Patents

Literature

112 results about "Differential gain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Differential gain is a kind of linearity distortion which affects the color saturation in TV broadcasting.

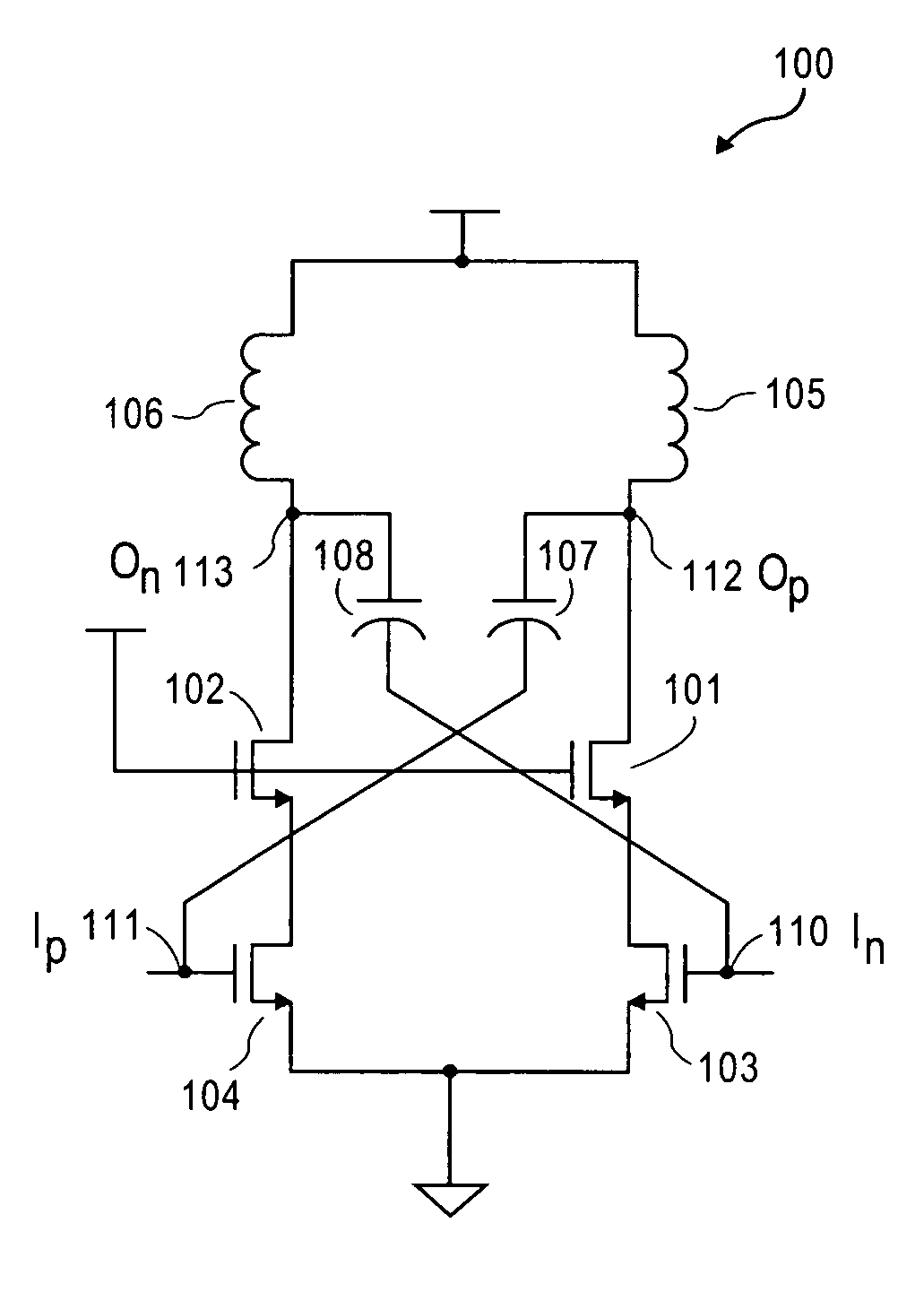

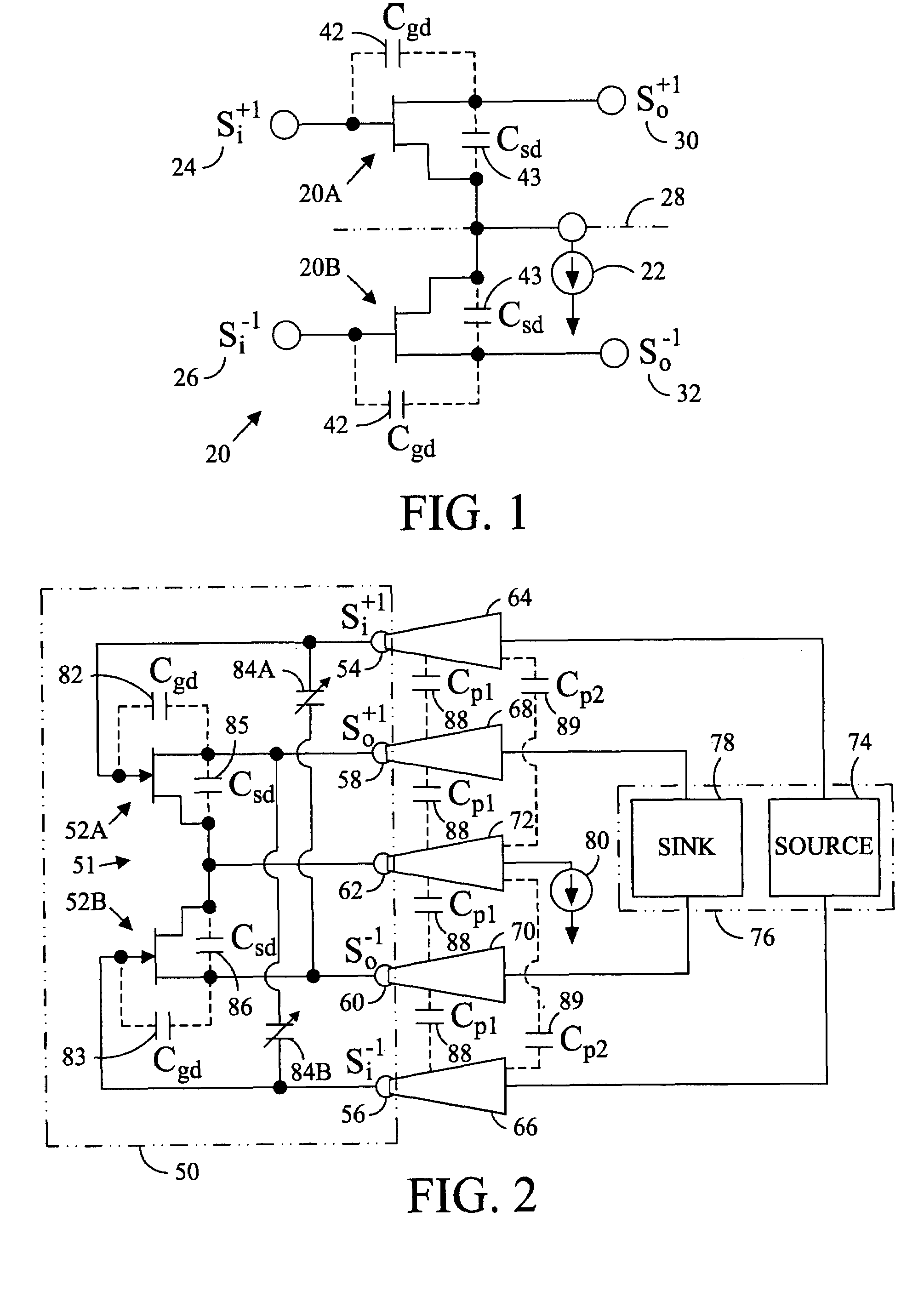

Gain boosting RF gain stage with cross-coupled capacitors

ActiveUS7697915B2Tighter current flow controlHigh gainHigh frequency amplifiersRadio transmissionCapacitanceGain stage

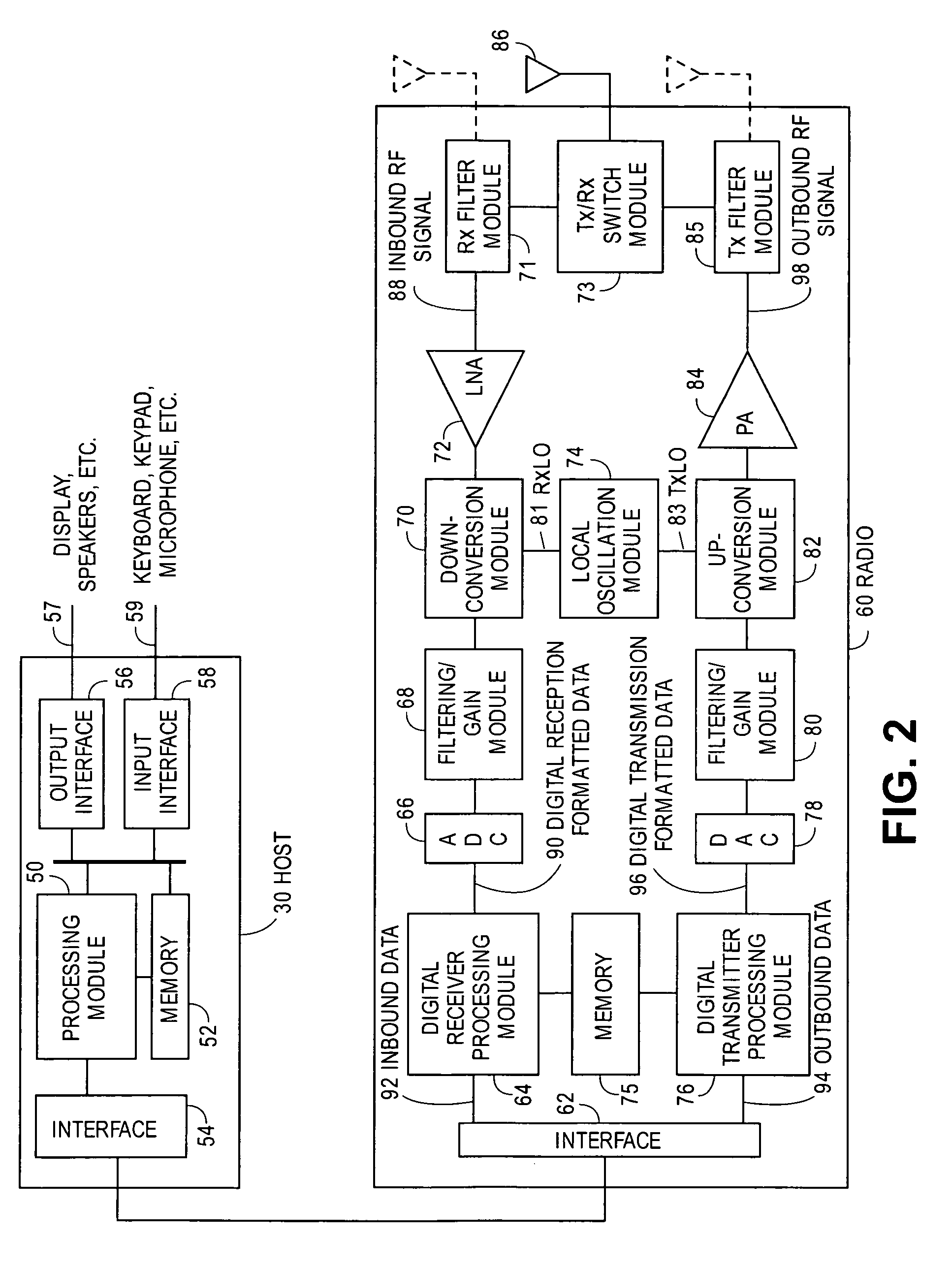

A RF differential gain stage has cross-coupled capacitors between input and output nodes of the amplifier stage to boost gain. The gain boost allows cancellation of the series resistance of an inductive load of the amplifier stage.

Owner:QUALCOMM INC

Test structure and probe for differential signals

InactiveUS7403028B2Electrical measurement instrument detailsElectrical testingDifferential signalingInput impedance

A test structure including a differential gain cell and a differential signal probe include compensation for the Miller effect reducing the frequency dependent variability of the input impedance of the test structure.

Owner:CASCADE MICROTECH

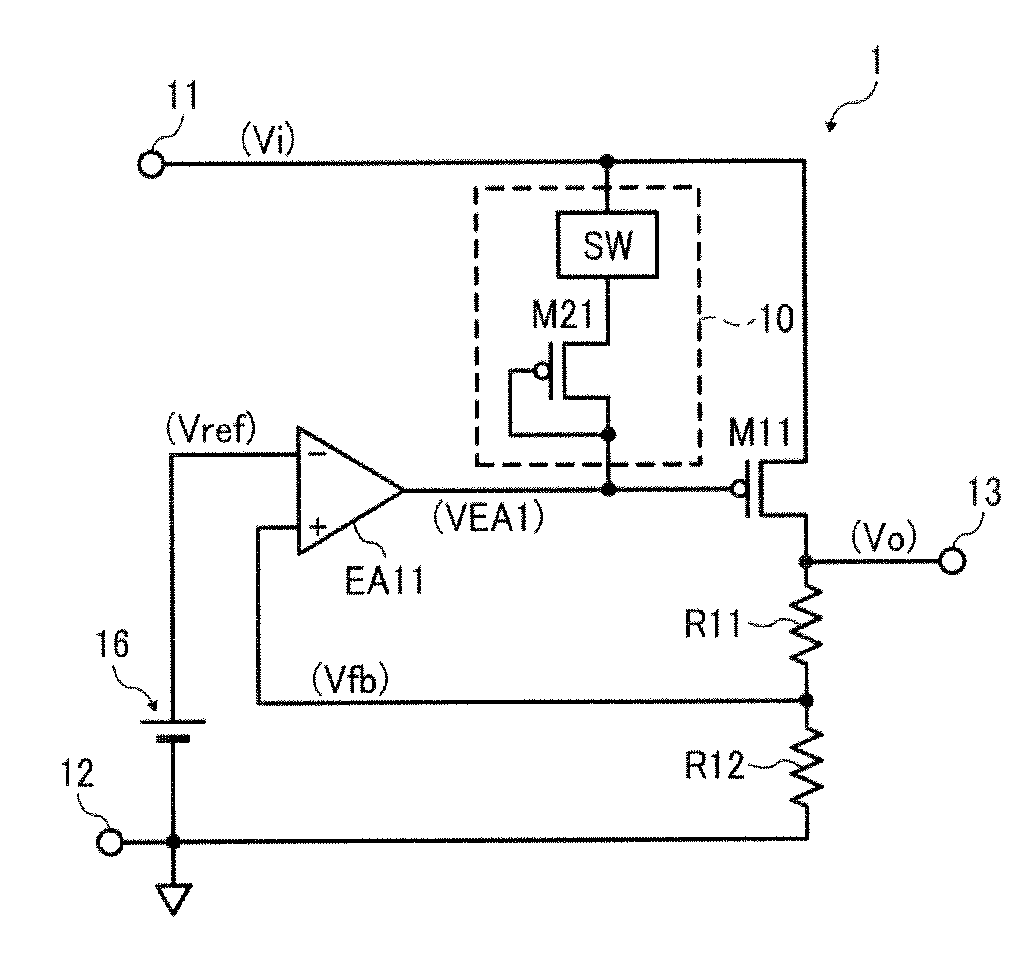

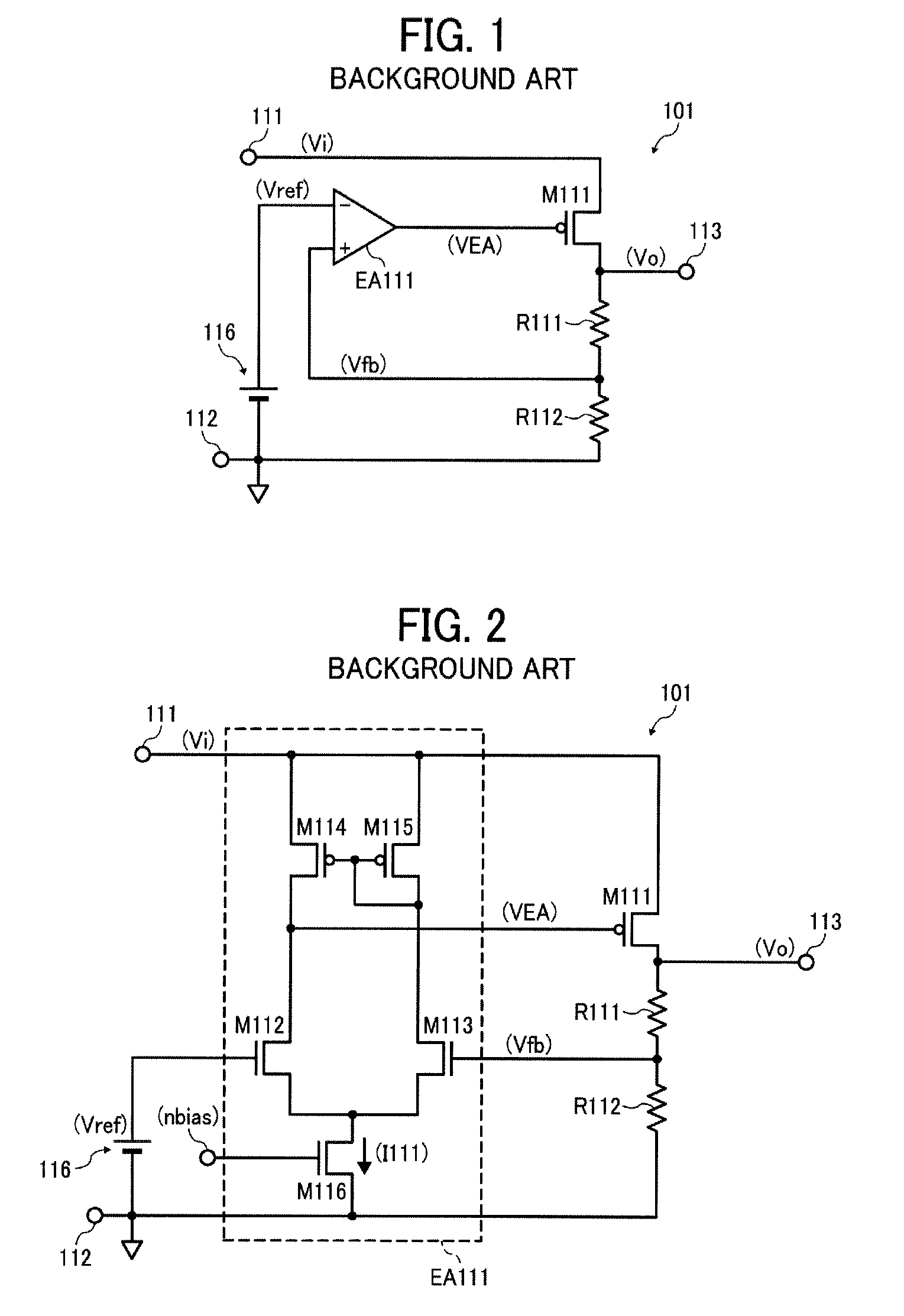

Constant voltage regulator

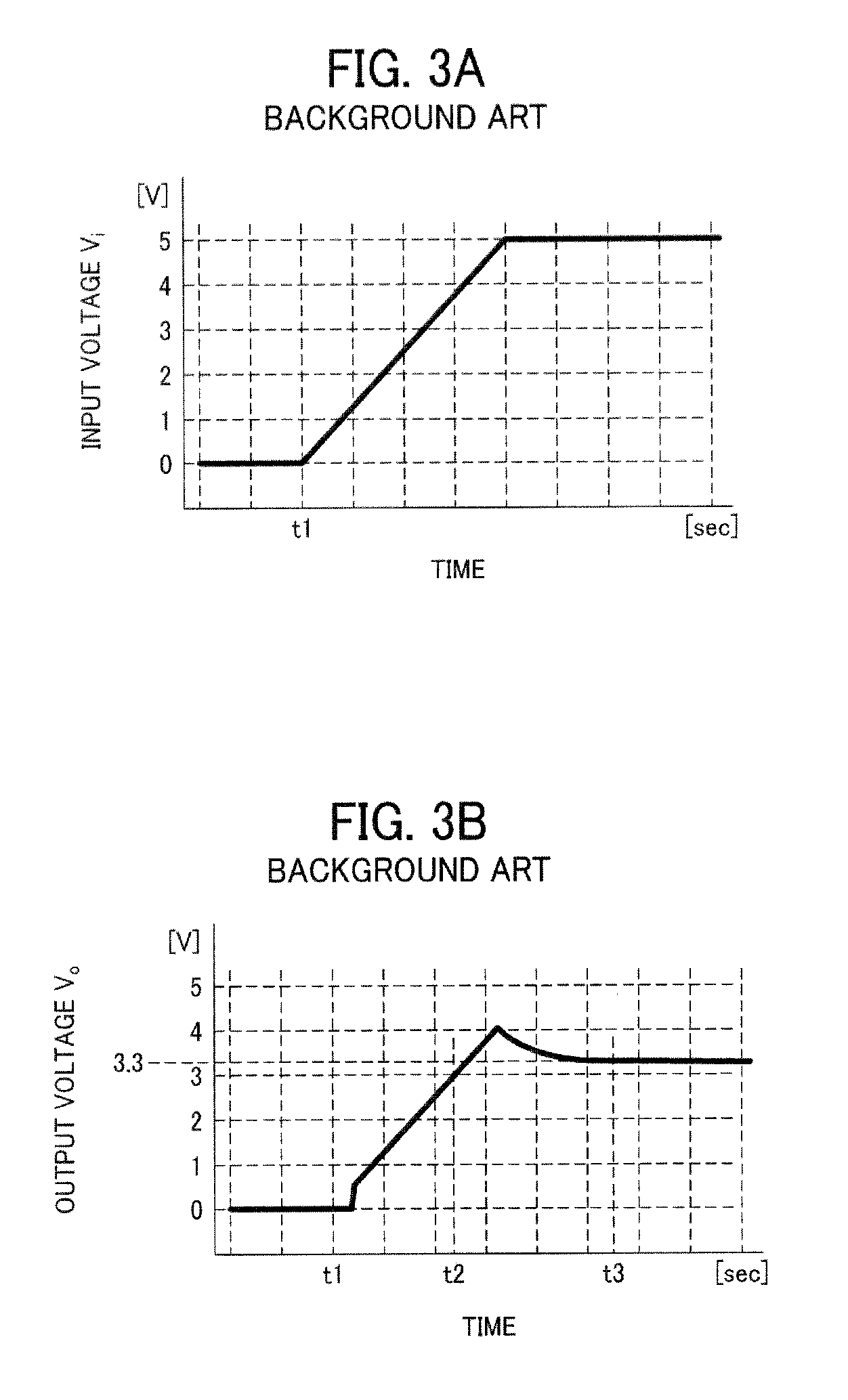

A voltage regulator includes a driver transistor, a feedback voltage generator, a reference voltage generator, a first differential amplifier, and a differential gain controller. The driver transistor is connected between input and output terminals to conduct a current therethrough according to a control signal applied to a gate terminal thereof. The feedback voltage generator is connected to the output terminal to generate a feedback voltage. The reference voltage generator generates a reference voltage. The first differential amplifier has an output thereof connected to the gate terminal of the driver transistor, and a pair of differential inputs thereof connected to the feedback voltage generator and the reference voltage generator, respectively, to generate the control signal at the output thereof. The differential gain controller is connected to the output of the first differential amplifier to control the differential gain according to a difference between the input and output voltages.

