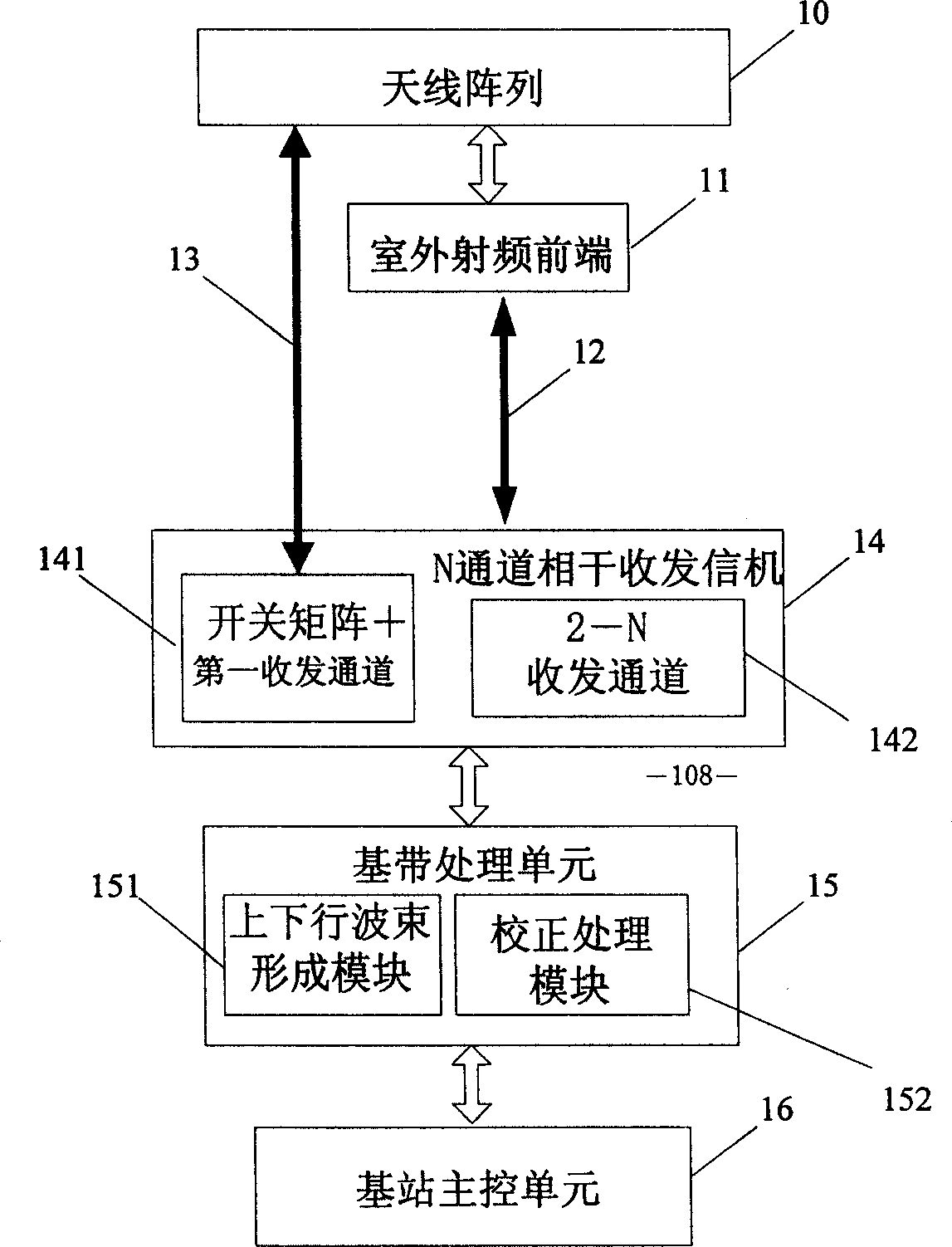

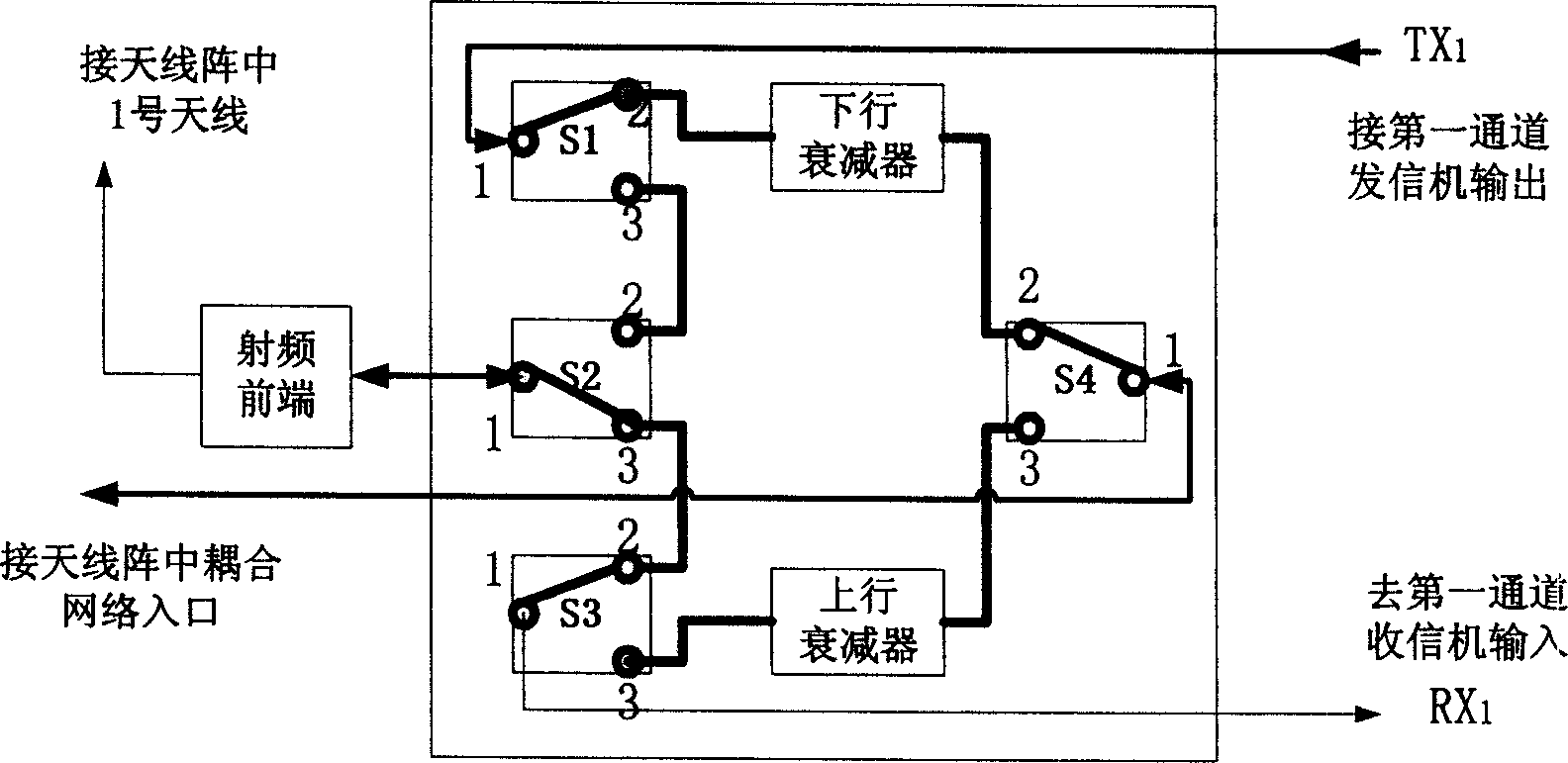

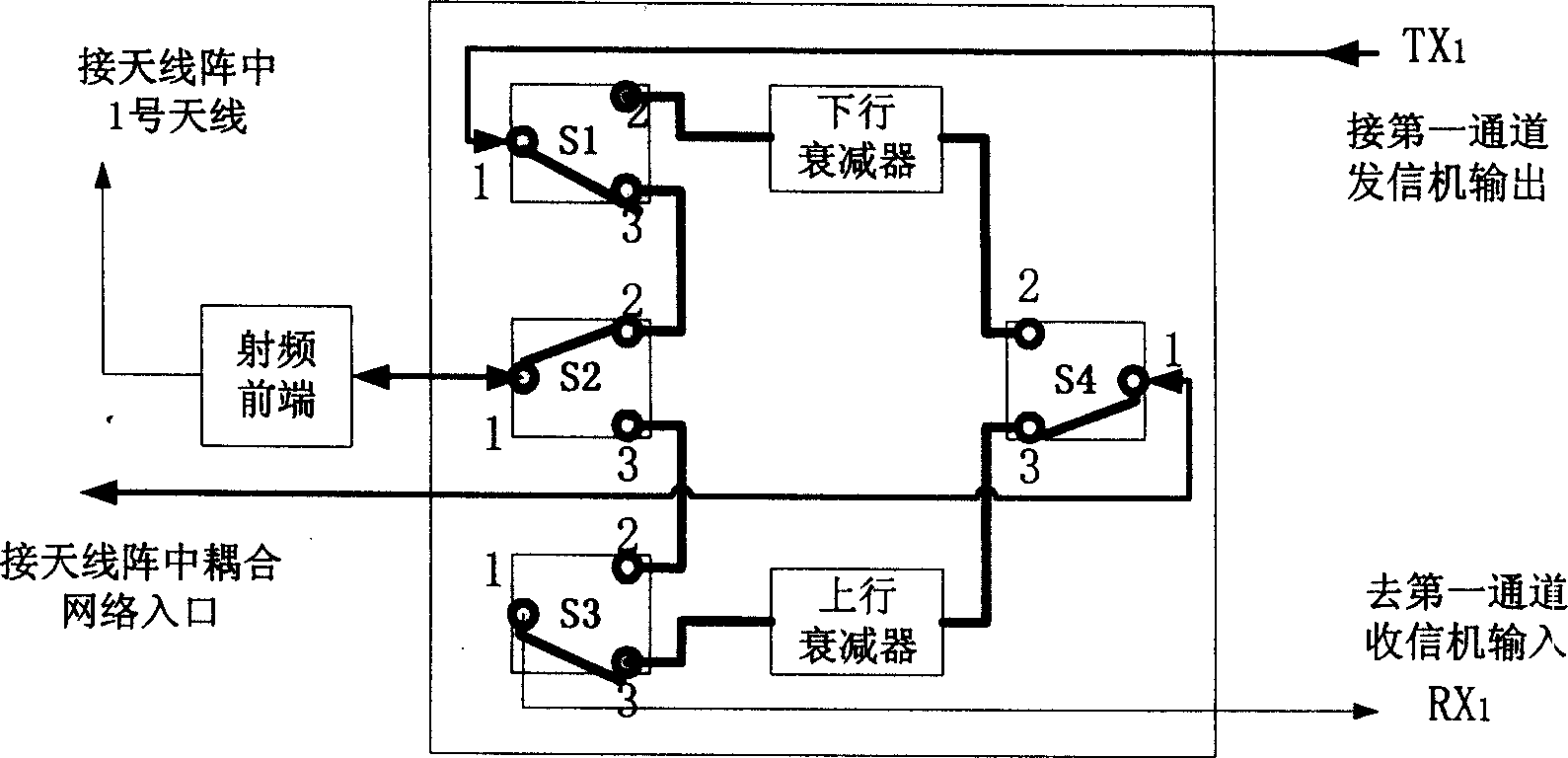

Array channel correcting method and device for time-division and duplex intelligent antenna

ActiveCN1747569AAchieve correctionReal-time correctionSpatial transmit diversityAntenna arraysTransceiverPhase difference

A method and equipment for correcting the amplitude and phase difference of array channels in a time-shared duplex intelligent antenna system is disclosed. Said method includes such steps as setting up a switch array in the front of transceiver of the first channel for switching between transmission and receiving and between up and down correcting links, performing up correction through outputting a known sequence to the transmitter of the first channel, connecting up correcting link, detecting the responses of all receiving channels and sampling while storing, or performing down correction through sequentially transmitting a known sequence to transmitters of N down channels, connecting down correcting link, detecting the known characteristic signal of the response from currently corrected channel, and sampling while storing, and calculating the correcting right of all up and down channels for weighting the wave beams.

Owner:ZTE CORP

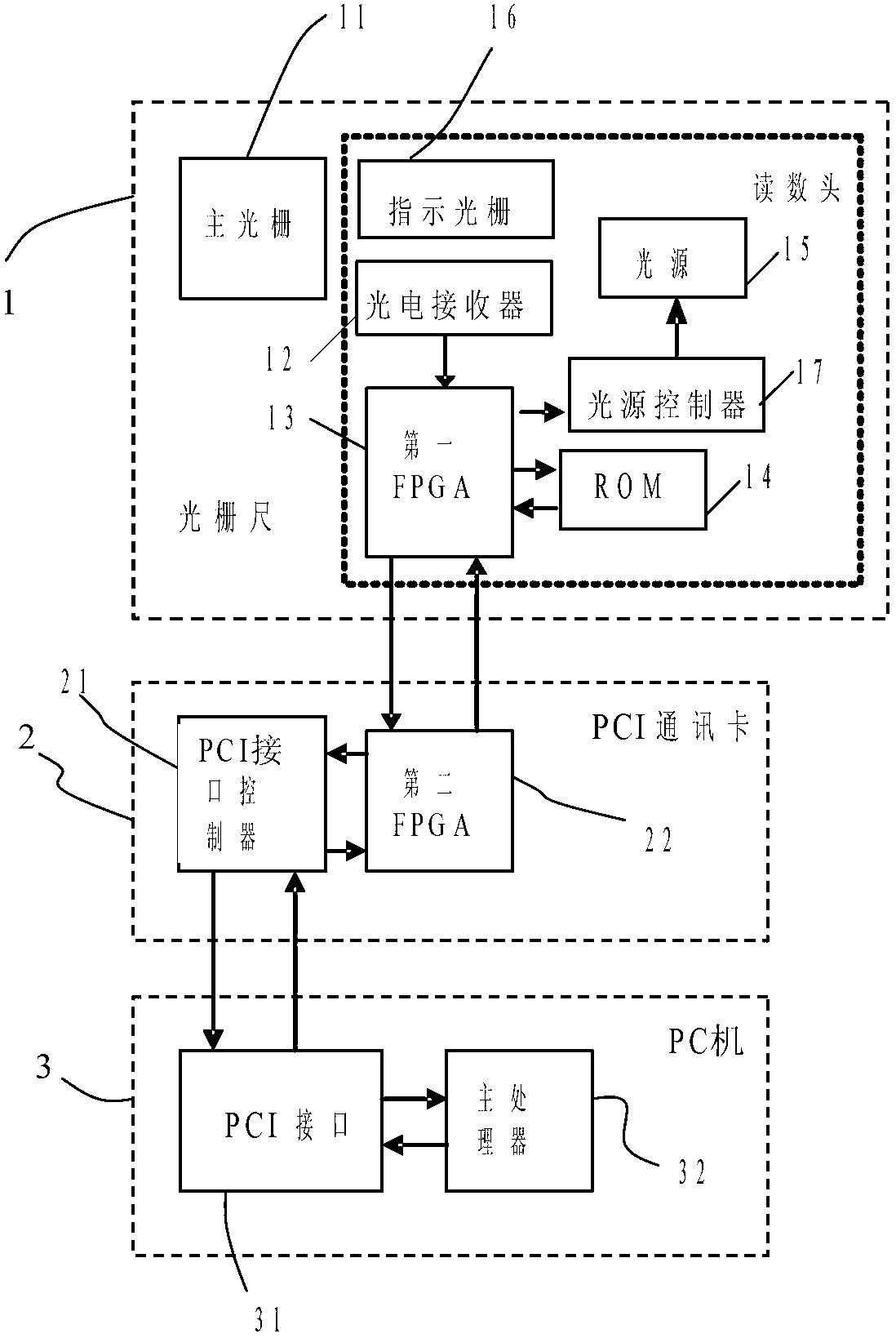

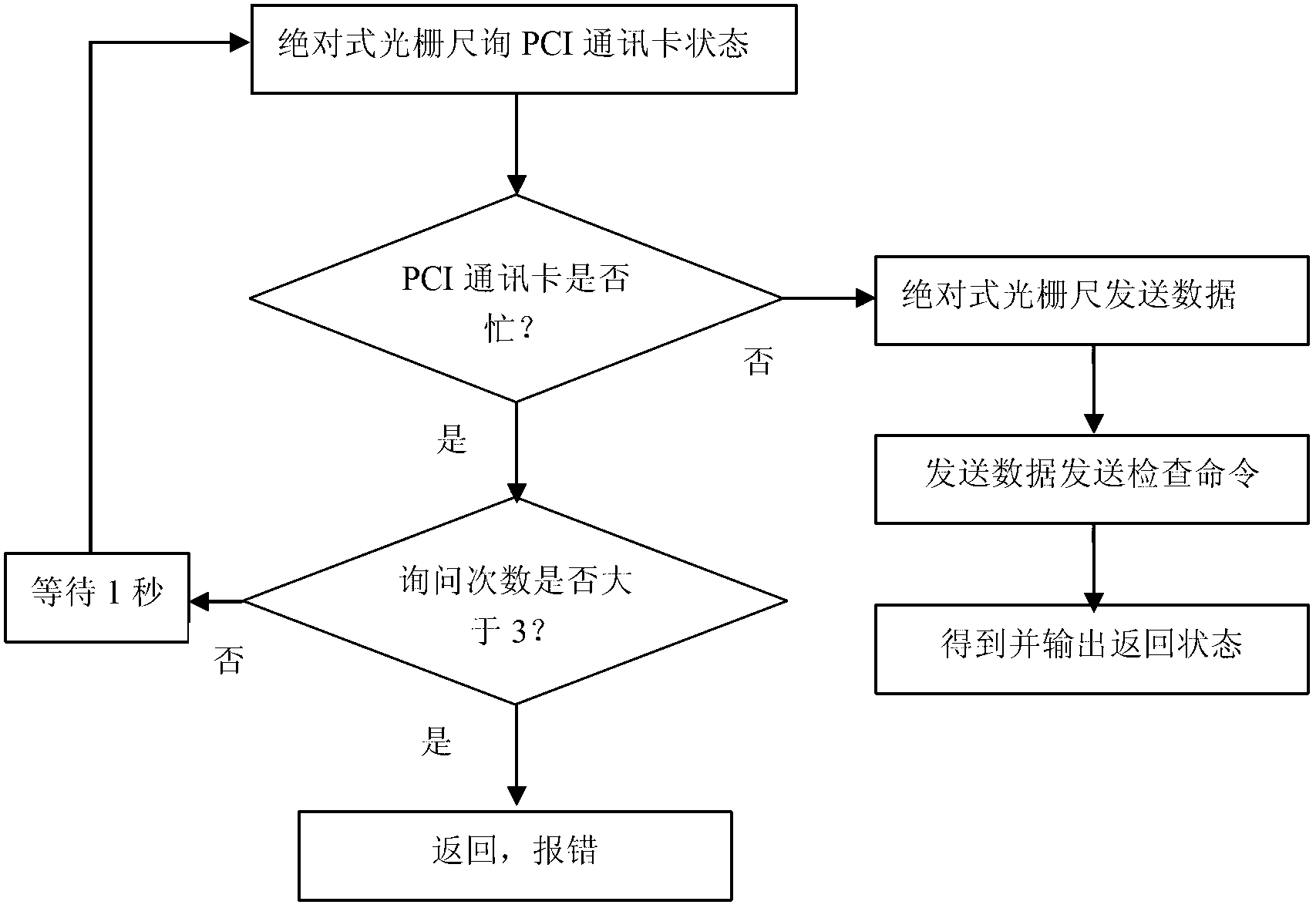

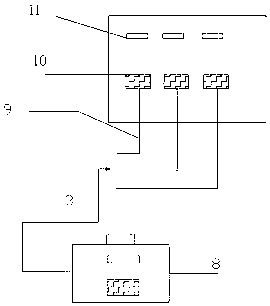

Online correcting device of absolute grating ruler reading head parameters

InactiveCN103175567AImprove correction efficiencyRealize online correctionInstrumentsData transmissionRead-only memory

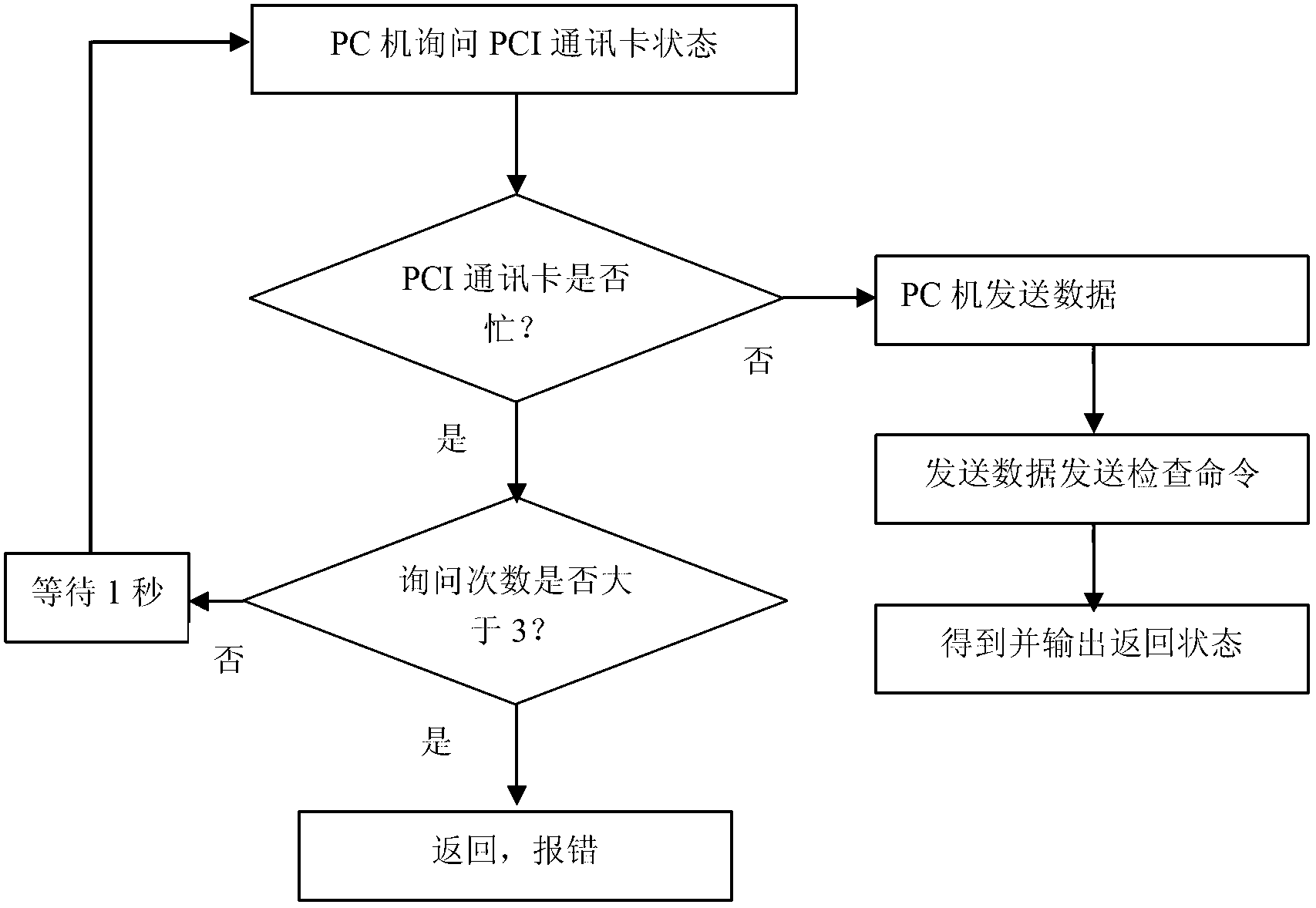

An online correcting device of absolute grating ruler reading head parameters relates to the technical field of grating ruler measuring. The online correcting device comprises a PCI (peripheral component interconnect) communication card and a PC (personal computer). The PCI communication card comprises a PCI interface controller and a second FPGA (field programmable gate array). The PC comprises a PCI interface and a main processor. Command parameters are sent to the PCI interface controller, the second FPGA receives the command parameters and transmits the same to a first FPGA of a grating ruler reading head, and the first FPGA writes data into a ROM (read only memory) in the reading head. During data transmission, state of the PCI communication card is inquired, when the PCI communication card is idle, data and data CRC (cyclic redundancy check) codes are transmitted, so that integrity and accuracy of data transmission is guaranteed. By the correcting device, online correction of grating ruler reading head parameters is achieved, and correction efficiency of grating ruler reading head is improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

