Calibration method for measurement accuracy of online argon blowing flowmeter in continuous casting crystallizer

A continuous casting mold, argon blowing flow technology, applied in liquid/fluid solid measurement, measuring device, test/calibration device, etc., can solve the problem that the factory does not have the conditions and qualifications for self-calibration of flowmeters, the continuous casting production process is passive, Calibration is not realistic and other problems, to achieve the effect of facilitating large-scale promotion and application, saving work time, and eliminating tedious steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: The on-site argon gas control box feels abnormal, or has not been corrected for a long time, and the process technicians have certain doubts about the authenticity of the current flow display. Utilize the present invention to solve as follows:

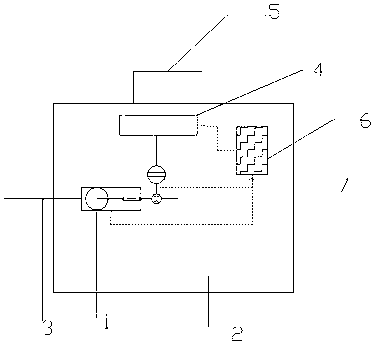

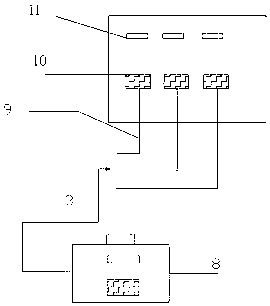

[0033]1) Select an electronic flowmeter with the same model and measurement accuracy as the online argon gas measuring device, and after calibration and testing by a professional department, follow the figure 1 Assembled; the calibration device includes a box, the box is provided with a handle, the inside of the box is provided with a stabilized power supply (6) and a mass flow regulating valve (1) mass flowmeter (7), and the box is provided with There is an electronic display screen (4) for flow display during measurement, and an external pipeline (3) for connecting argon gas is arranged in the box.

[0034] 11), according to figure 1 The installation shown is equipped with a mobile online calibration device, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com