Owner:NISSHINBO MICRO DEVICES INC

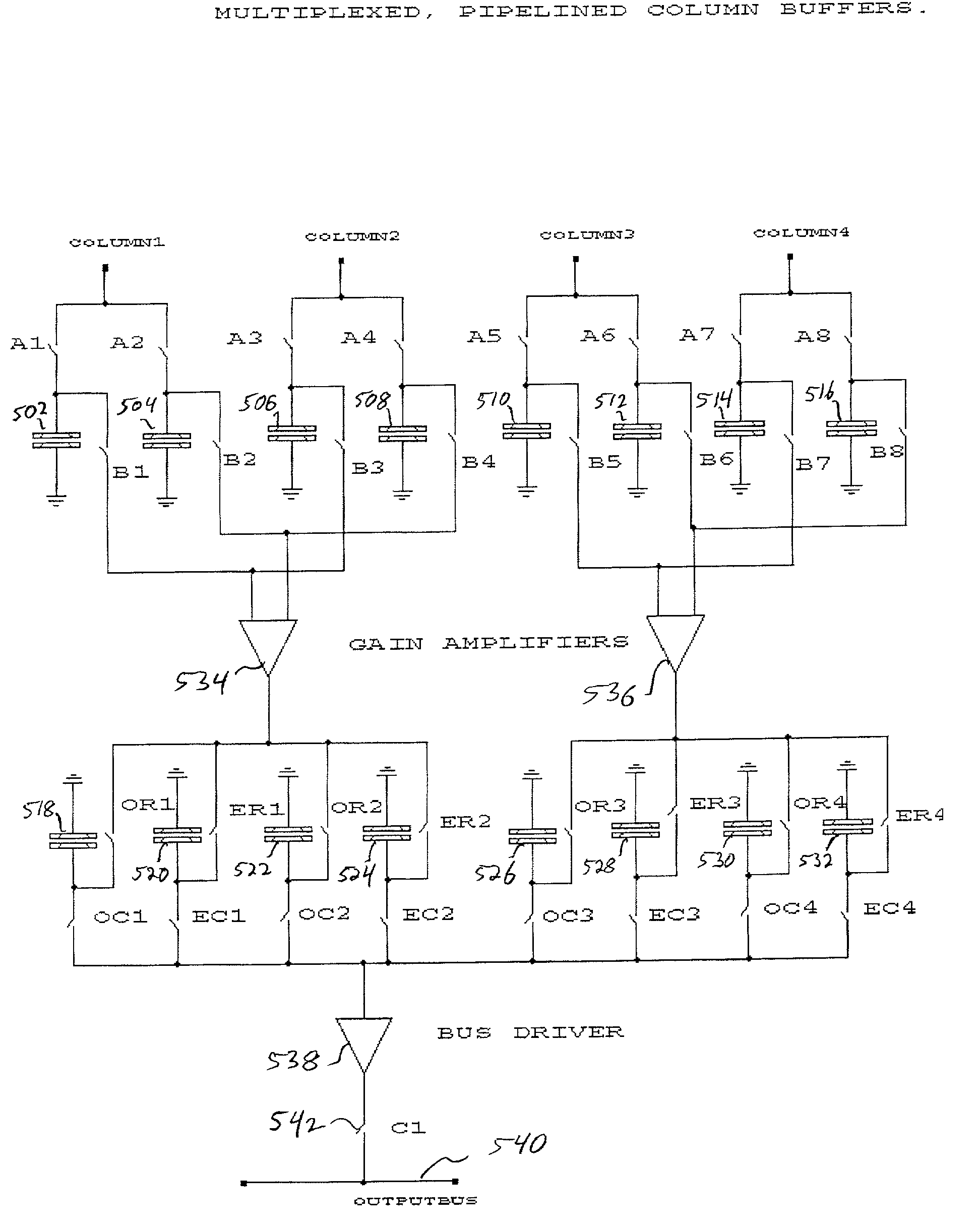

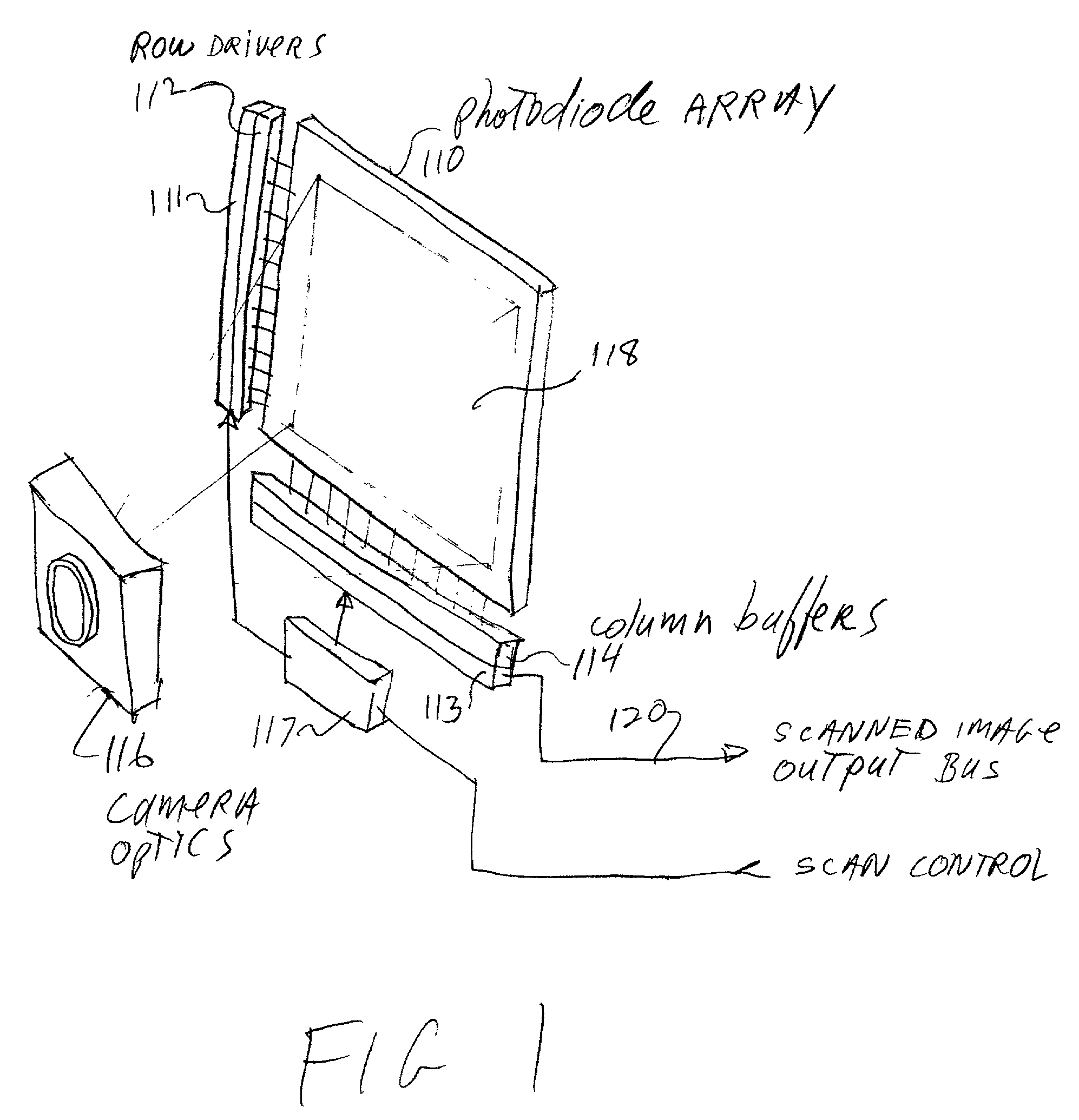

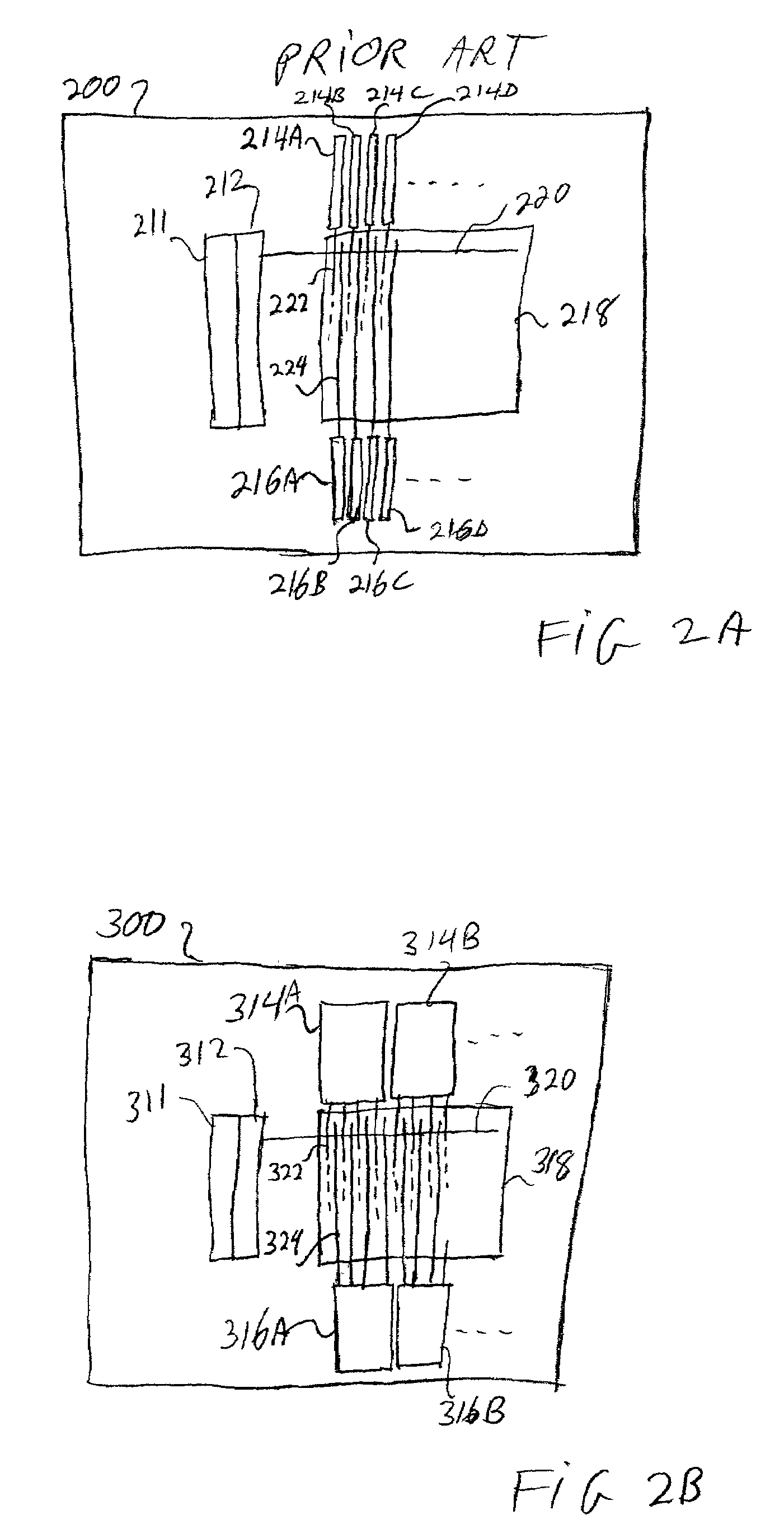

Multiplexed and pipelined column buffer for use with an array of photo sensors

InactiveUS7154548B2Television system detailsTelevision system scanning detailsMultiplexingSensor array

An electronic imaging chip containing an array of photodiodes includes a multiplexed column buffer. The multiplexed column buffer serves a plurality of columns in the photodiode array. By multiplexing active amplifier elements, such as the differential gain amplifiers and the bus driver amplifiers, a wider area than one column width is available on the semiconductor chip for layout of the column buffer. In the disclosed embodiment, 4 columns share a common multiplexed column buffer. The area available for layout of the multiplexed column buffer is 4 times as wide as compared to that for a non-multiplexed column buffer.

Owner:VALLEY OAK SEMICON

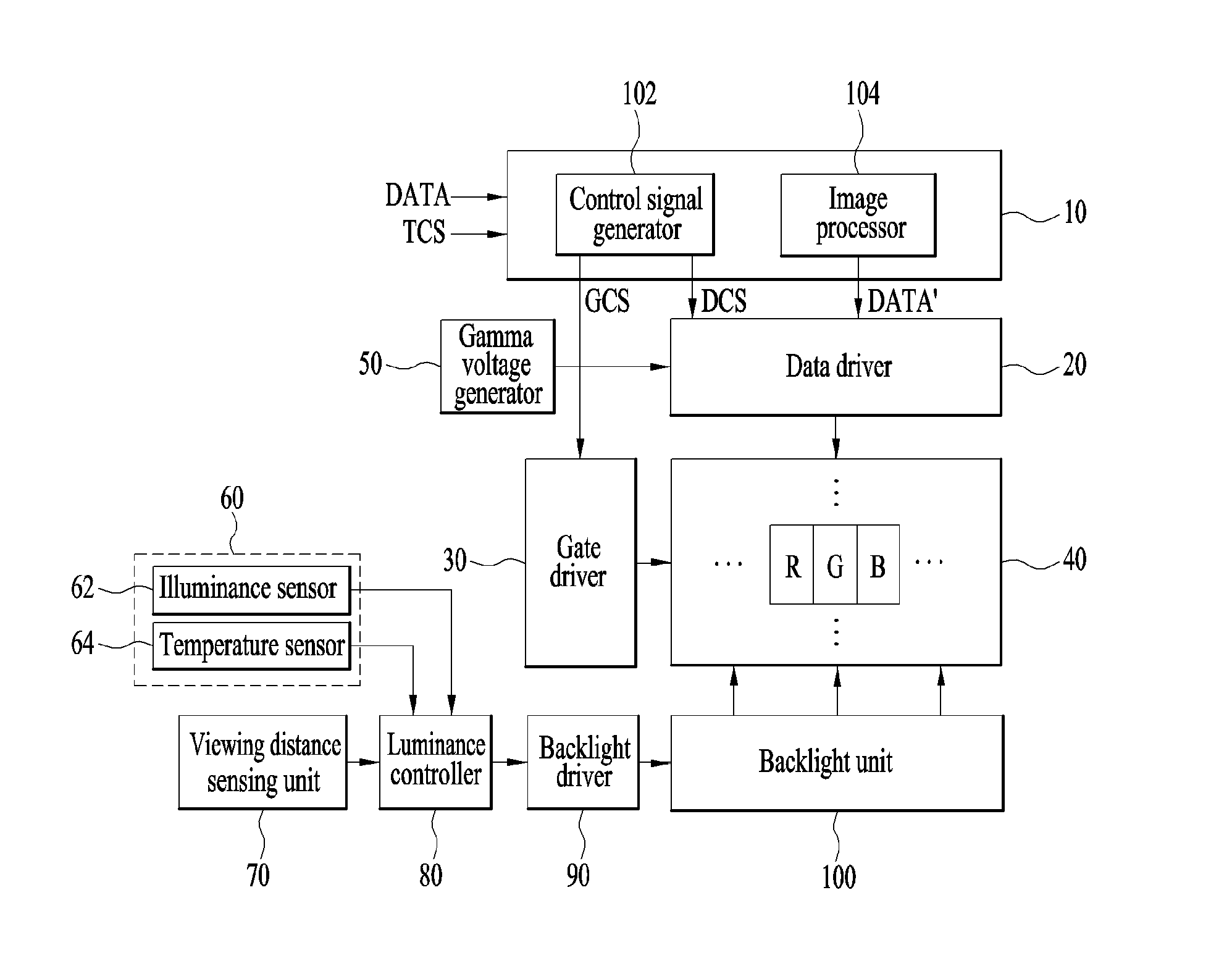

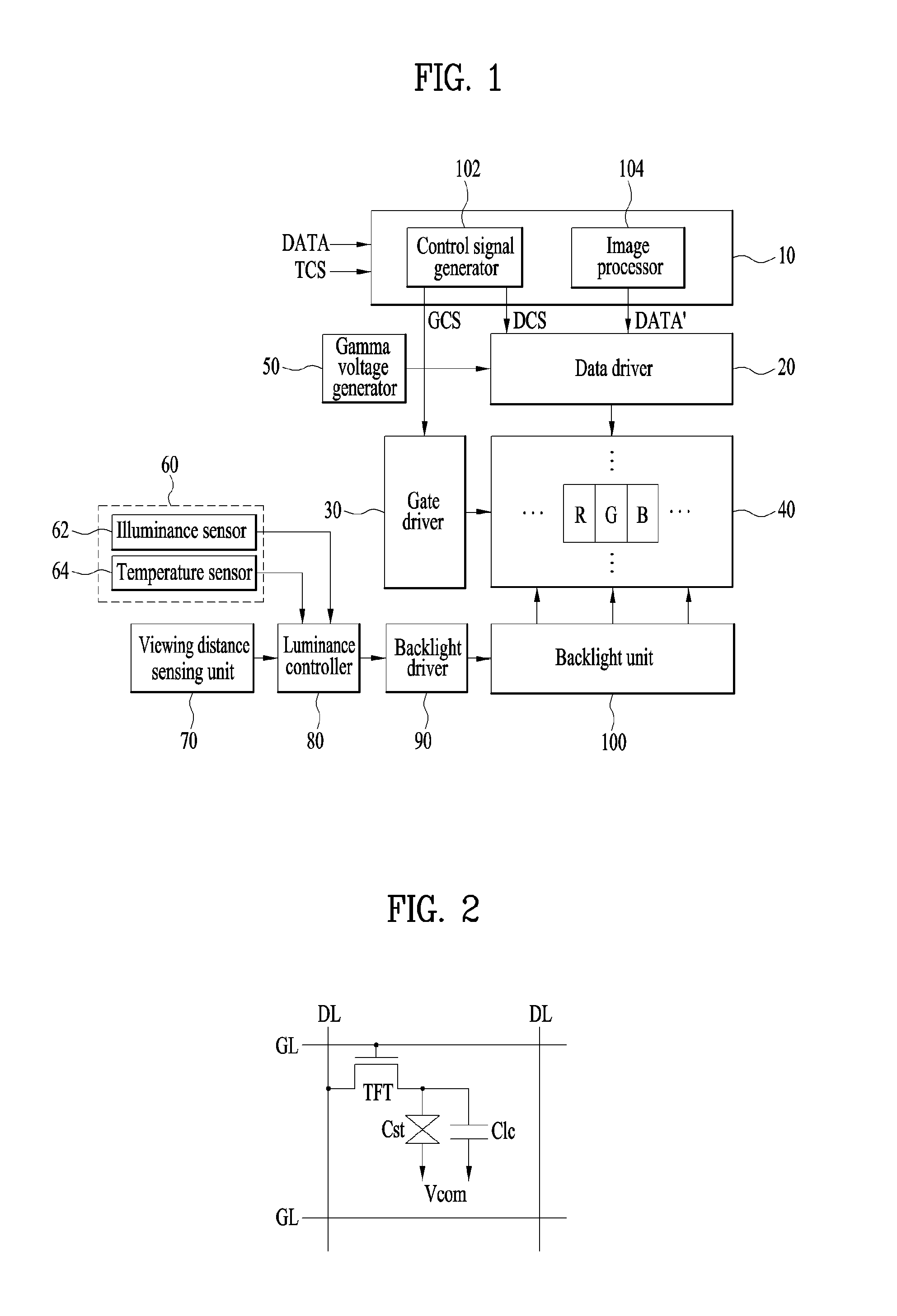

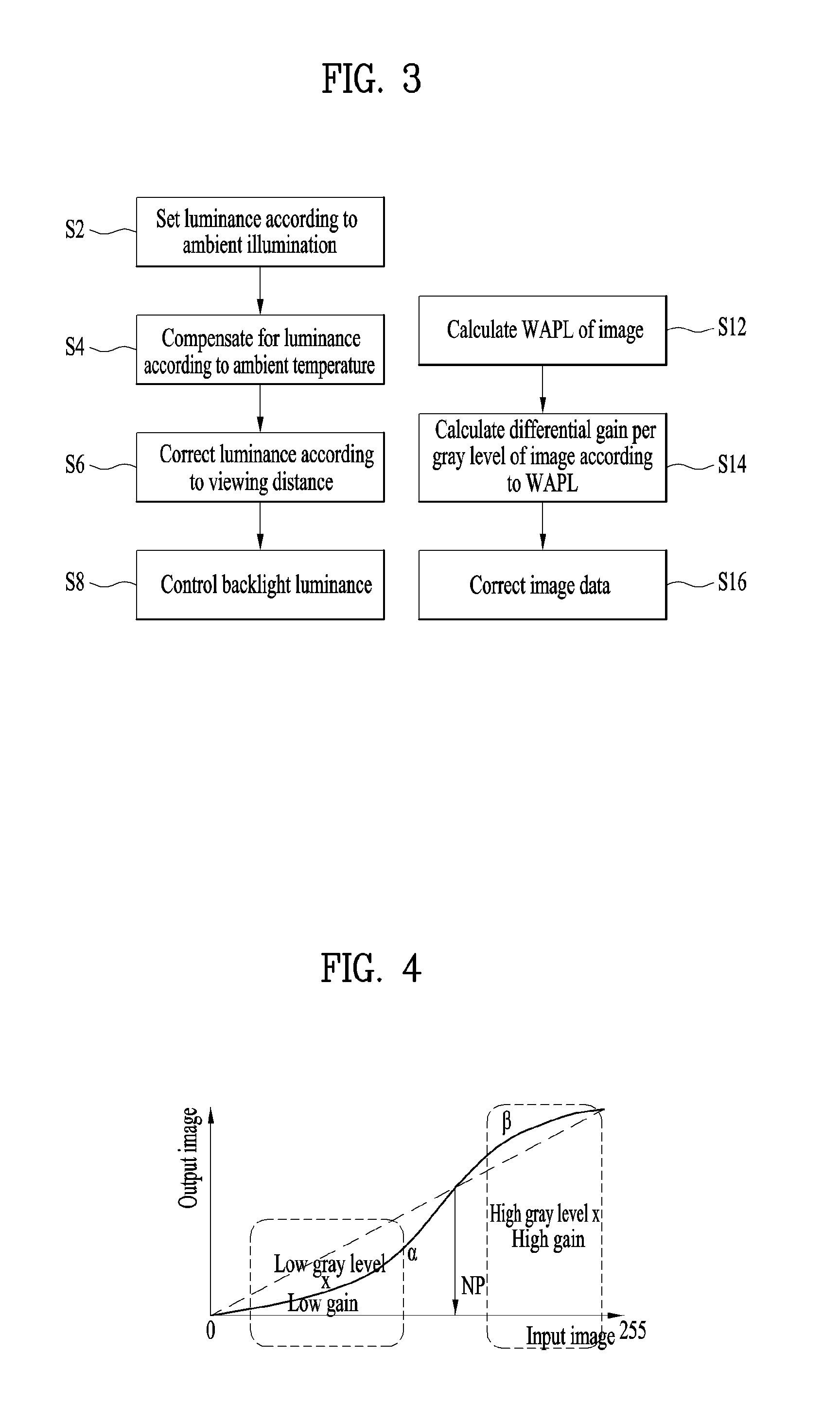

Display Device for Improving Picture Quality and Method for Driving the Same

ActiveUS20160351133A1Improve visibilityImprove picture qualityCathode-ray tube indicatorsVisibilityIlluminance

The present invention relates to a display device which can provide optimal luminance and visibility to viewers by considering a viewing environment, a viewing distance and image characteristics in an associated manner and a method for driving the same. The method for driving a display device includes: determining final luminance by applying sensed results of ambient illumination, ambient temperature and a viewing distance from a user in an associated manner; adjusting luminance of the display device according to the determined final luminance; and calculating a weighted average picture level (WAPL) from an input image, calculating a differential gain per gray level according to the calculated WAPL, correcting the input image by applying the calculated differential gain per gray level to the input image and outputting the corrected input image.

Owner:LG DISPLAY CO LTD

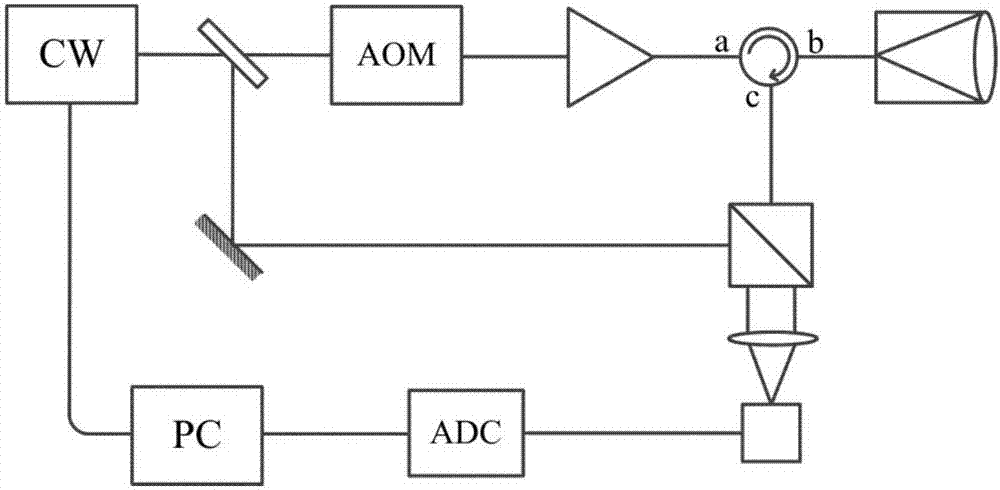

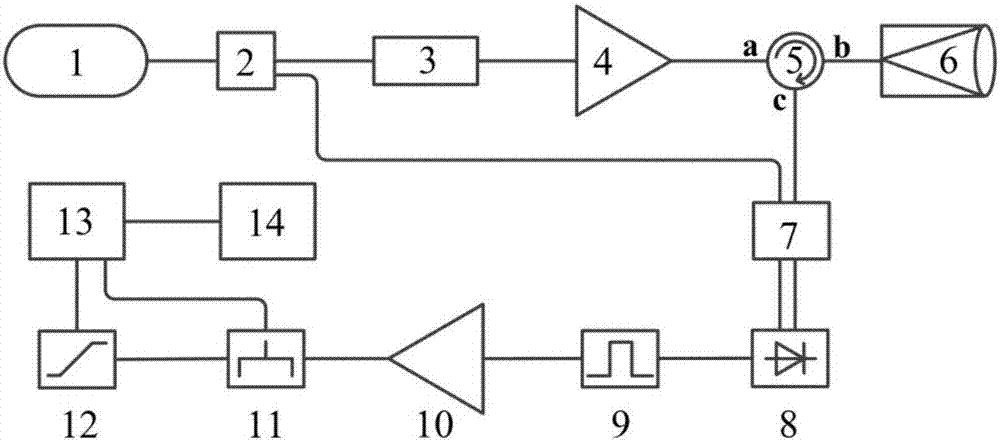

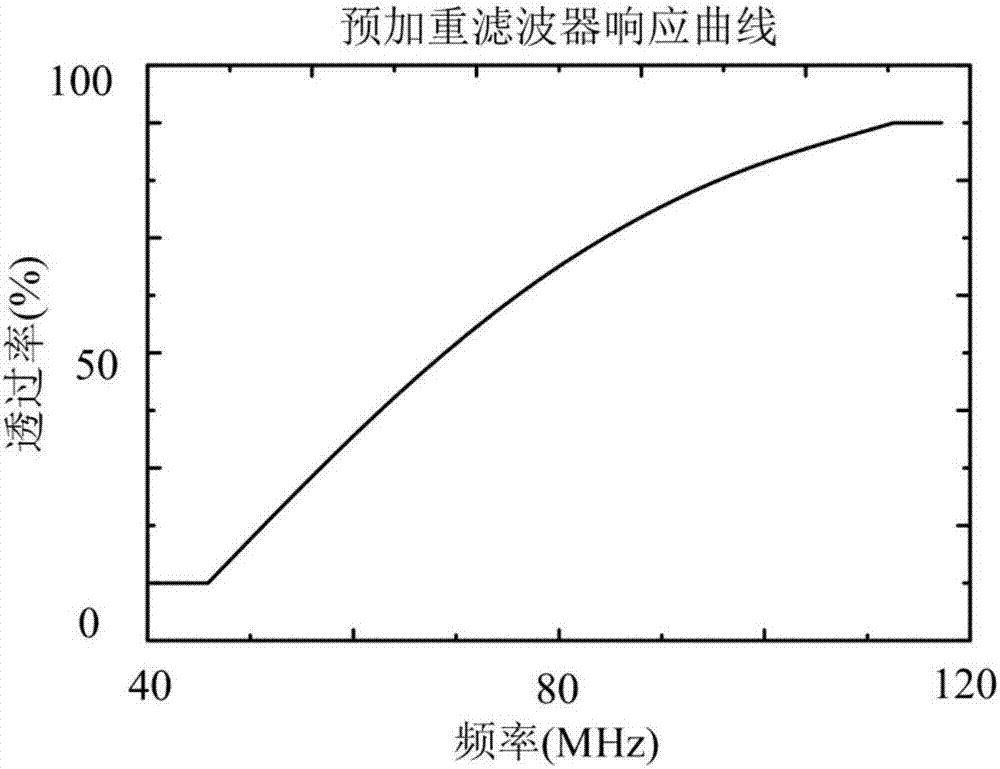

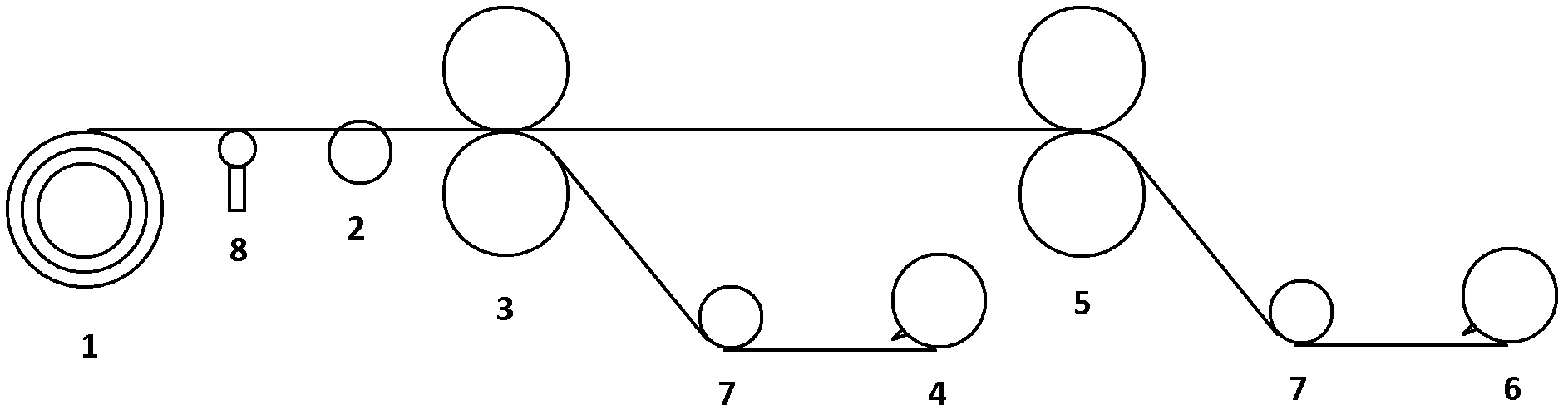

Microwave differential gain-based coherent Doppler wind lidar

ActiveCN106940444AReduce computationHigh range resolutionElectromagnetic wave reradiationICT adaptationBandpass filteringWind lidar

The invention discloses a microwave differential gain-based coherent Doppler wind lidar. According to the technical scheme of the invention, a balanced detector is connected with a bandpass filter, so that invalid signals, away from the Doppler frequency shift, are filtered and eliminated. A pre-amplifier is adopted to amplify an electrical signal outputted by the detector. Meanwhile, a power divider is adopted to divide amplified electrical signal into a monitoring channel and a detection signal. The detection signal is filtered by a pre-emphasis filter. The frequency-domain change of the detection signal is converted to the intensity change of the signal. Through the comparison with the monitoring channel and the transmittance curve of the pre-emphasis filter, the Doppler shift information is obtained. The interference of invalid echo signals is reduced. By adopting the pre-emphasis filter, echo signals are subjected to frequency discrimination, so that the computation amount of signal processing is reduced. The sensitivity and the signal-to-noise ratio of the system are improved. The coherent Doppler wind lidar is higher in resolution distance.