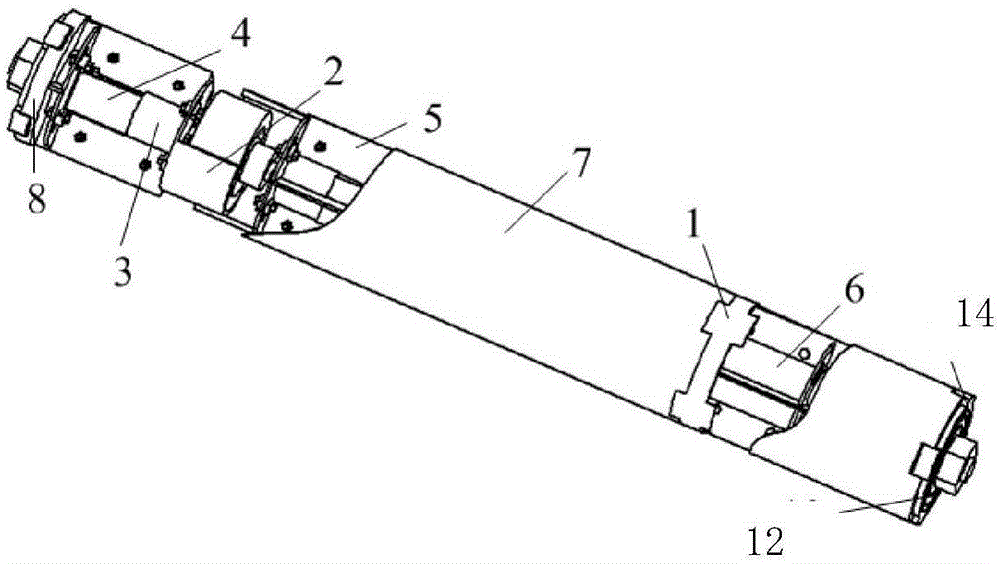

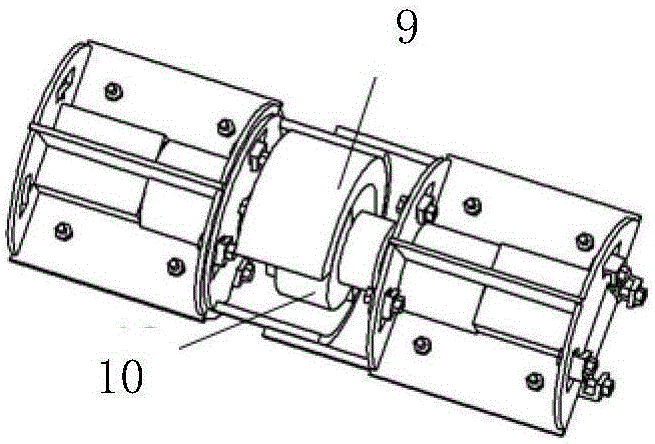

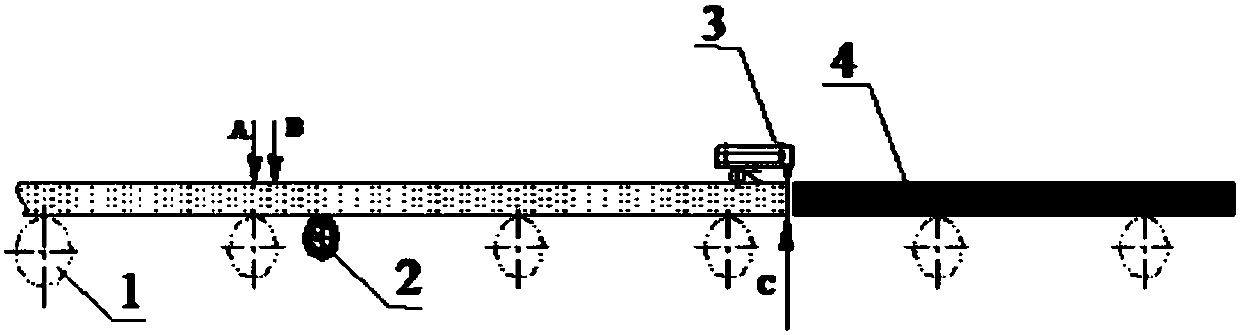

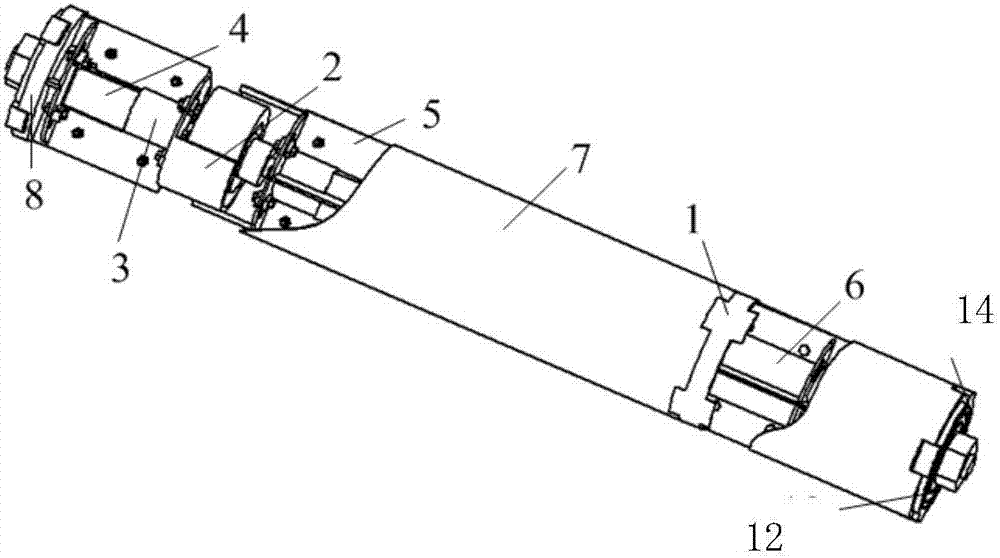

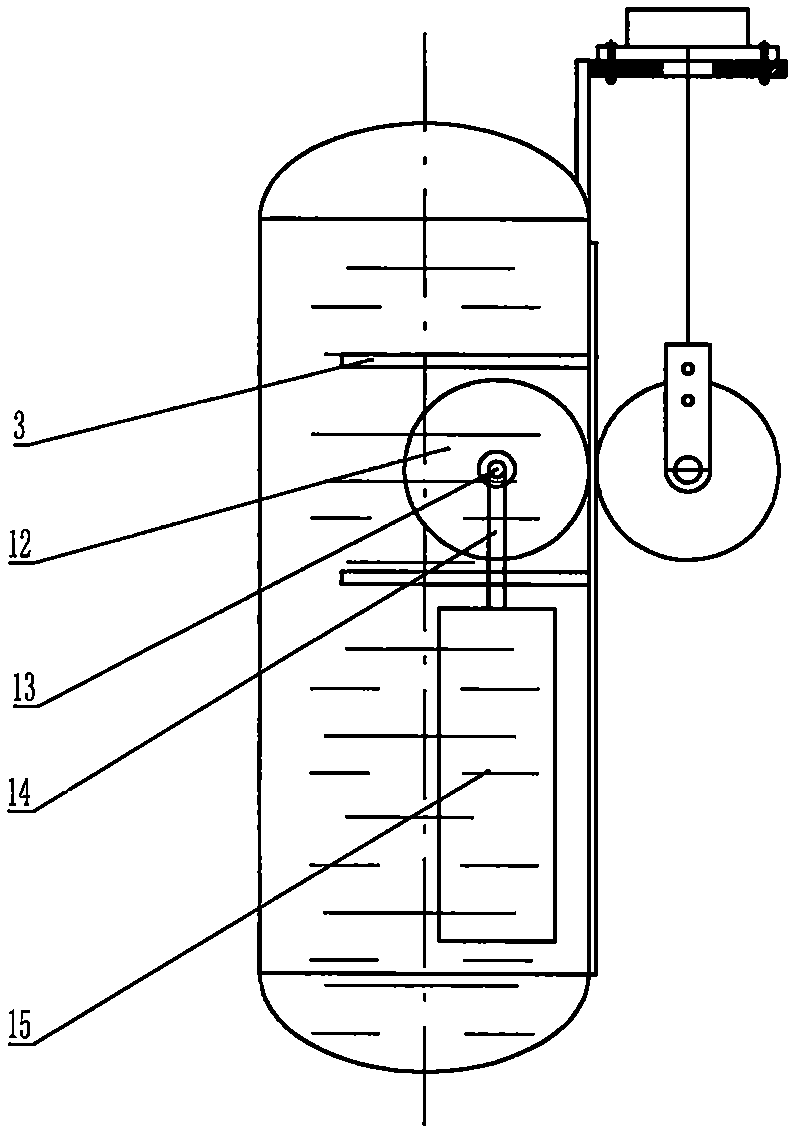

Adjusting method of built-in mechanical on-line dynamic balancing system of main shaft

ActiveCN104990670ARealize online correctionRealize processingProgramme controlComputer controlDynamic balanceDisplay device

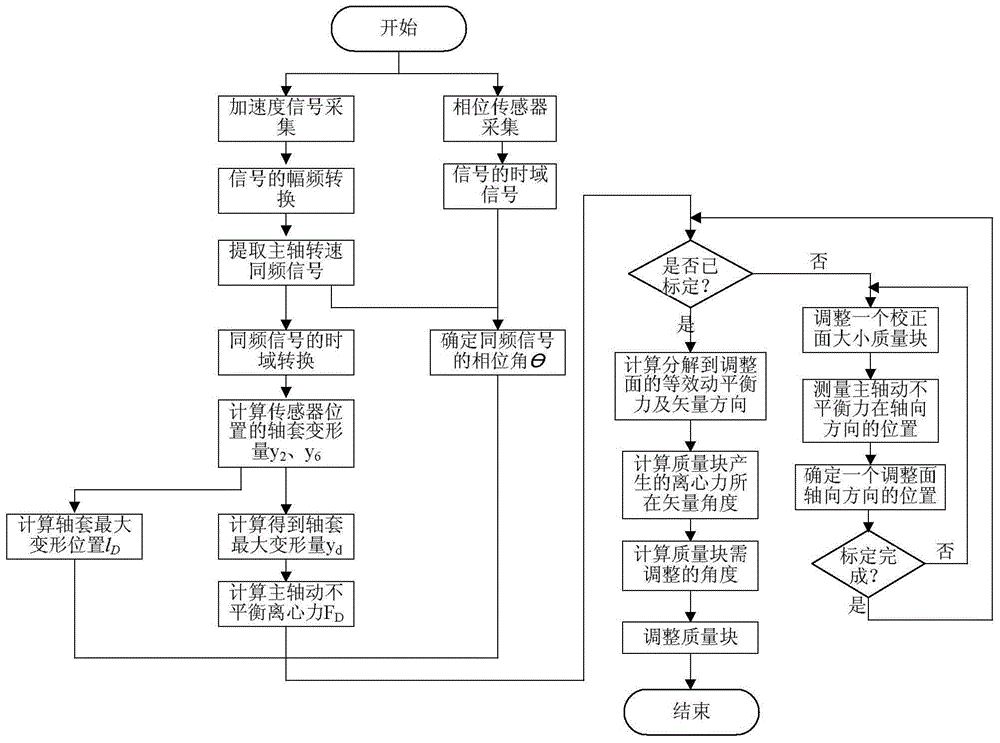

The invention, which belongs to the technical field of the high-speed main shaft on-line dynamic balancing, provides an adjusting method of a built-in mechanical on-line dynamic balancing system of a main shaft. The method comprises: step 1, installing an on-line dynamic balancing system; step 2, carrying out calibration of on-line dynamic balancing correction; to be specific, calibrating two adjustment balancing surface axial position parameters 1A and 1B; step 3, carrying out dynamic unbalance measurement and carrying out calculation to obtain a dynamic unbalance equivalent centrifugal force FD and location thereof 1D; step 4, carrying out dynamic unbalance correction of the main shaft; to be specific, carrying out calculation based on the obtained parameters to obtain an needed angle beta 1 or beta 2 for a mass block for adjustment, controlling the motor to make rotation, and adjusting the corresponding mass block; and step 5, displaying the dynamic unbalance data of the main shaft and adjustment data of the mass block on a display device of an industrial personal computer in real time to realize real-time monitoring of the whole process. According to the invention, the method is suitable for operation conditions of various main shafts to realize on-line correction of the dynamic unbalance states of the main shafts. The rotation precision of the main shaft is improved, thereby realizing processing of high-quality parts.

Owner:SHENYANG JIANZHU UNIVERSITY

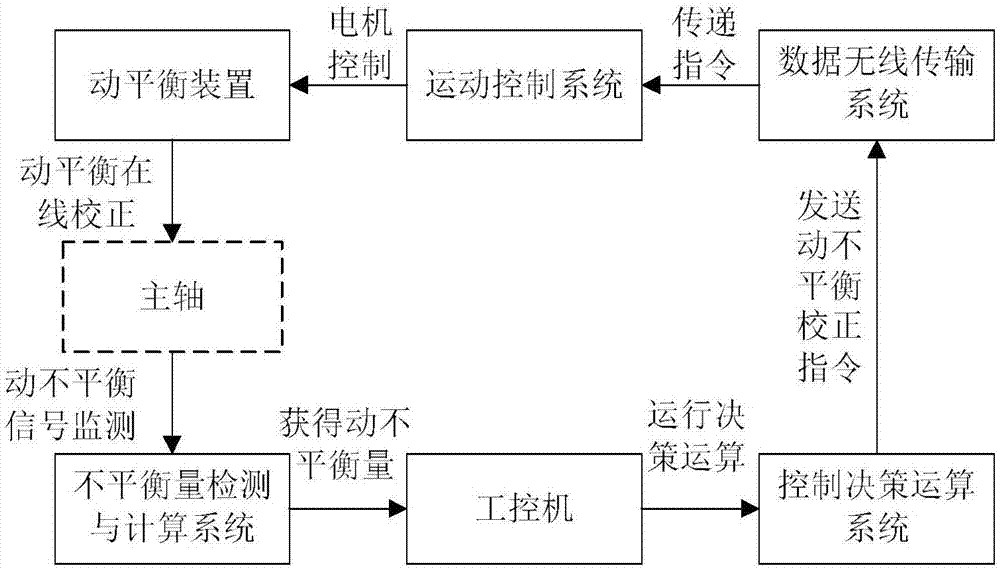

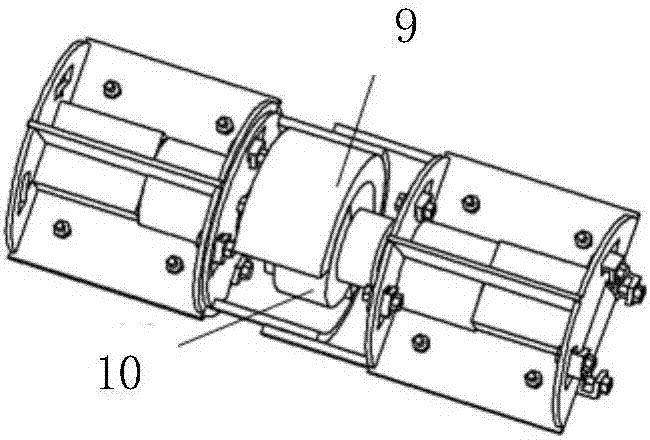

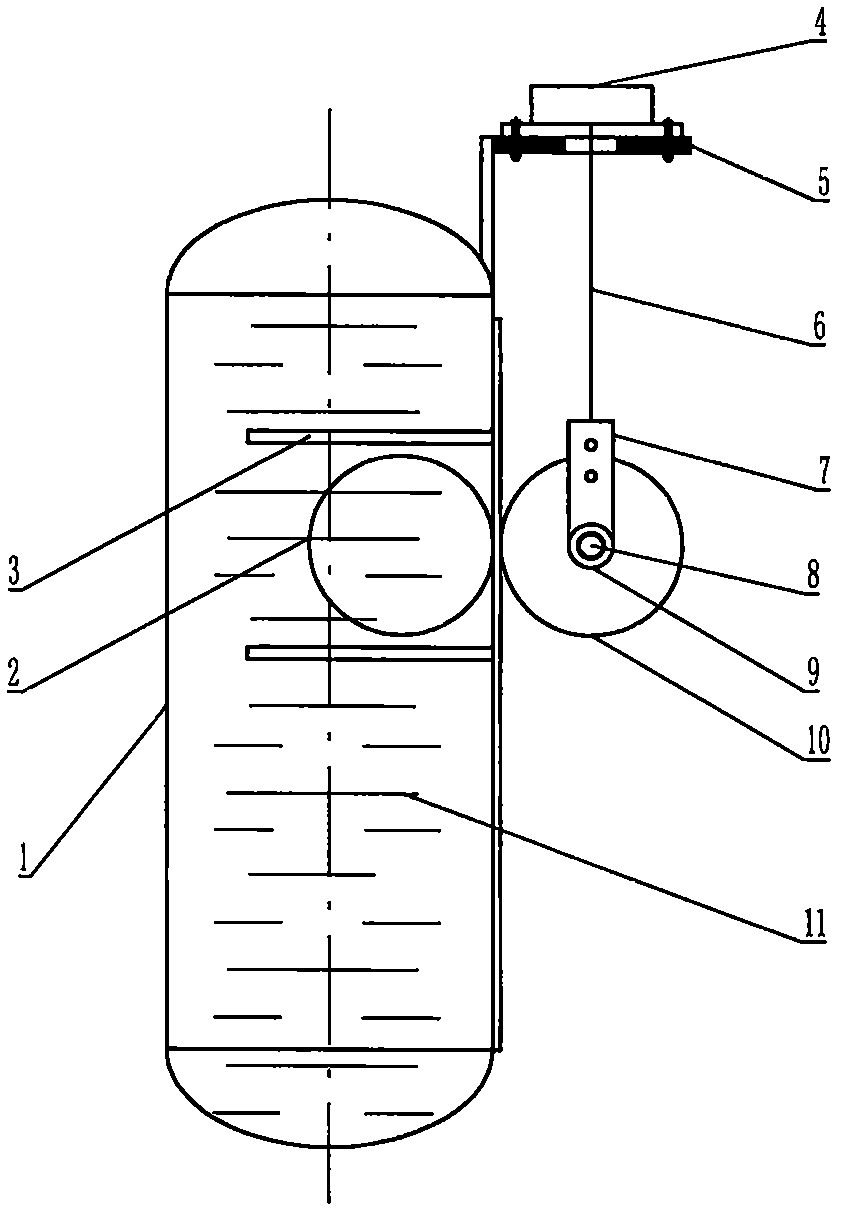

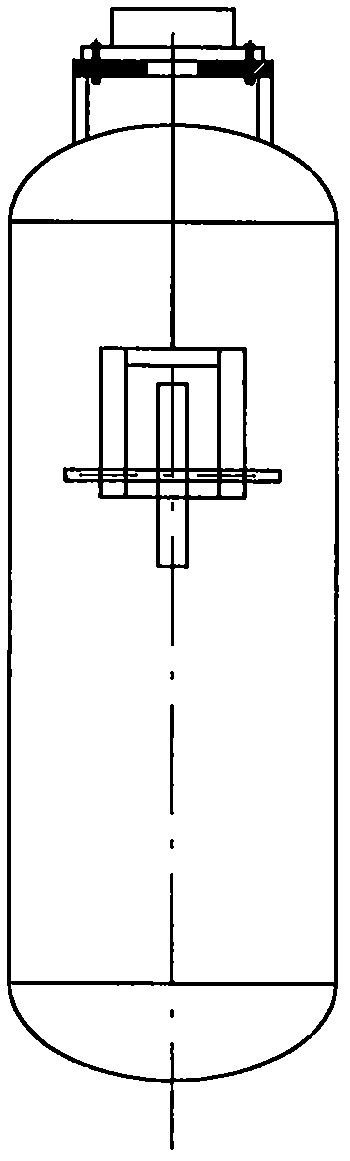

Main shaft built-in mechanical on-line dynamic balancing system

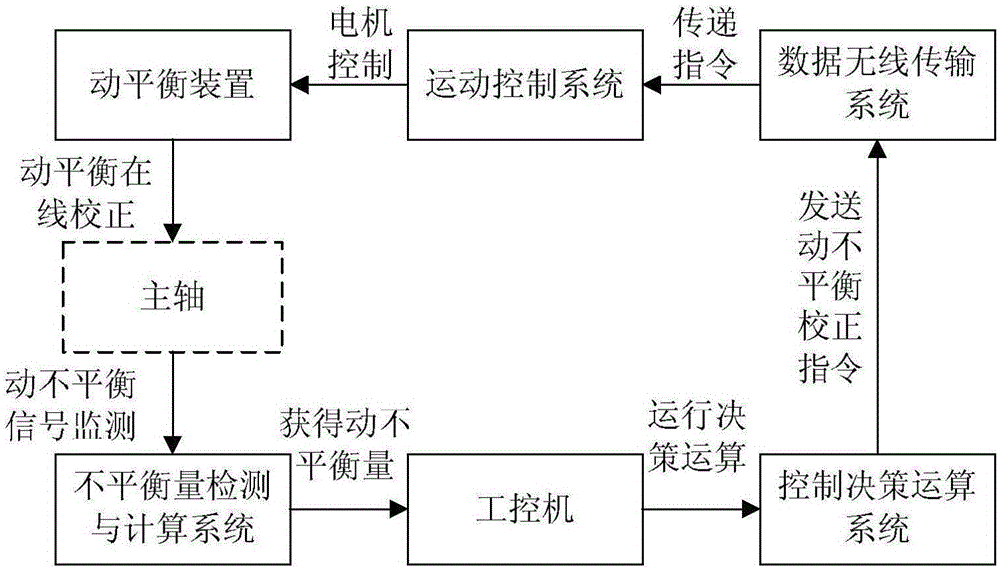

ActiveCN105021352AHigh rotation accuracyRealize processingStatic/dynamic balance measurementDecompositionMovement control

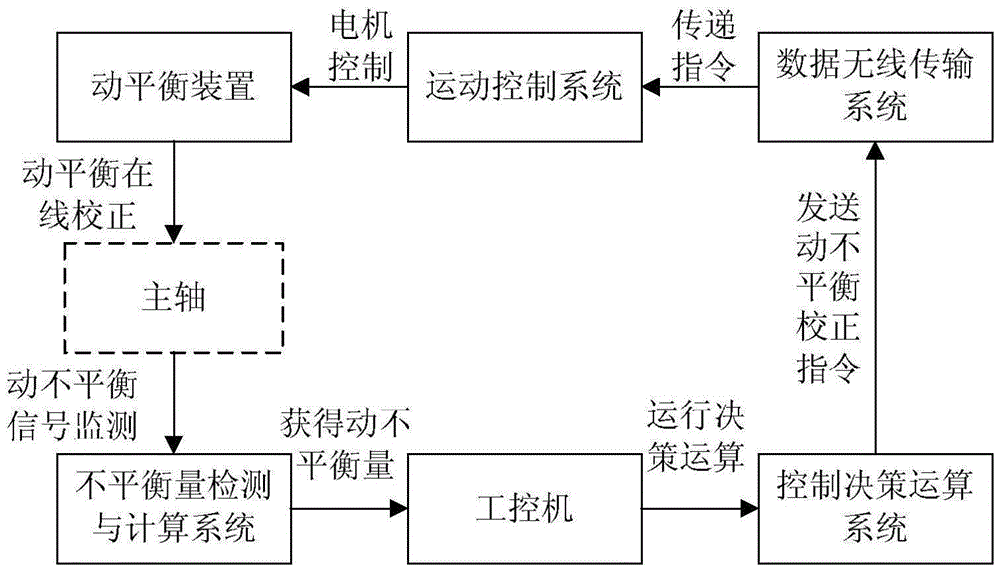

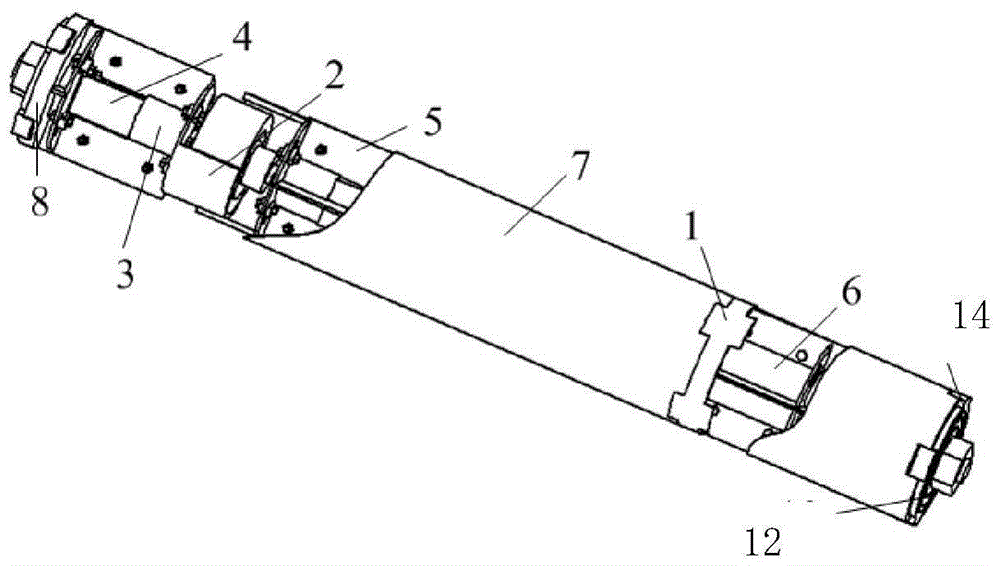

The invention provides a main shaft built-in mechanical on-line dynamic balancing system and belongs to the high-speed main shaft on-line dynamic balancing technology field. The main shaft built-in mechanical on-line dynamic balancing system comprises a dynamic balancing device, a movement control system, a data wireless transmission system, a dynamic unbalancing detection calculation system and a control decision operation system. The dynamic balancing device is placed in a main shaft. The dynamic unbalancing detection calculation system detects an unbalancing signal of the main shaft, and analyzes and calculates a main shaft dynamic unbalancing equivalent centrifugal force, a vector direction of the force and a position of the force. The control decision operation system carries out equivalent decomposition of the equivalent centrifugal force to two dynamic unbalancing adjustment planes, calculates a dynamic unbalancing equivalent centrifugal force of each plane, and makes a mass distribution strategy of each mass block group. The data wireless transmission system receives and transmits a dynamic unbalancing correction instruction. The movement control system is installed in a control cavity of the dynamic balancing device, receives the dynamic unbalancing correction instruction and controls rotation of a motor in the dynamic balancing device. The main shaft built-in mechanical on-line dynamic balancing system is suitable for various main shaft operation conditions, and achieves main shaft dynamic unbalancing state on-line correction.