Owner:夏海云

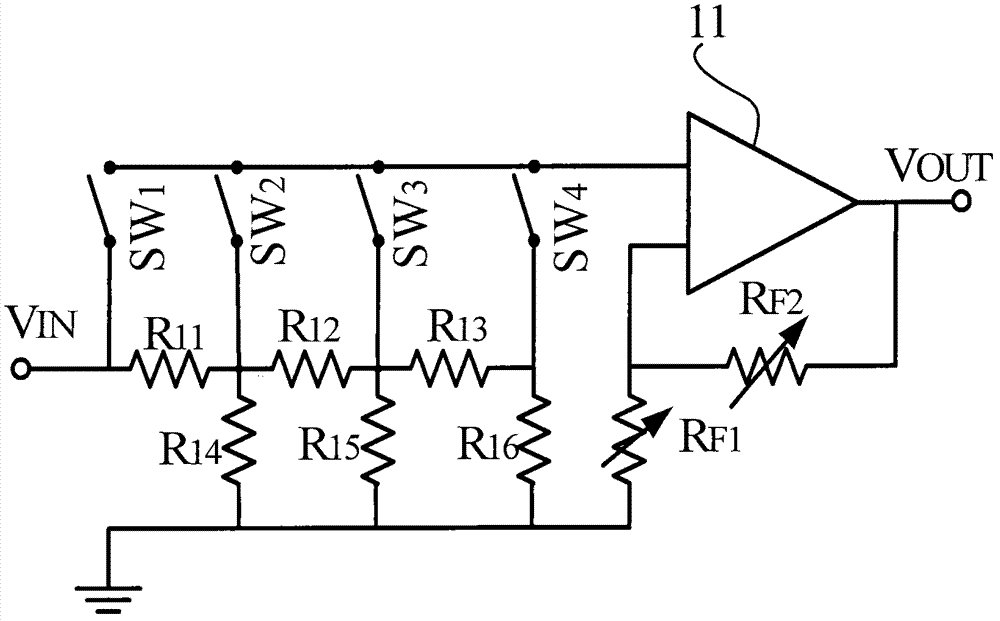

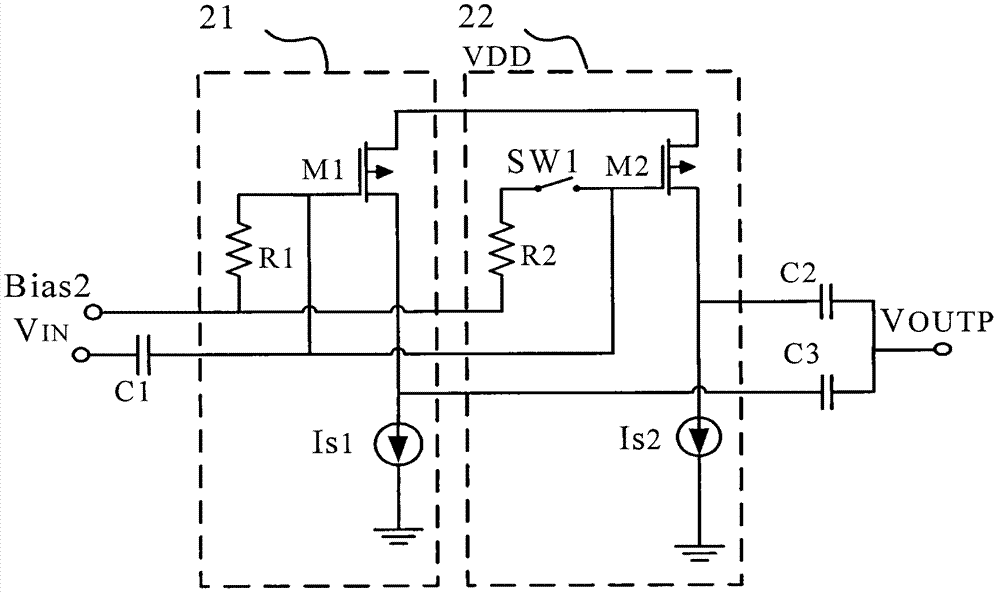

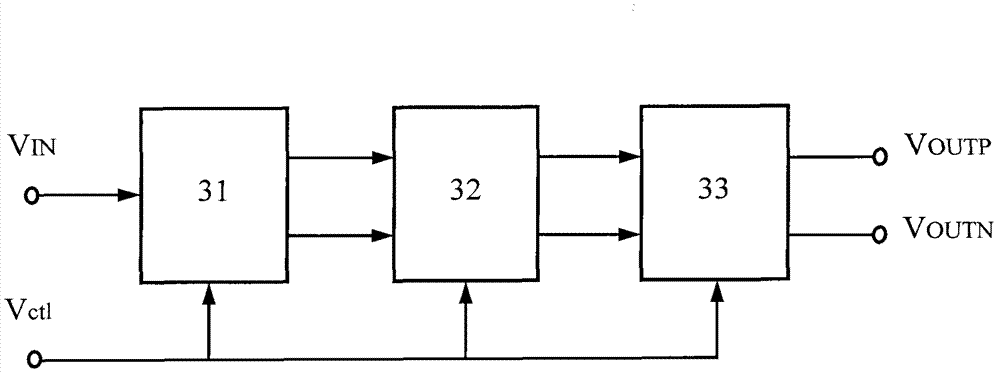

Single ended differential gain amplifier with configurable radio frequency broadband gain

ActiveCN102790595AAchieve amplified outputStrong interference signal suppressionGain controlDifferential amplifiersControl signalMultiple modes

The invention discloses a single ended differential gain amplifier with a configurable radio frequency broadband gain. The gain amplifier comprises a single ended differential circuit with a configurable gain, a broadband amplifying circuit with the configurable gain and a buffer driving circuit with the configurable gain which are sequentially connected in series. Gain control ends of the circuits are connected with a gain control signal from an outer digital base band processing module to form a gain value of the single ended differential gain amplifier with the configurable radio frequency broadband gain in combination, according to the control of each circuit at a set fixed step pitch, fine adjustment on the gain is implemented, thus a range of the broadband signal output by the differential conforms to a range value of a set signal, and strong disturbance is effectively restrained. Since the strong detection and processing capability of a digital processing module chip of the outer base band is good for a gain control mode, the gain control is enabled not to be affected from temperature, process, noise and the like, and more precise and flexible control can be realized. The control range of the gain is a summation of the maximum gain control ranges of the three circuits with the configurable gains, so that the gain amplifier is suitable for application of the high dynamic input with strong disturbance or weak signal, and is suitable for a radio frequency chip with multiple frequencies and multiple modes of a single ended broadband radio frequency signal input.

Owner:杭州中科微电子有限公司

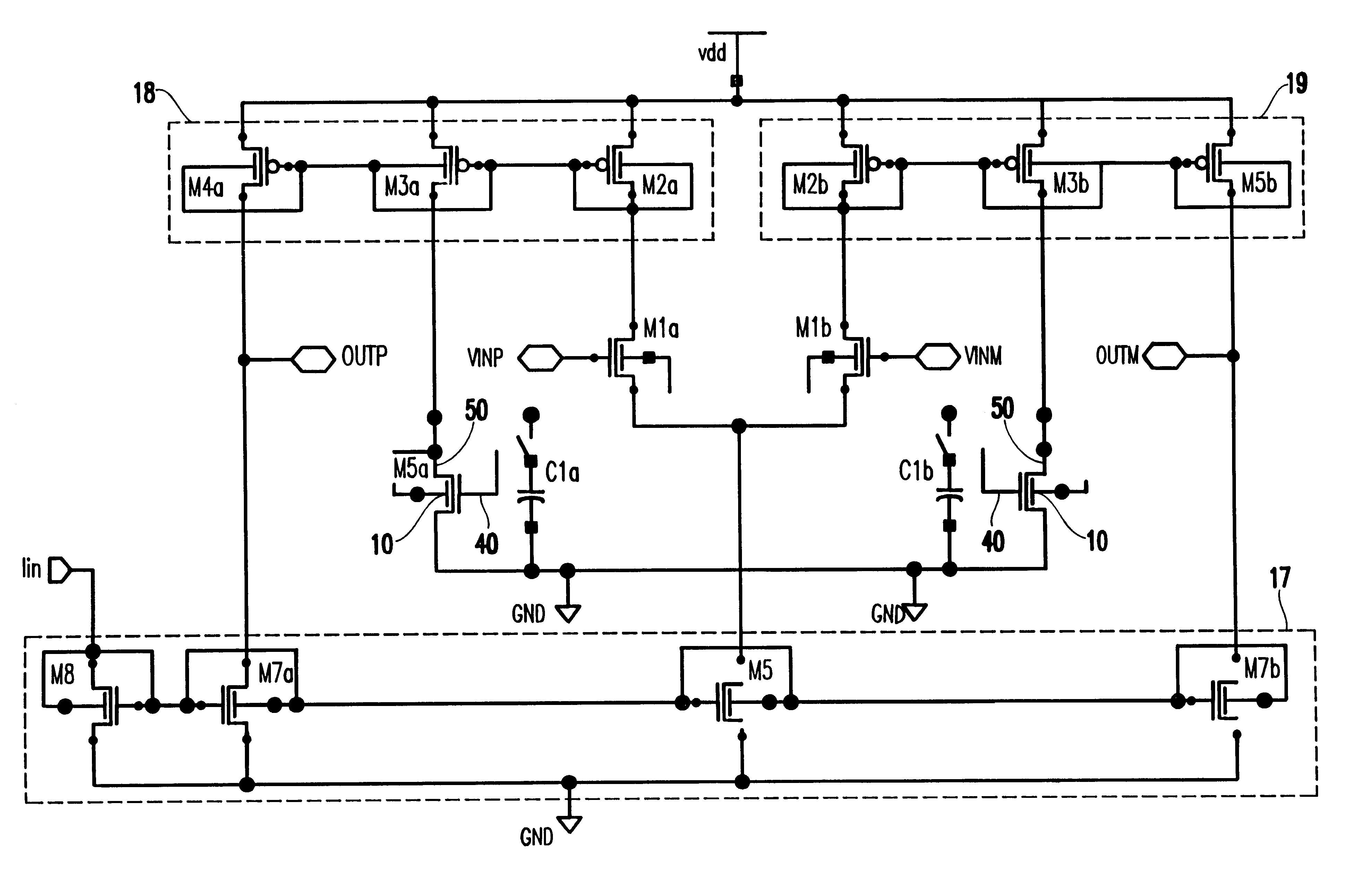

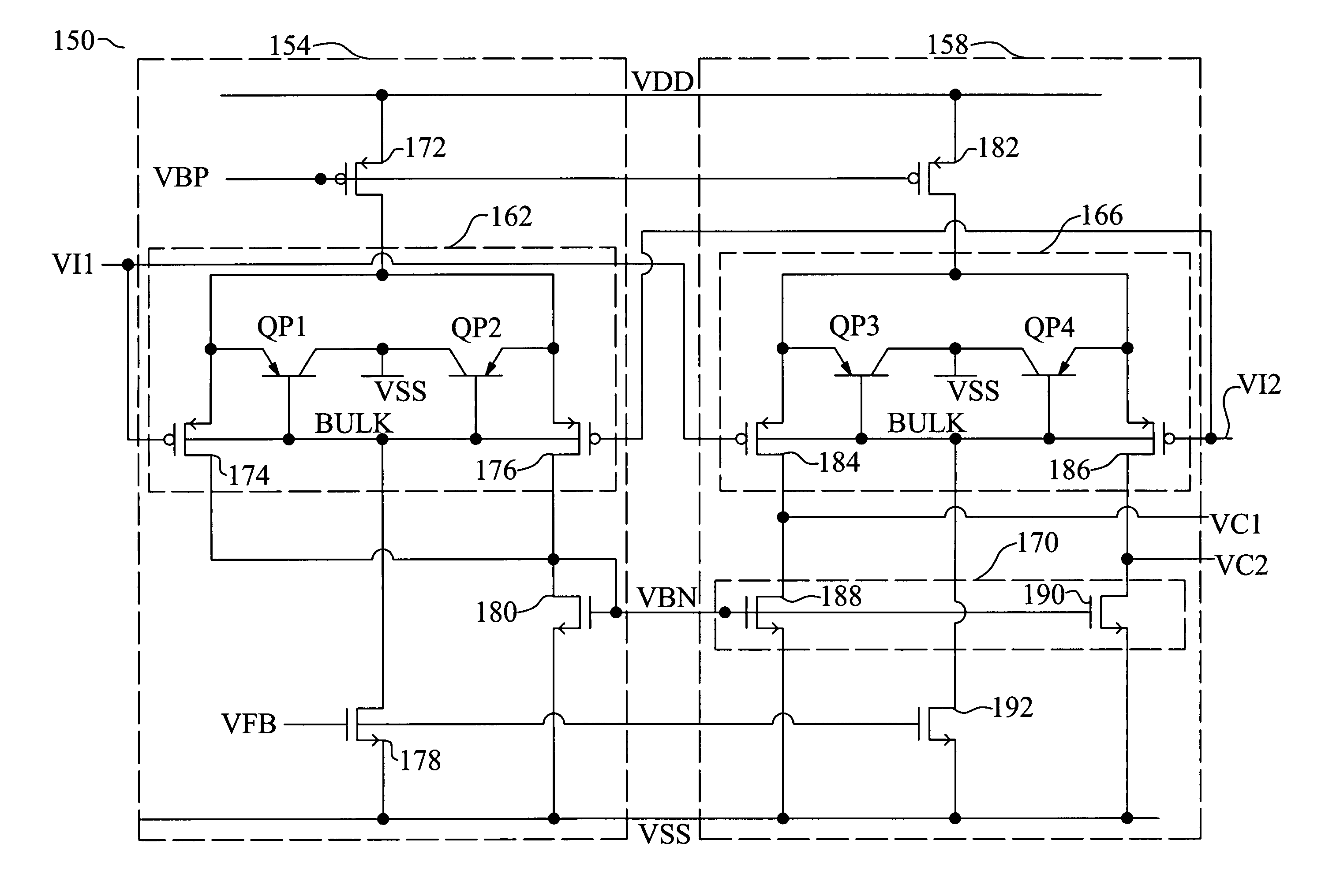

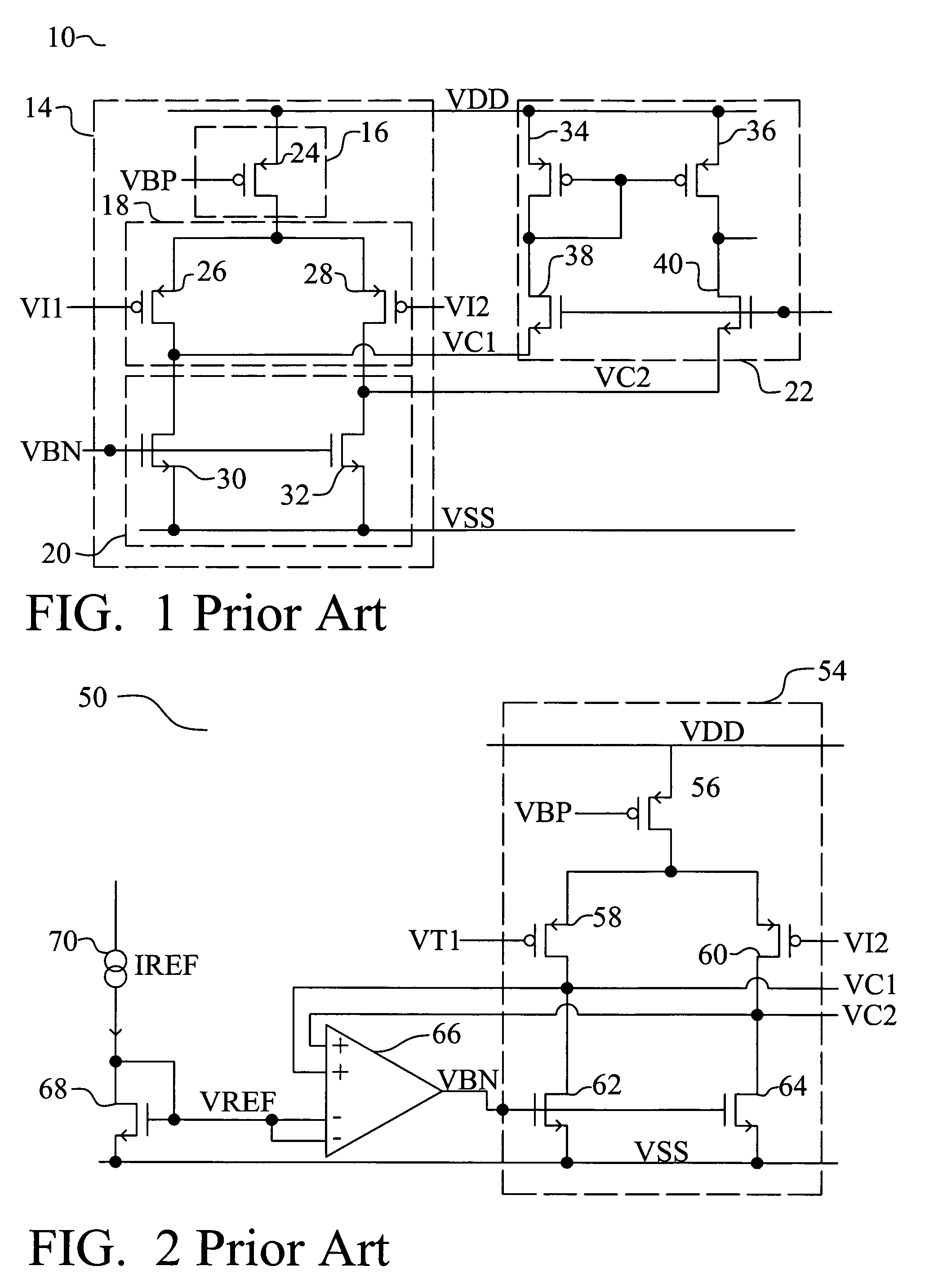

Family of analog amplifier and comparator circuits with body voltage control

InactiveUS6452448B1Differential amplifiersDc-amplifiers with dc-coupled stagesAudio power amplifierComparators circuits

A structure for an amplifier circuit which includes a pair of source-coupled differential transistors, each of source-coupled differential transistors having a body and a gate, and input transistors electrically connected to the source-coupled transistors. Also, the input transistors load the body and the gate of the source-coupled transistors with positive feedback signals. As a result, a differential gain is increased and a common mode gain is not increased. The output of the pair of source-coupled differential transistors is directed to second pair of transistors. The second pair of transistors generates mirrored voltages which track with input voltages. The second pair of transistors generates mirrored voltages translated by an offset voltage to values near ground, mirrored voltages which represent a voltage gain over an input voltage, and mirrored voltages which are largely differential and includes approximately no common mode input voltage.

Owner:IBM CORP

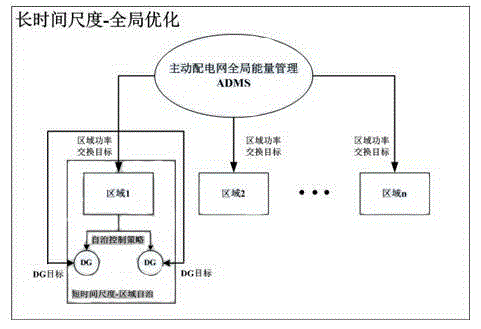

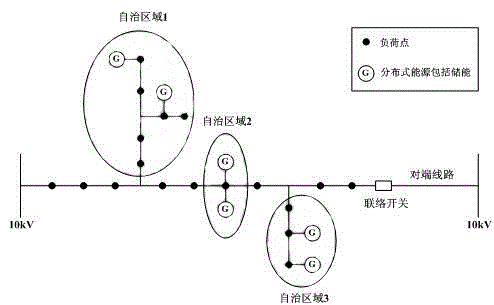

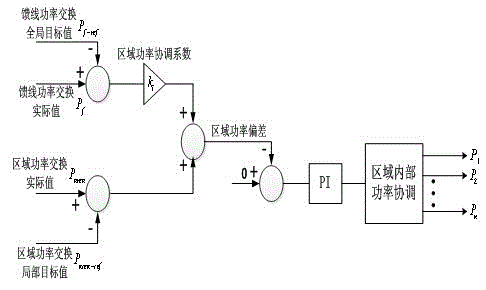

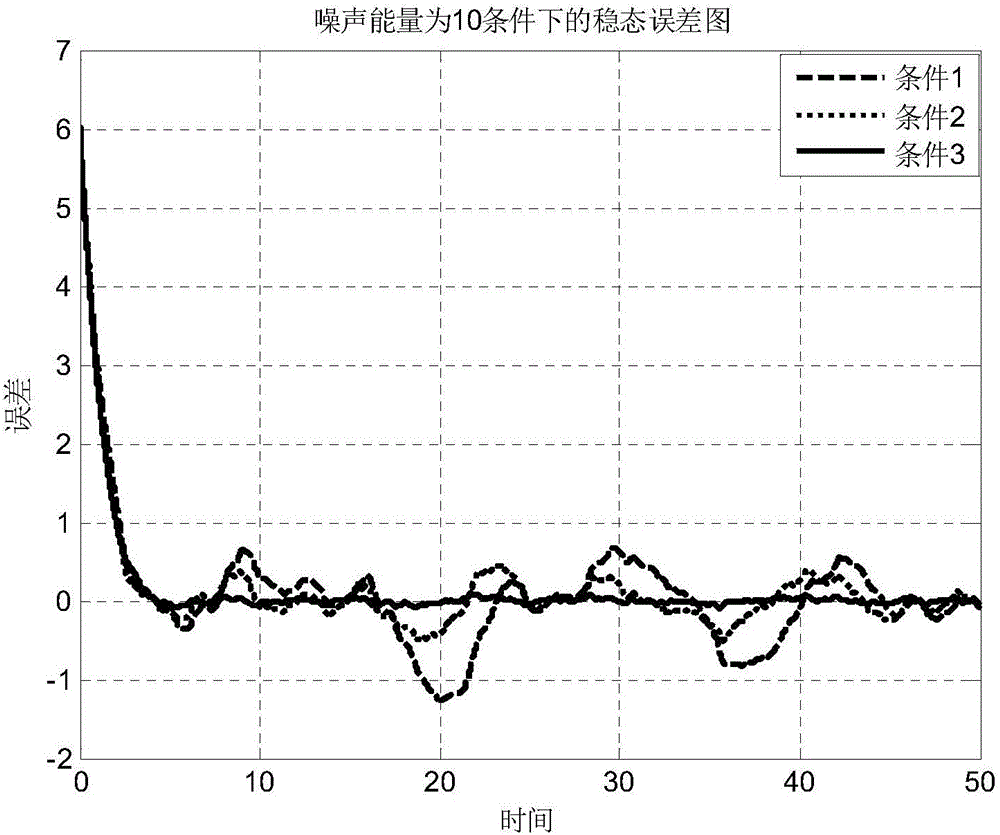

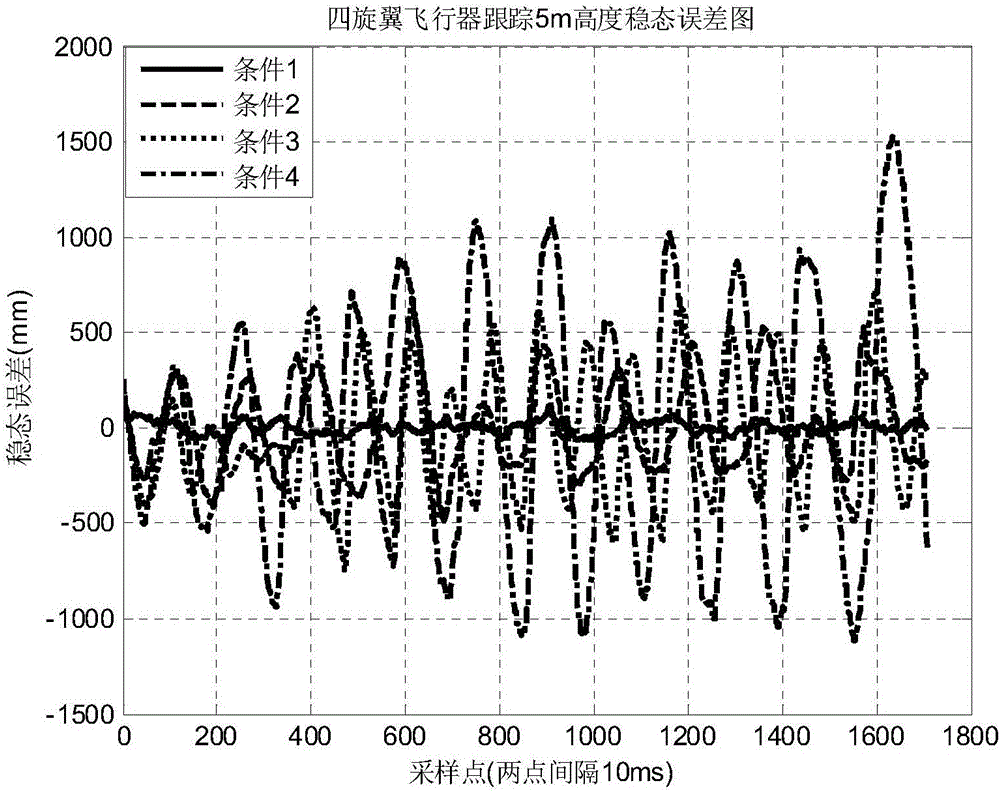

Coordinated control system and method for DG (Differential Gain) of multi-time scale active power distribution network

ActiveCN103151802AEfficient use ofImprove operating conditionsSingle network parallel feeding arrangementsControl systemEngineering

The invention discloses a coordinated control system for a DG (Differential Gain) of a multi-time scale active power distribution network. A local optimized target in each control subarea and an optimal capacity of each distributed generating unit under the condition of a long time scale are solved according to an optimal target function of an active power distribution network. On the basis of optimal running, according to the control subarea autonomy, the optimal target function is controlled to realize the real-time coordinated control on each DG in the area. The coordinated control system realizes the coordination for the global optimization and local autonomy of a distributed energy resource accessed to the active power distribution network, so that the network is under a more optimized running state and the utilization for the distributed energy resource is increased. Meanwhile, the influence of different time scales is considered, the economical efficiency of the system running is enhanced, the running robustness is optimized, and the popularization and application of the distributed energy resource are more benefited.

Owner:SHANGHAI JIAO TONG UNIV

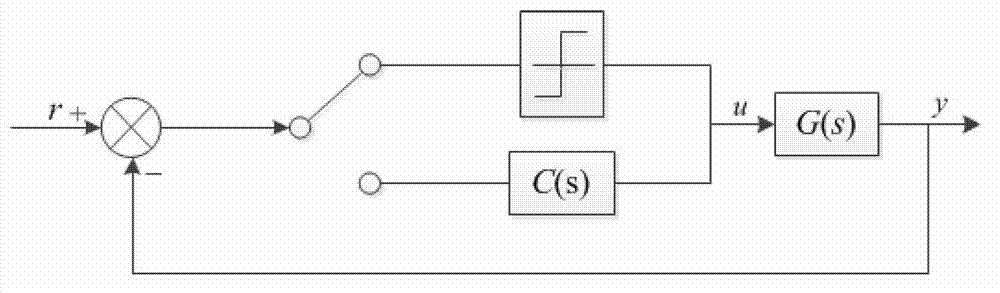

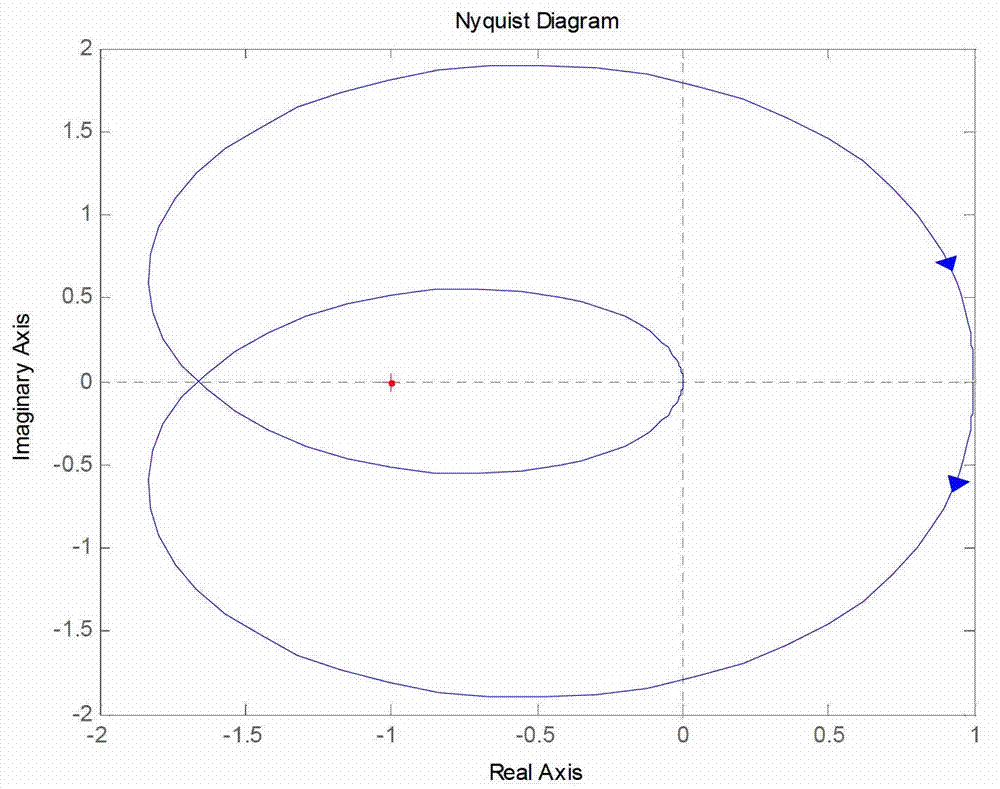

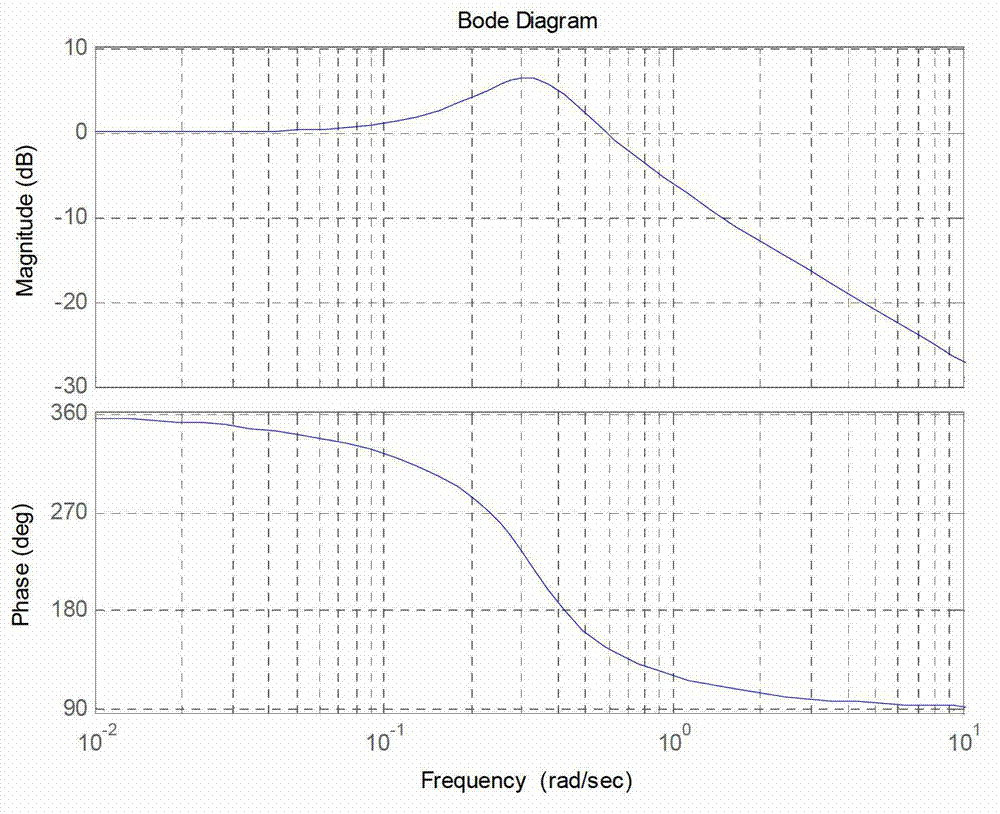

Time delay system PID controller stabilization method based on data drive

Provided is a time delay system PID controller stabilization method based on data drive. The time delay system PID controller stabilization method based on the data drive comprises the steps of firstly using relay identification of multiple frequency points, giving input frequency domain response data of a controlled time delay object and output frequency domain response data of the controlled time delay object, and extracting characteristic parameters; then obtaining the maximum permissible stabilization range of proportional gain k in a PID controller through necessary conditions of PID stabilization; for a fixed k value, obtaining a necessary and sufficient condition which can enable a closed-loop system to be stable, and determining a two-dimensional parameter domain which can enable the closed-loop system to be stable and relates to differential gain k<d> in the PID controller and integral gain k in the PID controller; and determining a two-dimensional stabilization domain with a convex polygon characteristic of the (k<d>, k) to ergodic points of each k through going through the maximum permissible stabilization range of the k, and obtaining a stabilization set of the PID controller. As long as a control parameter is selected from the obtained stabilization set of the PID controller, the stability of the closed-loop system can be ensured. According to the time delay system PID controller stabilization method based on the data drive, under the condition that a transfer function of the time delay object or a state space model of the time delay object does not need to be obtained, the PID controller stabilization method is offered based on frequency response data, complex calculation processes of pattern identification are avoided, and an approach which is simple and effective is offered for the design of a PID controller without a model time delay system.