Owner:SHENYANG JIANZHU UNIVERSITY

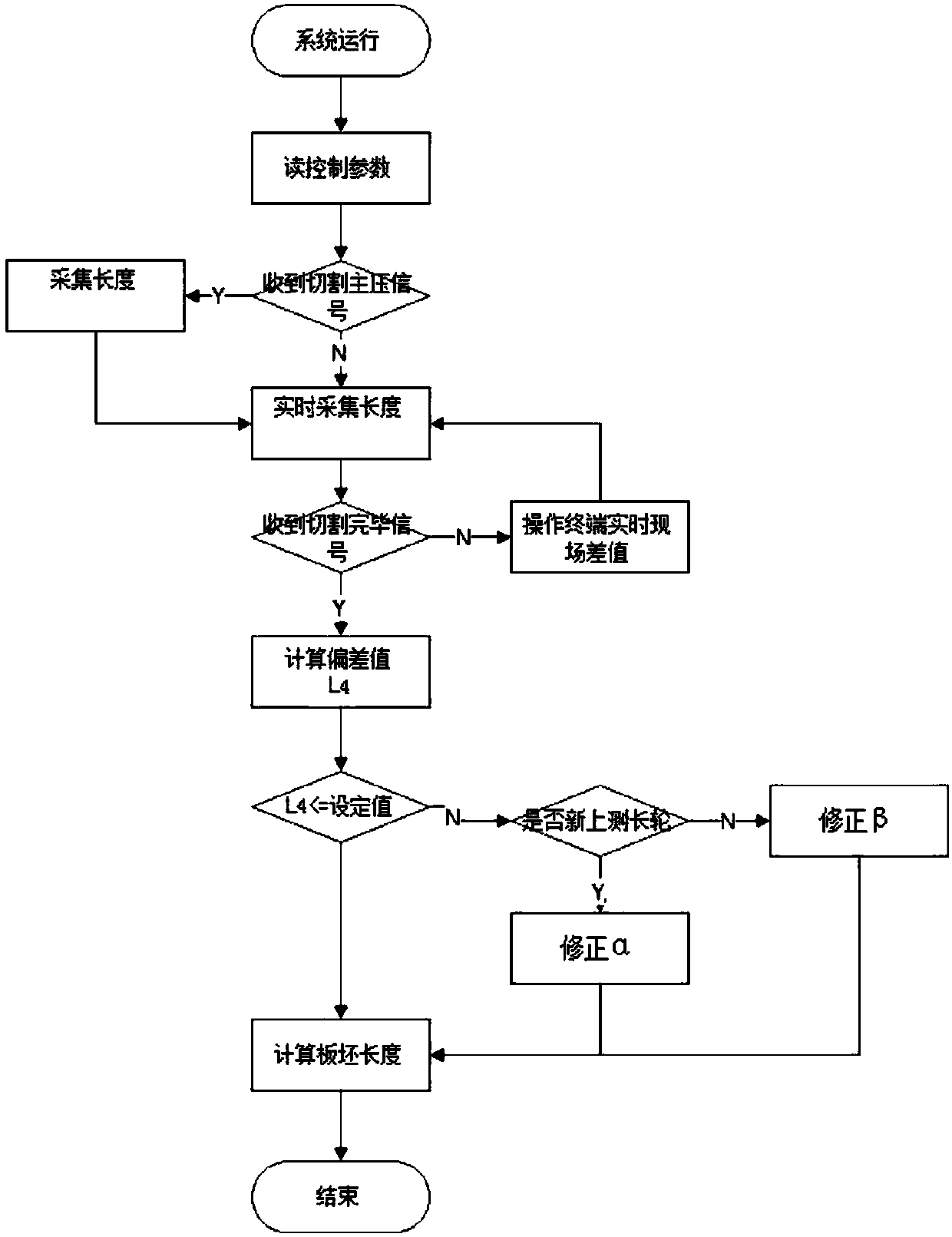

Accurate measurement method of length of continuous casting billet

The invention provides an accurate measurement method of the length of a continuous casting billet. The method comprises the steps of (1) collecting the cart position S1 under the main pressure of a cutting machine when the casting billet starts to be cut by a cart position detection system of the cutting machine, collecting the cart position S2 when the casting billet stops cutting, and collecting the walking distance S which is equal to (S2-S1) of the cutting machine; (2) collecting the length L1 of the continuous casting billet under the main pressure of the cutting machine when the castingbillet starts to be cut by a length measurement monitoring system of the casting billet, collecting the length L2 of the continuous casting billet when the casting billet stops cutting, and collecting the measurement variation L which is equal to (L2-L1) of a length measurement system of a length measurement wheel; (3) judging and correcting; (4) calculating the length of the billet; and (5) giving an alarm for abnormity of length variation of the billet. According to the accurate measurement method, a measurement error generated by mechanical wear of the length measurement wheel during use can be avoided, and the length control requirement of the billet is satisfied.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

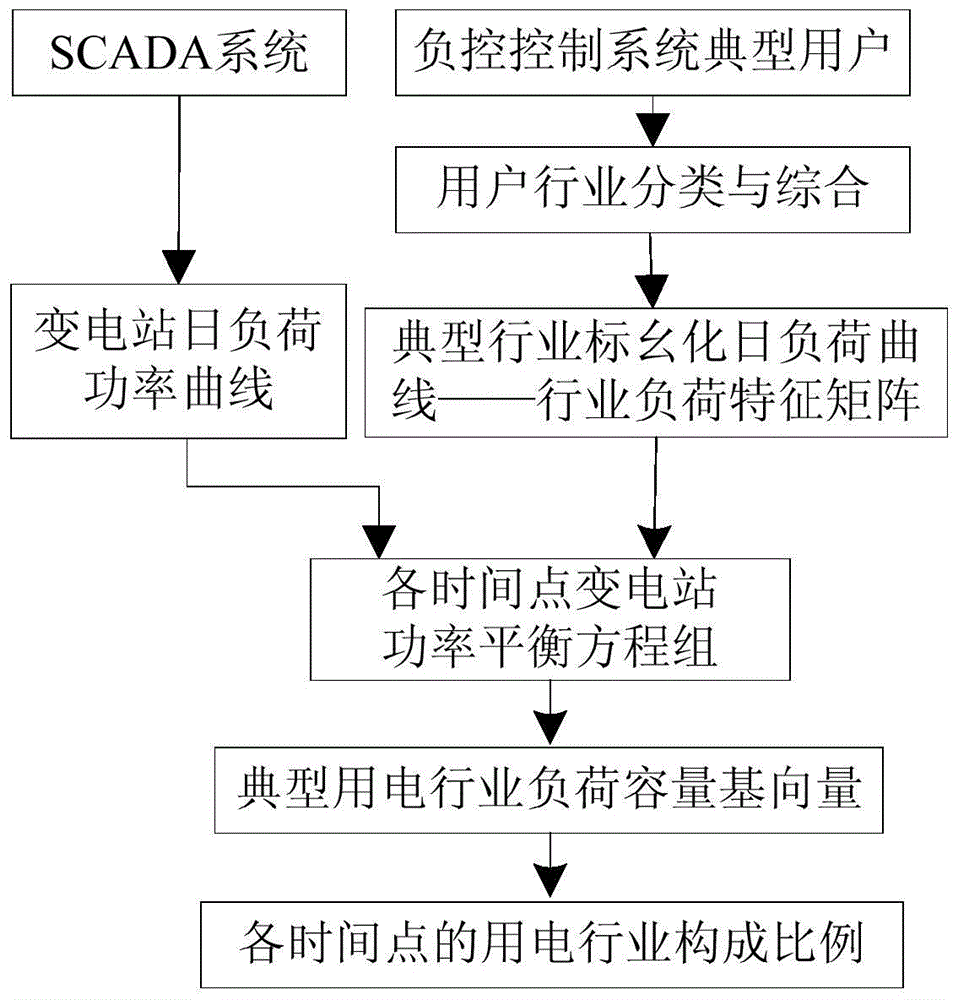

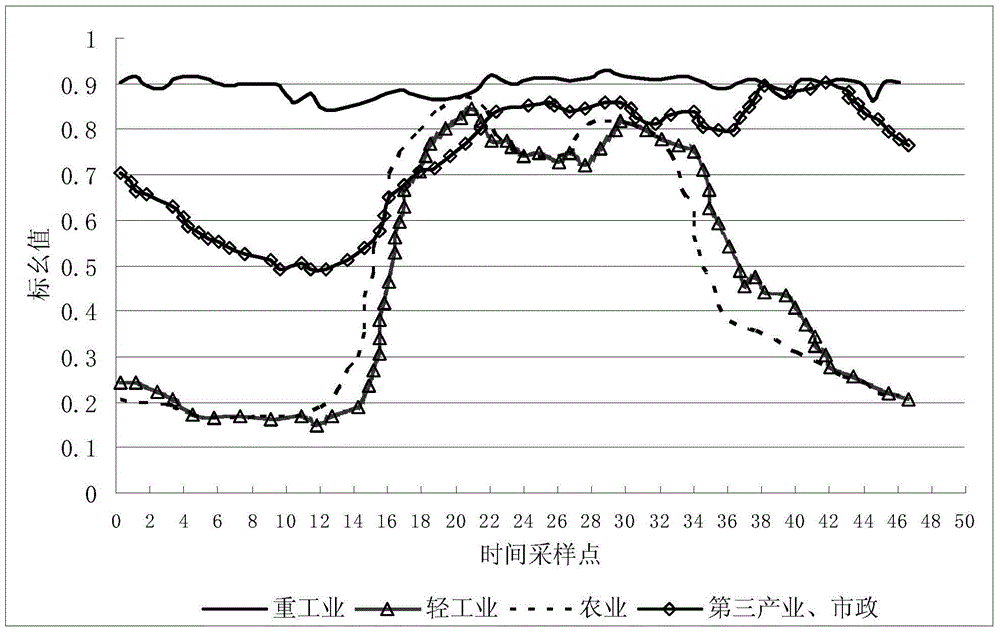

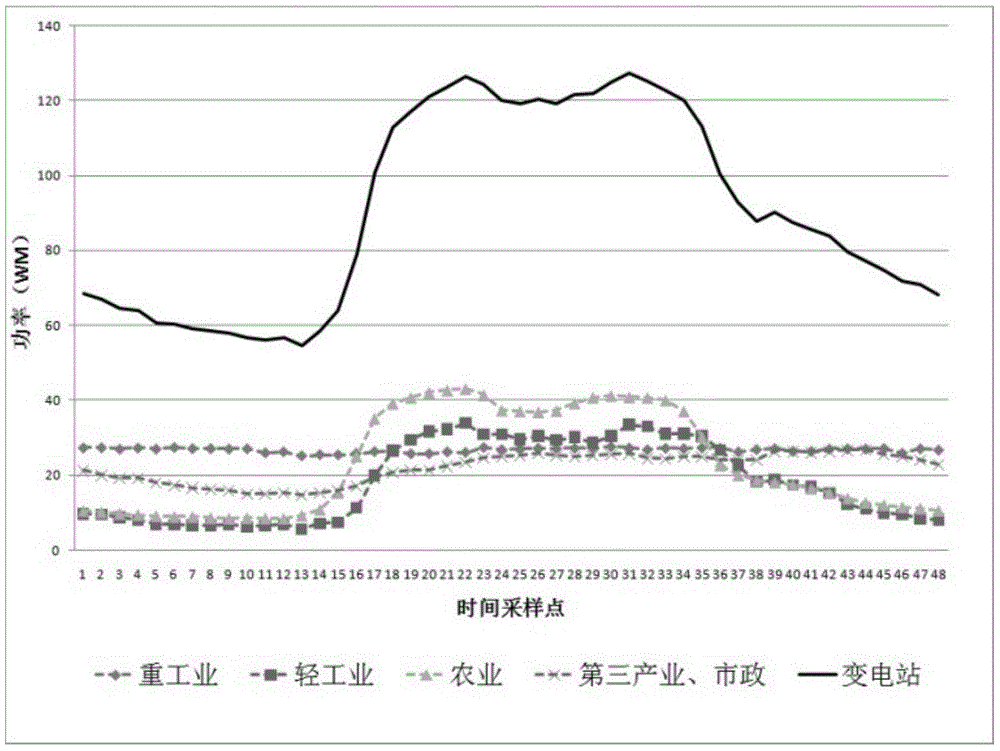

Method of acquiring comprehensive load model parameters in online mode based on daily load curve

InactiveCN104915889ARealize online correctionEfficient use ofData processing applicationsPower balancingModel parameters

The invention discloses a method of acquiring comprehensive load model parameters in an online mode based on a daily load curve. A typical power consumption industry load feature matrix is built for a typical user daily load curve acquired by a load control system; according to a substation daily load power curve synchronized with the above user daily load curve in time and acquired by an SCADA system, power balance equations are built, and a column vector for each typical power consumption industry load reference capacity is obtained; the typical power consumption industry load feature matrix is combined with column vectors formed by the typical power consumption industry load reference capacities to obtain a typical power consumption industry component ratio for the substation comprehensive load at each time point corresponding to the daily load curve. The method can effectively use the daily load curve of typical users and substations within an overall grid range conveniently acquired in actual engineering, a substation power consumption industry component ratio at each sampling time point of the daily load curve can be acquired, and a substation power consumption industry component ratio of each time period can be obtained in a simplified mode.

Owner:HUNAN UNIV

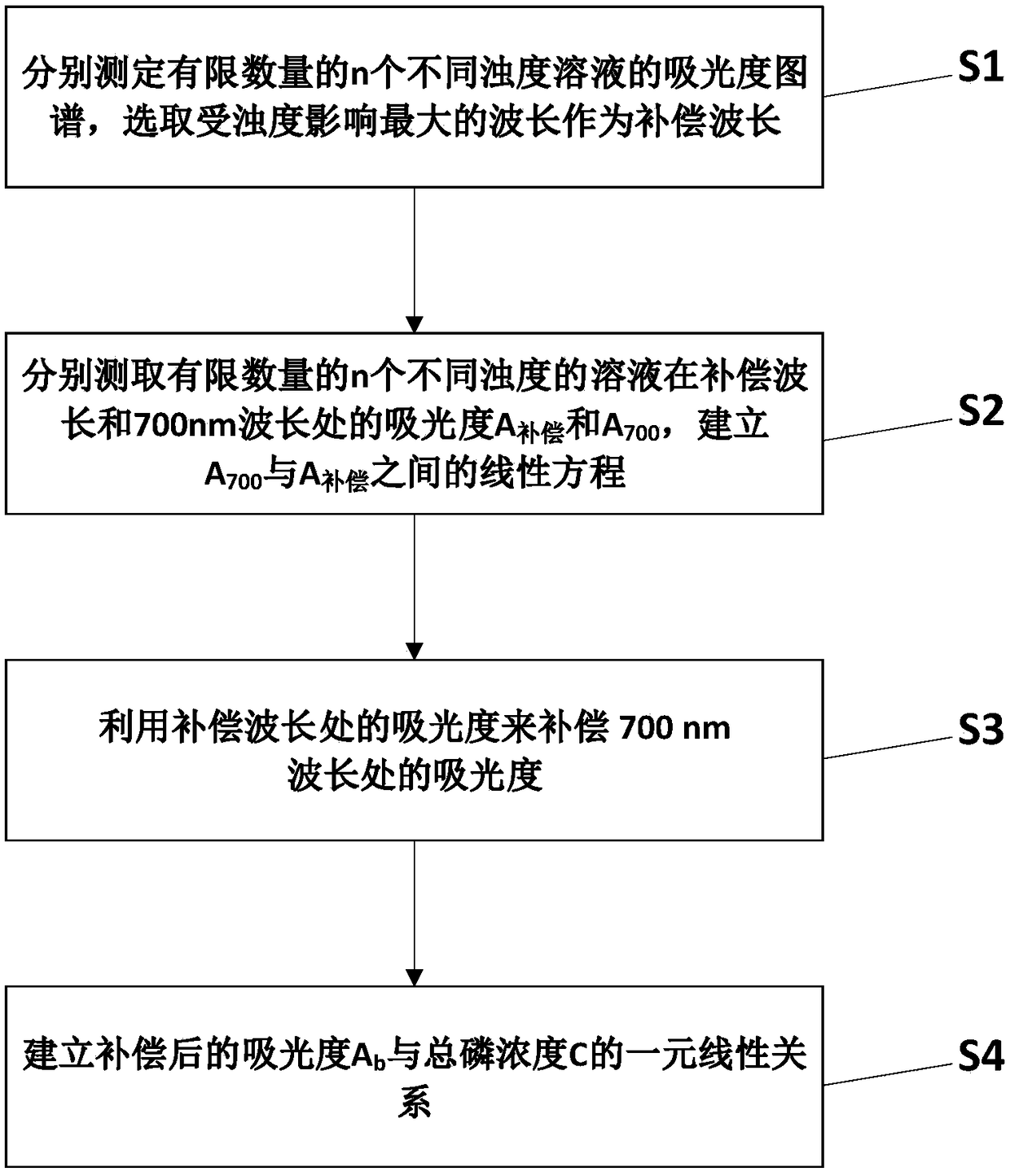

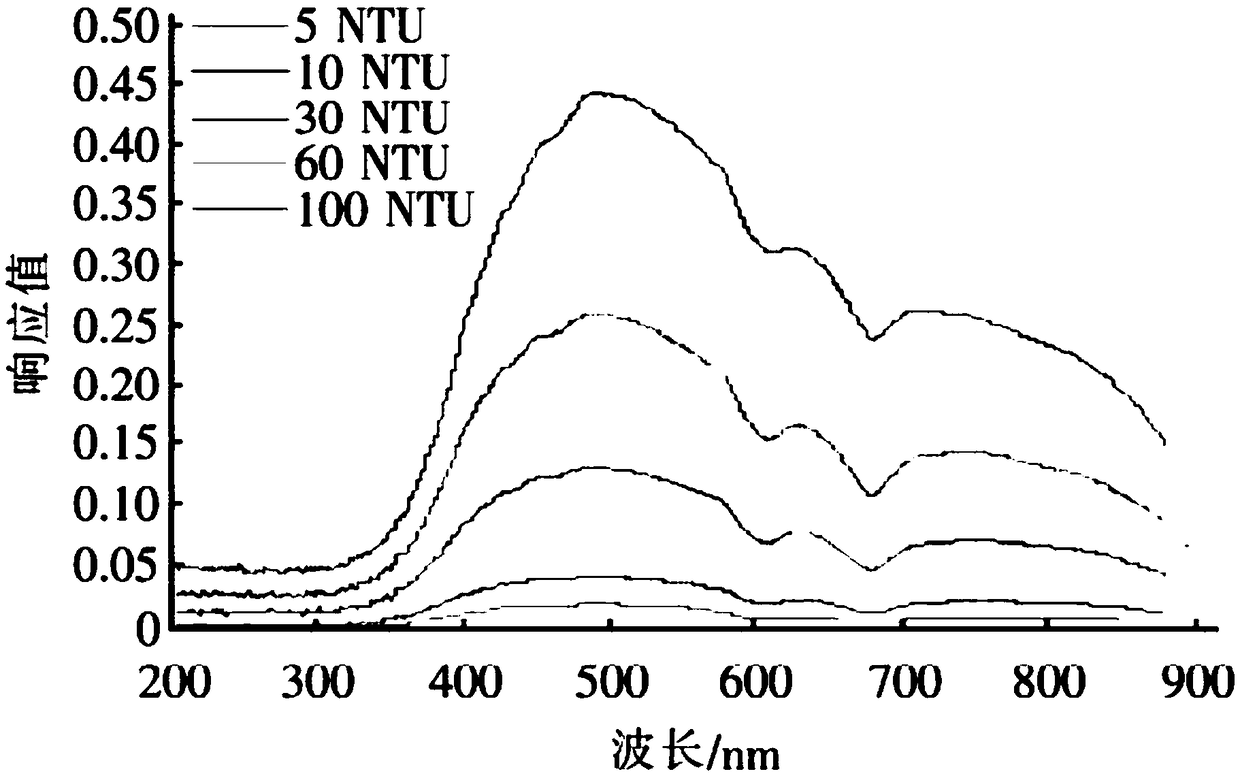

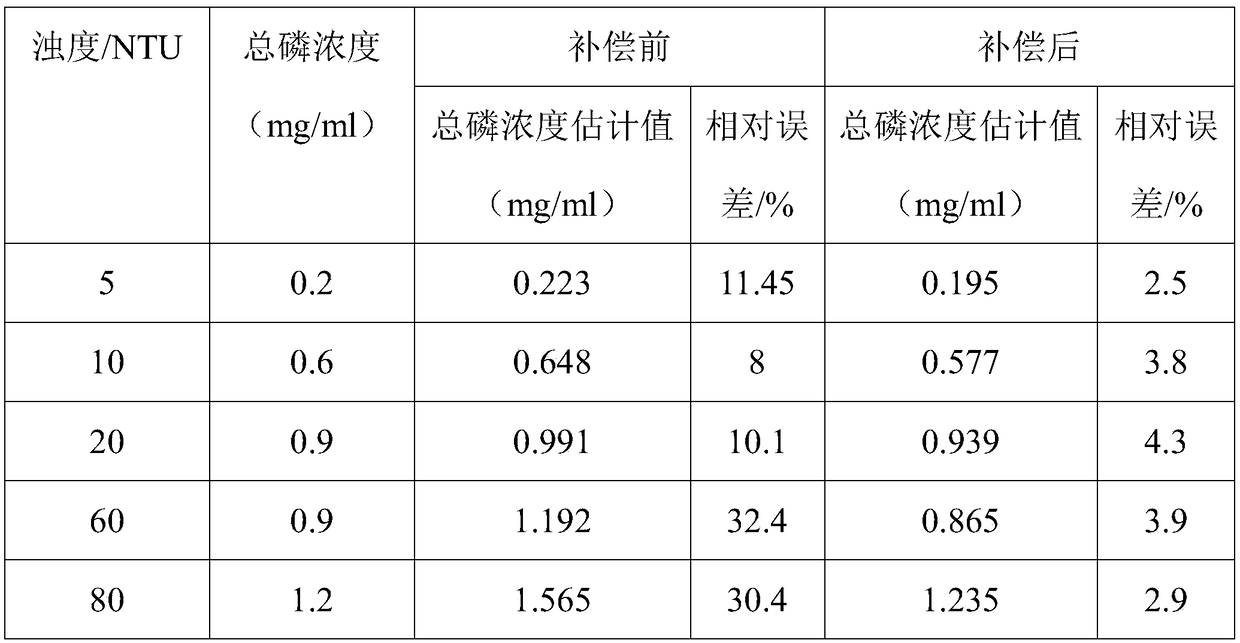

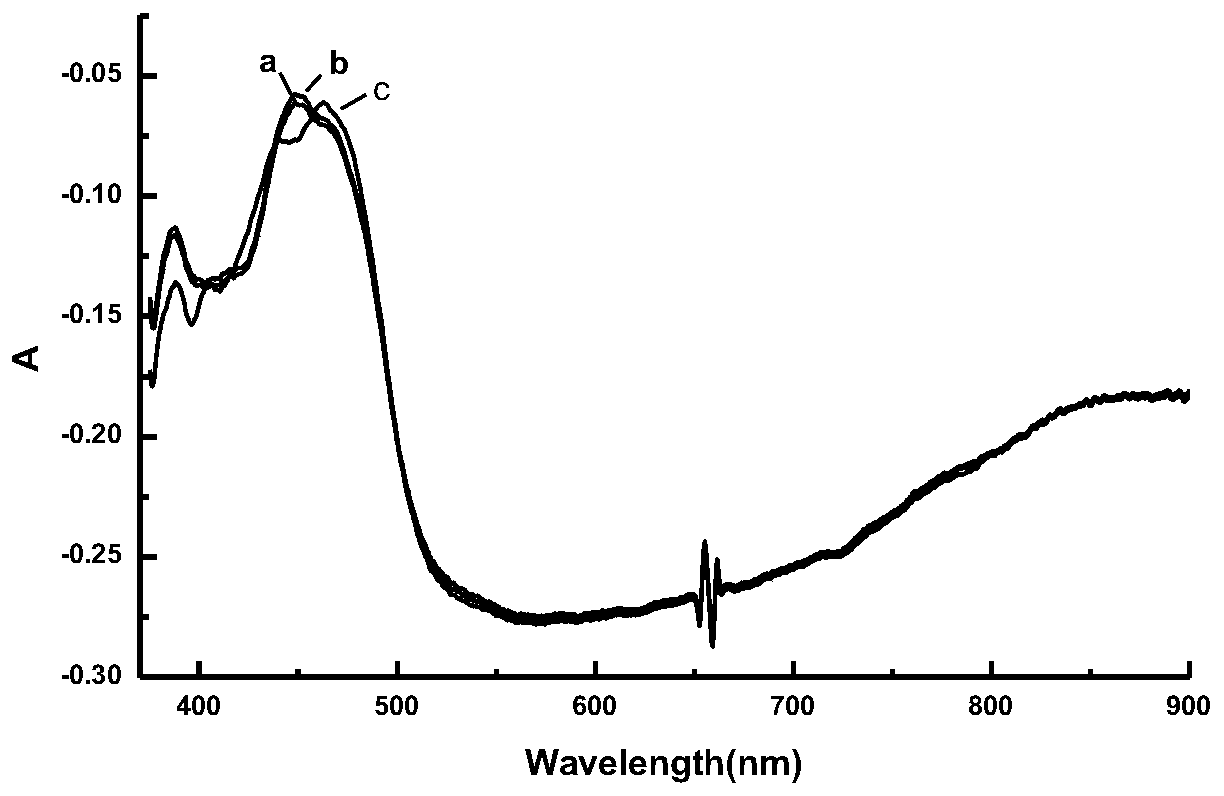

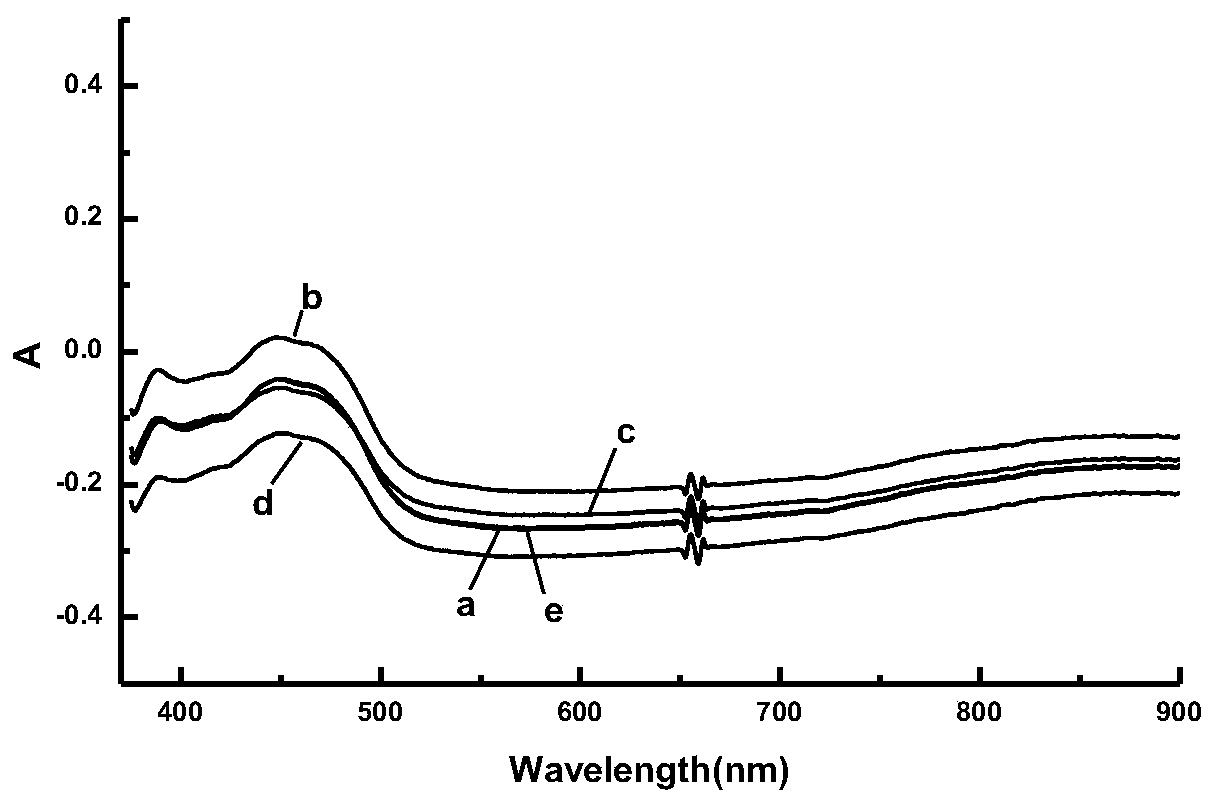

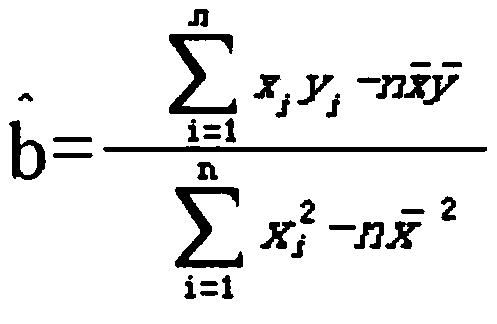

Establishing method for turbidity compensation model applied to total phosphorus measurement

InactiveCN109323997AReduce error interferenceRealize online correctionColor/spectral properties measurementsTurbidityLuminosity

The invention discloses an establishing method for a turbidity compensation model applied to total phosphorus measurement. The establishing method for the turbidity compensation model applied to the total phosphorus measurement comprises the following steps that absorbance spectra of a finite number of n solutions with different turbidity are separately measured, and a wave length most impacted bythe turbidity is selected to be used as a compensating wave length; absorbance A<compensation> and absorbance A<700> of the finite number of n solutions with the different turbidity at the compensating wave length and the wave length of 700 nm are correspondingly measured and selected, the A<compensation> is used as a horizontal ordinate, the A<700> is used as a vertical ordinate, and the least square method is used for linear fitting to obtain a linear equation between the A<700> and the A<compensation>: A<700>=a<1>A<compensation>-b<1>; the absorbance after the compensation is obtained: A=A<700>-a<1>A<compensation>-b<1>; and the least square method is used for linear fitting, and a unitary linear relation of the absorbance A after the compensation and the total phosphorus concentration C: C=a<2>A+b<2> is established. According to the establishing method for the turbidity compensation model applied to the total phosphorus measurement, the error interference caused by the turbidity to the total phosphorus measurement can be effectively reduced, the accuracy and stability of total phosphorus content measurement are improved, and on-line correction of the turbidity is realized.

Owner:宁波万泽微测环境科技股份有限公司

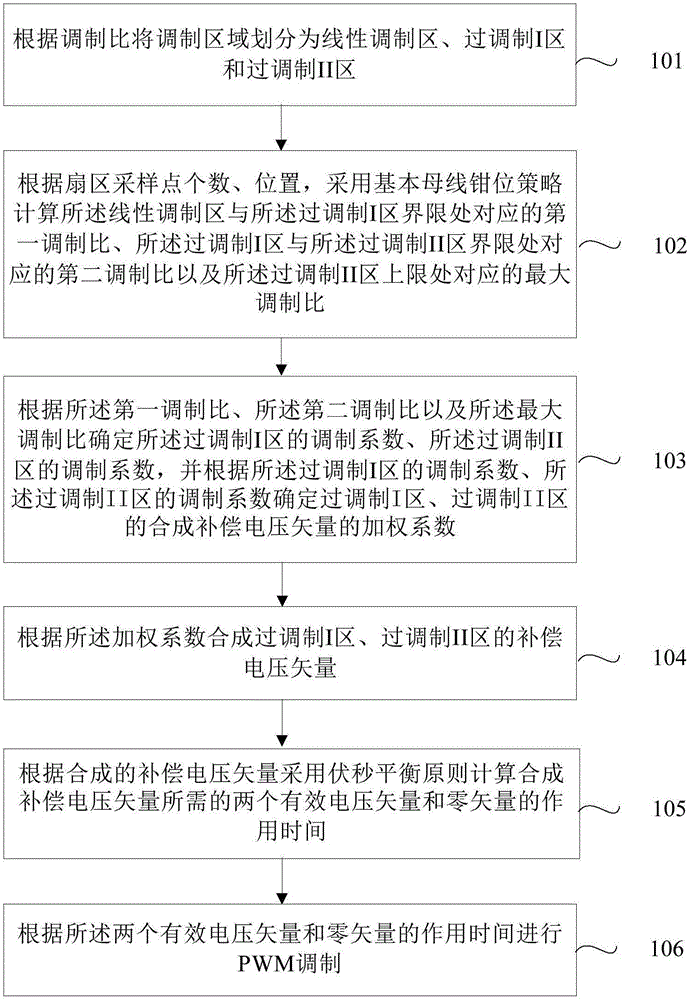

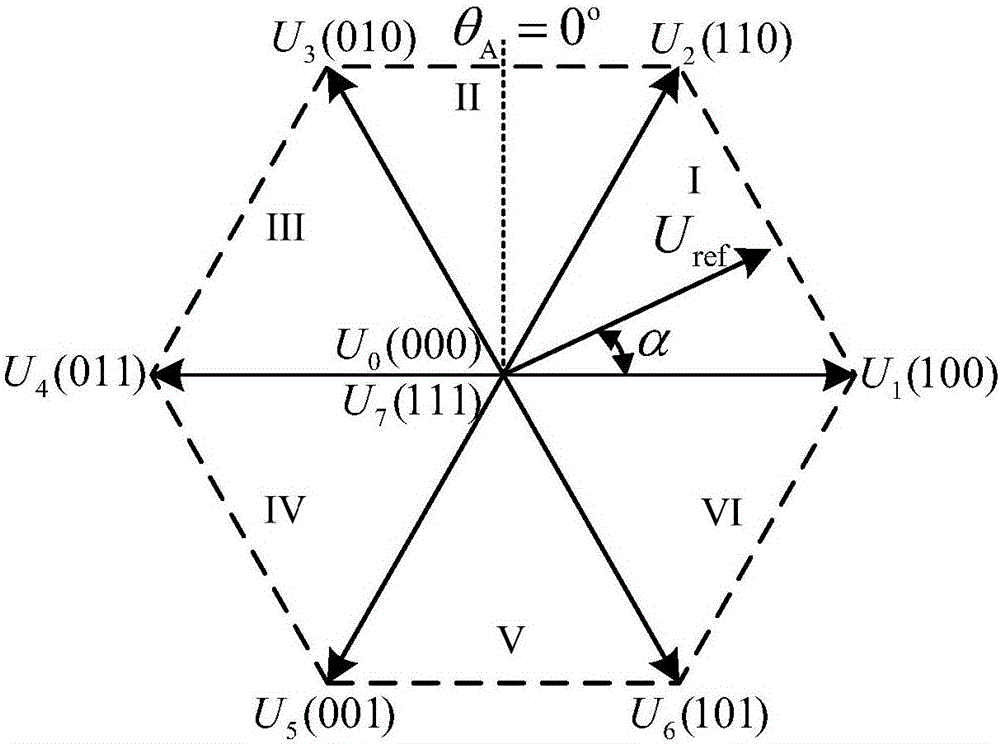

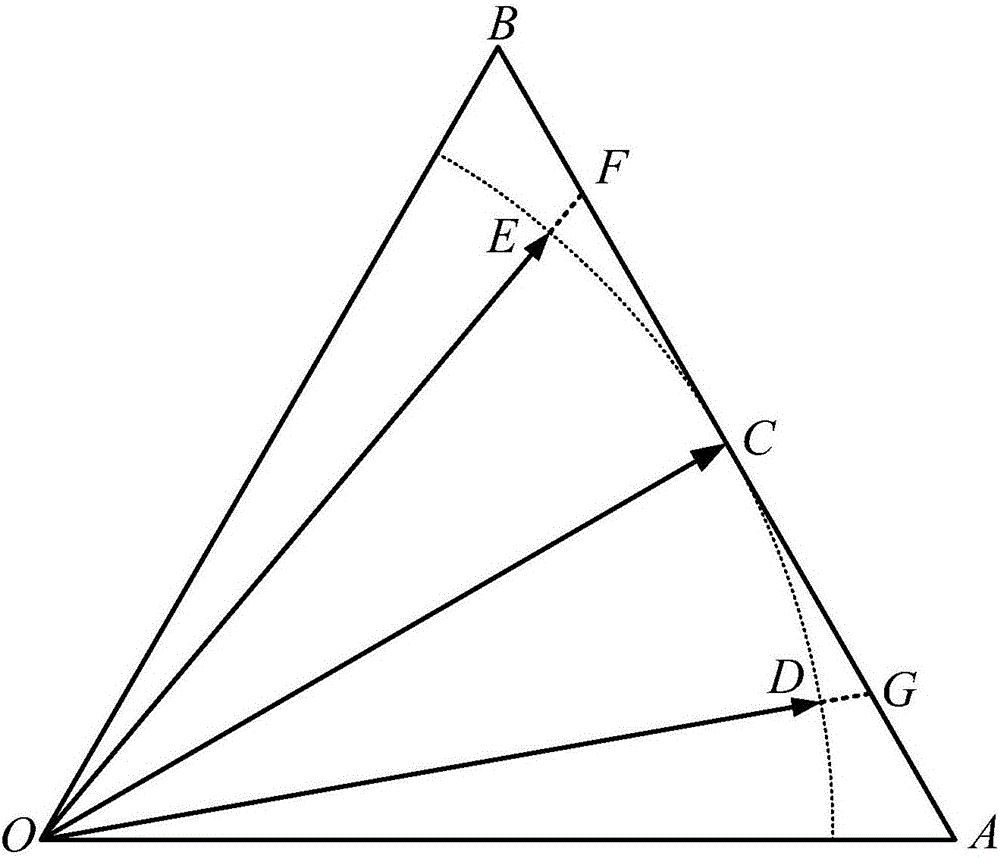

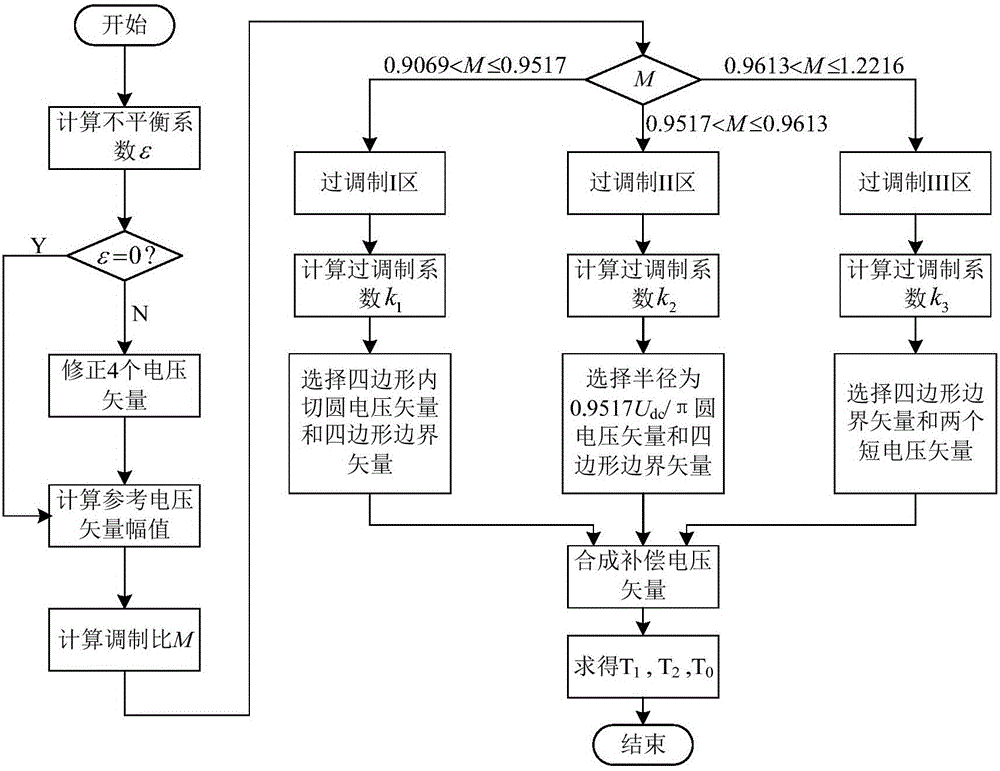

SVPWM (Space Vector Pulse Width Modulation) synchronous modulation/overmodulation method of high-power AC transmission system

InactiveCN106301149ARealize online correctionHarmonic reductionAC motor controlSynchronous motorVoltage vector

The invention provides a SVPWM (Space Vector Pulse Width Modulation) synchronous modulation / overmodulation method of a high-power AC transmission system. The SVPWM synchronous modulation / overmodulation method comprises the following steps of dividing a modulation region to a linear modulation region, an overmodulation region I and an overmodulation region II according to a modulation ratio; calculating a first modulation ratio corresponding to a boundary of the linear modulation region and the overmodulation region I, a second modulation ratio corresponding to a boundary of the overmodulation region I and the overmodulation region II and maximum modulation ratio corresponding to an upper limit of the overmodulation region II by using a basic bus clamping strategy according to number and positions of sampling points in a fan-shaped region; determining a modulation coefficient according to the modulation ratios, determining a weighting coefficient of synthesis compensation voltage vector according to the modulation coefficient, and synthesizing compensation voltage vectors of the overmodulation region I and the overmodulation region II; and calculating action time of two effective voltage vectors and a zero vector required by the synthesis compensation voltage vector for PWM (Pulse Width Modulation) by using a volt-second balance pricinple. By the SVPWM synchronous modulation / overmodulation method, a high-power inverter can be smoothly transitioned to a six-beat wave working state from linear modulation.

Owner:DALIAN UNIV OF TECH

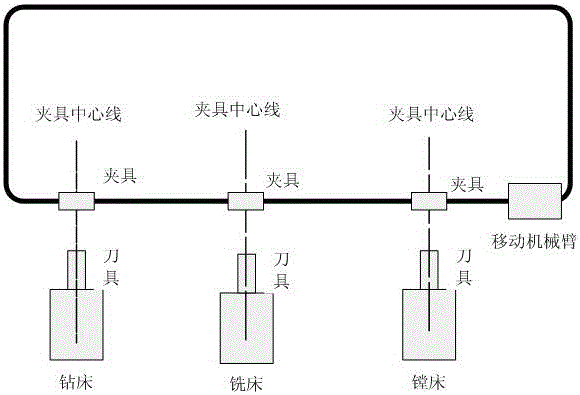

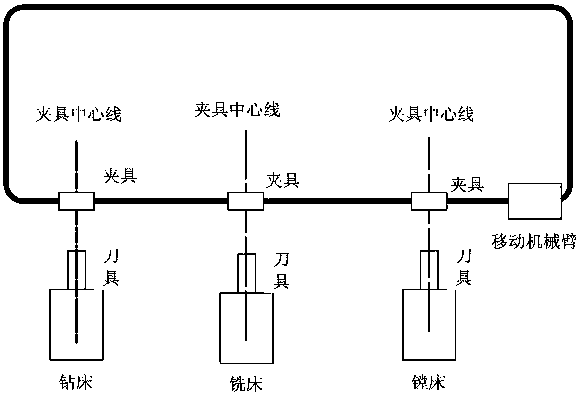

Multi-coordinate machining center combination method based on vision and movable mechanical arm

ActiveCN105058168ARealize online correctionRealize positioning controlMeasurement/indication equipmentsLaser rangingEngineering

The invention provides a multi-coordinate machining center combination method based on vision and a movable mechanical arm, and aims to overcome the large technical defect that a movable robot, a boring machine, a milling machine, a drilling machine and the like cannot be directly combined into a multi-coordinate machining center. The method comprises the steps that machining tasks and procedures are set on the movable mechanical arm, the boring machine, the milling machine and the drilling machine; a movable mechanical arm rail and clamps are arranged, a CCD and a laser ranging device or a connect camera is arranged on the movable mechanical arm, and a plurality of light mark points are arranged on the boring machine, the milling machine and the drilling machine towards the movable mechanical arm rail; then a workpiece to be machined is moved to a preset position by the movable mechanical arm through multi-joint control of the movable mechanical arm; and meanwhile, online locating monitoring and error correction are carried out in the machining process, fault alarms are given to a machining system, and multi-coordinate machining center combination is achieved. The great technical aim of directly combining the mobile robot, the boring machine, the milling machine, the drilling machine and the like into the multi-coordinate machining center is achieved.