Owner:ZHEJIANG UNIV OF TECH

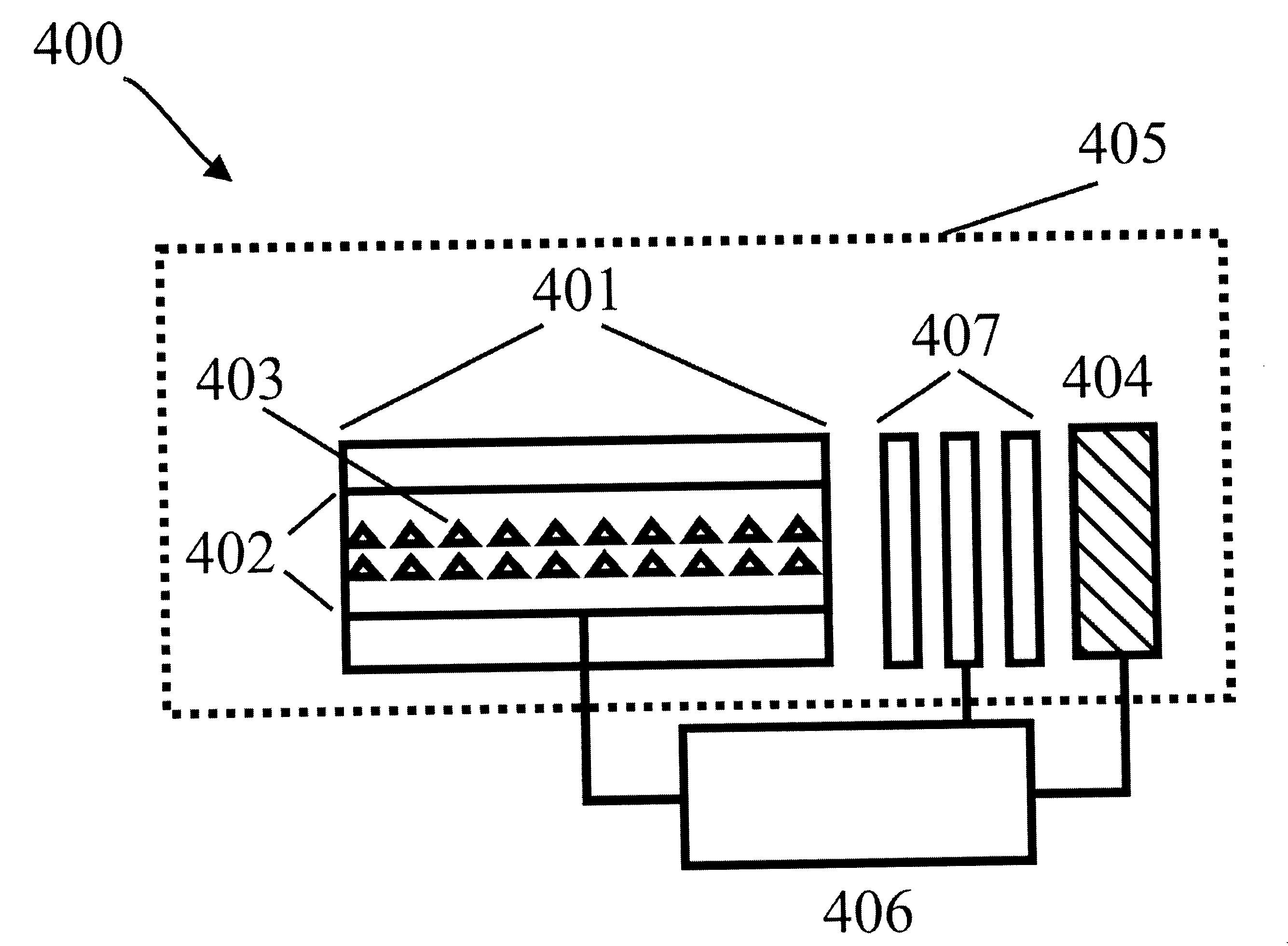

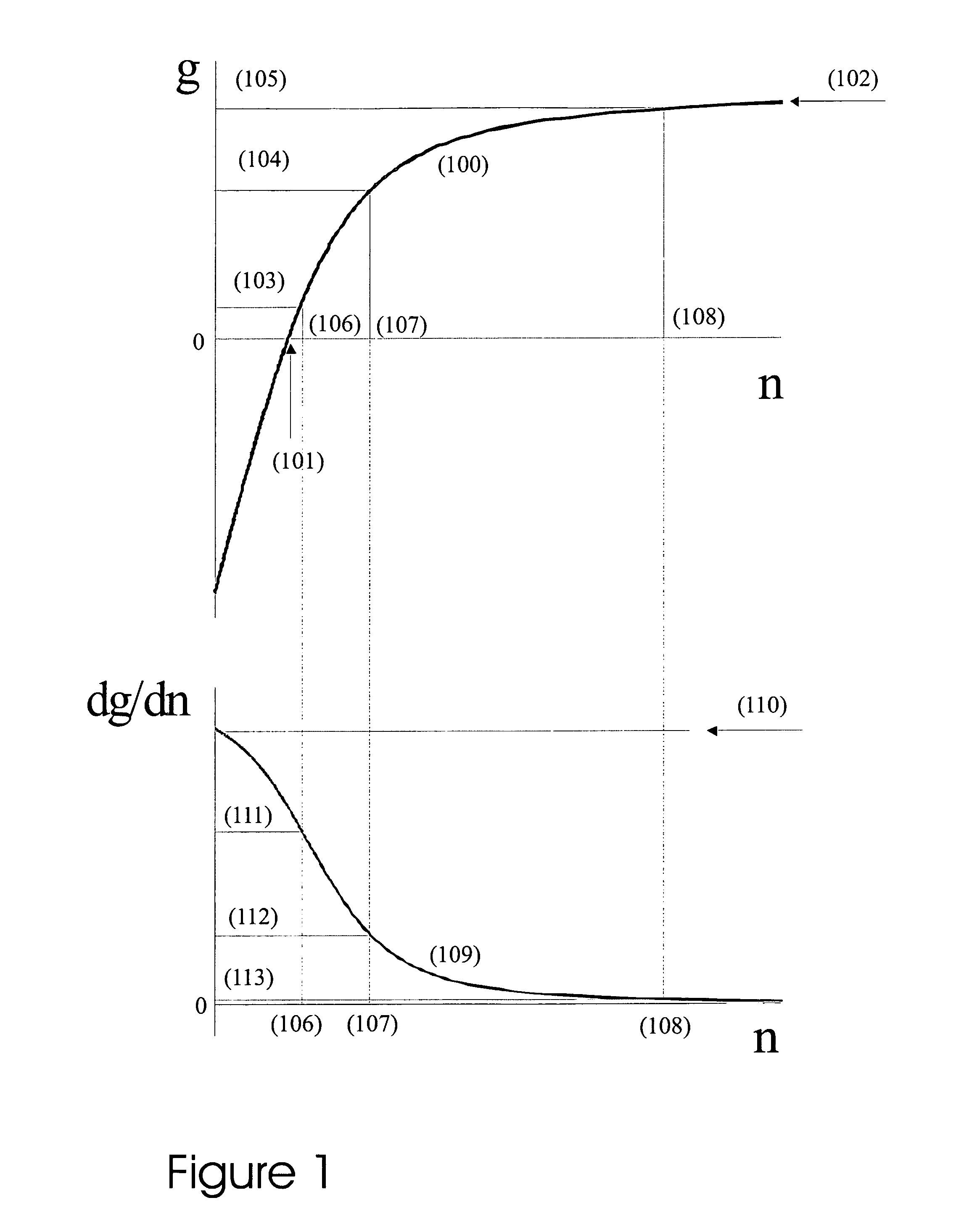

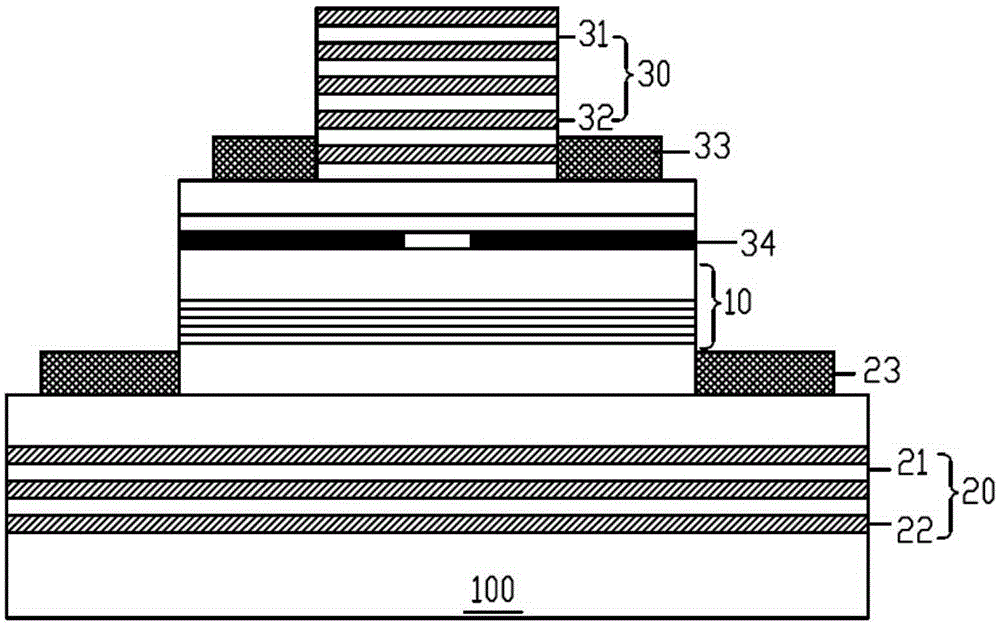

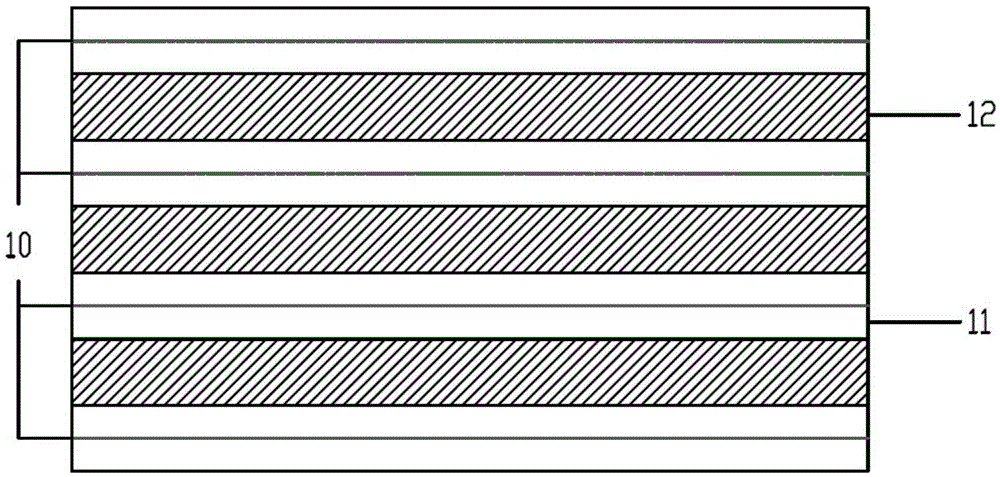

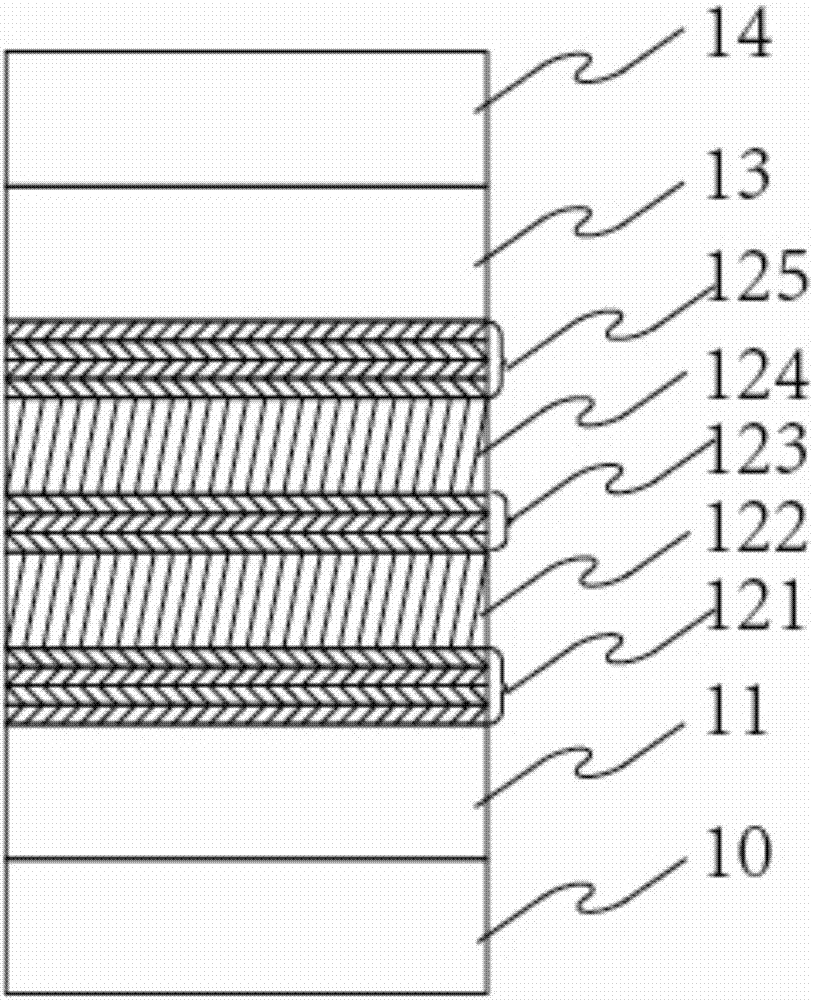

Mode-locked quantum dot laser with controllable gain properties by multiple stacking

InactiveUS20060227825A1Easy to controlImprove efficiencyLaser detailsNanoinformaticsMode-lockingQuantum dot

The optical gain and the differential gain of a quantum dot gain region in a gain section of a passive or hybrid mode-locked laser is varied by stacking at least two planes of quantum dots. All quantum dot planes are preferably formed by the same fabrication method and under the same fabrication conditions. The number of stacked planes of quantum dots is selected such that the optical gain and the differential gain are both in their optimal range with respect to the optical loss in the laser resonator and to the differential gain in the saturable absorber element. This results in a device with a short pulse width, stable mode-locking, high-power, and temperature-independent operation.

Owner:INNOLUME

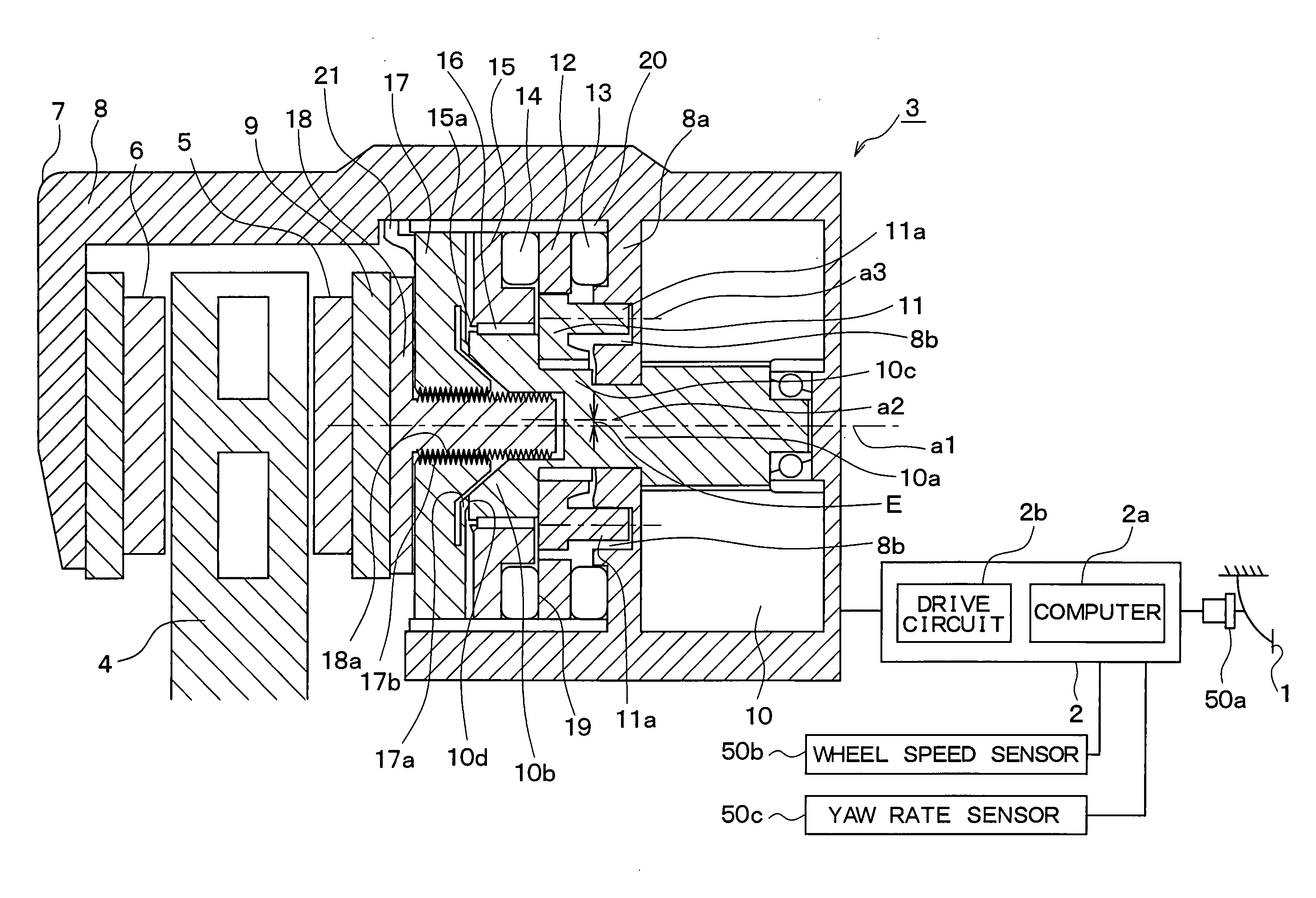

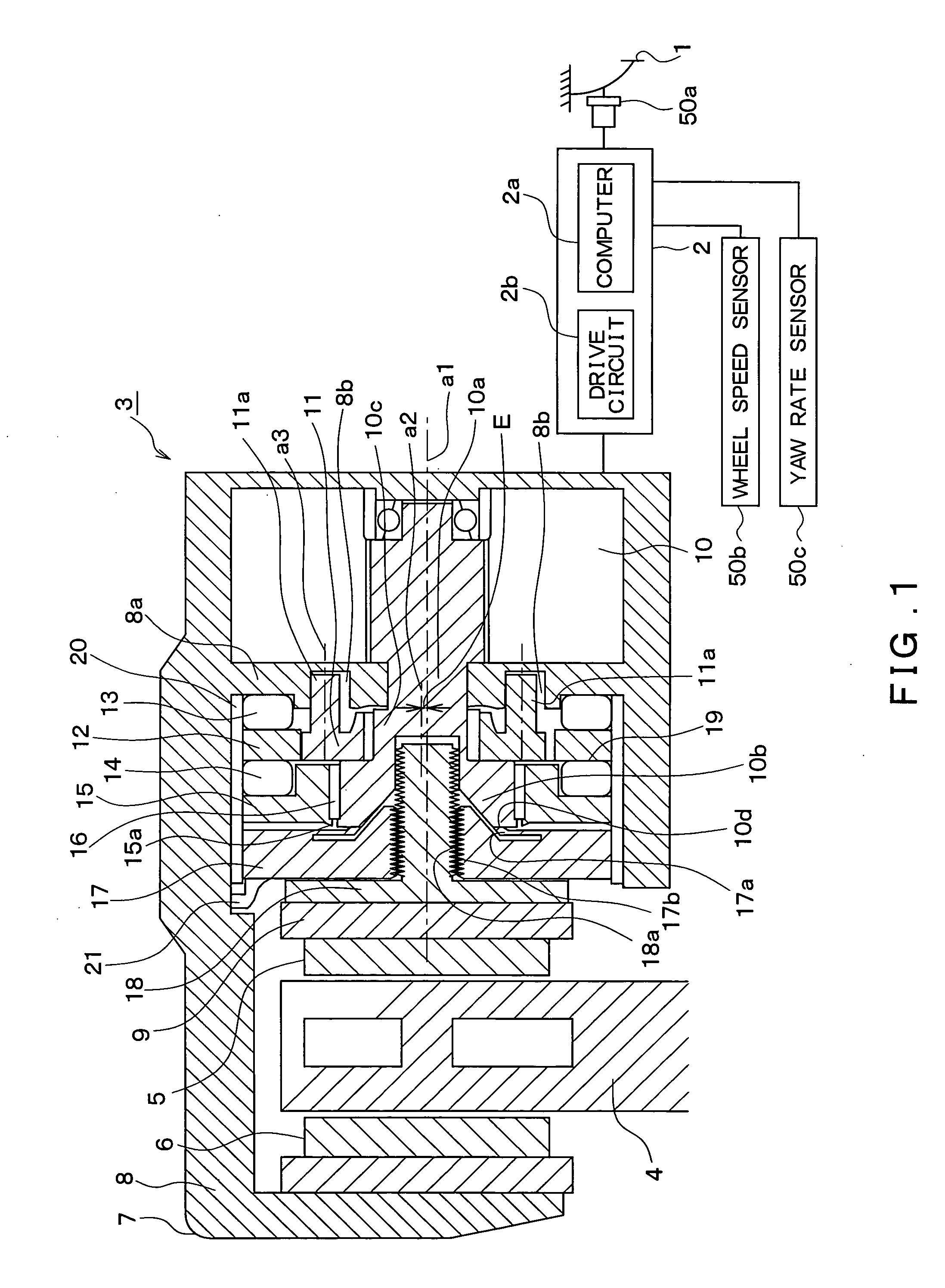

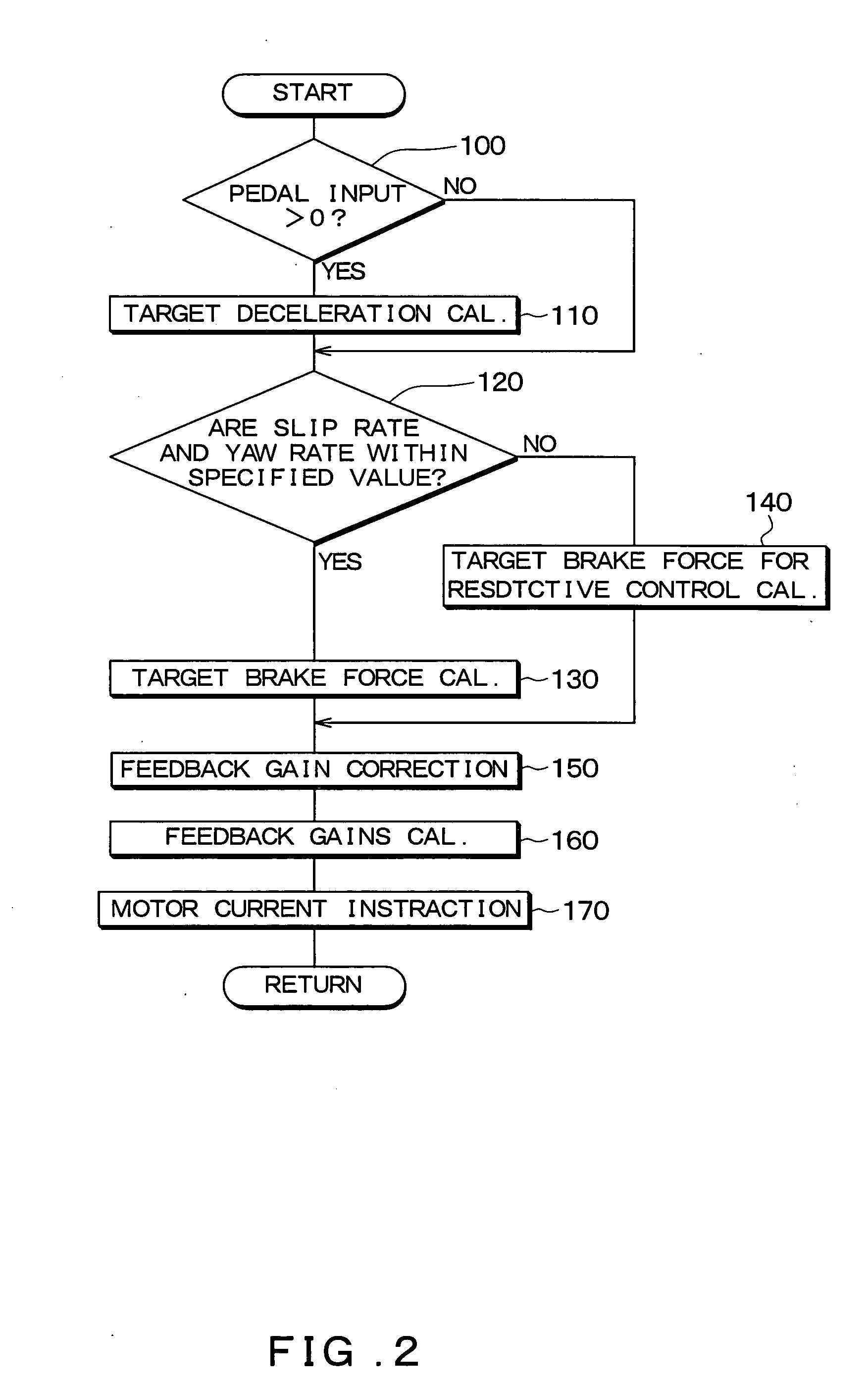

Electric brake system

InactiveUS20050046368A1Improve responseSuppress oscillation phenomenonTemperatue controlAsynchronous induction motorsEngineeringFeedback control

The present invention provides an electric brake system which detects the occurrence of overshooting, and corrects a feedback gain in the PID feedback control at overshooting. For example, it increases a differential gain Kd. Accordingly, a damping force increases from the time when the overshooting is determined, and after the overshooting, the output of an electric brake moderately decays to get closer to the target value with the passage of time.

Owner:ADVICS CO LTD

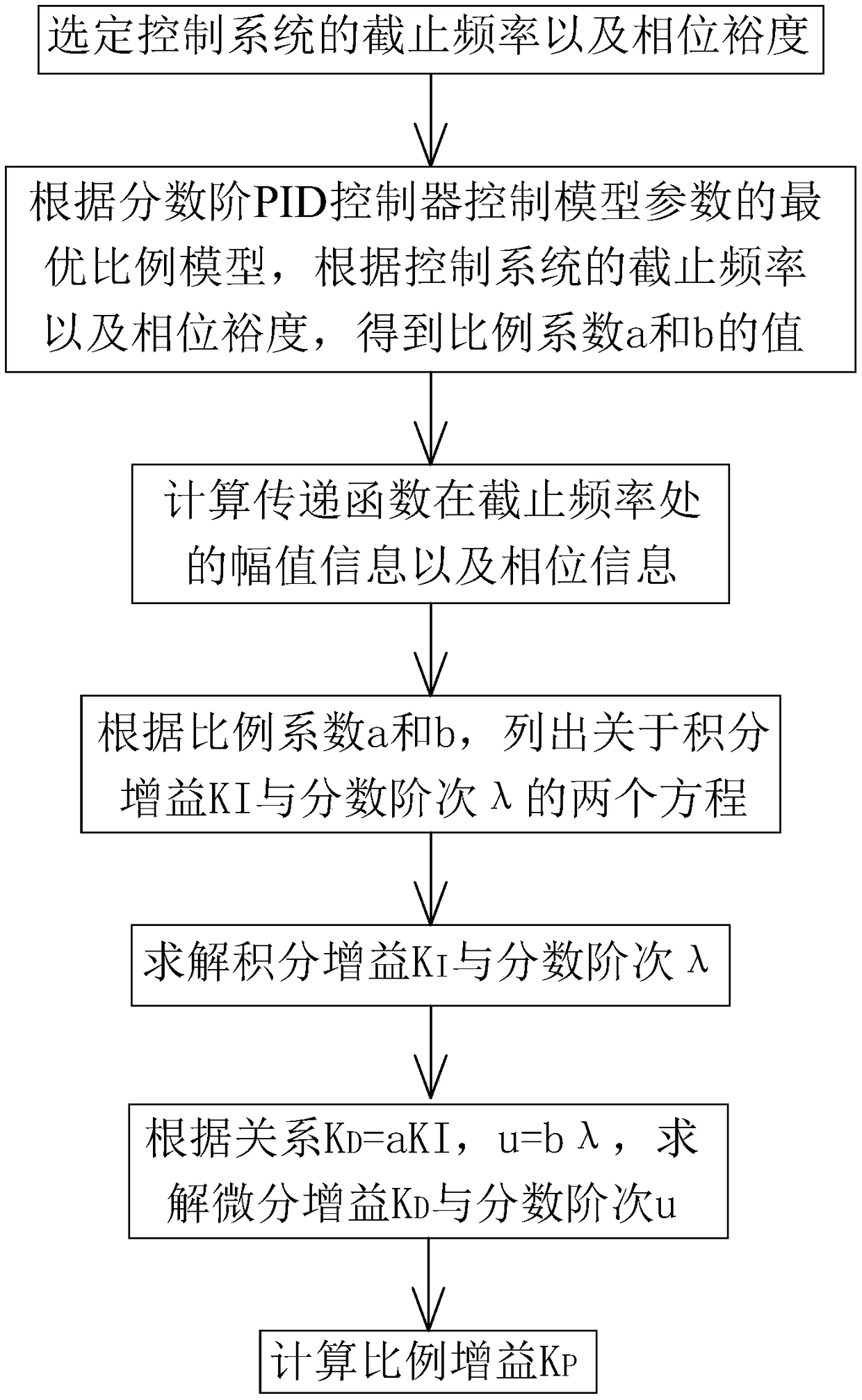

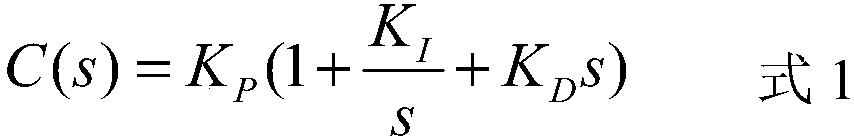

PID controller design method

InactiveCN108803311ALess freedomReduce the difficulty of settingSampled-variable control systemsControllers with particular characteristicsControl systemDifferential of a function

The invention discloses a PID controller design method. A control model of a PID controller is C(s)=Kp(1+K / S<lambda>+K<D>S) in which K<D>=aK, u=blambda, and a and b represent proportional coefficients respectively, and the control model of the PID controller is reset as C(s)=Kp(1+K / S<lambda>+ aKS<blambda>). A transfer function of a controlled object in the control system is set as G(s)=K / (S<3>+tau1S<2>+tau2S). According to the method, the cutoff frequency omegac and phase margin phim are selected; an optimal proportion model of model parameters is controlled according to the fractional order PID controller, and values of the proportional coefficients a and b are obtained according to the cutoff frequency omegac and phase margin phim; amplitude information and phase information of the transfer function in the cutoff frequency omegac are calculated; two equations related to the integral gain KI and the fractional order lambda are listed; the integral gain KI and the fractional order lambda are solved; a differential gain KD and a fractional order u are solved; and the proportional gain KP is calculated. The proportional relation between the integral gain KI and the differential gain KD of the fractional order PID controller as well as the proportional relation between the integral order lambda and the differential order u are established, the freedom degree of parameters of the fractional order PID controller is reduded, and the difficulty in parameter setting is reduced.

Owner:FOSHAN UNIVERSITY

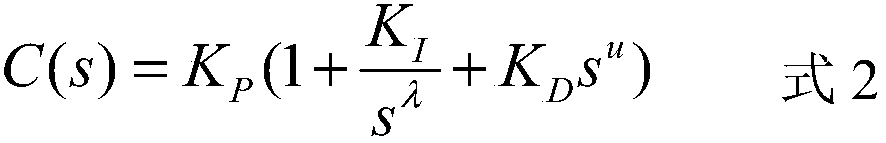

PID parameter adjusting method based on interference compensator

ActiveCN106094510ASave tuning timeImprove controlControllers with particular characteristicsControl signalFeedback controller

The invention discloses a PID parameter adjusting method based on an interference compensator, and belongs to the PID control field, especially to a parameter adjusting method of PID control. According to the method, a system closed-loop adjusting loop which comprises control input, a controlled object and control output is established, control input comprises a reference control signal and a PID feedback controller, control output represents a practical state of the controlled object, and the PID feedback controller controls the practical state of the controlled object according to the reference control signal. Under certain conditions of virtual proportion gain kp and virtual differential gain kd, the output state of the PID controller is linearly correlated to change of a virtual filter constant T. According to the invention, the parameter adjusting time is reduced substantially, and the control effect is improved greatly.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

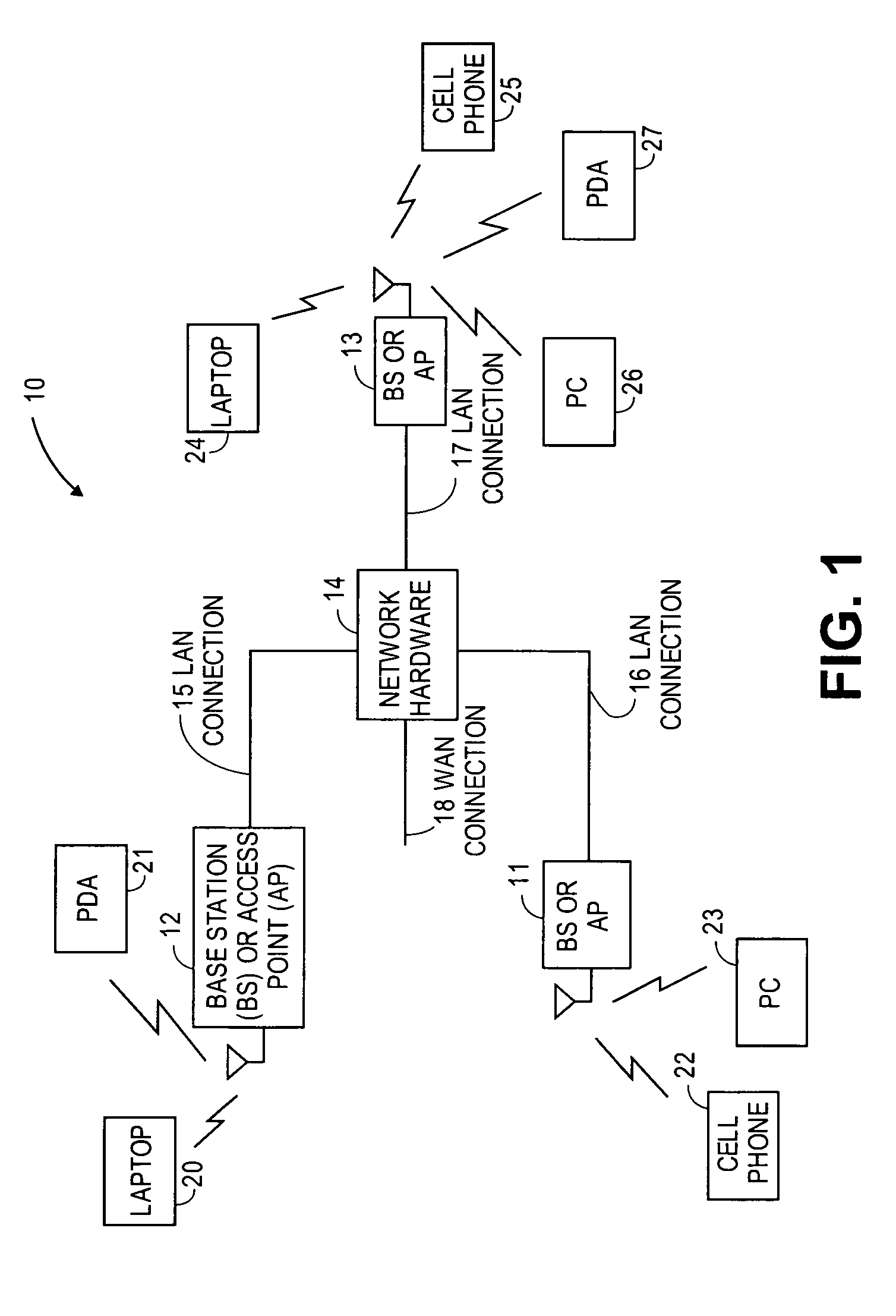

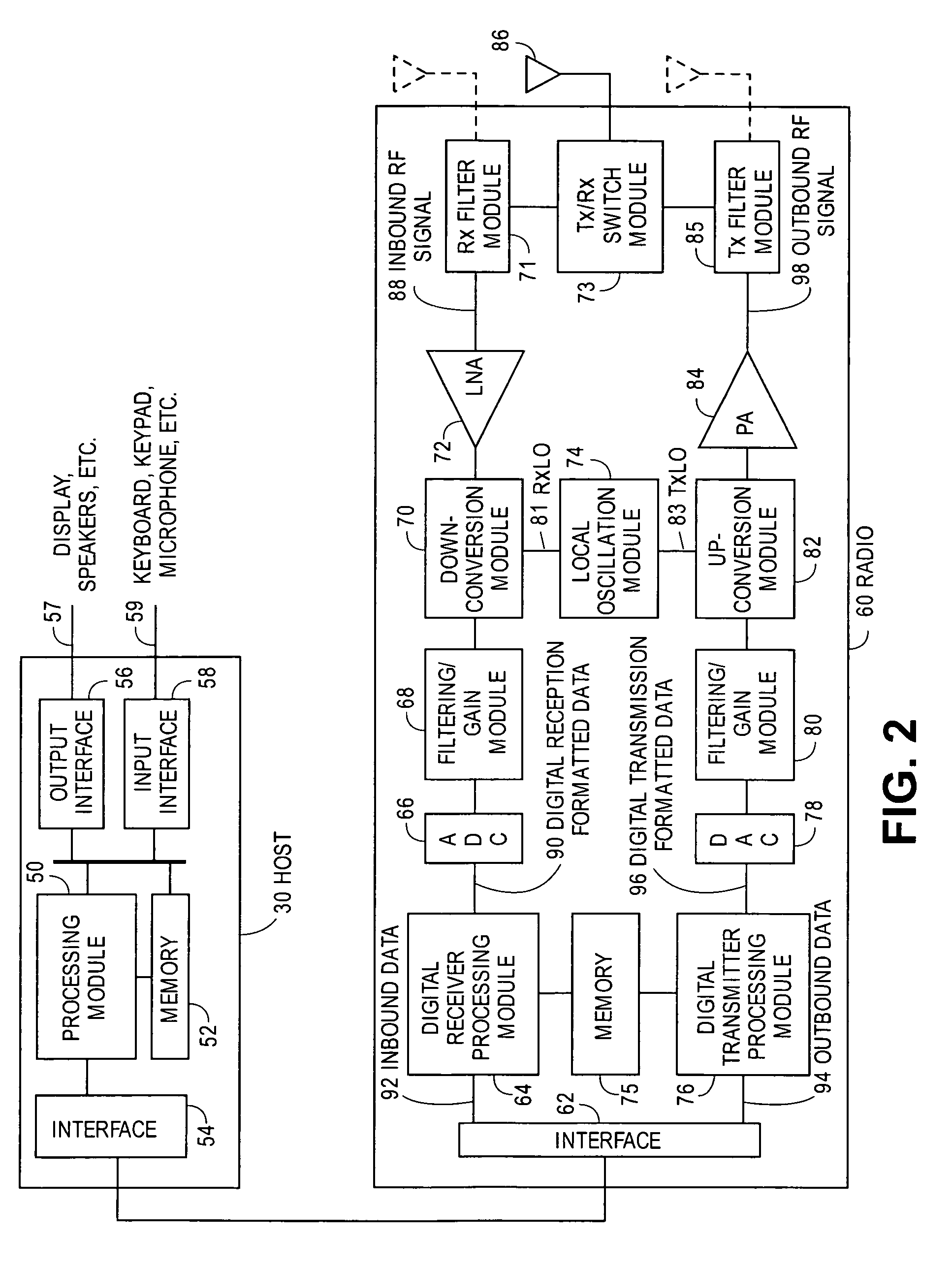

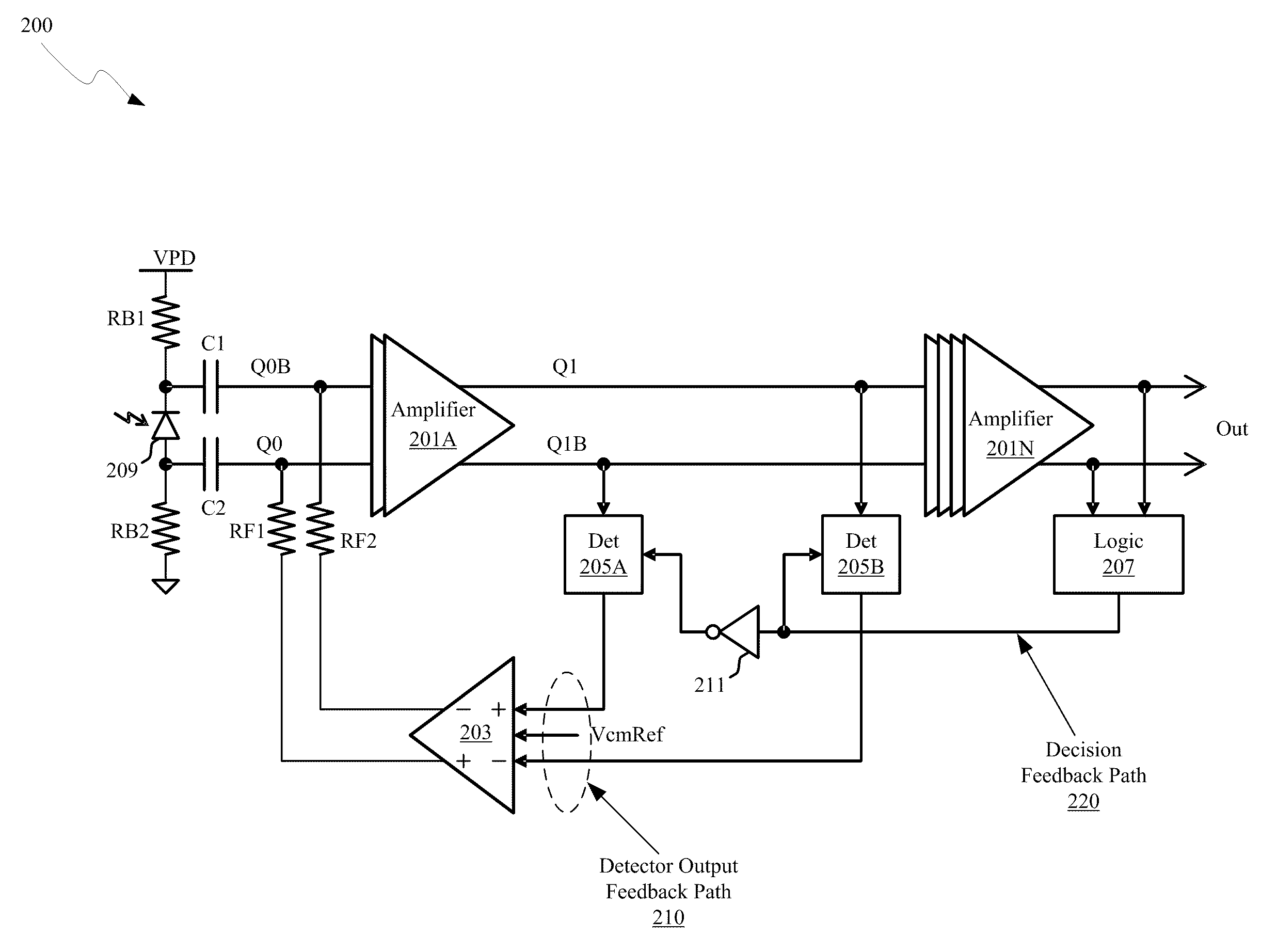

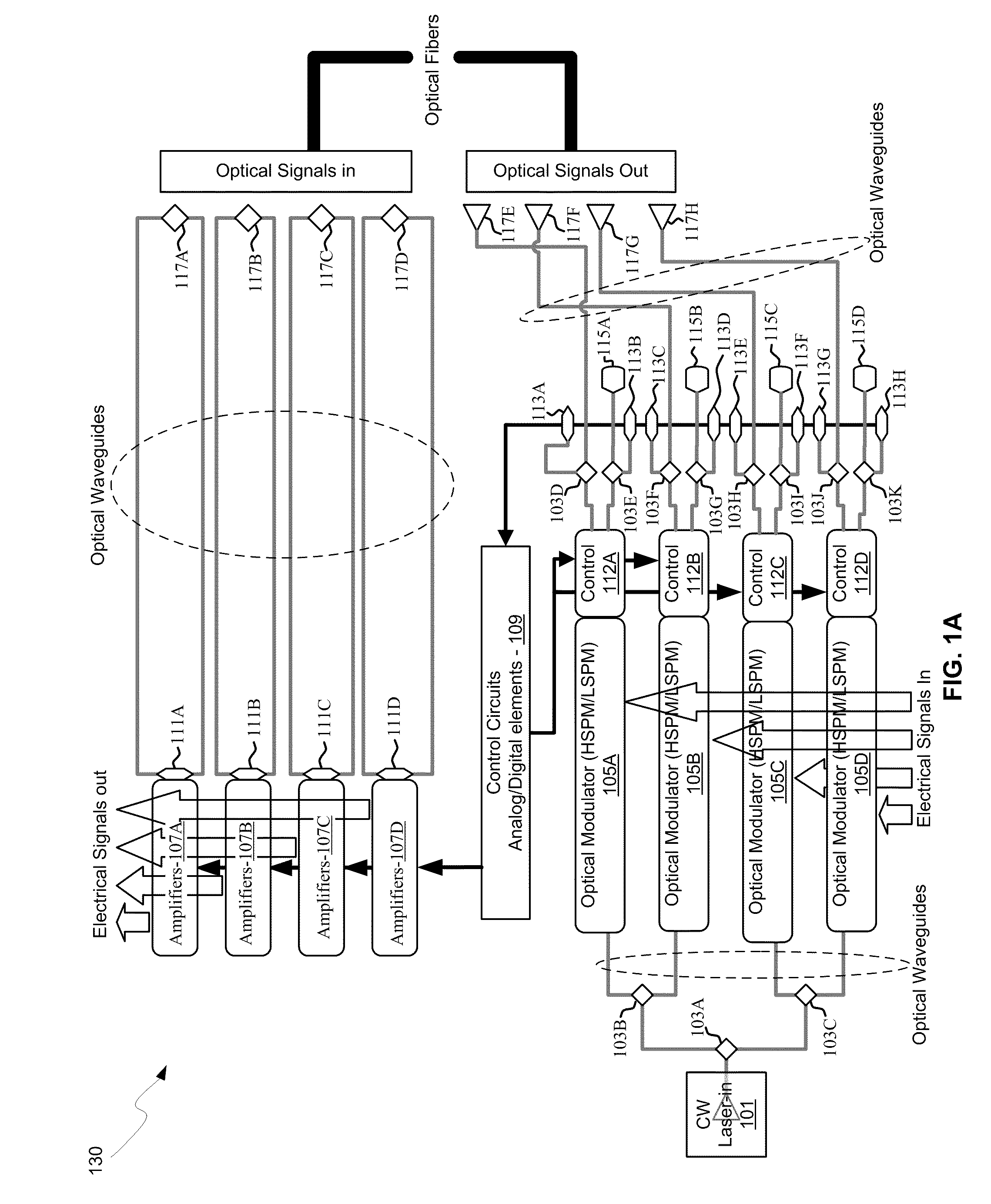

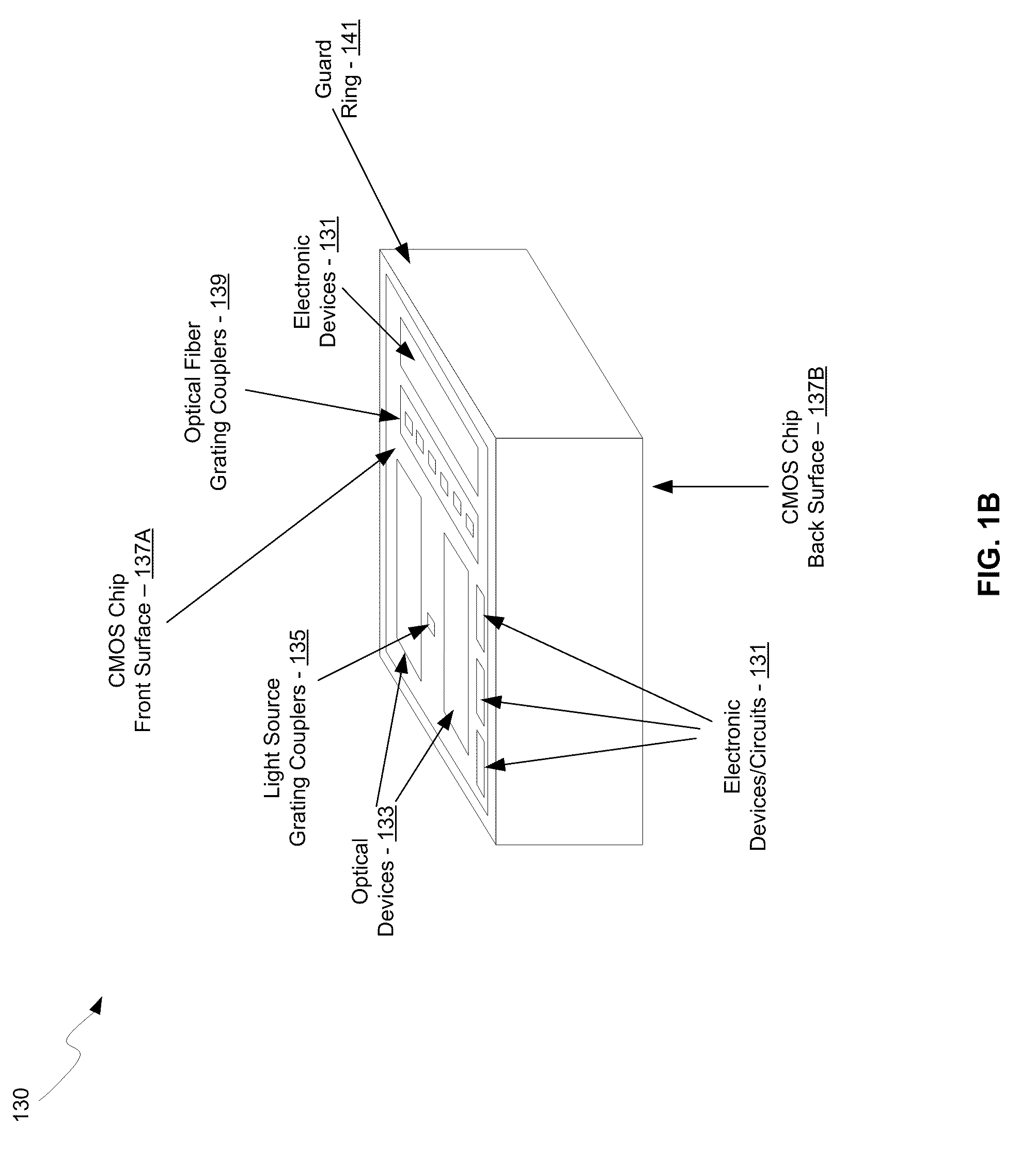

Method and system for optoelectronic receivers for uncoded data

A method and system for optoelectronic receivers for uncoded data are disclosed and may include amplifying received electrical signals in a signal amplifier comprising differential gain stages with signal detectors coupled to the outputs. First and second output voltages may be tracked and held utilizing the signal detectors. A difference between the tracked and held value may be amplified in a feedback path of the gain stage, which enables the dynamic configuration of a decision level. The received electrical signals may be generated from an optical signal by a PIN detector, an avalanche photodiode, or a phototransistor. The electrical signal may be received from a read channel. The feedback path may comprise digital circuitry, including an A / D converter, a state machine, and a D / A converter. The detectors may comprise envelope detectors utilized to detect maximum or minimum voltages. The signal amplifier may be integrated in a photonically-enabled CMOS chip.

Owner:CISCO TECH INC

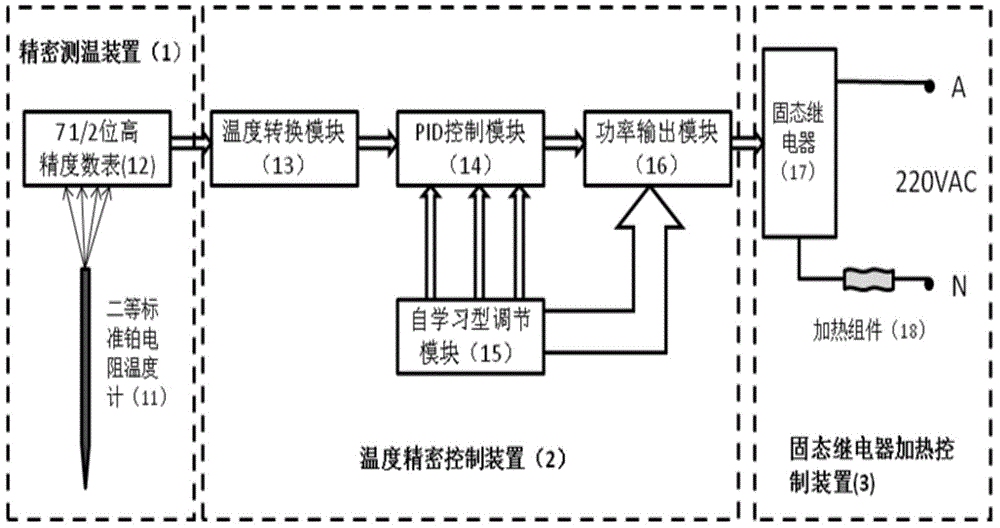

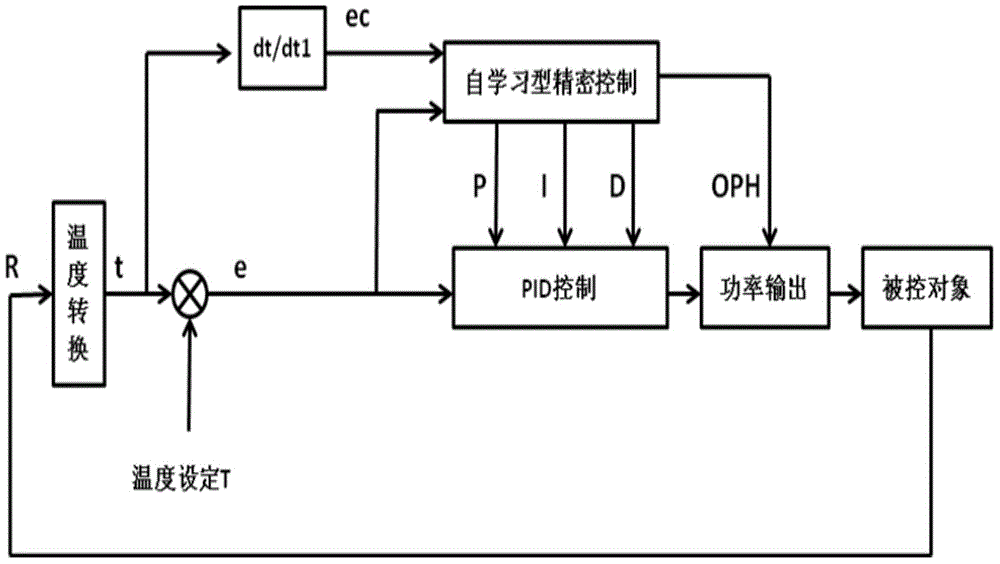

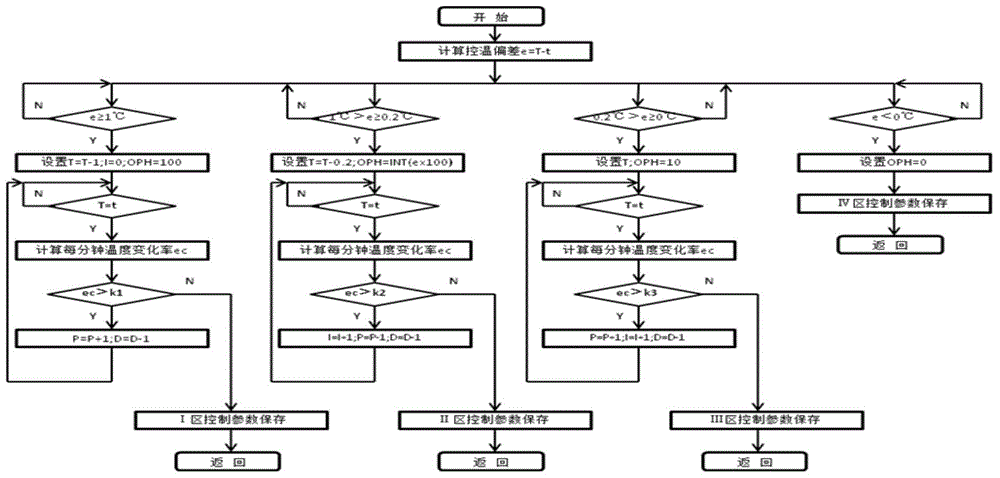

Self-learning temperature precise control method

ActiveCN104991589AEasy to controlAuxillary controllers with auxillary heating devicesHysteresisTemperature control

A self-learning temperature precise control method is provided. Aiming at the fact that a temperature control system has the characteristics of non-linearity, hysteresis and time variation, the temperature control system is adopted by the invention to automatically adjust and determine the proportion gain P, the integration gain I, the differential gain D and the output power OPH of each temperature control point automatically according to a temperature control error e and a temperature change rate ec, so that the precise control with + / - 0.005 DEG C deviation is realized for each temperature control point. According to the invention, the automatic learning balance of the PID control parameters and the output power OPH are ingeniously utilized to realize the precise control of temperature. The invention is the innovated exploration and try of the temperature precise control method, the high-speed processing capability of an embedded ARM processor and intelligent control parameter learning are used to replace a normal PID control adjusting technology, so that the temperature control precision is improved, and the self-learning temperature precise control method is simple, reliable and effective.