Owner:XIAN FEISIDA AUTOMATION ENG

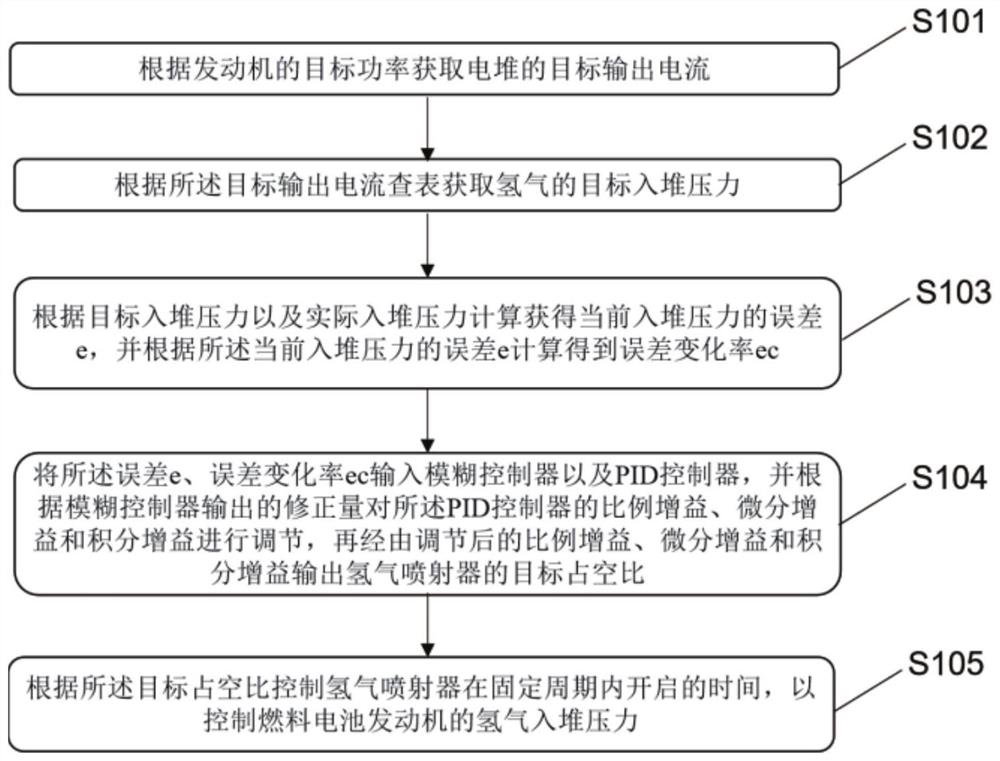

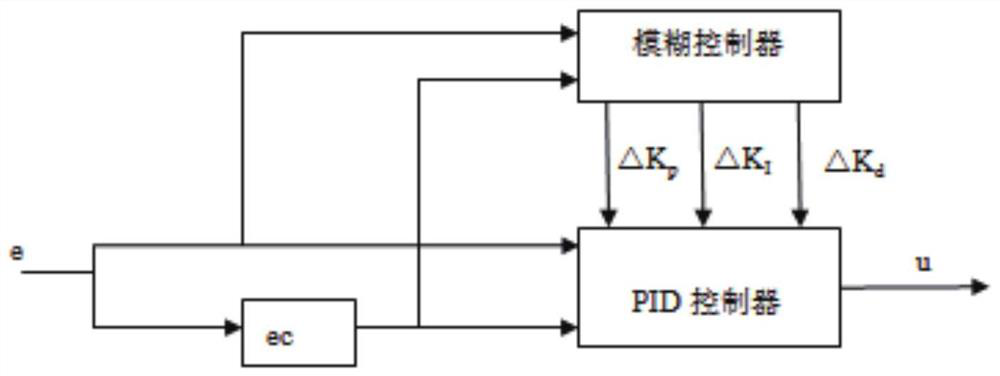

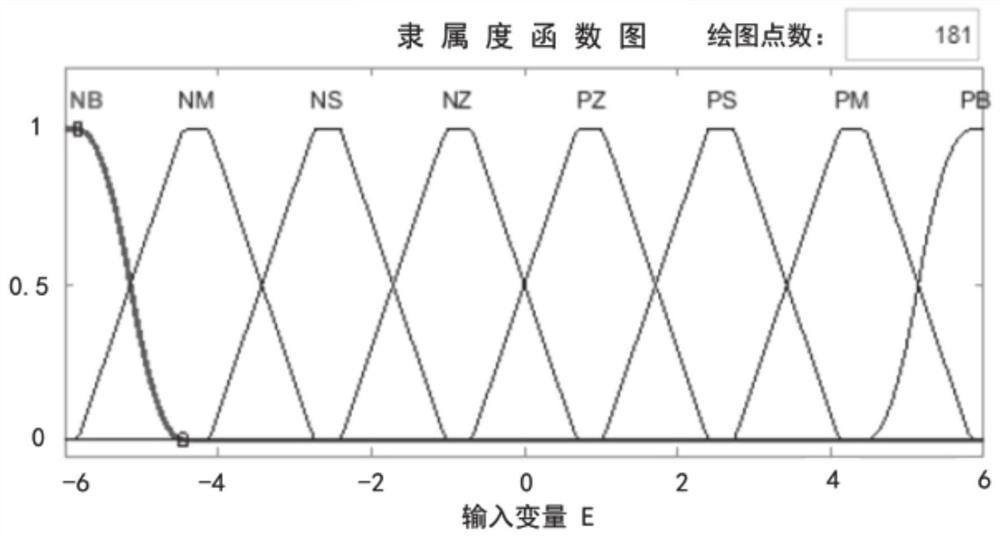

Fuel cell engine hydrogen in-pile pressure control method, device and equipment

PendingCN113093524ARealize online correctionThe stacking pressure is constantControllers with particular characteristicsFuel cellsStart time

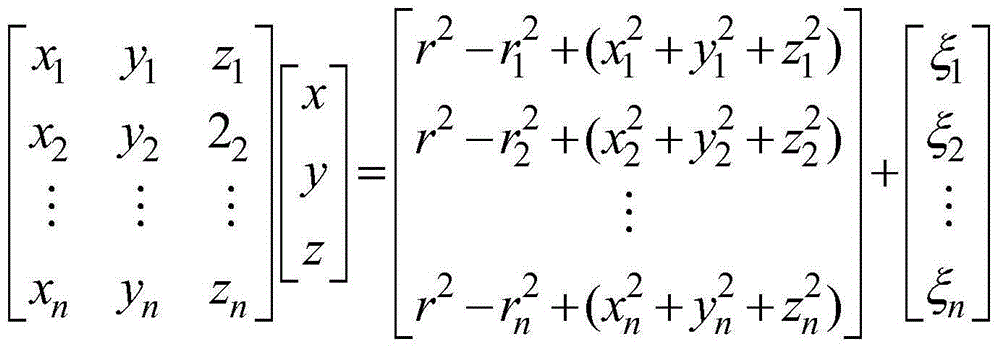

The invention provides a fuel cell engine hydrogen stack entering pressure control method, device and equipment. The method comprises the following steps of acquiring a target output current of a stack according to a target power of an engine; obtaining target in-pile pressure of hydrogen according to the target output current; calculating according to the target in-pile pressure and the actual in-pile pressure to obtain an error e, and calculating according to the error e to obtain an error change rate ec; the error e and the error change rate ec being inputted into a fuzzy controller and a PID controller, the proportional gain, the differential gain and the integral gain of the PID controller being adjusted according to the correction outputted by the fuzzy controller, and the target duty ratio of the hydrogen injector is outputted through the adjusted proportional gain, differential gain and integral gain; and controlling the starting time of the hydrogen injector in the fixed period according to the target duty ratio. According to the method, the hydrogen in-pile pressure can be kept constant under the condition that the drain valve is frequently opened and closed, the adjustment time is shorter, and the overshoot is smaller.

Owner:北京氢澜科技有限公司

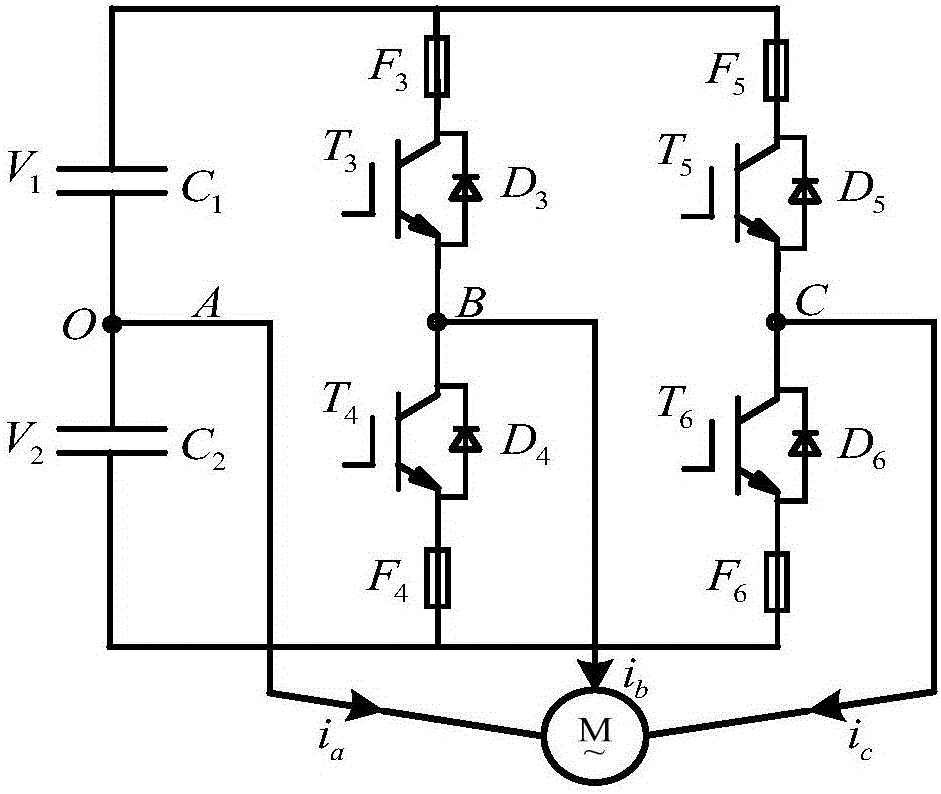

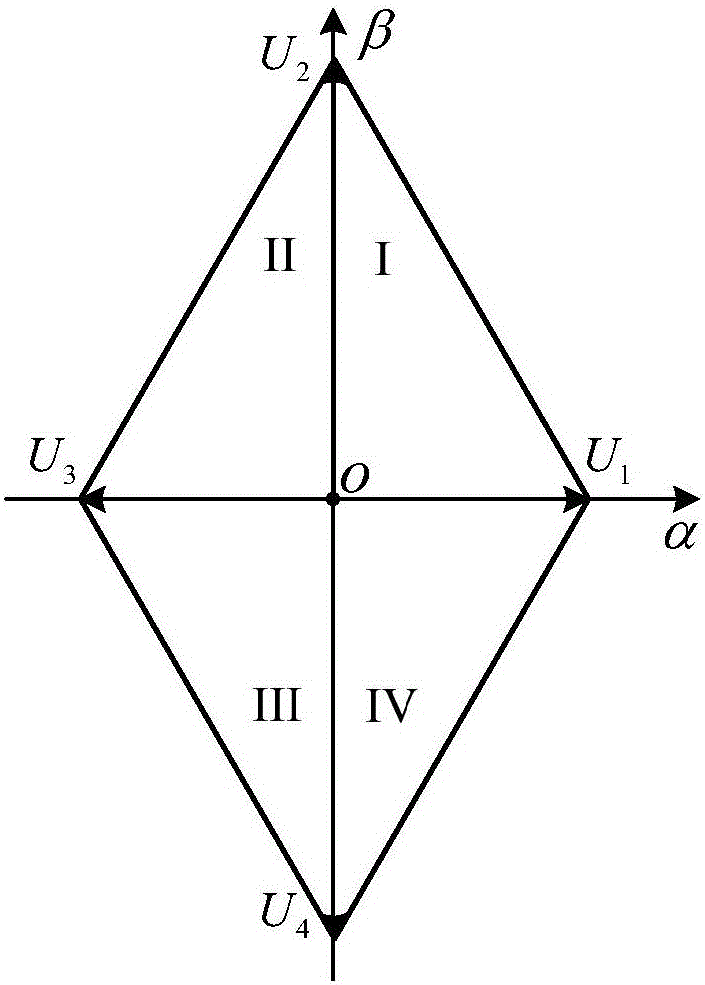

Method and system for improving DC voltage utilization ratio of three-phase and four-switch fault-tolerant inverter

ActiveCN106208787ARealize online correctionImprove DC voltage utilizationAc-dc conversionPower inverterElectromagnetic torque

The invention discloses a method and system for improving the DC voltage utilization ratio of a three-phase and four-switch fault-tolerant inverter. The method comprises the steps of (S1) calculating and judging whether an unbalanced coefficient epsilon of capacitor voltage at a DC side is zero or not, if so, executing the step (S3), or else, executing the step (S2); (S2) correcting four effective voltage vectors of the four-switch fault-tolerant inverter and calculating corrected voltage vector amplitudes respectively; (S3) calculating a reference voltage vector amplitude; (S4) calculating a modulation ratio parameter M on the basis of the reference voltage vector amplitude; (S5) carrying out modulation area division on a complex plane formed by the four voltage vectors; (S6) setting overmodulation algorithms corresponding to various areas respectively and selecting corresponding vectors to synthesize corresponding compensation voltage vectors; and (S7) calculating action time of two effective voltage vectors corresponding to the compensation voltage vectors and an equivalent zero vector to finish PWM modulation. By the method and the system, the DC voltage utilization rate of the inverter is improved; meanwhile, electromagnetic torque is improved; output harmonics are reduced; and the method is simple and easy to implement in engineering.

Owner:DALIAN UNIV OF TECH

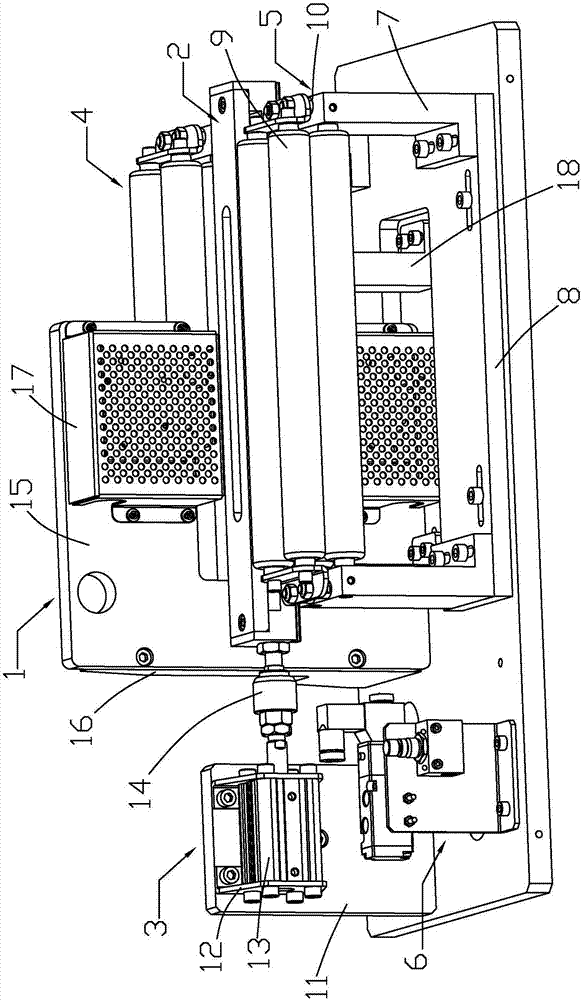

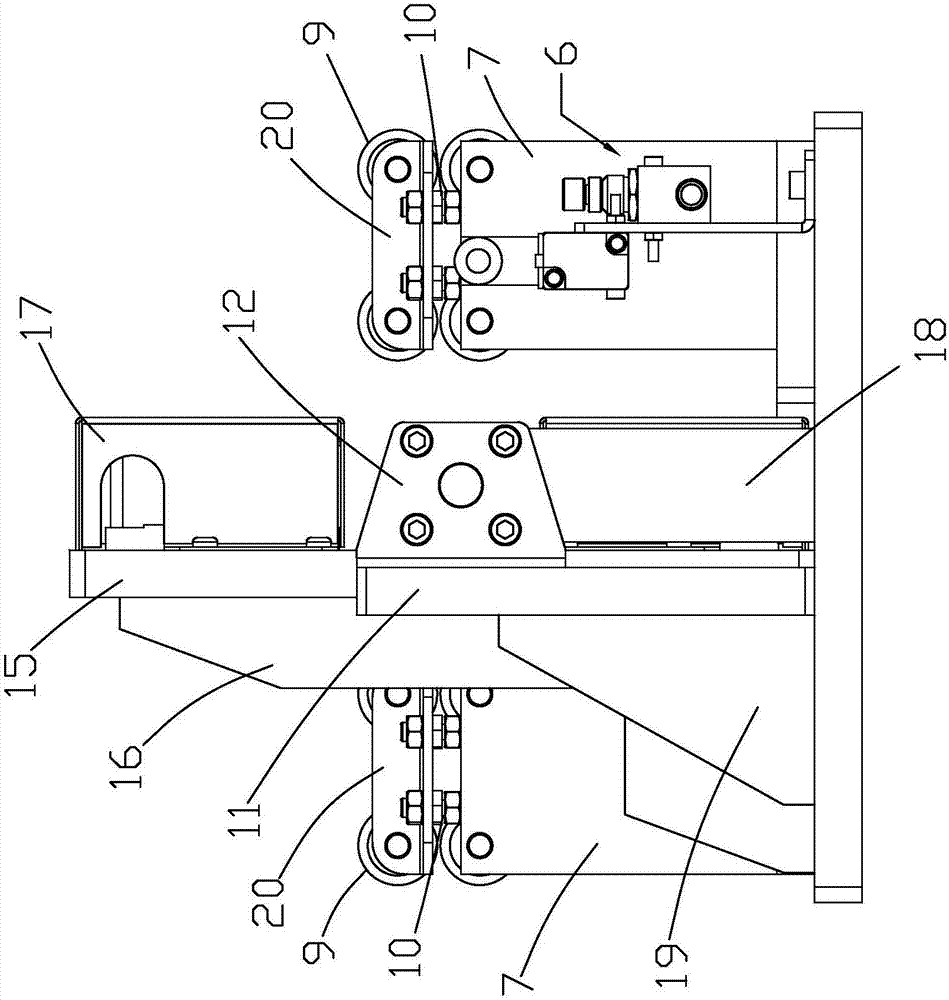

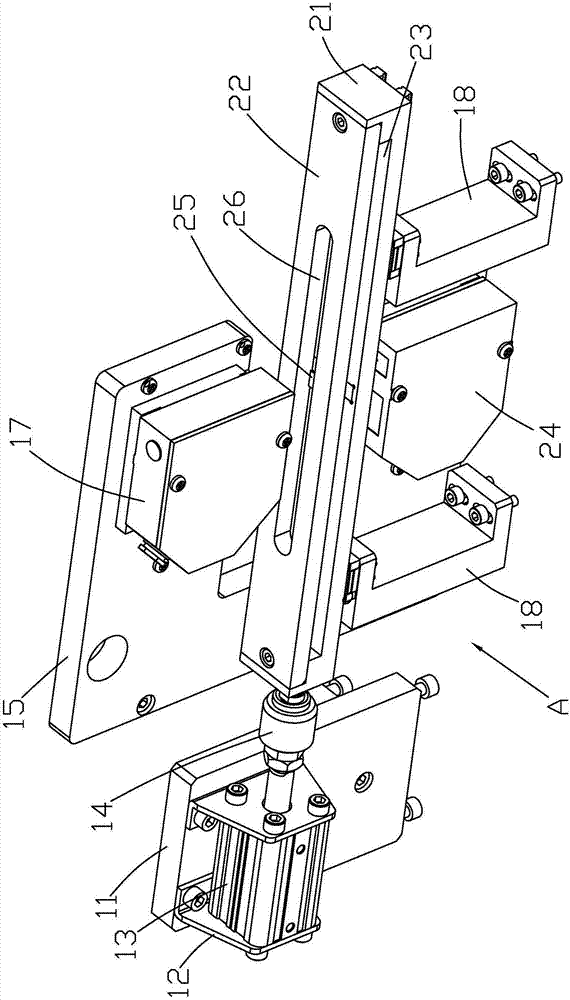

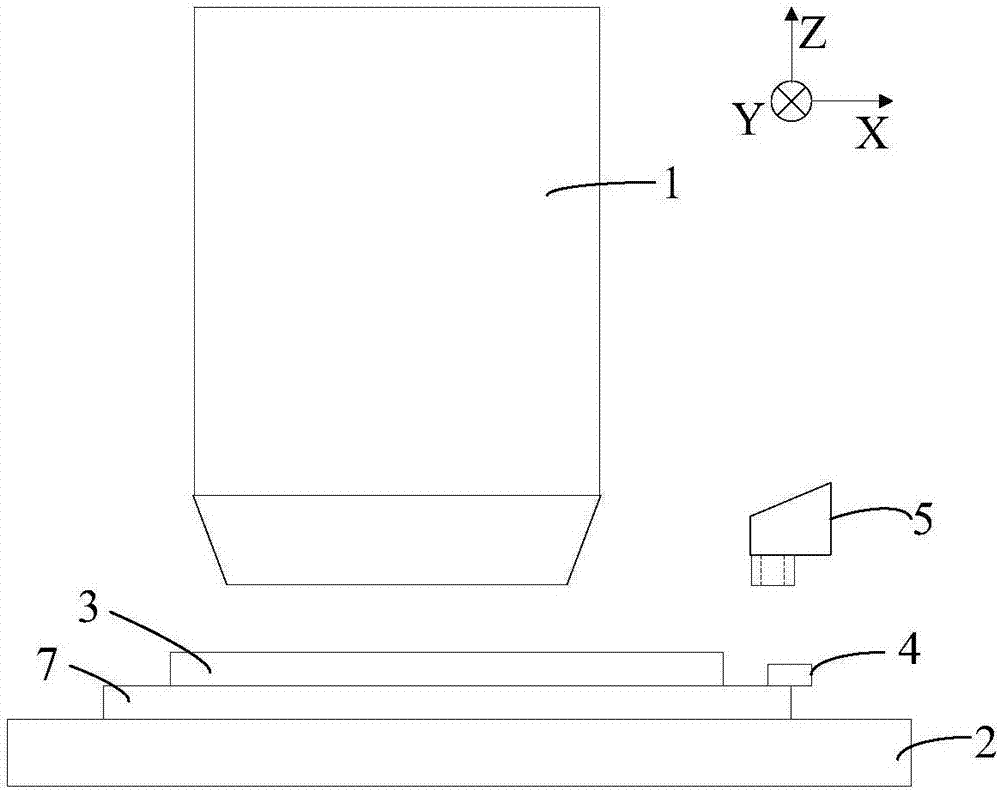

Measurement device applied to online thickness detection and correction of stator or rotor

The invention discloses a measurement device applied to online thickness detection and correction of a stator or rotor. The measurement device comprises a laser adjustment mechanism, a gauge block adjustment mechanism, an air cylinder motion mechanism, an electromagnetic valve installation assembly, a first roller guide assembly and a second roller guide assembly, wherein the laser adjustment mechanism comprises a laser head installing vertical plate, a first laser head housing and a second laser head housing; laser heads are arranged in the first laser head housing and the second laser head housing; the gauge block adjustment mechanism comprises a correction device and a linear guide rail installation base plate; a correction device is movably connected with the upper part of the linear guide rail installation base plate; one end of the correction device is connected with the air cylinder motion mechanism through a floating joint; and the electromagnetic valve installation assembly is arranged at the front end of the air cylinder motion mechanism. The measurement accuracy of the measurement device is greatly improved, the measurement error caused by a temperature change is reduced, regular online correction can be achieved, and the measurement device is simple in structure, convenient to use and high in equipment applicability.