Owner:YUNNAN POWER GRID CO LTD KUNMING POWER SUPPLY BUREAU

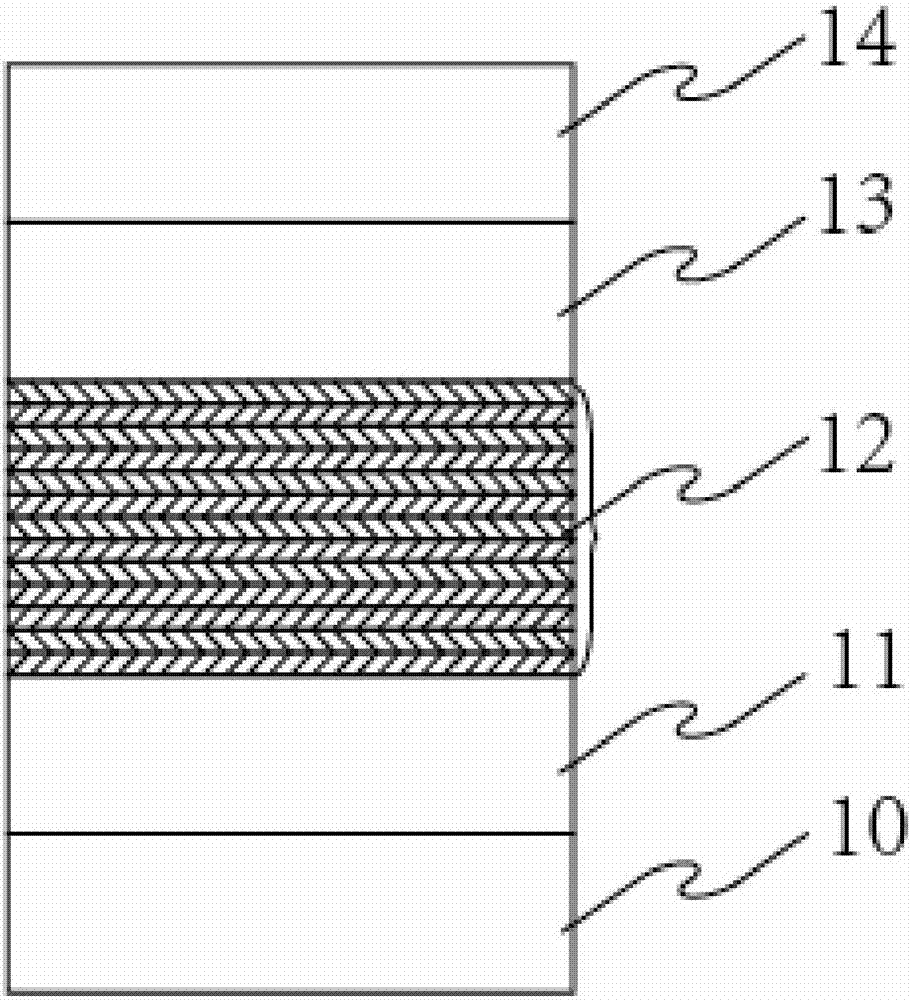

Molecular beam epitaxy growing method of high-speed vertical-cavity surface-emitting laser

ActiveCN105337166AReduce the impactReduce spreadLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserDelta doping

The invention provides a molecular beam epitaxy (MBE) growing method of a high-speed vertical-cavity surface-emitting laser. The method comprises the steps that deoxidation pretreatment is conducted on a GaAs substrate, and epitaxial growth of a GaAs buffer layer, a lower DBR, an active region, an oxidation confinement layer and an upper DBR is sequentially achieved; in the growth process, the active region is clamped between the upper DBR and the lower DBR, and a delta-doping method is adopted by the potential barrier middle position of the active region, wherein a doping source adopts carbon (C), and growth is stopped for a period of time under the protection of As after delta-doping is completed. By means of the method, the technical problems of reducing a threshold, increasing differential gain and reducing nonlinear gain compression are solved, and the good effects of reducing optical losses, decreasing line width and increasing output power and intrinsic bandwidth are achieved.

Owner:WUHAN TELECOMM DEVICES

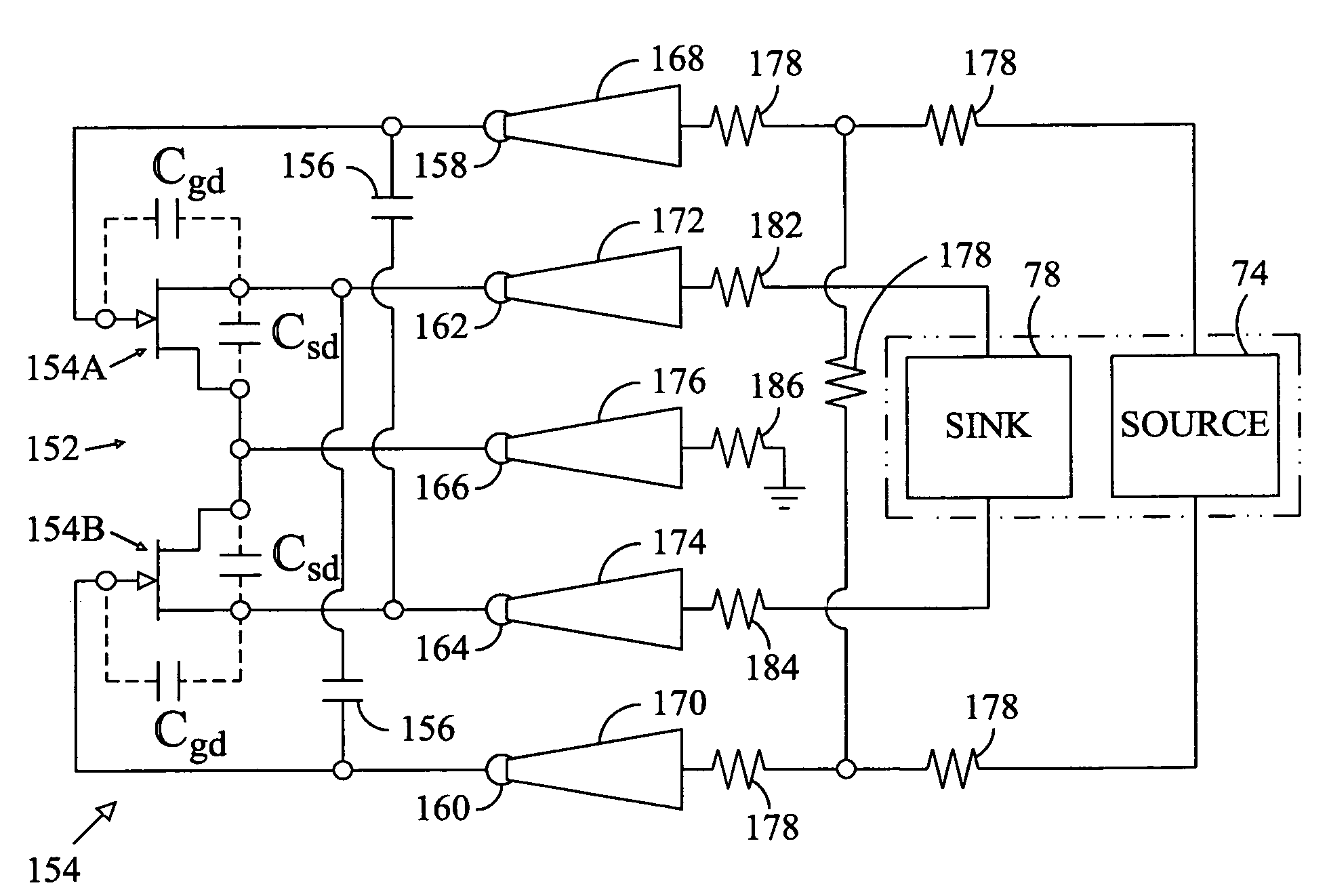

Wideband variable gain amplifier with low power supply voltage

InactiveUS6583668B1Amplifier combinationsDifferential amplifiersAudio power amplifierVariable-gain amplifier

A circuit for a variable gain amplifier is disclosed that uses two differential gain stages with independently adjustable bias currents. By changing the bias currents of the gain stages, the overall gain and phase of the amplifier can be adjusted over a wide range. Neither in-series nor in-parallel circuitry is required to implement or perform gain control. In addition to minimal part requirements for mechanization, the present invention features low power supply requirements while maintaining a wide operational bandwidth.

Owner:EUVIS

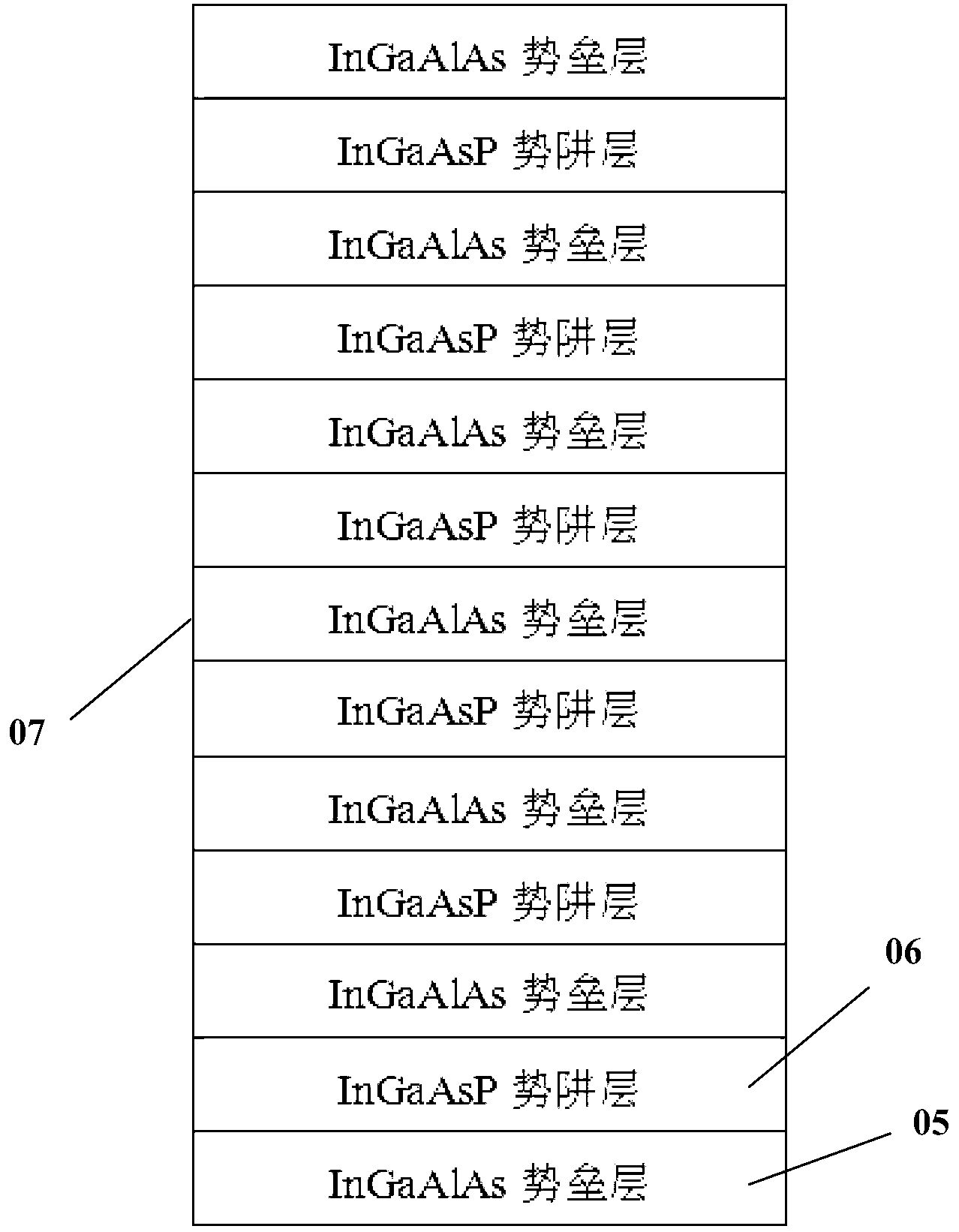

Active area of laser unit, semiconductor laser unit and manufacturing method of laser unit

ActiveCN103326242ALower threshold currentRaise the characteristic temperatureLaser detailsSemiconductor lasersPotential wellCharge carrier

The invention discloses an active area of a laser unit. The active area comprises a multiple-quantum well structure, wherein a potential well layer in the multiple-quantum well structure is made from InGaAsP, and a barrier layer in the multiple-quantum well structure is made from InGaAlAs; a cycle of the multiple-quantum well structure is K, and K ranges from 3 to 20. Furthermore, the invention discloses a semiconductor laser unit and a manufacturing method of the laser unit, wherein the semiconductor laser unit comprises the active area. The semiconductor laser unit provided by the invention has a lower threshold current and higher characteristic temperature, to realize no-refrigeration work; the laser unit has relatively high differential gain, and can provide a laser output in a Tencent Messenger (TM) mode; the laser unit has a relatively high conduction band order, so as to simultaneously restrict injected carriers effectively and distribute the carriers among wells uniformly and enhance the modulation characteristic of the laser unit.

Owner:苏州市吴中中科育成科技发展有限公司

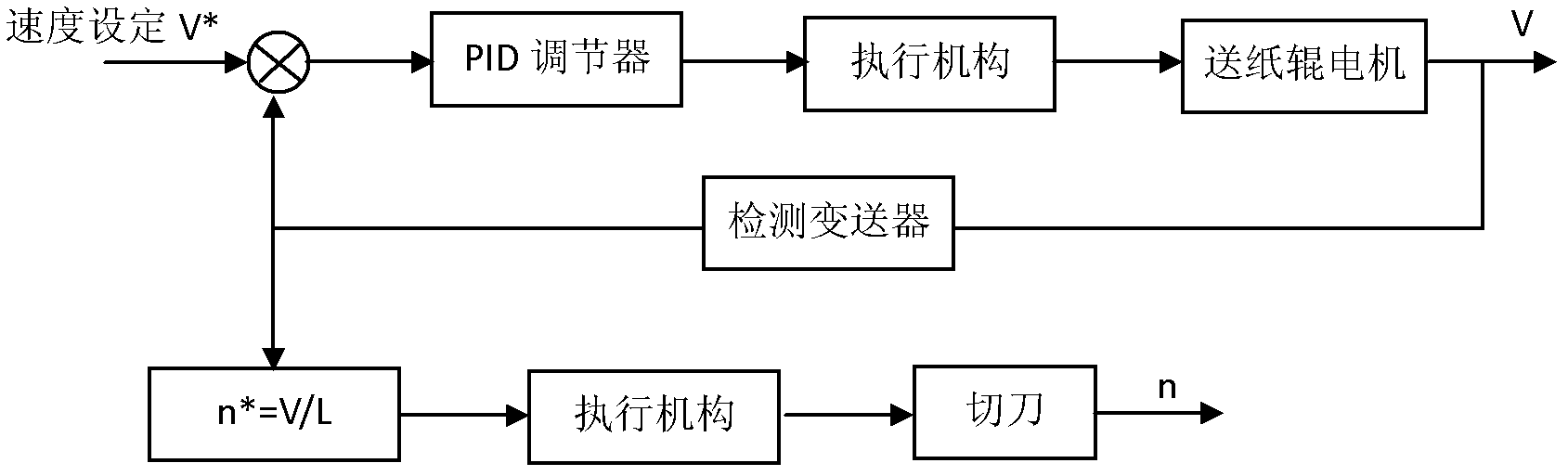

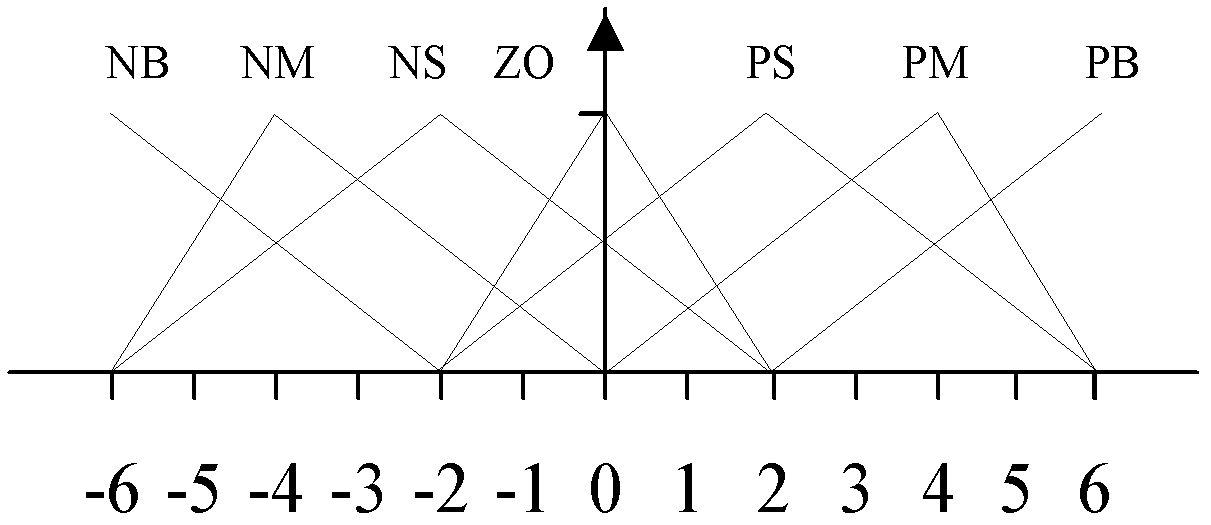

Feed-forward-fuzzy proportion integration differentiation (PID) control-based control method for paper cutting machine

InactiveCN102621882AImprove anti-interference abilityImprove dynamic performanceControllers with particular characteristicsMetal working apparatusProportion integration differentiationControl system

The invention relates to a feed-forward-fuzzy proportion integration differentiation (PID) control-based control method for a paper cutting machine. The method comprises the following steps of: setting a paper cutting length and the frequency of a cutter after system initialization, cutting paper under the control of a single-closed loop control and ratio control system, and stopping the paper cutting machine after the cutting of the paper is finished. The speed V of a paper feeding roller is controlled in a fuzzy PID control way on the basis of the conventional single-closed loop control andratio control over the speed of the cutter, so that the dynamic response and steady-state characteristics of a system are improved; namely, a fuzzy control mode is adopted, and a fuzzy controller is additionally arranged on a PID regulator, takes an error value E and an error change rate DeltaE as input language variables, and takes a proportional gain coefficient KP, an integral gain coefficientKI and a differential gain coefficient KD as output language variables, so that the PID regulator is controlled; and in addition, a feed-forward controller is arranged behind an execution mechanism, so that the problem that the speed V of the paper feeding roller is fluctuated by load disturbance is solved, and the fluctuation of the rotating speed n of the cutter is also alleviated.

Owner:QILU UNIV OF TECH

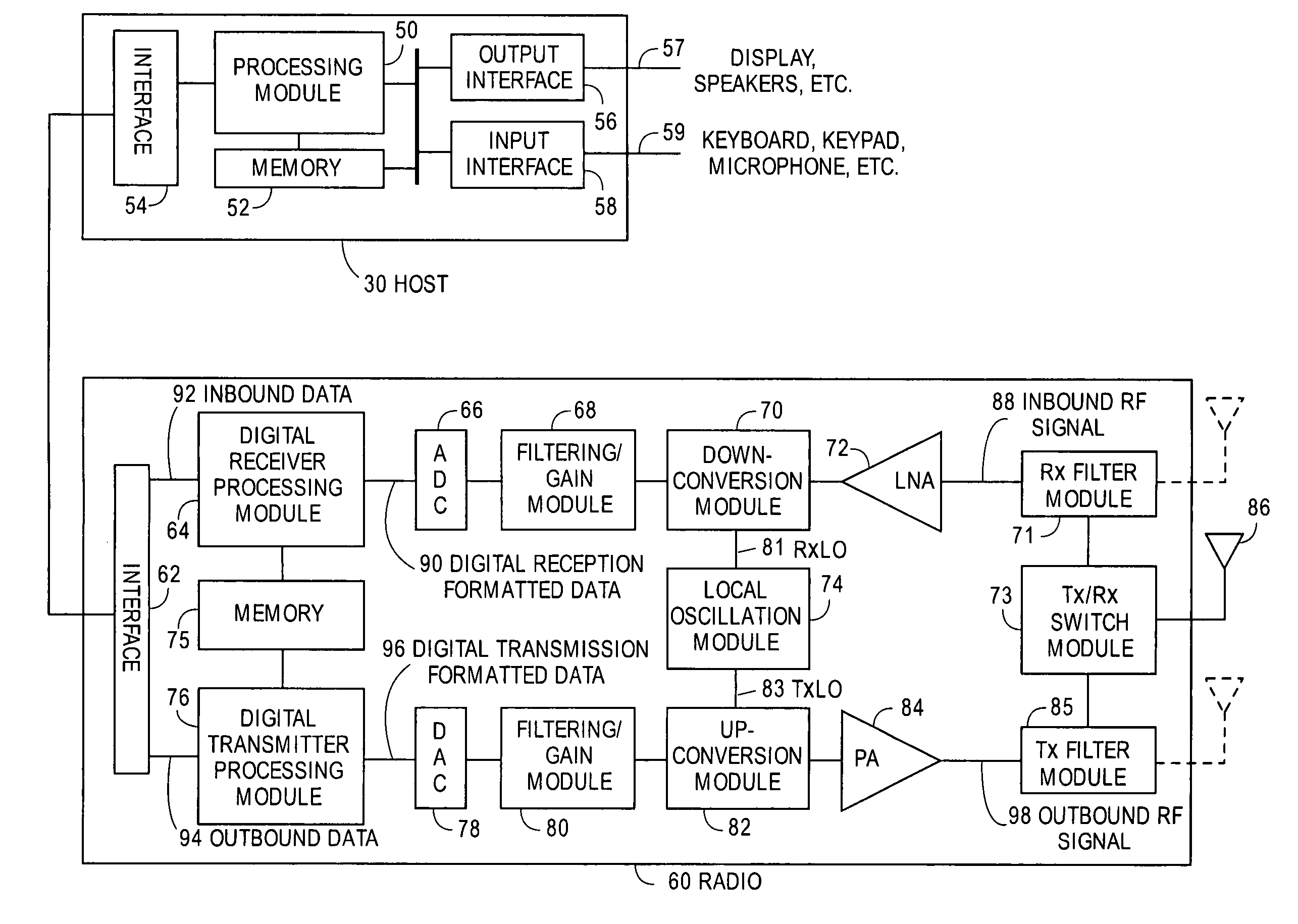

Gain boosting RF gain stage with cross-coupled capacitors

ActiveUS20060057990A1Tighter current flow controlHigh gainHigh frequency amplifiersRadio transmissionCapacitanceCapacitor

A RF differential gain stage has cross-coupled capacitors between input and output nodes of the amplifier stage to boost gain. The gain boost allows cancellation of the series resistance of an inductive load of the amplifier stage.

Owner:QUALCOMM INC

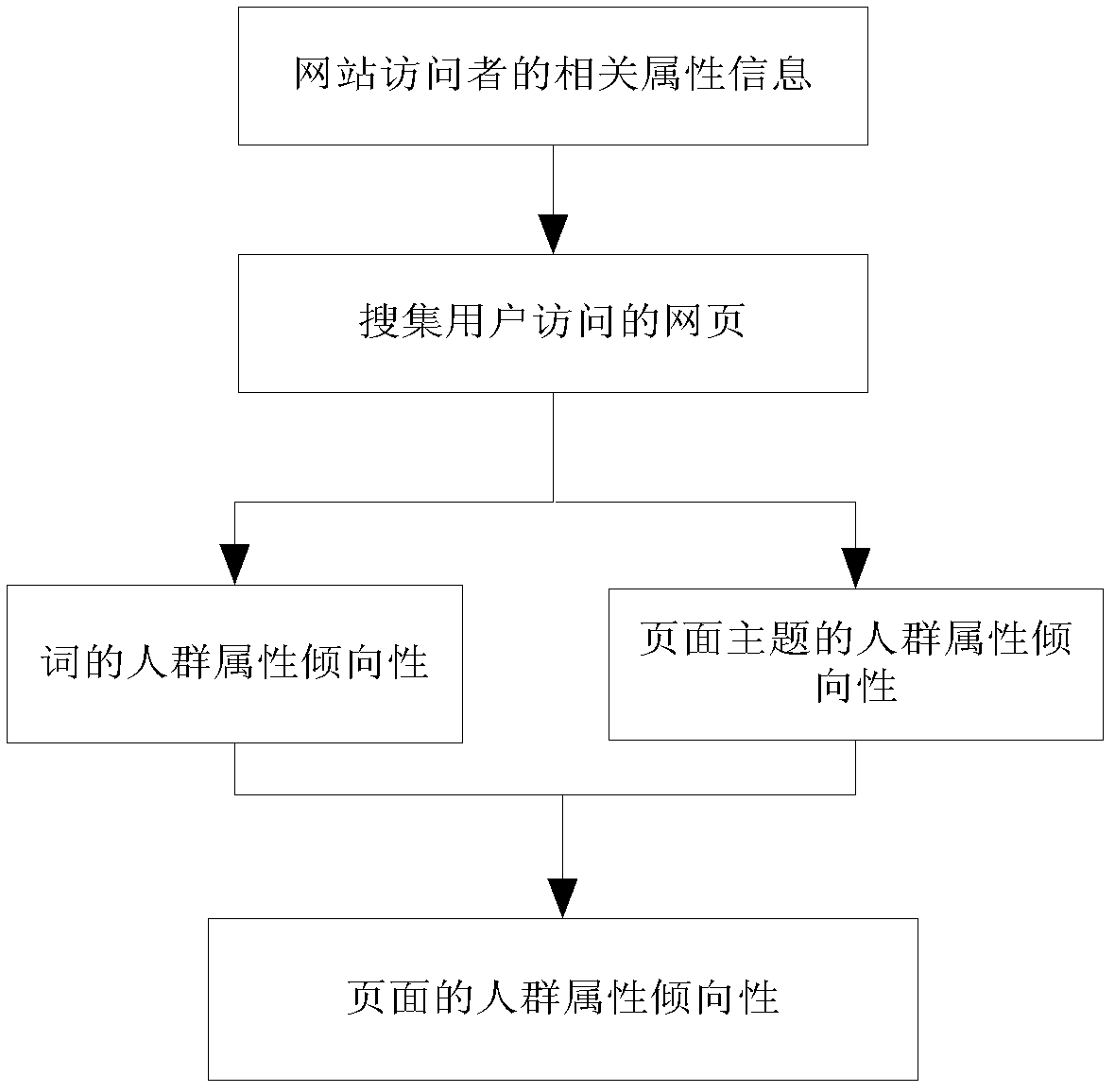

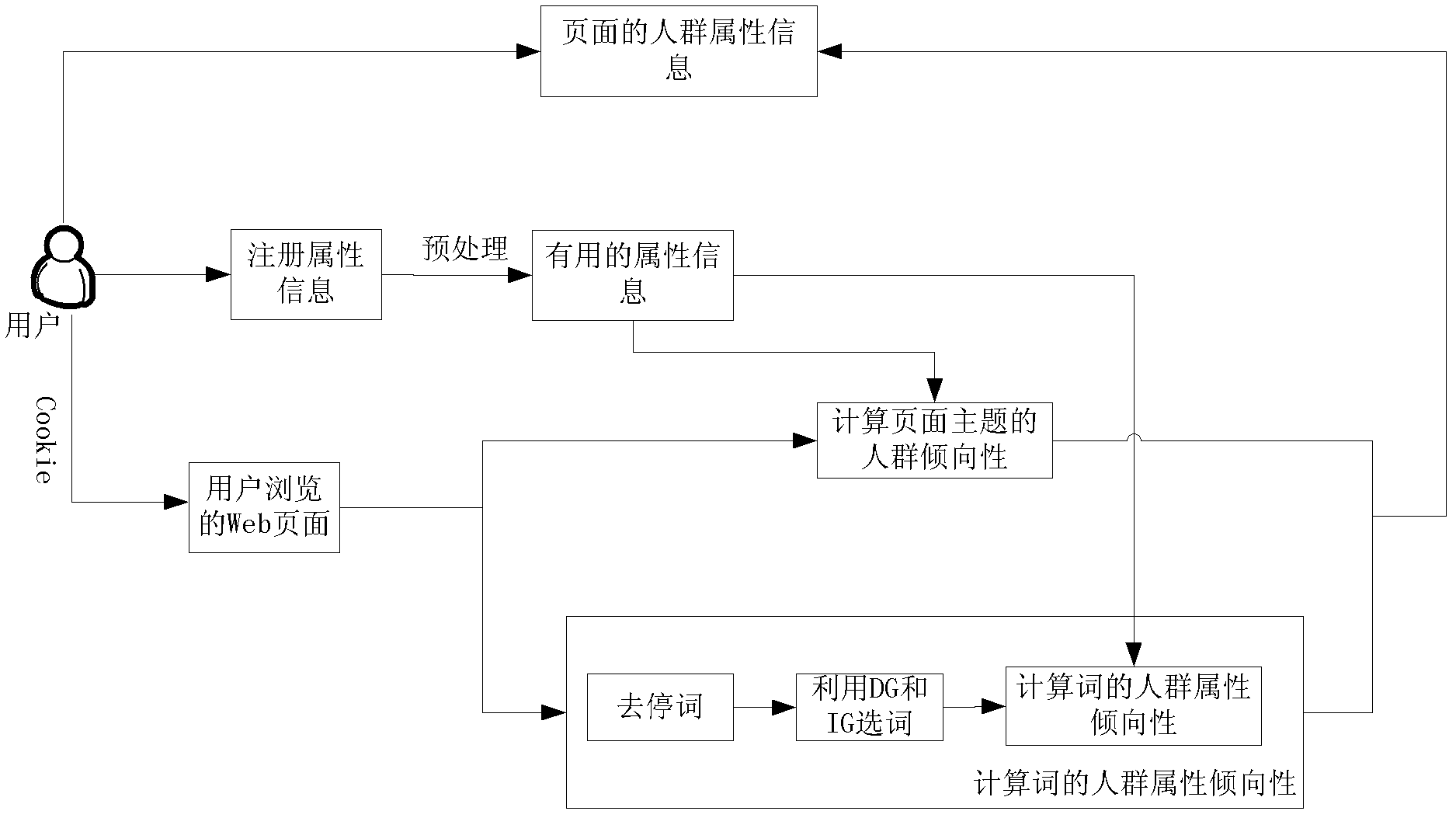

Method for predicting attributes of webpage crowd

InactiveCN102663027AReduce deliveryClassification is detailed and clearSpecial data processing applicationsInformation gainCrowds

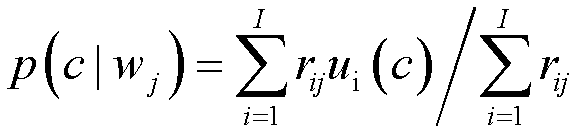

A method for predicting attributes of webpage crowd includes steps of (1) obtaining basic attribute information of users according to registration information of the user or user IDs (identifications), and preprocessing the basic attribute information to remove unreasonable attribute information of the user; (2) tracking webpage accessed by the user by the aid of loaded Cookie when the users access webpage, and collecting the accessed webpage; (3) computing influence of the word-pair webpage on tendency of the attributes of the users; (3.1) selecting text vector feature words according to differential gain DG of the attributes of the crowd and information gain; (3.2) computing influences of the words on the tendency of the attributes of the webpage crowd; (4) computing the tendency of the attributes of the crowd of a webpage theme; and (5) predicting the tendency of the attributes of the webpage crowd from the respects of the theme and the words respectively and then obtaining integral tendency of the attributes of the webpage crowd. The method is a reliable method for effectively determining the attributes of the webpage crowd in a targeted delivery manner.

Owner:ZHEJIANG PANSHI INFORMATION TECH

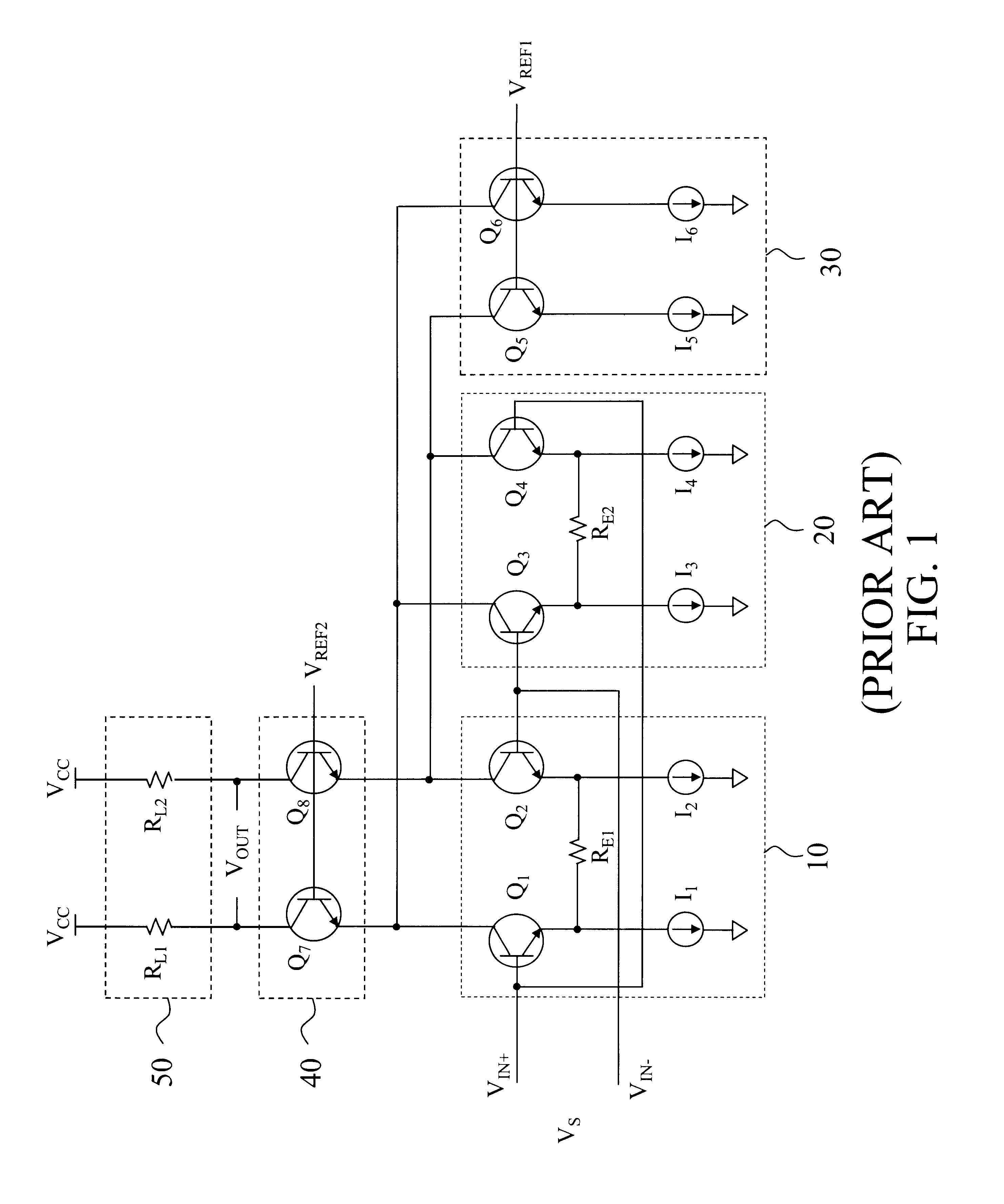

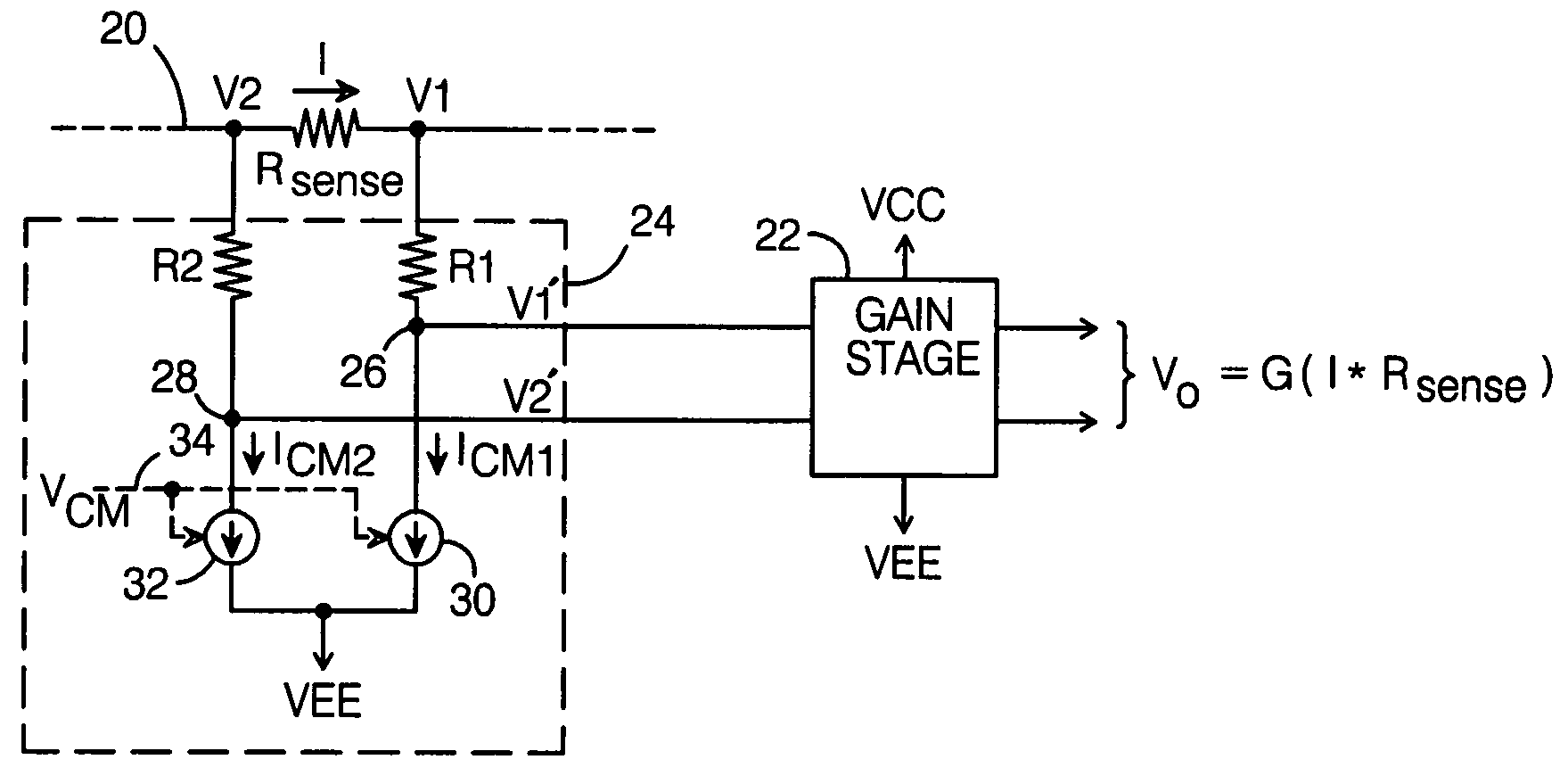

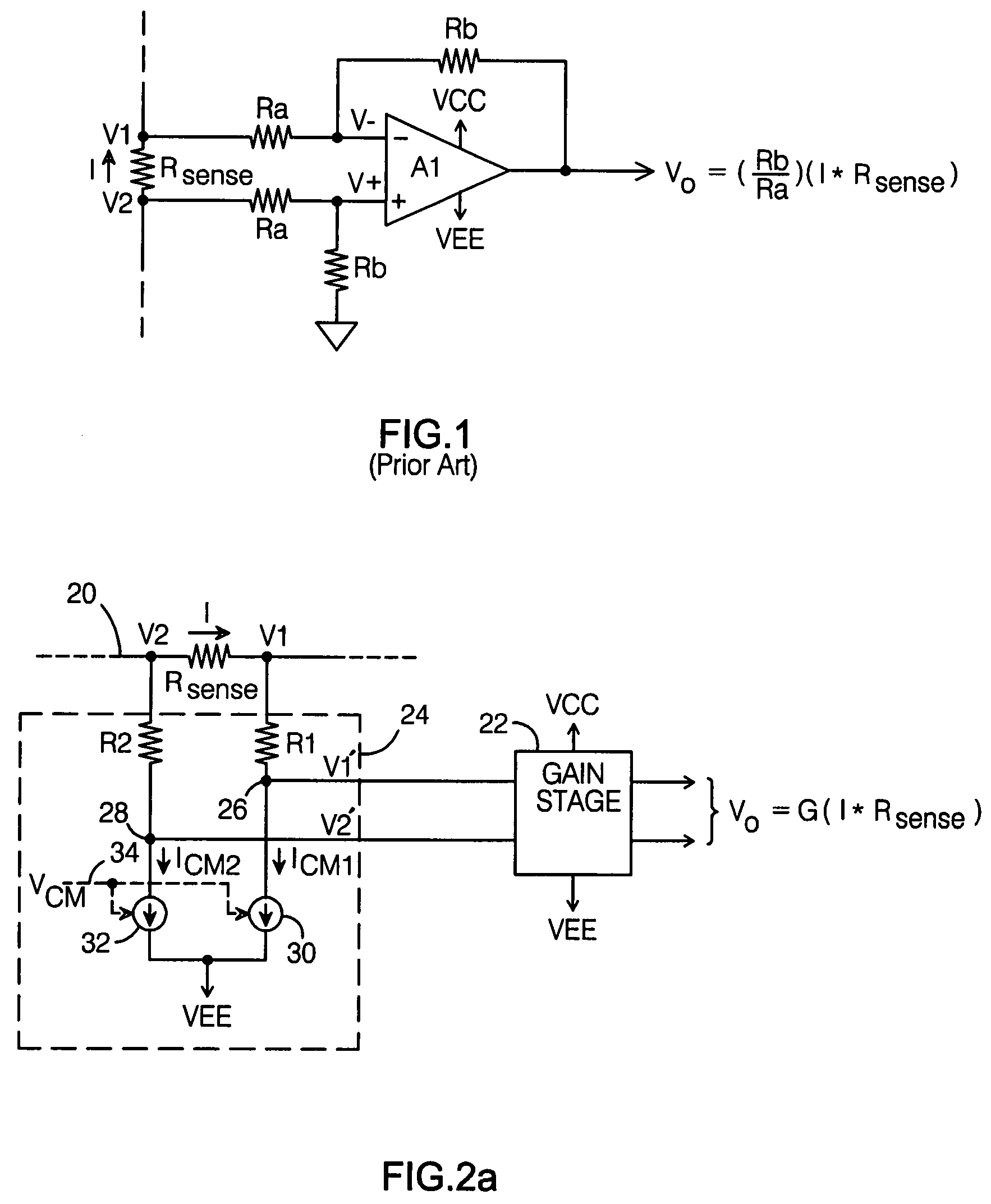

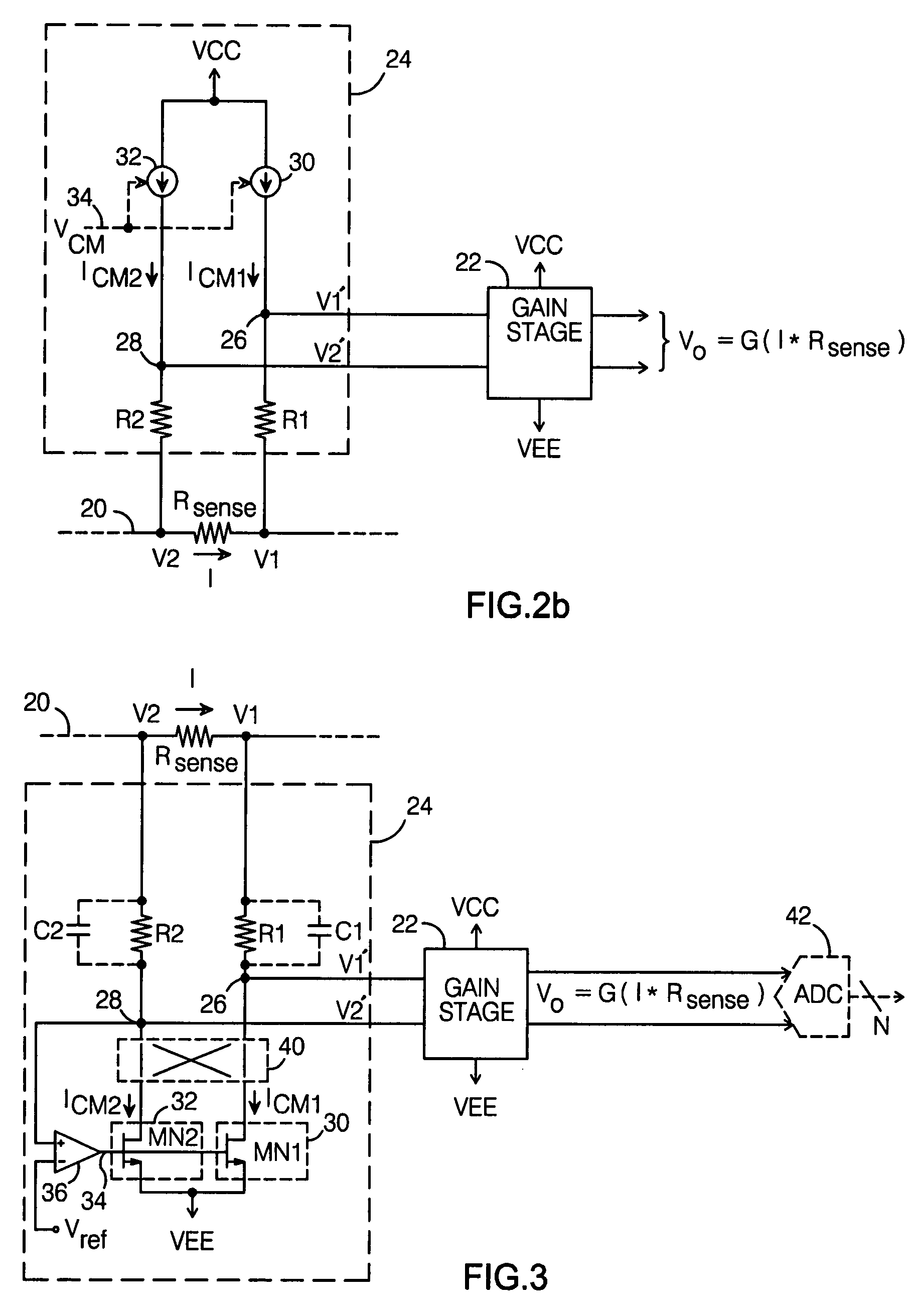

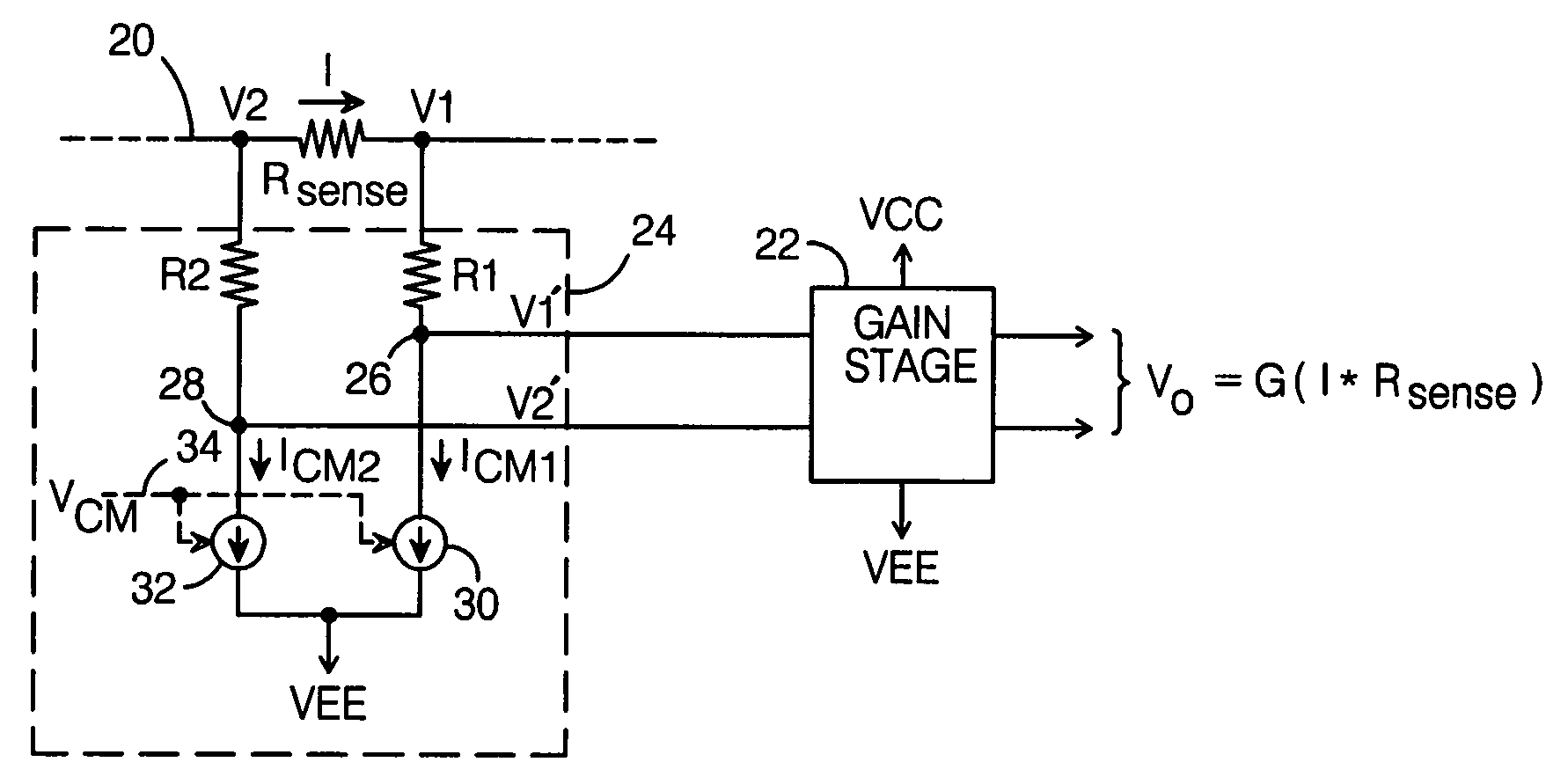

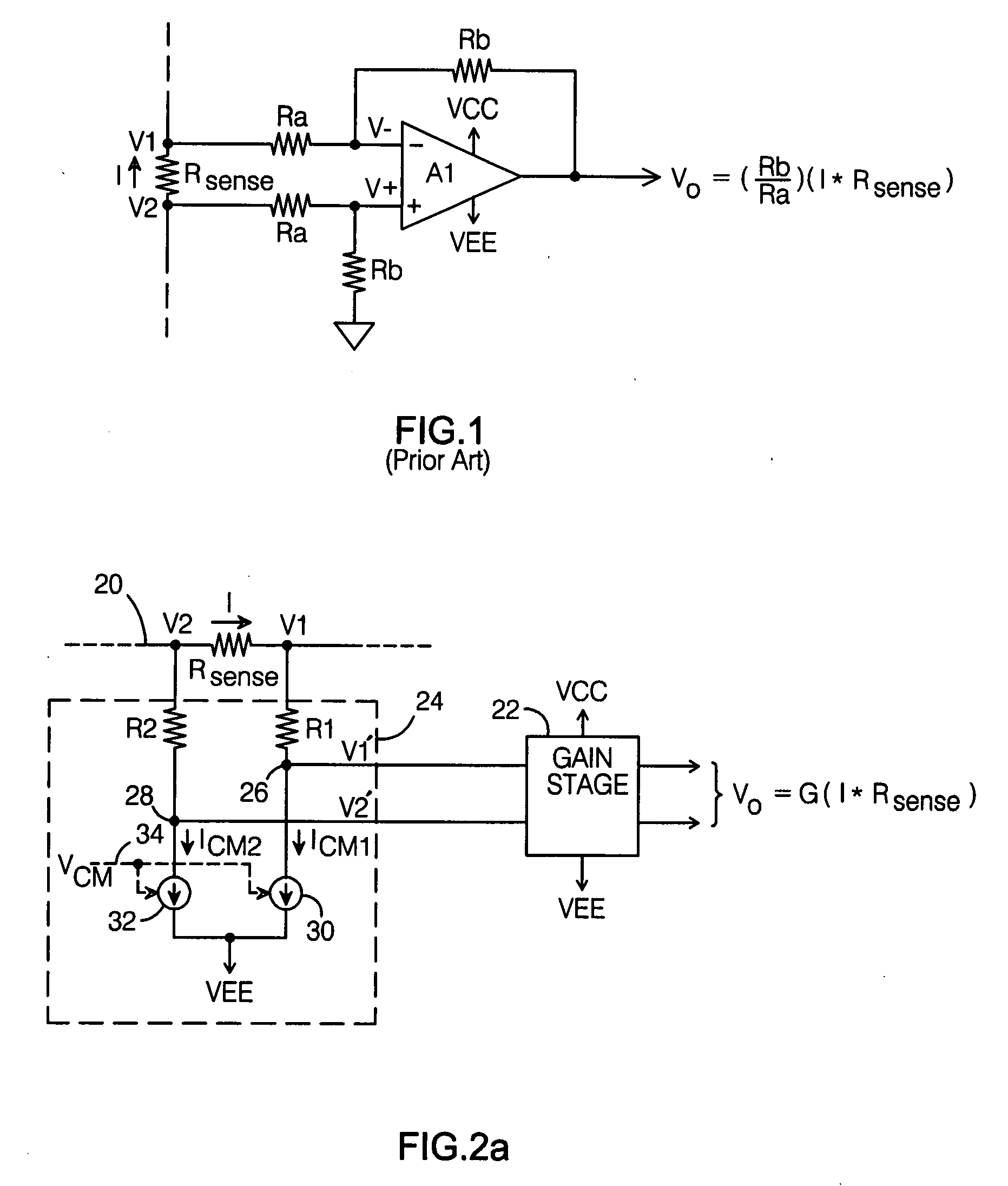

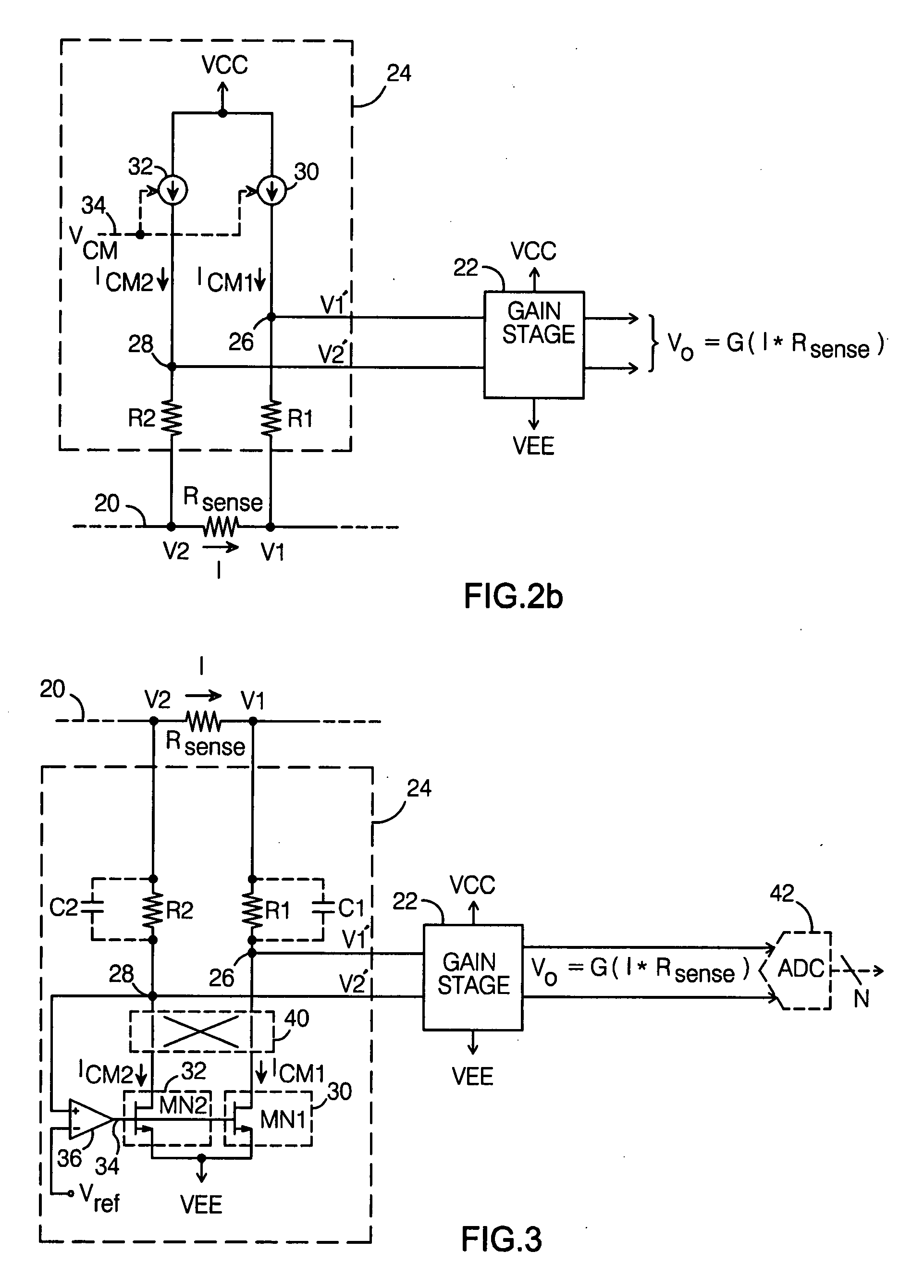

High-side current sense circuit with common-mode voltage reduction

A high-side current sense circuit comprises a sense resistance Rsense connected in series with a signal having an associated current to be measured I, which develops voltages V1 and V2 on either side of Rsense. A differential gain stage powered by supply voltages VCC and VEE produces an output voltage which varies with the difference between its input signals. To keep the common mode portion of the input signal between voltages VCC and VEE, a voltage modification circuit subtracts or adds a common mode voltage to or from V1 and V2 to produce modified voltages V1′ and V2′, which are coupled to the gain stage inputs. The voltage modification circuit is arranged to ensure that VEE≦V1′ and V2′≦VCC.