Owner:NINGBO JIUZONG INTELLIGENT TECH

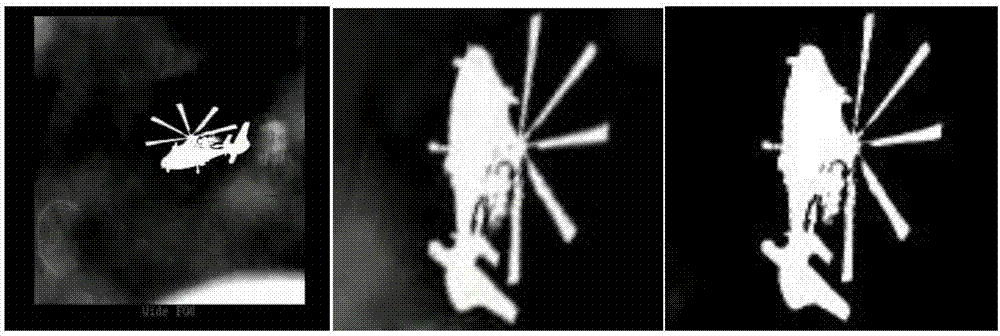

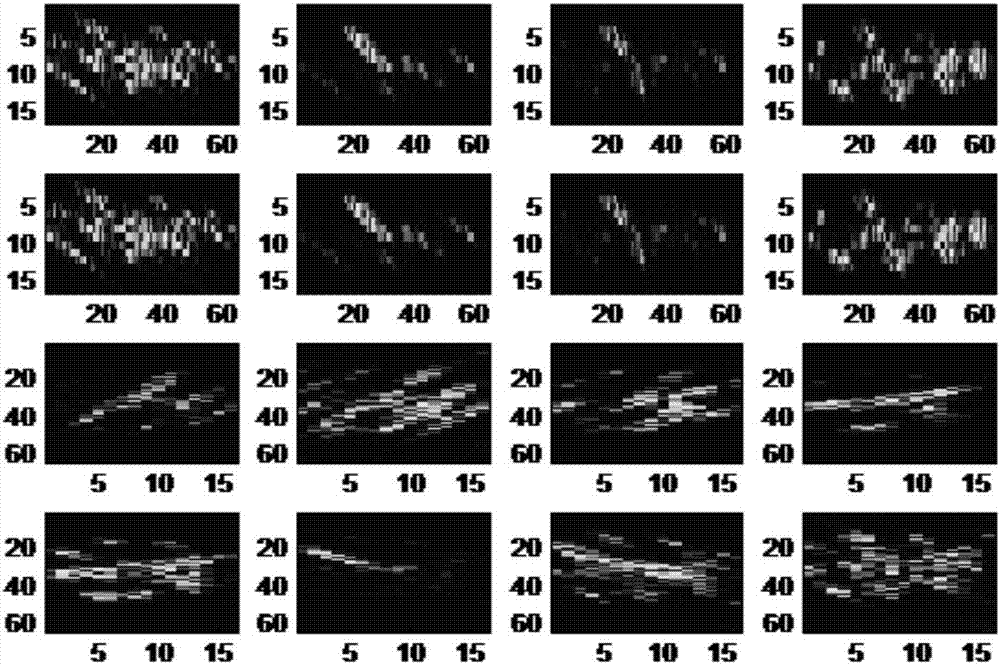

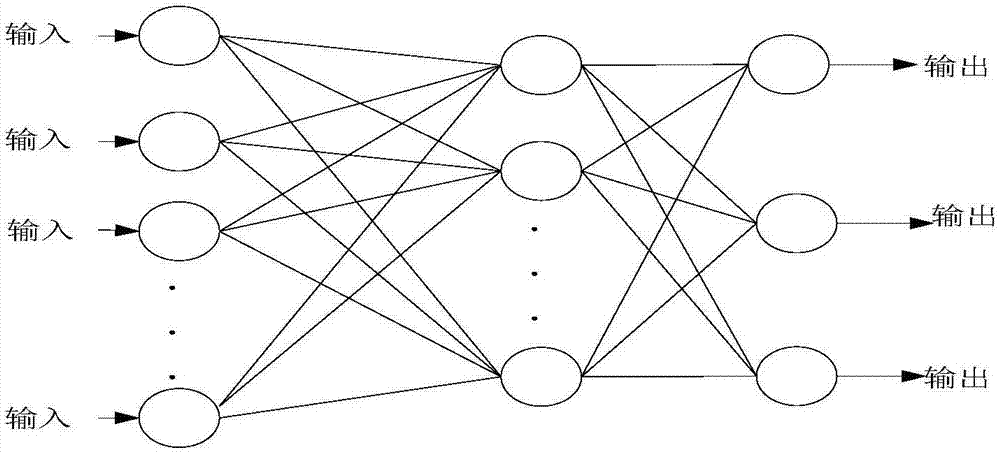

Target identification method based on geometry reconstruction and multi-scale analysis

InactiveCN107516069AGood for preprocessing and extractionApproximate energy is goodScene recognitionNeural learning methodsAlgorithmContourlet

The invention relates to a target identification method based on target geometry reconstruction and a multi-scale analysis theory. The method is characterized by firstly, reconstructing a target attitude, which includes flight attitude normalization and image preprocessing; then using Contourlet conversion to extract low frequency and high frequency characteristic vectors of an image and taking the vectors as a basis input training set and a correction base entry training set of a BP neural network; and finally, designing the BP neural network, designing a BP neural network correction model, using high frequency detail data to correct low frequency contour data, and determining an input and output layer, a middle layer number and an algorithm, wherein a trained network possesses an identification capability. Different types of nonoverlapping picture materials in an infrared picture database are selected to test precision of the identification method, and a result display identification rate is high and identification time is short. The method of the invention possesses high engineering applicability and has a certain meaning and a wide application prospect.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

Spectrum detection device of element components in haze and method of device

PendingCN110412017ARealize continuous online collectionImprove stabilityAnalysis by thermal excitationParticle suspension analysisParticulatesAutomatic control

The invention relates to device for conducting spectrum detection on element components in haze on spot with high sensitivity and high stability and a method of the device, and relates to the field ofatmosphere mass detection. According to the device, through a stepping motor which is automatically controlled, roll-type filter paper is driven, and then particulate matter in the haze is continuously collected online; by spraying enhancing powder and applying carrier gas, the LIBS signal strength is enhanced, and high detection sensitivity of a system is achieved; through colloid components andthe heating function of the enhancing powder, the attachment stability of the particulate matter is improved, and the quantitative detection precision of the system is achieved; by designing a collection area and a correction area on the roll-type filter paper at an interval, detection signals of the system are corrected on line, and finally, according to the data obtained through LIBS detectionand through correction, the final qualitative and quantitative analysis result of the element components in the haze is obtained. By means of the device, the types and contents of elements in the atmospheric suspended particulate matter can be subjected to rapid, continuous, multi-component and high-sensitivity detection, and the device is suitable for on-spot, online and high-precision atmospheremass analysis.

Owner:QINGDAO UNIV

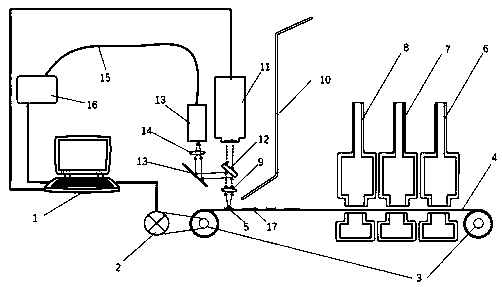

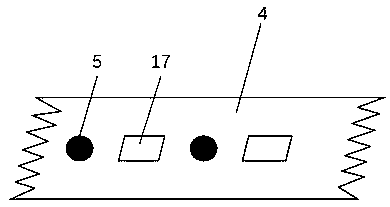

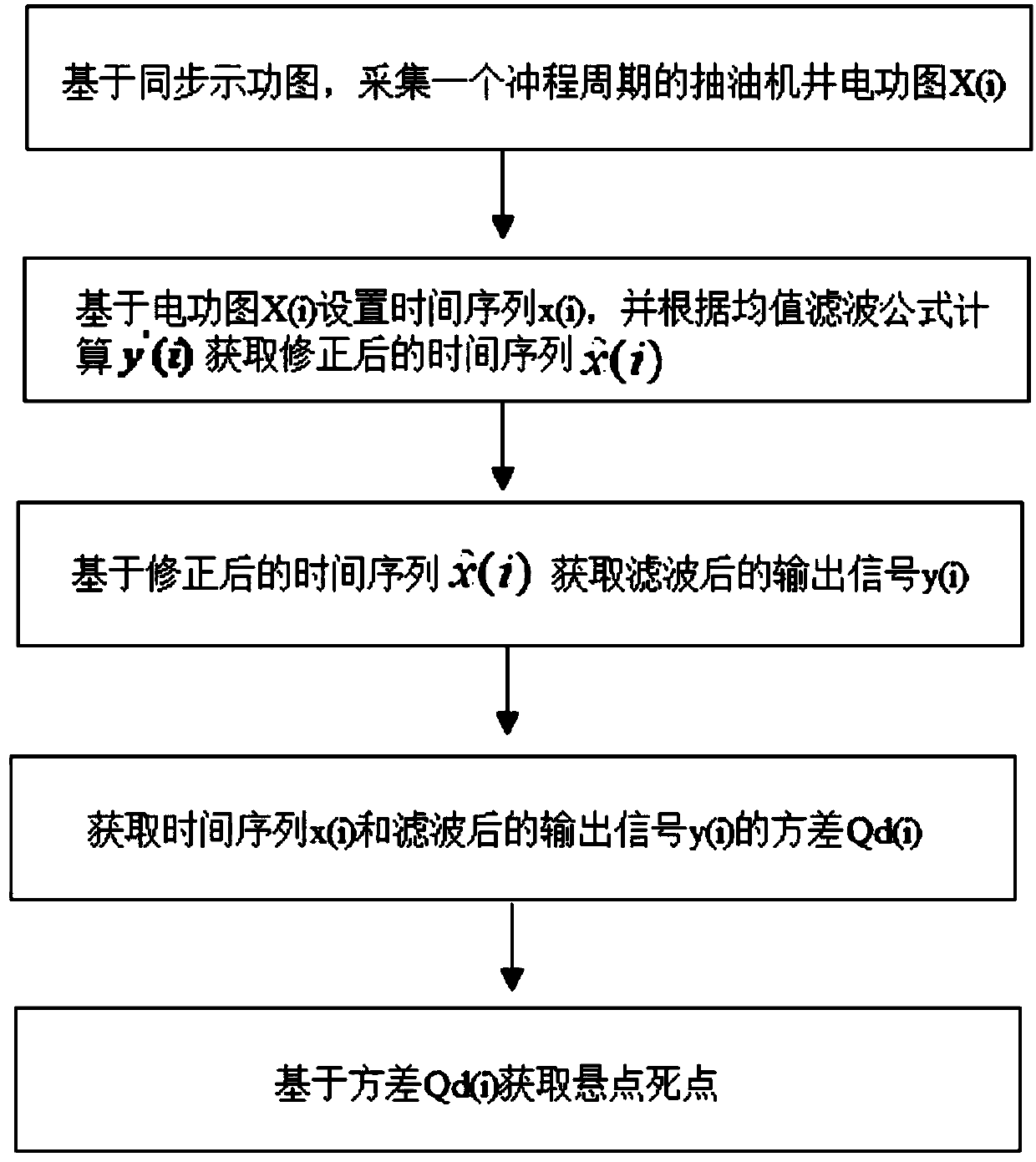

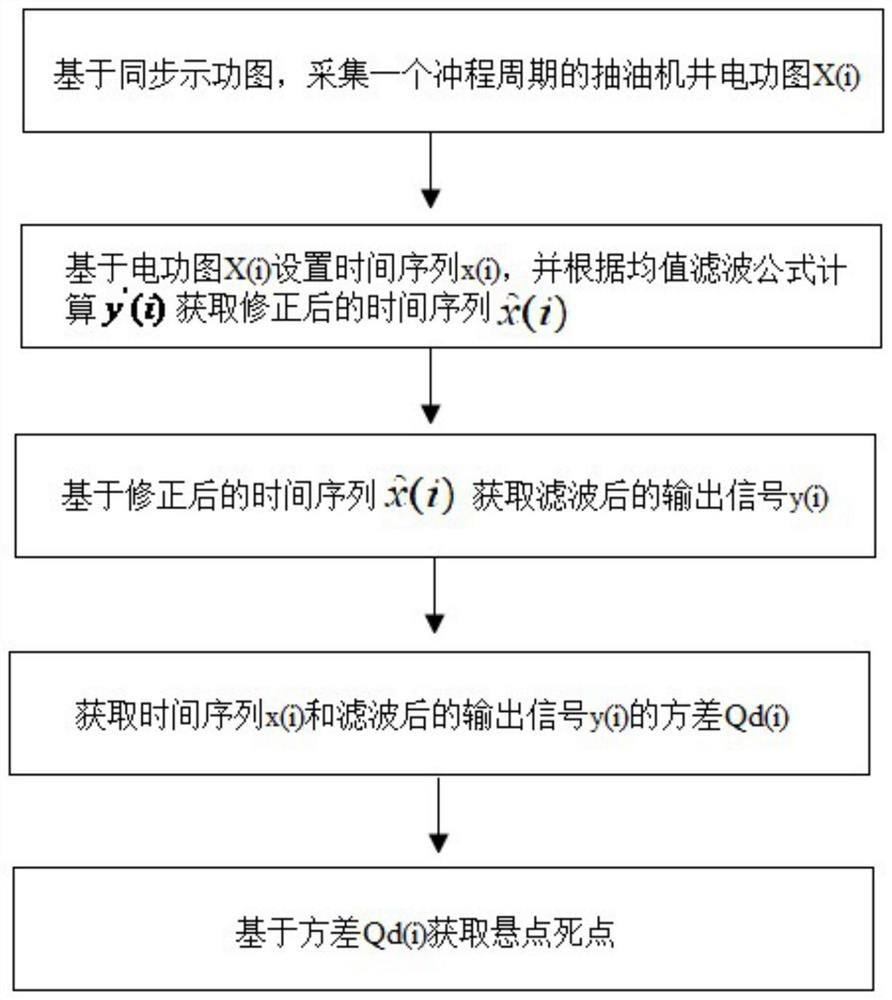

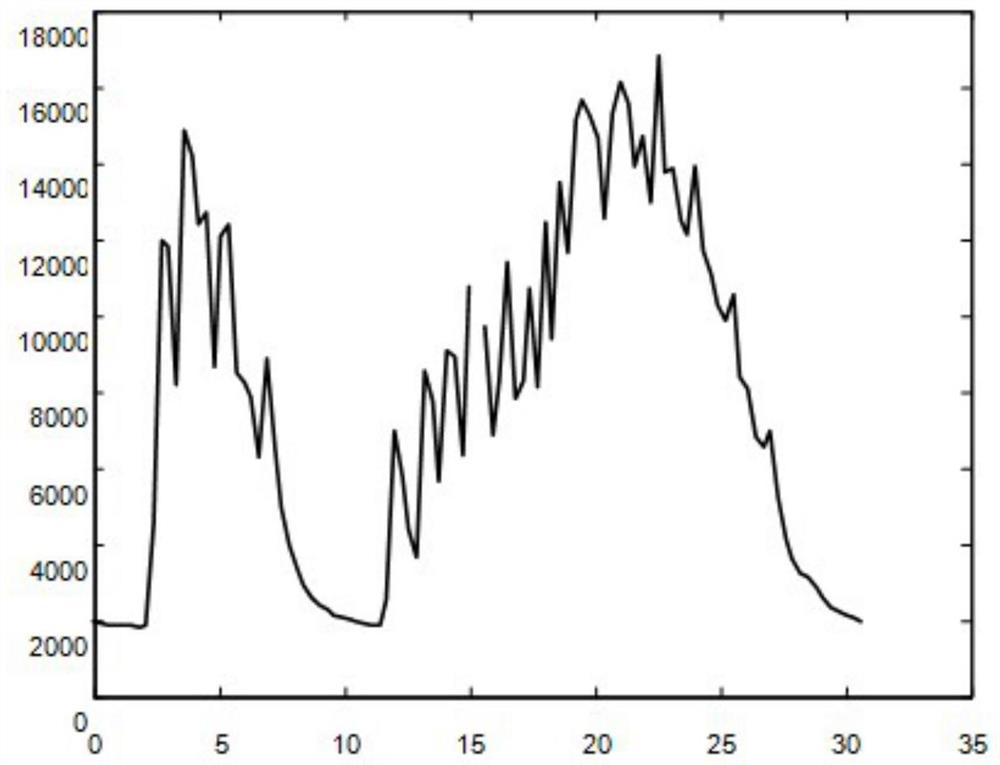

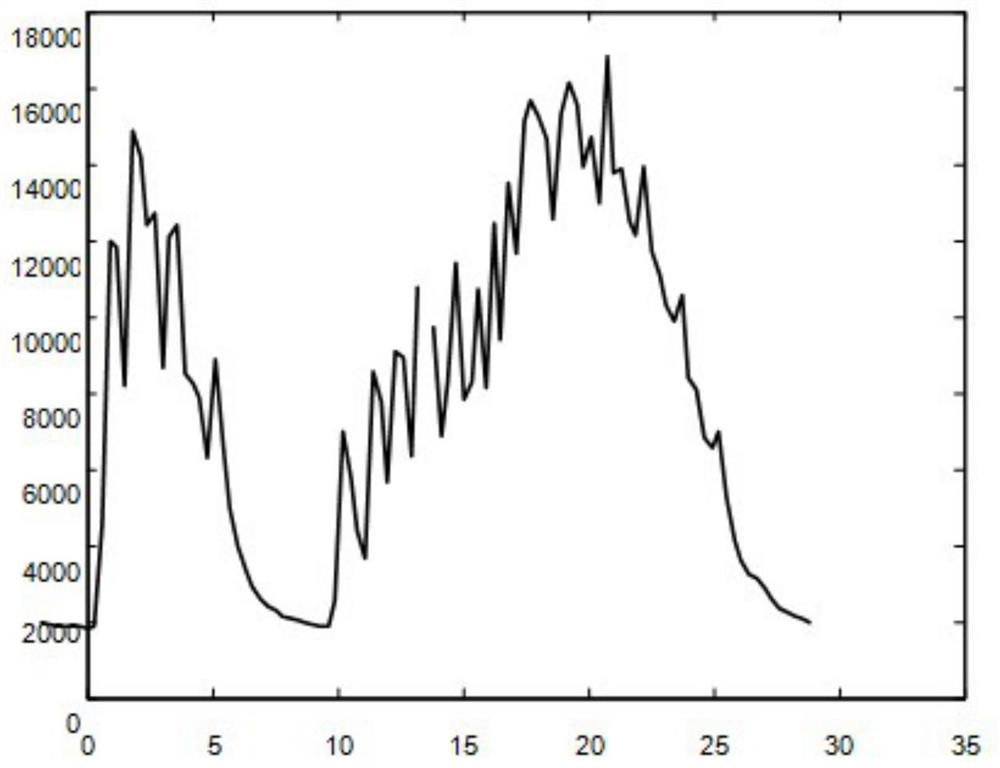

Method and a system for detecting rod pumped well polish rod suspension center dead point

ActiveCN110410057AImprove working condition monitoring abilityRealize online correctionSurveyDrilling rodsIndicator diagramTime series

The invention discloses a method and system for detecting a rod pumped well polish rod suspension center dead point. The detecting method comprises the steps that a rod pumped well electric work diagram X(i) in one stroke period is collected based on a synchronous indicator diagram; a time series x(i) is set based on the electric work diagram X(i), y'(i) is calculated according to a mean filteringformula, a corrected time series is obtained, and a filtered output signal y(i) is obtained based on the corrected time series; a variance Qd(i) of the time series x(i) and the filtered output signaly(i) is obtained; and the suspension center dead point is obtained based on the variance Qd(i). The method and system have the advantages that online correction of the electric work diagram and the indicator diagram of a rod pumped well can be achieved, real-time detection of the suspension center dead point is helpful for judging whether a displacement sensor of the indicator diagram is normal or not, the monitoring capability of the rod pumped well working condition is improved, and the method is high in safety and convenient in actual application installation, operation and maintenance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electronic voltage transformer using data fusion technology and error calibration method thereof

The invention discloses an electronic voltage transformer using data fusion technology and an error calibration method thereof. The error calibration method comprises the following steps of: acquiring a secondary measured voltage by using a capacitive voltage divider and a sampling resistor R, accessing the voltage to a data acquisition processor for sampling, and tracing the frequency of the voltage; accessing a signal of a temperature sensor to the data acquisition processor, and computing the temperatures of measuring points; dynamically computing a divided voltage ratio of the capacitive voltage divider according to the temperature variation of the measuring points by using data acquisition device processing software so as to modify a transformation ratio error of the transformer; dynamically computing phase deviation according to signal frequency variation by using the data acquisition device processing software so as to modify a phase error; and outputting a digital sampling value through an optical fiber interface. The device is simple in structure, safe and practical; errors caused by manufacturing factors, temperature and signal acquisition circuits and the like can be effectively modified and restrained; and the measuring accuracy, temperature stability and transient performance of the electronic voltage transformer according to a capacitive voltage division principle are improved.

Owner:NARI TECH CO LTD +1

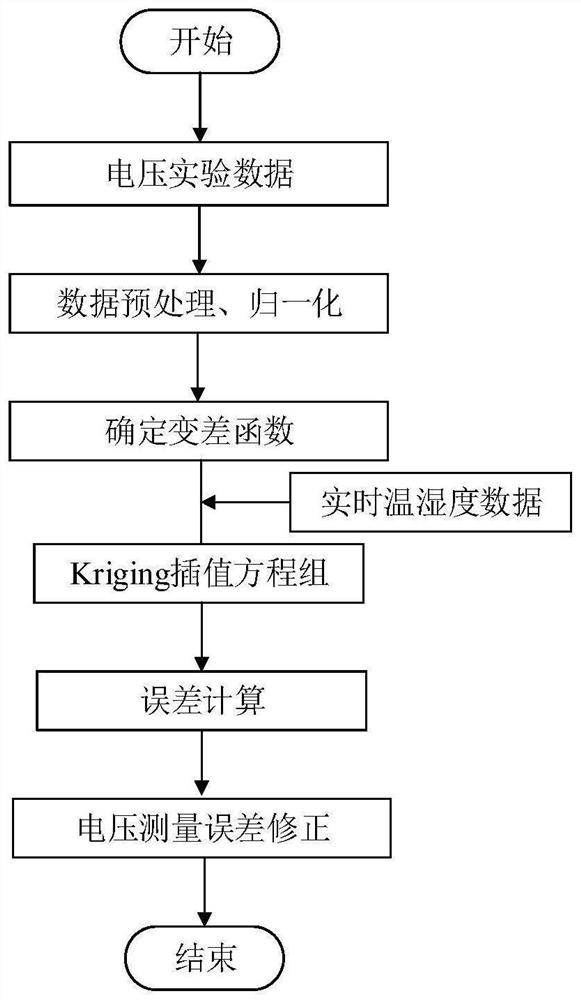

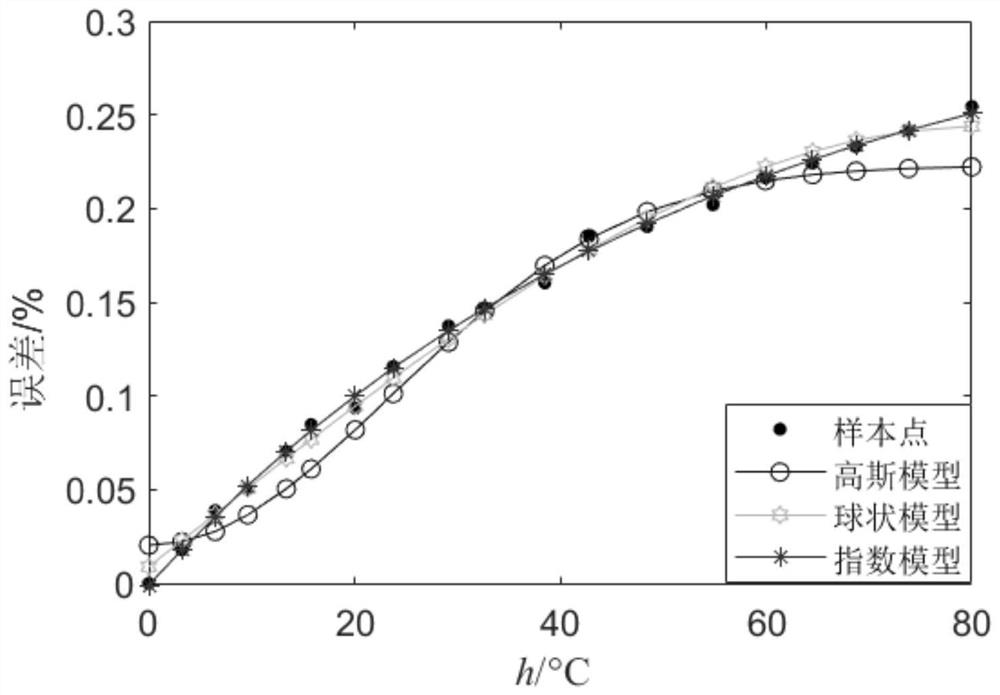

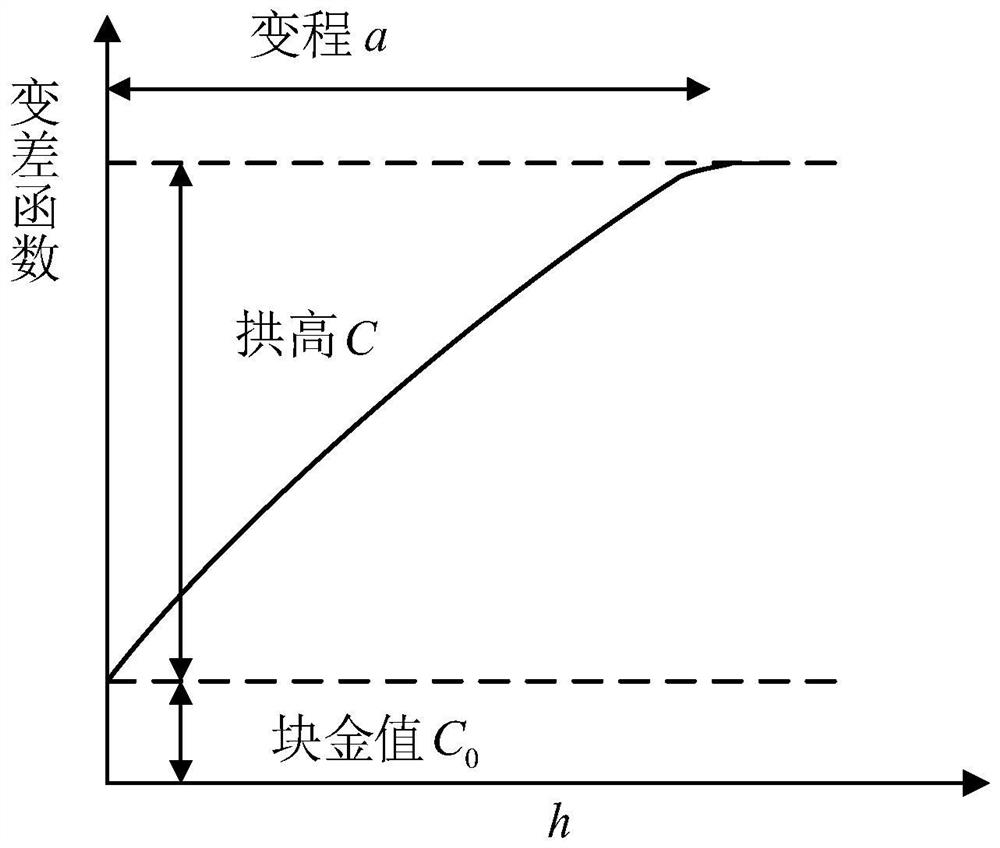

Direct current charging pile voltage error compensation method, system and device and readable storage medium

PendingCN114290939AImprove accuracyImplement interpolationCharging stationsElectric vehicle charging technologyMechanicsDirect current

The invention discloses a DC charging pile voltage error compensation method, system and device and a readable storage medium, and the method comprises the steps: taking an error as a dependent variable, and taking temperature and humidity as independent variables to carry out voltage standard meter measurement, and obtaining an error value under the condition that the temperature and humidity are taken as dependent variables; establishing a variation function model by taking the temperature, the humidity and the obtained error value as sample values; according to the humidity and the temperature collected in real time, Kriging interpolation is carried out to obtain a calculation error, a voltage measurement value of the direct current charging pile to be compensated is corrected according to the calculation error to obtain a corrected voltage value, and error compensation under any temperature and humidity conditions on site is realized by adopting Kriging interpolation. The accuracy of voltage measurement and electric energy metering is improved, and a theoretical basis is provided for large-scale remote online monitoring of the direct-current charging pile.

Owner:STATE GRID XINJIANG ELECTRIC POWER CO ECONOMIC TECH RES INST +1

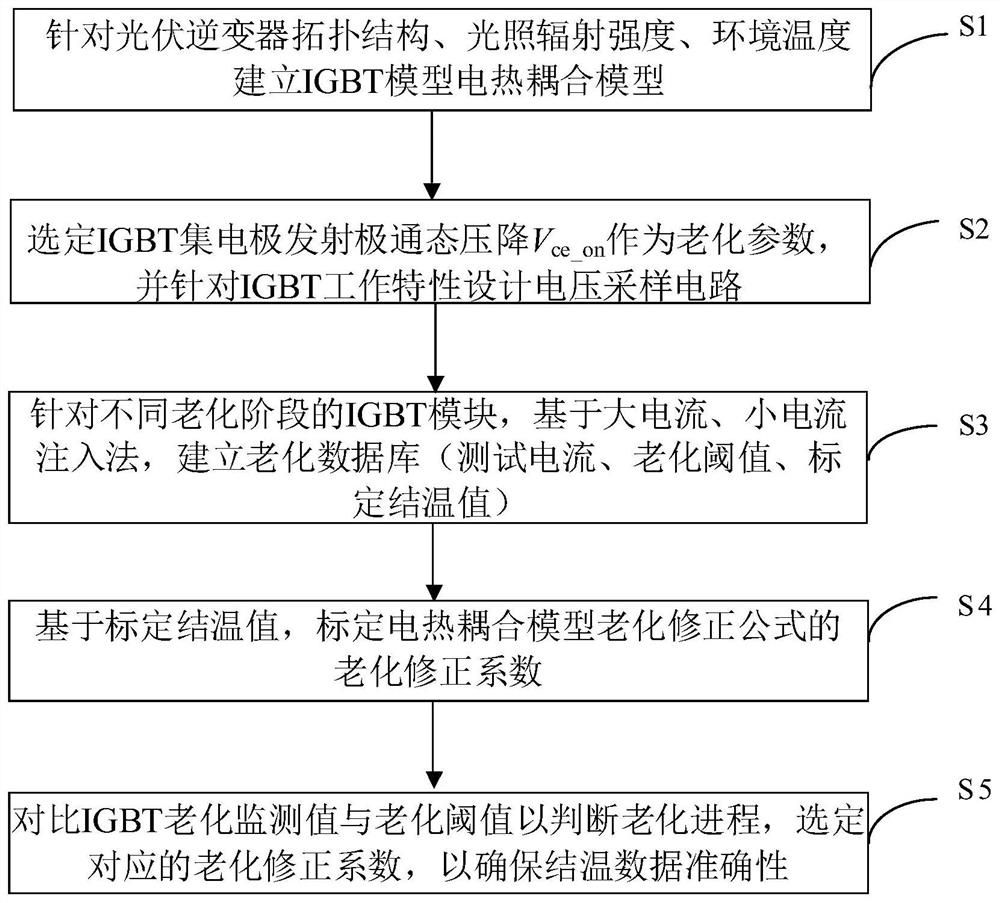

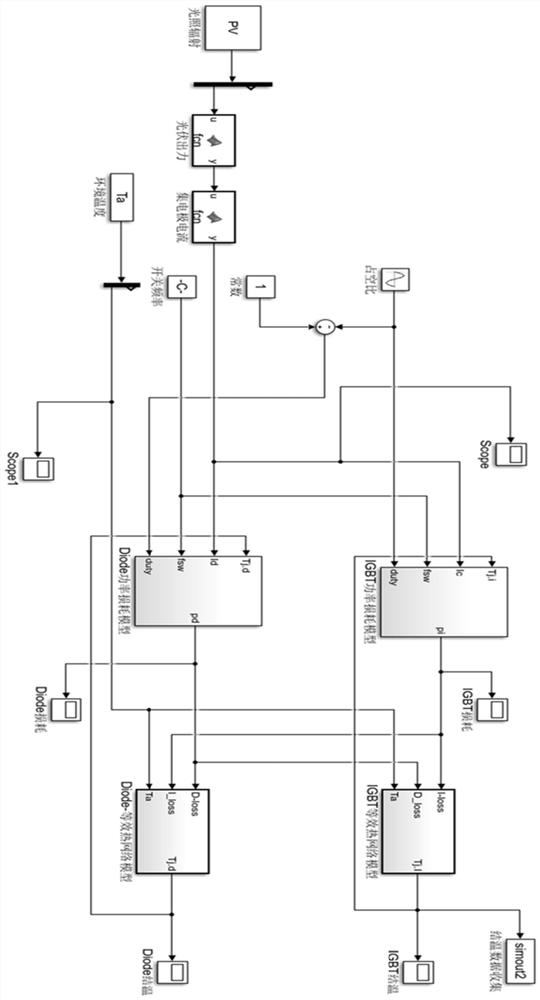

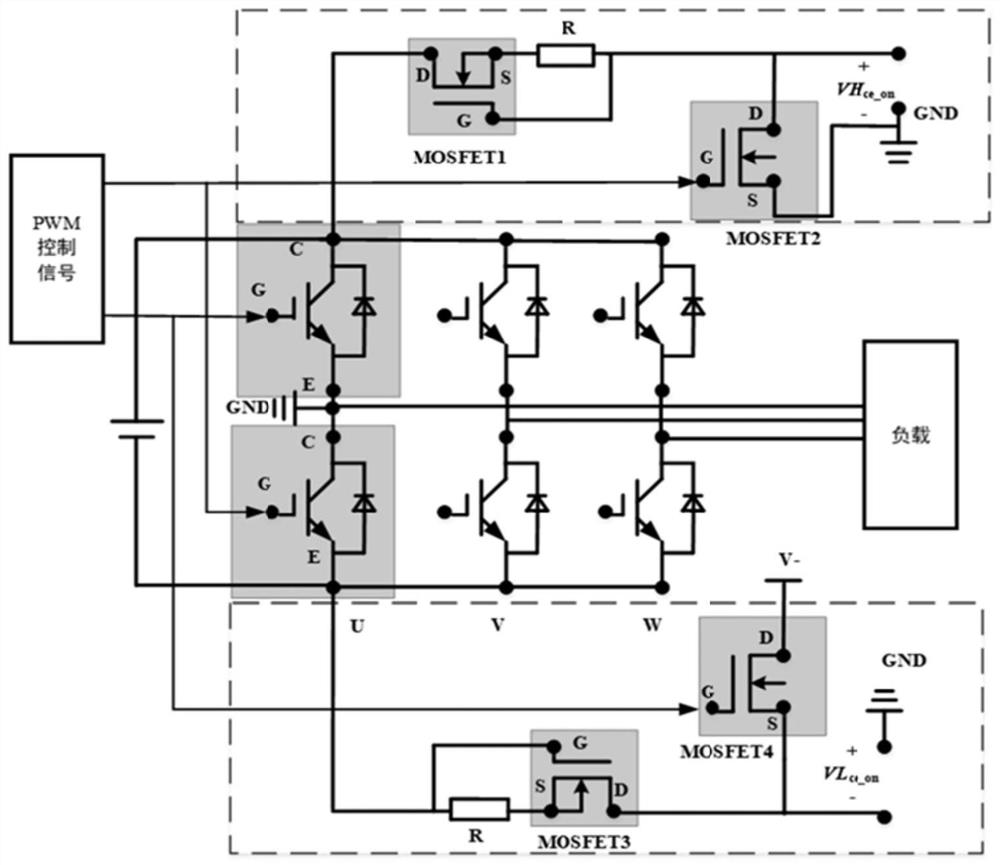

Photovoltaic inverter IGBT junction temperature online correction method and system considering aging

ActiveCN112906333ARealize online correctionGuarantee authenticityAc-dc conversionPhotovoltaicsJunction temperatureHemt circuits

The invention discloses a photovoltaic inverter IGBT module junction temperature online correction method and system considering an aging process, and belongs to the field of power electronic equipment core device reliability, and the method comprises the steps: building an IGBT model electrothermal coupling model according to a photovoltaic inverter topological structure, illumination radiation intensity and environment temperature; selecting an IGBT collector-emitter electrode on-state voltage drop as an aging parameter, and designing an on-state voltage drop sampling circuit to ensure the measurement precision; aiming at IGBT modules in different aging stages, based on a large-current and small-current injection method, establishing an aging database (test current, an aging threshold value and a calibrated junction temperature value); comparing a junction temperature value output by the electrothermal coupling model with a calibrated junction temperature value, and calibrating an aging process coefficient of an aging correction formula of the electrothermal coupling model; and comparing the IGBT aging monitoring value with the aging threshold value to judge the aging process, and selecting a corresponding aging correction coefficient to ensure the accuracy of junction temperature data.

Owner:WUHAN UNIV

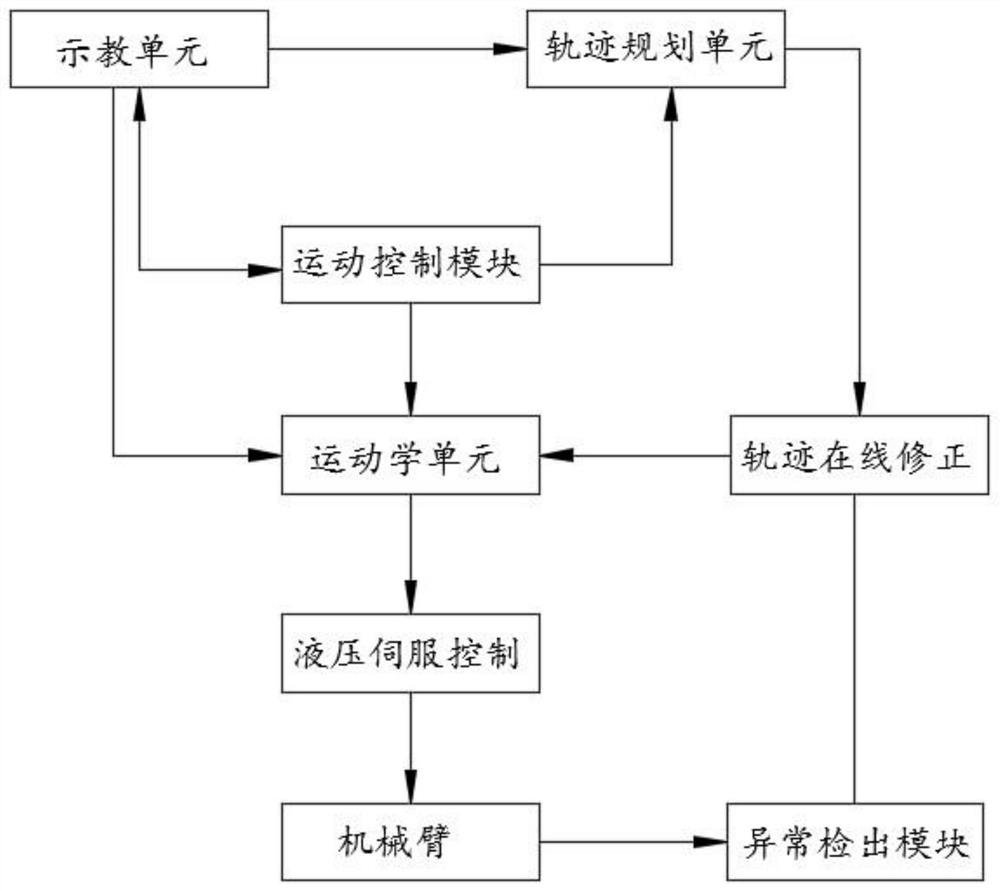

Grabbing arm type trash cleaning robot motion control system

InactiveCN112276911AEasy to controlControl system hardware mainly includes embedded control implementationProgramme-controlled manipulatorHydraulic cylinderControl system

The invention discloses a grabbing arm type trash cleaning robot motion control system. In order to thoroughly clean up trash attached to and wound around grid bars, grab bucket claw teeth of a trashcleaning machine need to stretch into the grid bars of a trash rack, and meanwhile, a grab bucket cannot collide with the trash rack and runs along the grid bars from top to bottom according to a settrack. In the work process of the trash cleaning machine, the running track of the grab bucket needs to be smooth and continuous, and the speed, the accelerated speed, the continuous change of pulsation and the execution efficiency of all joint nodes need to be well controlled. The trash cleaning robot is a plane three-degree-of-freedom series robot, the tail end posture is that the trash cleaningrobot rotates around the axis perpendicular to the plane, a track planning method of a tail end executor of the trash cleaning robot comprises the steps that according to the actual trash cleaning path of the trash cleaning robot, a track planning model is built, the whole path is divided into five stages, path interpolation is conducted through interpolation manners such as sine acceleration anddeceleration and quintic polynomial, and the track of all hydraulic cylinders is smooth and continuous after track planning.

Owner:安徽省六安恒源机械有限公司

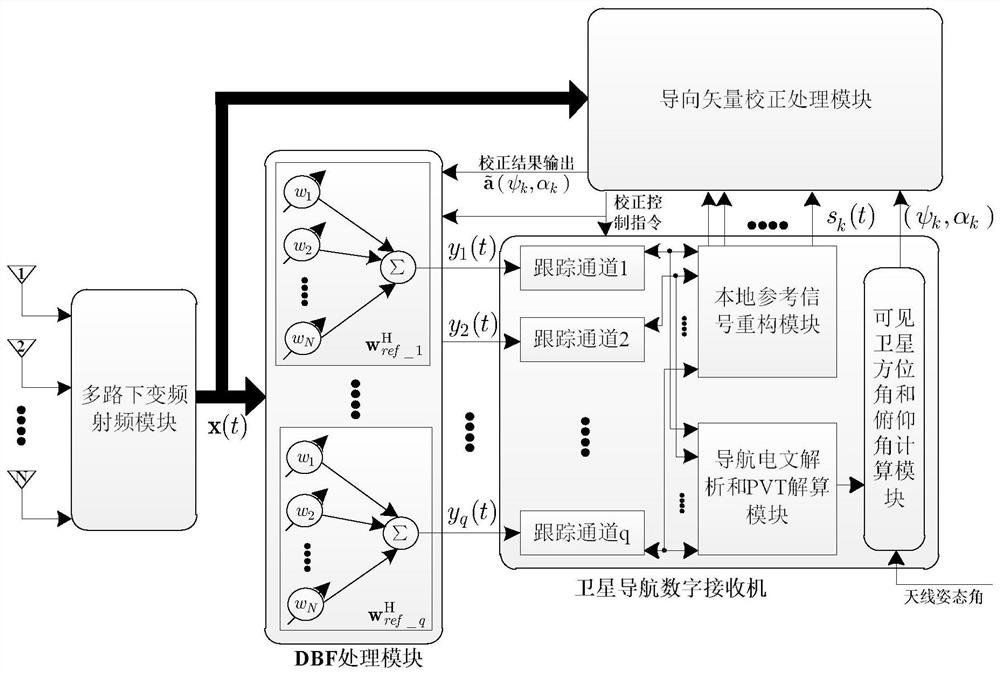

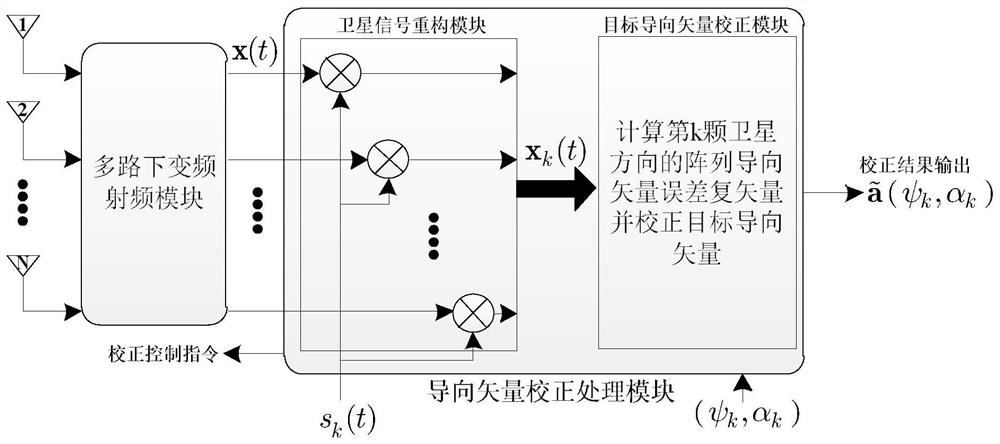

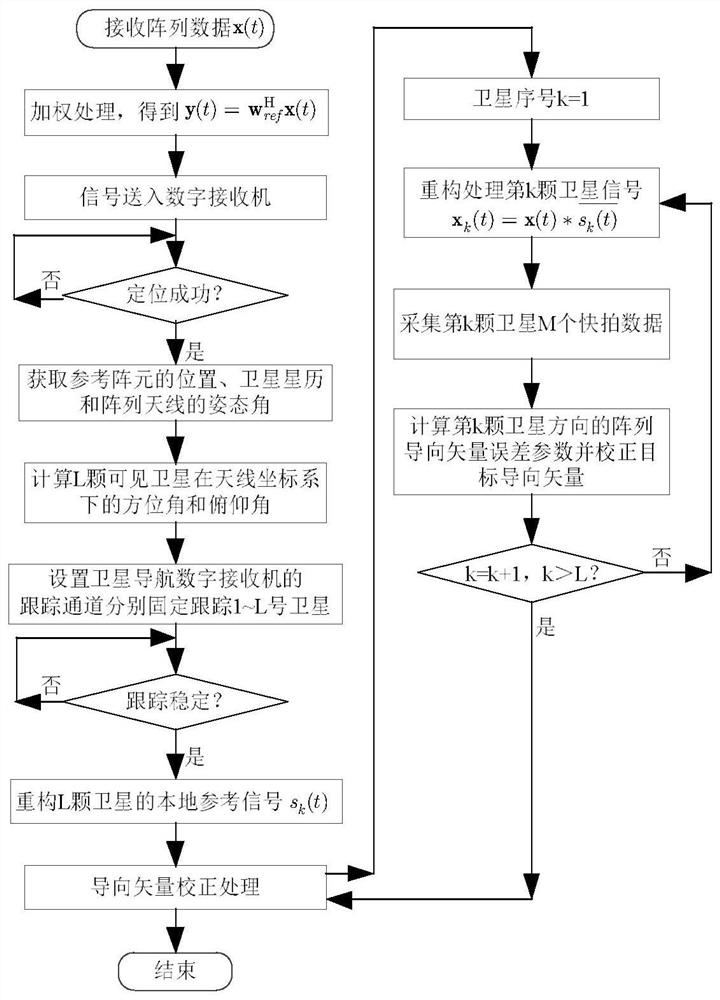

Satellite Navigation Anti-jamming Steering Vector Automatic Correction System

ActiveCN109507698BImprove estimation accuracyRealize automatic correctionSatellite radio beaconingHigh level techniquesAnti jammingIntermediate frequency

The invention discloses a satellite navigation anti-jamming steering vector automatic correction system. Using the invention, the on-site automatic correction of the steering vector can be realized without setting an external calibration source. The invention is realized by the following technical scheme: The module down-converts the received N-channel array antenna RF signals into N-channel intermediate frequency digital signal column vectors, and divides them into two channels, one is sent to the DBF processing module for weighting processing, and the other is sent to the steering vector correction processing module. When the steering vector correction processing module sends a correction control command to the satellite navigation digital receiver and the DBF processing module, the satellite navigation digital receiver and the DBF processing module cooperate with the steering vector correction processing module to perform steering vector correction processing, and the reconstructed kth satellite The satellite's local reference signal and N channels of intermediate frequency digital signals are subjected to correlation despreading processing, and the array steering vector error complex vector in the direction of the kth satellite is calculated and the target steering vector is corrected.

Owner:10TH RES INST OF CETC

A mechanical online dynamic balancing system with built-in spindle

ActiveCN105021352BRealize online correctionRealize processingStatic/dynamic balance measurementWireless transmissionDynamic balance

The invention discloses a mechanical online dynamic balancing system with a built-in spindle, which belongs to the technical field of high-speed spindle online dynamic balancing. Including dynamic balance device, motion control system, data wireless transmission system, dynamic unbalance detection calculation system, control decision calculation system; dynamic balance device is placed in the main shaft, dynamic unbalance detection and calculation system detects the unbalance signal of the main shaft, analyzes and calculates The equivalent centrifugal force of dynamic unbalance and its vector direction and position; the control and decision-making operation system decomposes the equivalent centrifugal force into two adjustment planes of dynamic unbalance, and calculates the equivalent centrifugal force of dynamic unbalance of each plane; and formulates the Mass distribution strategy; the wireless data transmission system receives and transmits dynamic unbalance correction instructions; the motion control system is installed in the control chamber of the dynamic balance device, receives the dynamic unbalance correction instructions, and controls the operation of the motor in the dynamic balance device. The invention is suitable for various operating conditions of the main shaft, and realizes online correction of the dynamic unbalanced state of the main shaft.

Owner:SHENYANG JIANZHU UNIVERSITY

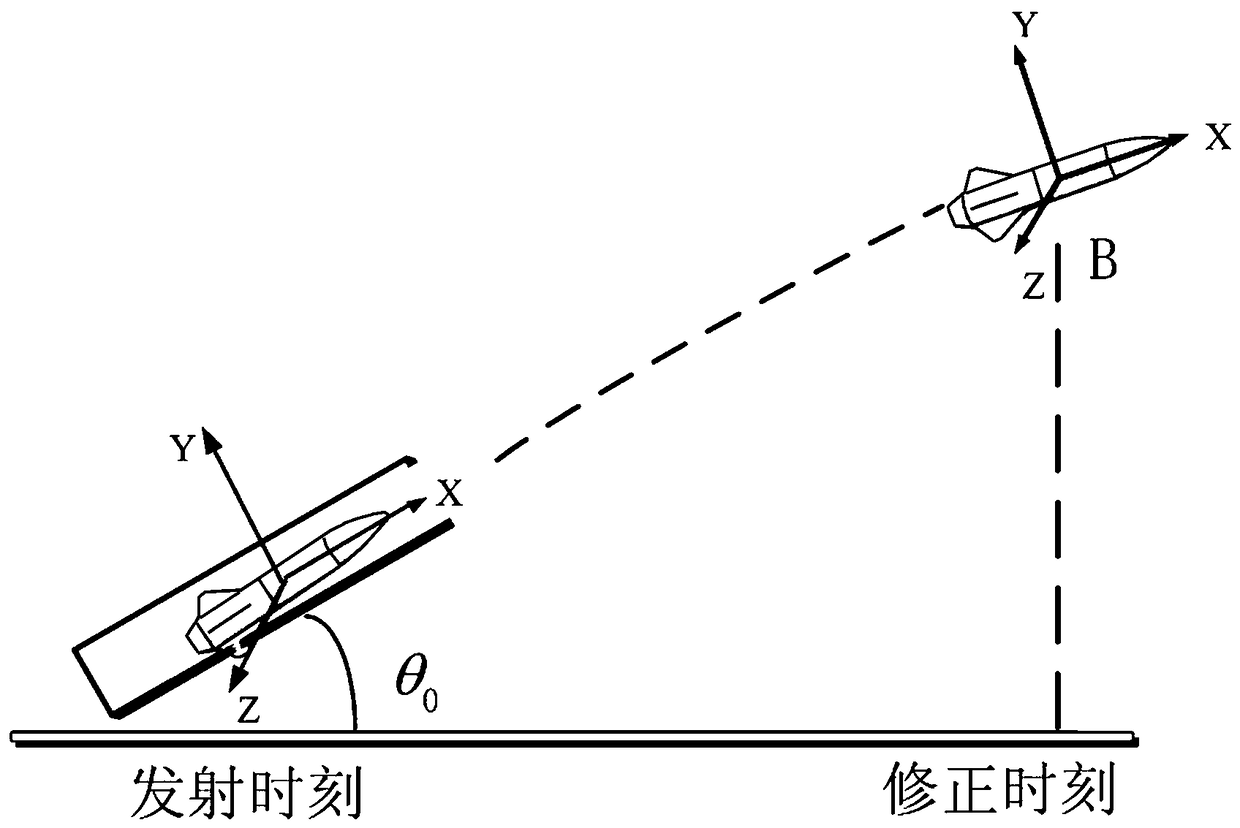

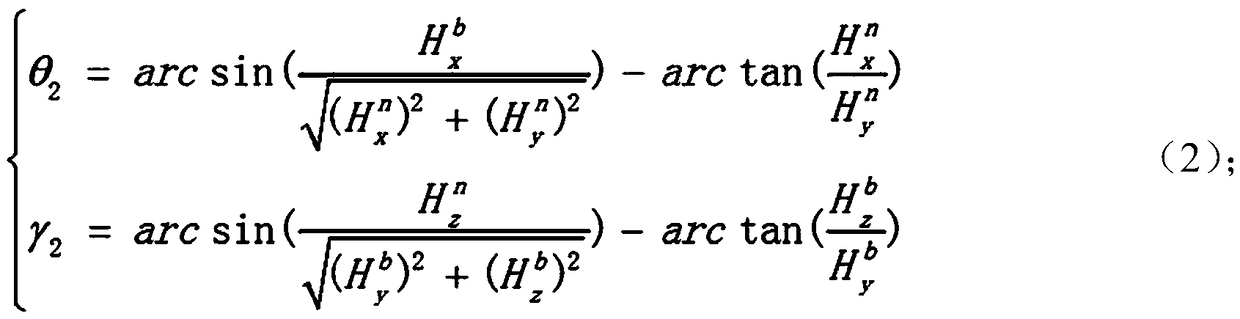

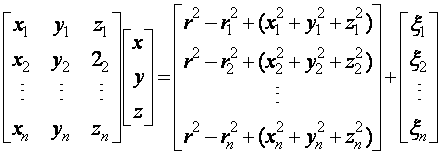

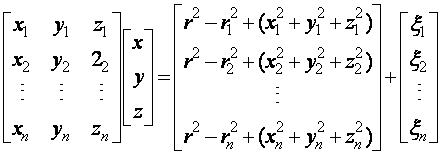

A Method of Gyro Zero Offset Correction after Shelling

ActiveCN106643797BImprove attitude measurement accuracyRealize online correctionNavigation by speed/acceleration measurementsGyroscopeClassical mechanics

The invention relates to a missile-borne MEMS (Micro-electromechanical System) gyro, and in particular to a post-bombardment gyro bias correction method. The invention solves the problem that the bias of a missile-borne MEMS gyro can lead to a great error in a missile body attitude measurement result. The post-bombardment gyro bias correction method is implemented by adopting the following steps: (Step S1) defining the moment of a missile body being 20m away from a muzzle as a zero correction moment; (step S2) initially aiming a missile-borne inertial navigation system; (Step S3) extracting a yaw angle Psi 1, pitch angle Theta 1 and rolling angle Gamma 1 of the missile body at the zero correction moment according to a real-time output of an MEMS gyro in the missile-borne inertial navigation system; (Step S4) working out a pitch angle Theta 2 and rolling angle Gamma 2 of the missile body at the zero correction moment according to (img file='DDA0001184784270000011.TIF' wi'475' he='71' / ); (Step S5) working out a zero variation of the MEMS gyro before and after the launch of the missile body according to Psi 1, Theta 1, Gamma 1, Theta 2 and Gamma 2; (Step S6) working out an accurate real-time output of the MEMS gyro. The invention is applicable to missile body attitude measurement.

Owner:ZHONGBEI UNIV

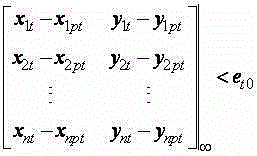

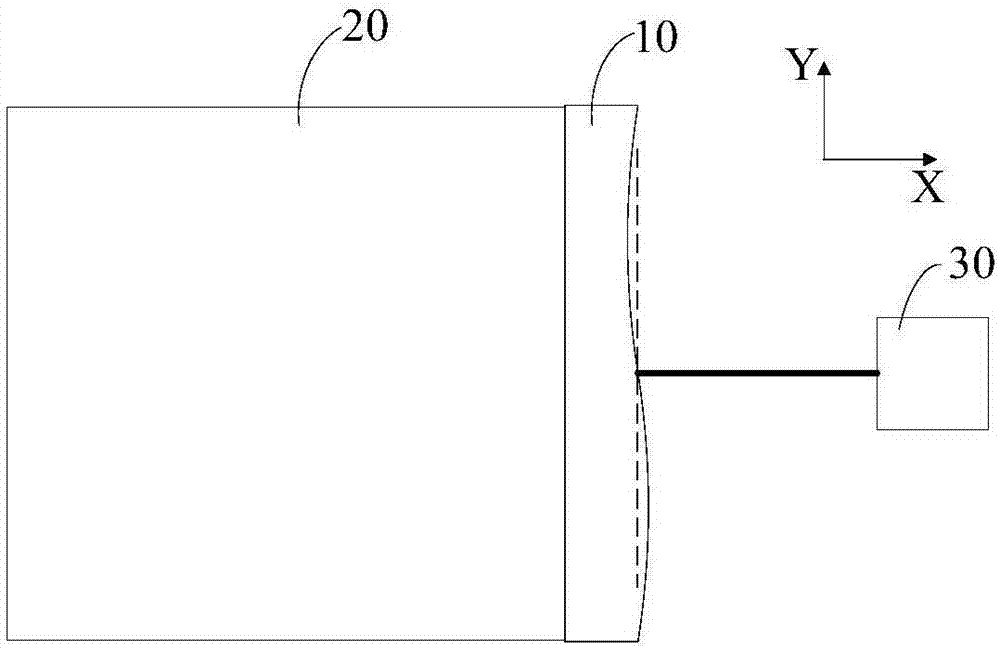

Non-orthogonal correction method for workpiece stage and correction device

ActiveCN107976869AReduce use costInfluence of TP control accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusCorrection methodVisual perception

The invention discloses a non-orthogonal correction method for a workpiece stage and a correction device. The correction device comprises non-orthogonal measurement marks, which are arranged on a coarse-movement turn table on the workpiece stage, wherein the coarse-movement turn table is used for bearing a base plate, and at least three measurement marks are arranged and are not located on a samestraight line; visual units, which are used for acquiring the positions of the non-orthogonal measurement marks; an interferometer measuring unit, which is used for measuring the position of the workpiece stage; and a correction unit, which calculates the non-orthogonal amount of the workpiece stage according to the nominal positions of the non-orthogonal measurement marks in a coordinate system of the turn table, the positions of the non-orthogonal measurement marks acquired by the visual units and the position of the workpiece stage, and transmitting the non-orthogonal amount to the interferometer measuring unit for compensation and correction. The correction method and correction device provided by the invention effectively prevent TP control precision from the influence of the surfacedeformation of the workpiece stage due to heat in the process of exposure, so the usage cost of materials is reduced.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

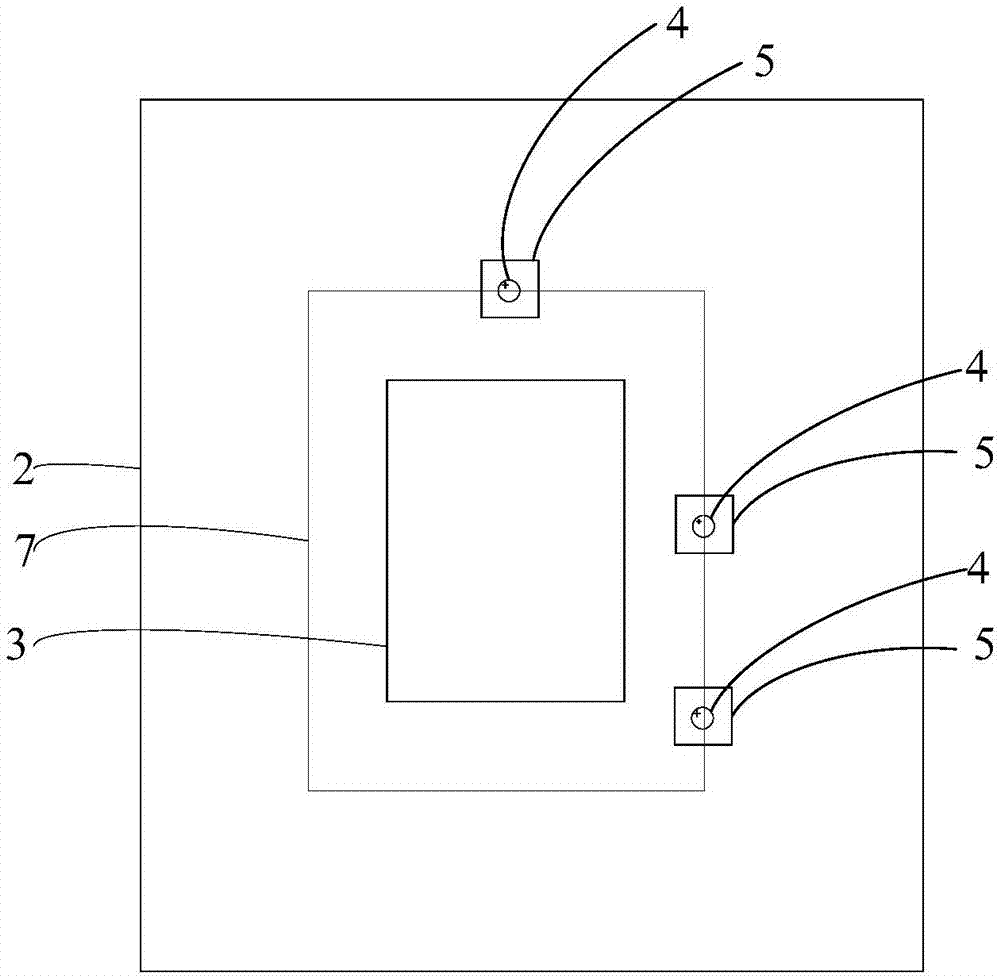

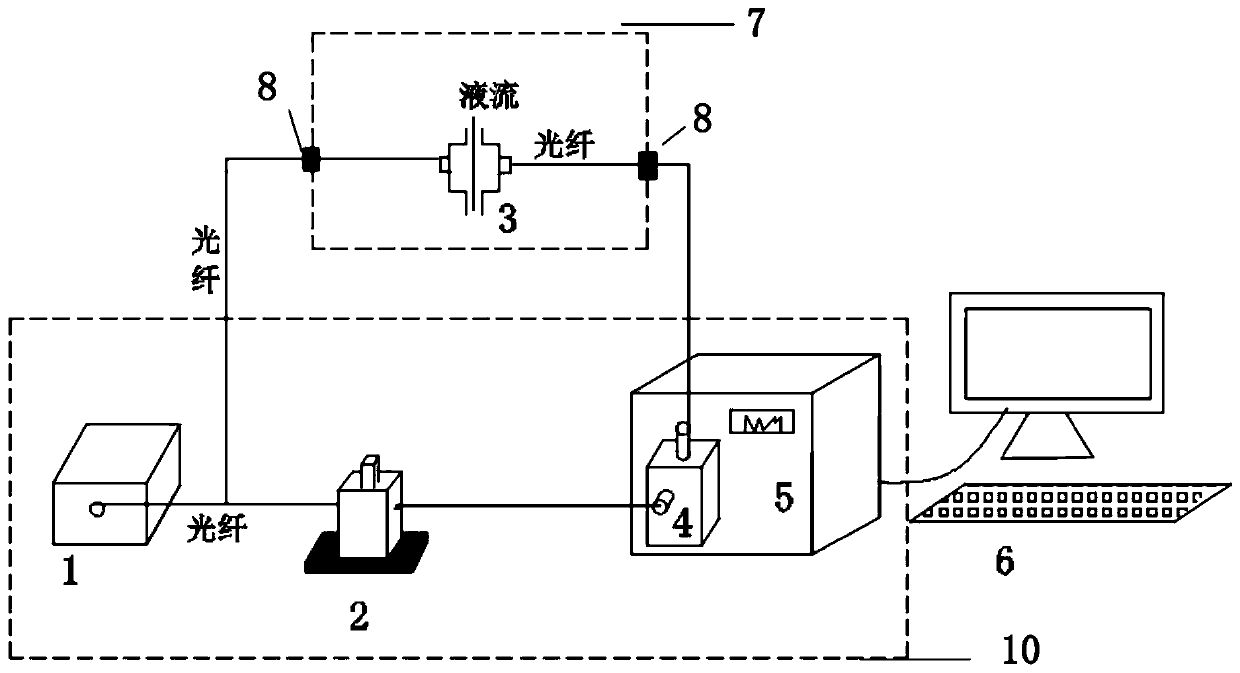

Optical path correction method and device for baseline drift in glove box type online spectral analysis

InactiveCN111175236ASimple structureFirmly connectedColor/spectral properties measurementsEngineeringWorkstation

The invention provides an optical path correction method and device for baseline drift in glove box type online spectral analysis. The method comprises the steps that a measuring light path arranged in a glove box is connected in parallel on the basis of a closed online spectrum reference light path, the random switching between the measuring light path and the reference light path is achieved through a workstation, the reference light path is used for measuring blanks, the measuring light path is used for measuring samples online, and the online correction of baseline drift is achieved whilethe samples are measured. According to the optical path correction method and device for baseline drift in online spectral analysis, the online correction of the baseline drift is achieved while sample measurement is conducted, the timeliness problem of correction is solved, meanwhile, a sample light path does not need to be emptied and cleaned, and the continuity of online monitoring is guaranteed. In order to facilitate instrument maintenance and guarantee instrument performance, a required and designed correction optical path is simple in structure, easy to maintain and few in rotating component.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Instrumentation for level, density or interface measurement of two liquids

ActiveCN107576368BReduce measurement errorGuaranteed accuracyMachines/enginesLubrication indication devicesEngineeringForce sensor

The invention discloses a meter used for liquid level, density measurement and measurement of an interface of two kinds of liquid. The meter comprises a drum, a sinker, and magnetic steel and furthercomprises a force sensor, a concave framework and a steel wire rope connecting to the force sensor and the concave framework. The sinker is disposed inside the drum and the magnetic steel is disposedoutside the drum. The magnetic steel is magnetically coupled to the sinker. With the meter, it is no longer difficult to measure liquid level or density in a high-temperature high-pressure medium or ahigh-pressure low-density medium and a high-pressure low-temperature low-density medium. The meter is high in measurement precision, simple in structure, low in manufacture and maintenance cost and convenient to use so that the meter is used widely.

Owner:DALIAN JIAXIN ELECTROMECHANICAL INSTR CO TD

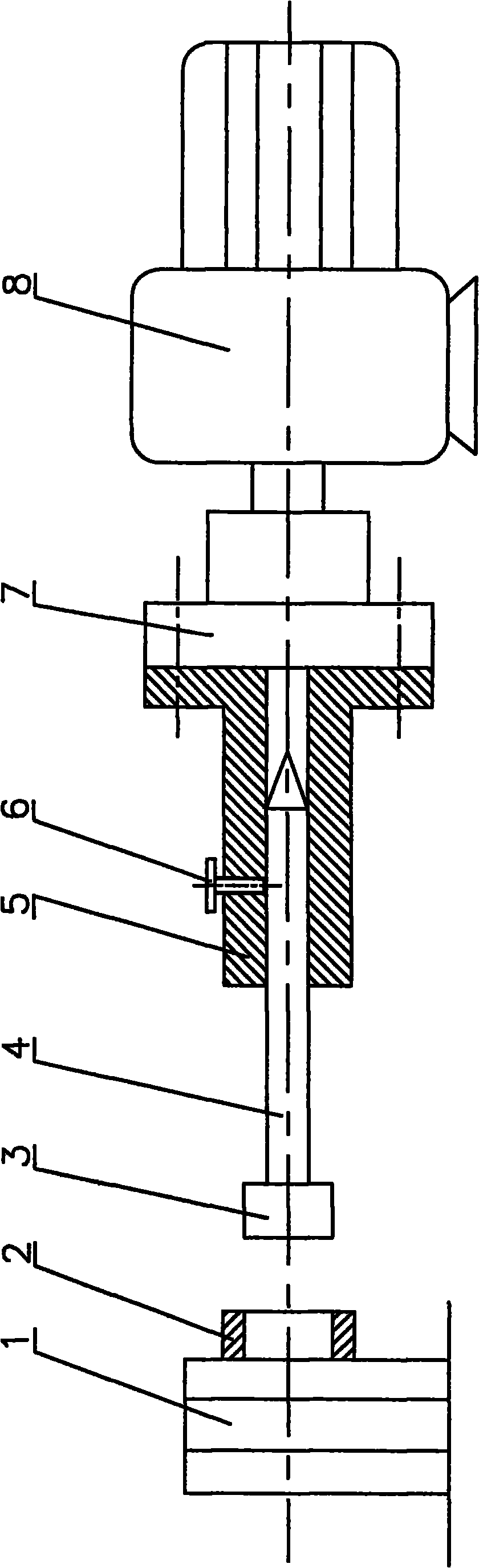

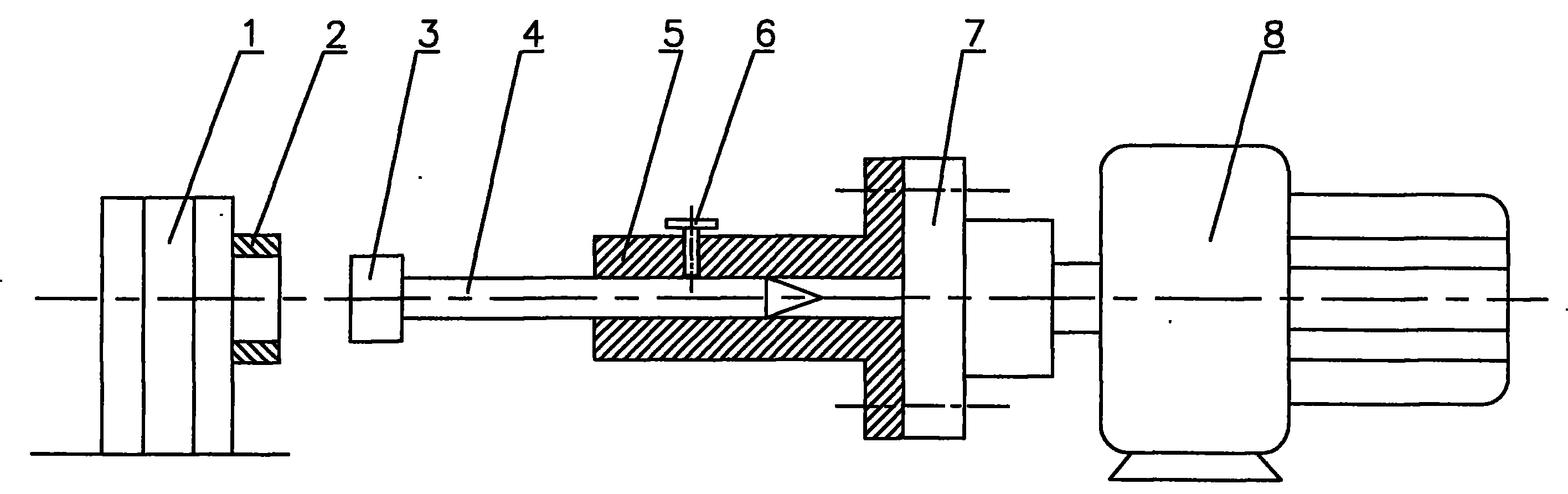

Correcting device of transmission center of metering pump of spinning machine

InactiveCN101988484ARealize online correctionAvoid failurePumpsPositive-displacement liquid enginesCouplingMetering pump

The invention discloses a correcting device of a transmission center of a metering pump of a spinning machine, which belongs to the technical field of chemical fiber spinning devices. The correcting device comprises a sleeve (5) and a correcting rod (4), wherein the sleeve (5) is provided with an axial center hole; the correcting rod (4) passes through the center hole of the sleeve (5) and can slide along the axial direction; and a jointing plate matched with a disc type coupling is arranged on one end of the sleeve (5), and a correcting head (3) matched with an axial hole of the coupling of the metering pump is arranged on the head end of the correcting rod (4). The correcting device is simple in structure, accurate in correction, safe and convenient in operation, and the invalidation problem of the metering pump caused by the decentraction between the metering pump and the transmission center can be solved.

Owner:唐元冰

Method and system for detecting dead point of suspended point of polished rod in pumping well

ActiveCN110410057BImprove working condition monitoring abilityRealize online correctionSurveyDrilling rodsEngineeringDynamometer

The invention discloses a method and a system for detecting the suspension and dead points of polished rods in pumping wells. The detection method includes: based on the synchronous dynamometer diagram, collecting the electric power diagram X(i) of the pumping well for one stroke cycle; setting the time series x(i) based on the electric power diagram X(i), and calculating y according to the mean value filter formula '(i), obtain the corrected time series based on the corrected time series to obtain the filtered output signal y(i); obtain the variance Qd(i) of the time series x(i) and the filtered output signal y(i) ); Obtain the dead point of the suspension point based on the variance Qd(i). Its advantages are: it can realize the online correction of the electric power diagram and the indicator diagram of the pumping well, and the real-time detection of the dead point of the suspension point is helpful to judge whether the displacement sensor of the indicator diagram is normal, and improves the monitoring ability of the working condition of the pumping well. The safety is high, and the practical application is easy to install, operate and maintain.

Owner:CHINA PETROLEUM & CHEM CORP +1

Calibration method for measurement accuracy of online argon blowing flowmeter in continuous casting crystallizer

ActiveCN106323426BRealize online correctionOnline calibration is fastTesting/calibration apparatusRegulated power supplyArgon gas

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Combination method of multi-coordinate machining center based on vision and moving manipulator

ActiveCN105058168BRealize online correctionRealize positioning controlMeasurement/indication equipmentsLaser rangingEngineering

Owner:XIAN FEISIDA AUTOMATION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com