Owner:ANALOG DEVICES INC

Low voltage high gain amplifier circuits

InactiveUS20050007195A1Differential amplifiersSingle-ended push-pull amplifiersAudio power amplifierLow voltage

In one embodiment, the present invention provides an amplifier circuit including a cascode input stage coupled to a differential stage. In another embodiment, an amplifier includes a differential stage coupled to a common gate stage. Embodiments of the present invention also include an improved low voltage amplifier using a 3-stage topology including a wide-swing folded-cascode input stage followed by a differential gain stage which provides improved gain and output compliance. Embodiments of the present invention improve the available cascode stage headroom and reject process and temperature induced parametric variations.

Owner:ANALOG DEVICES INT UNLTD

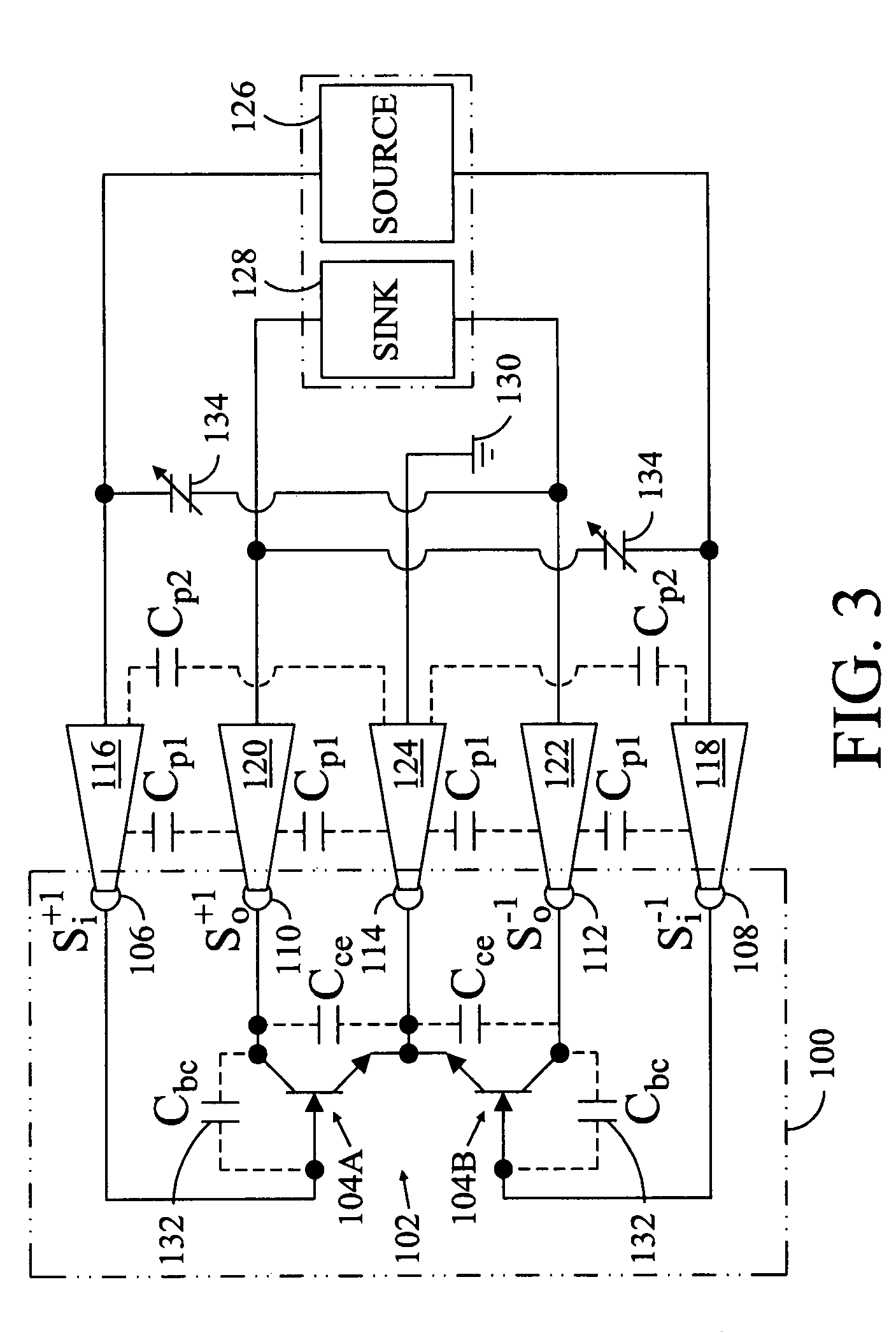

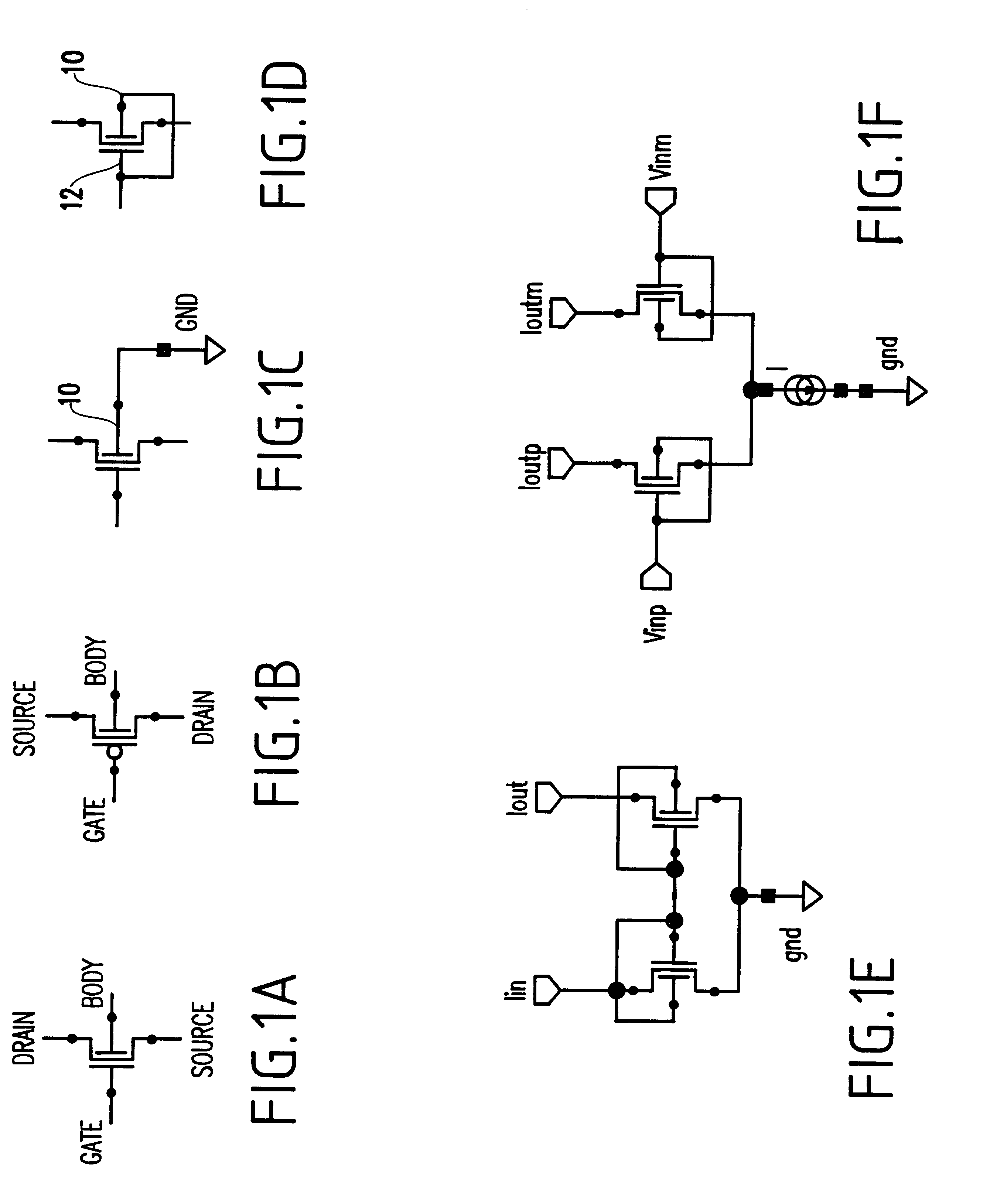

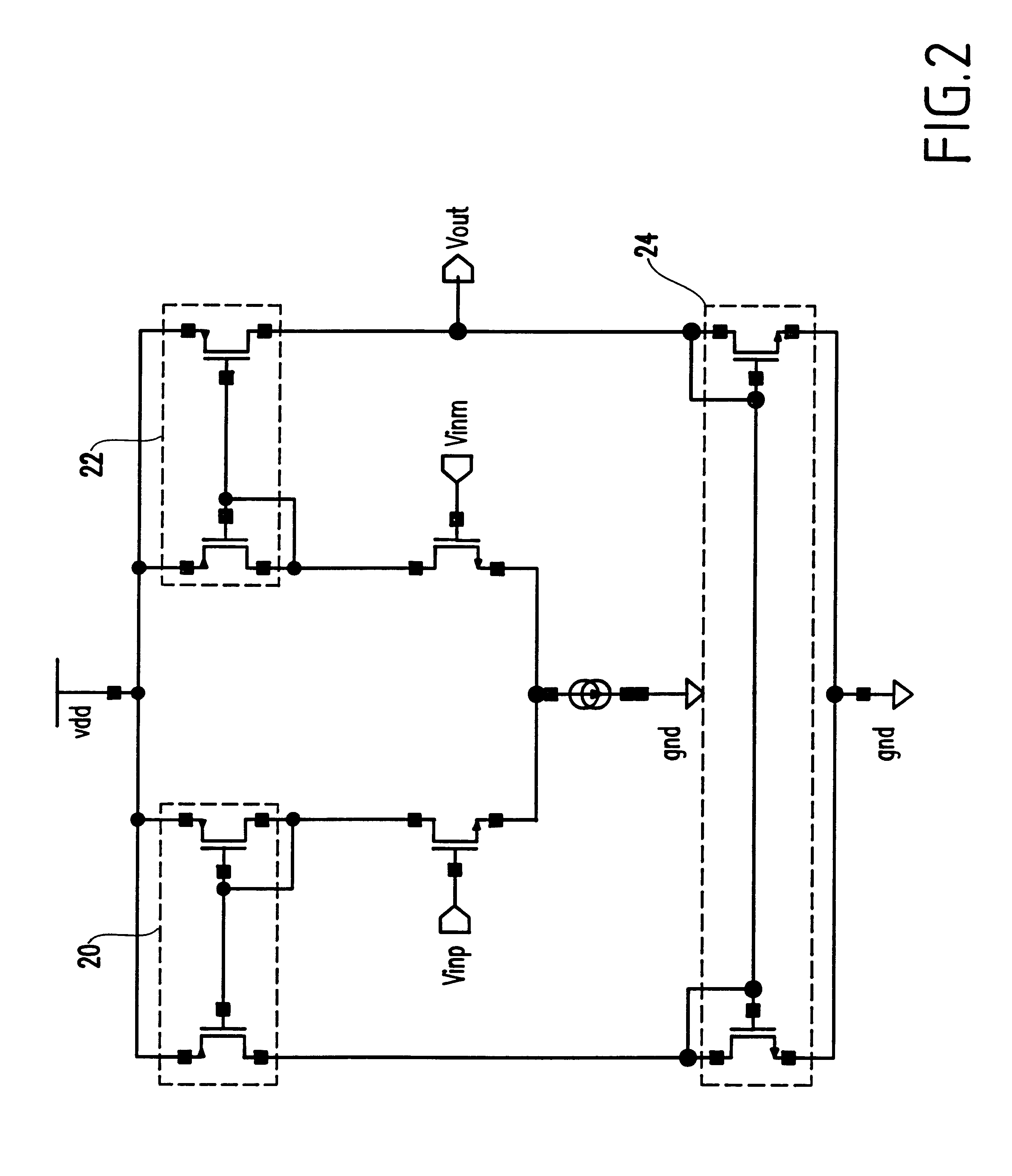

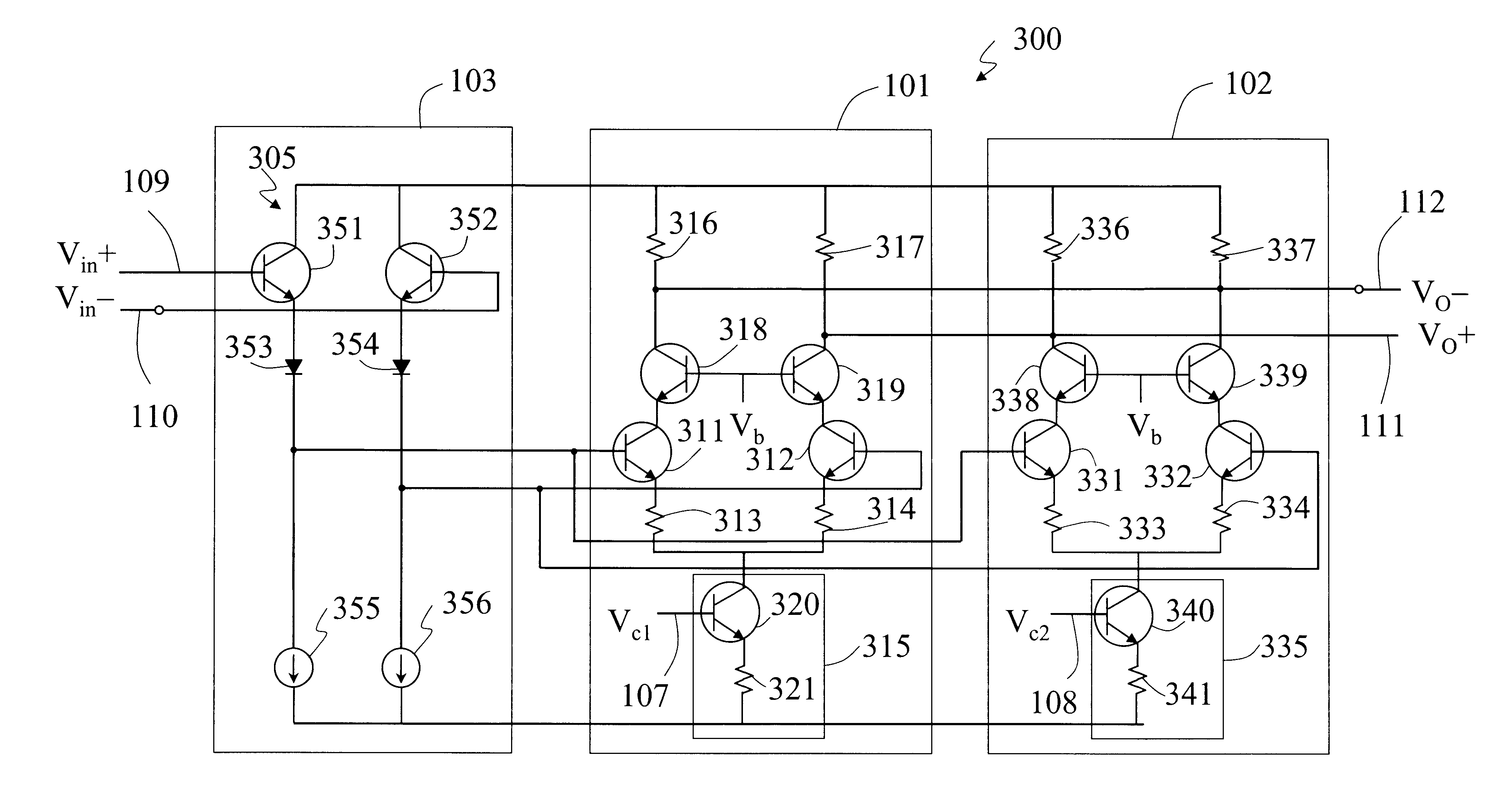

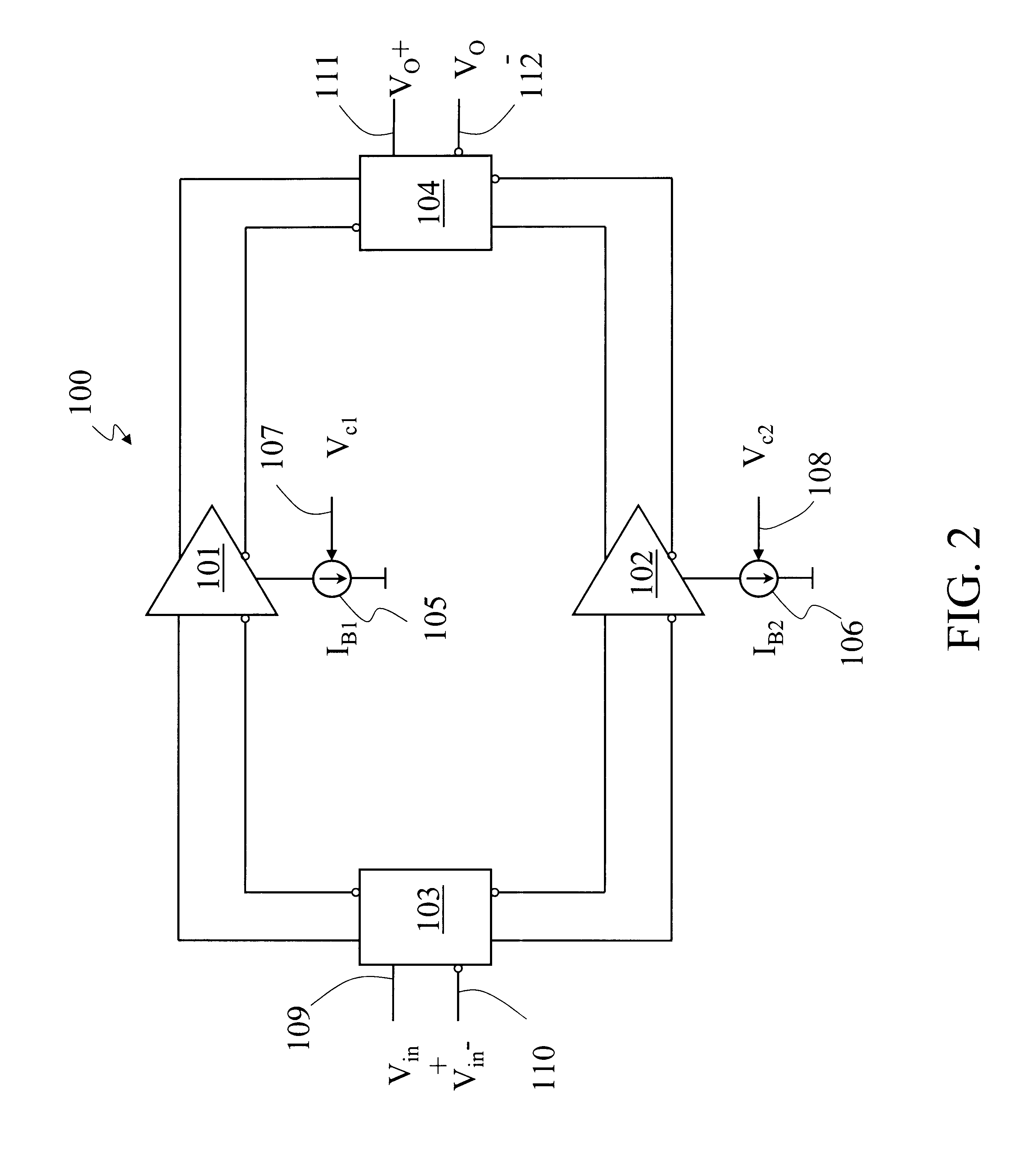

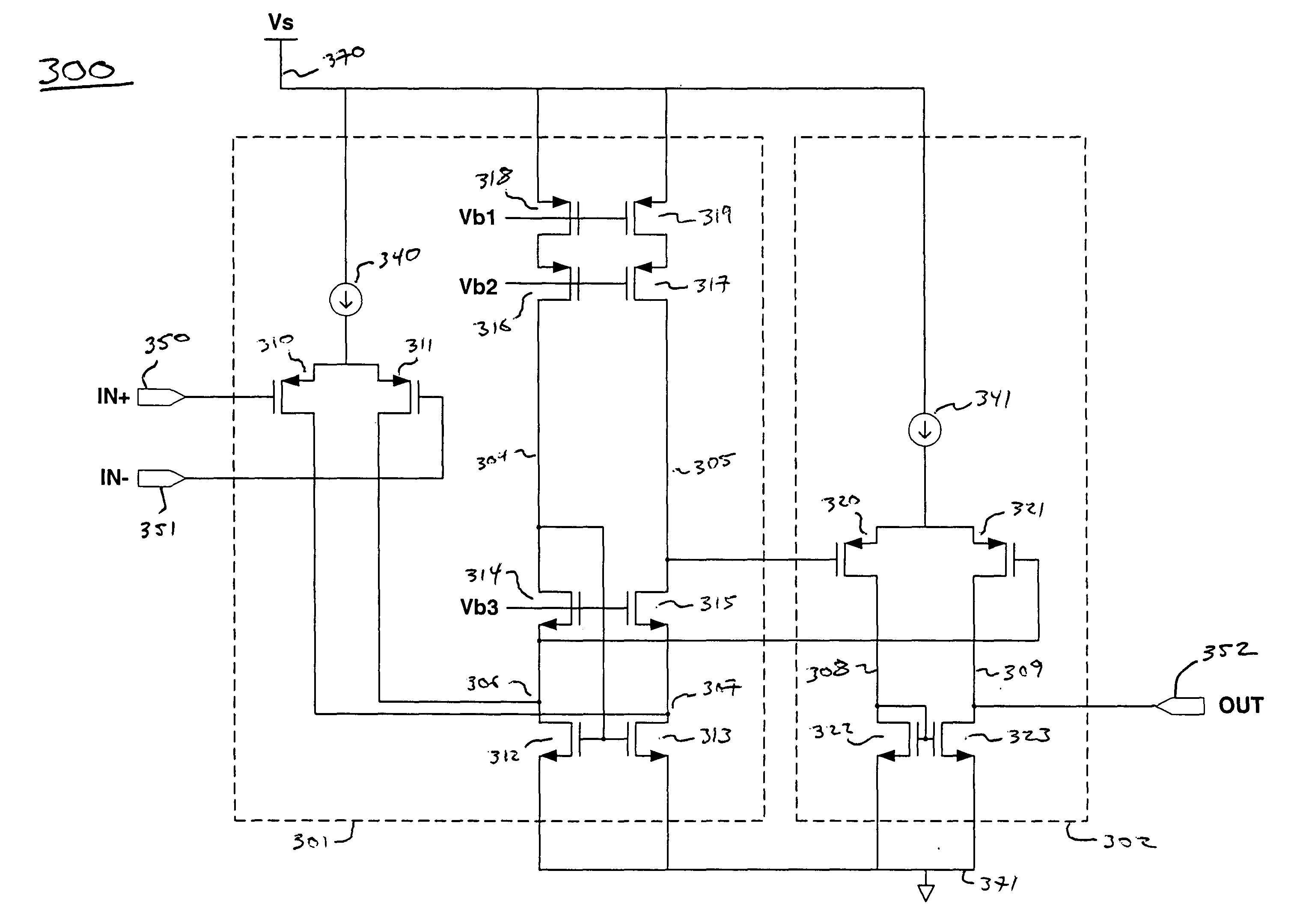

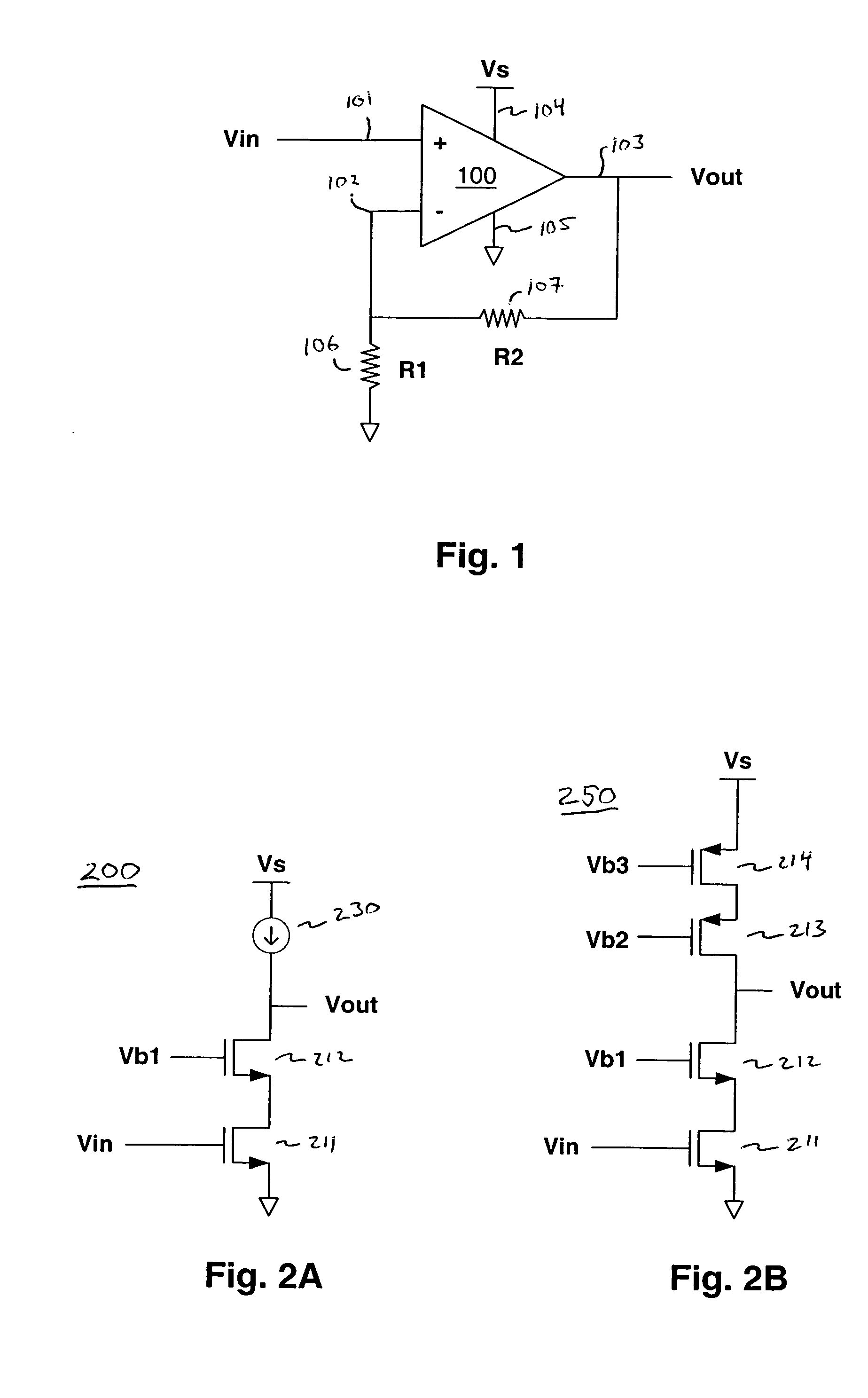

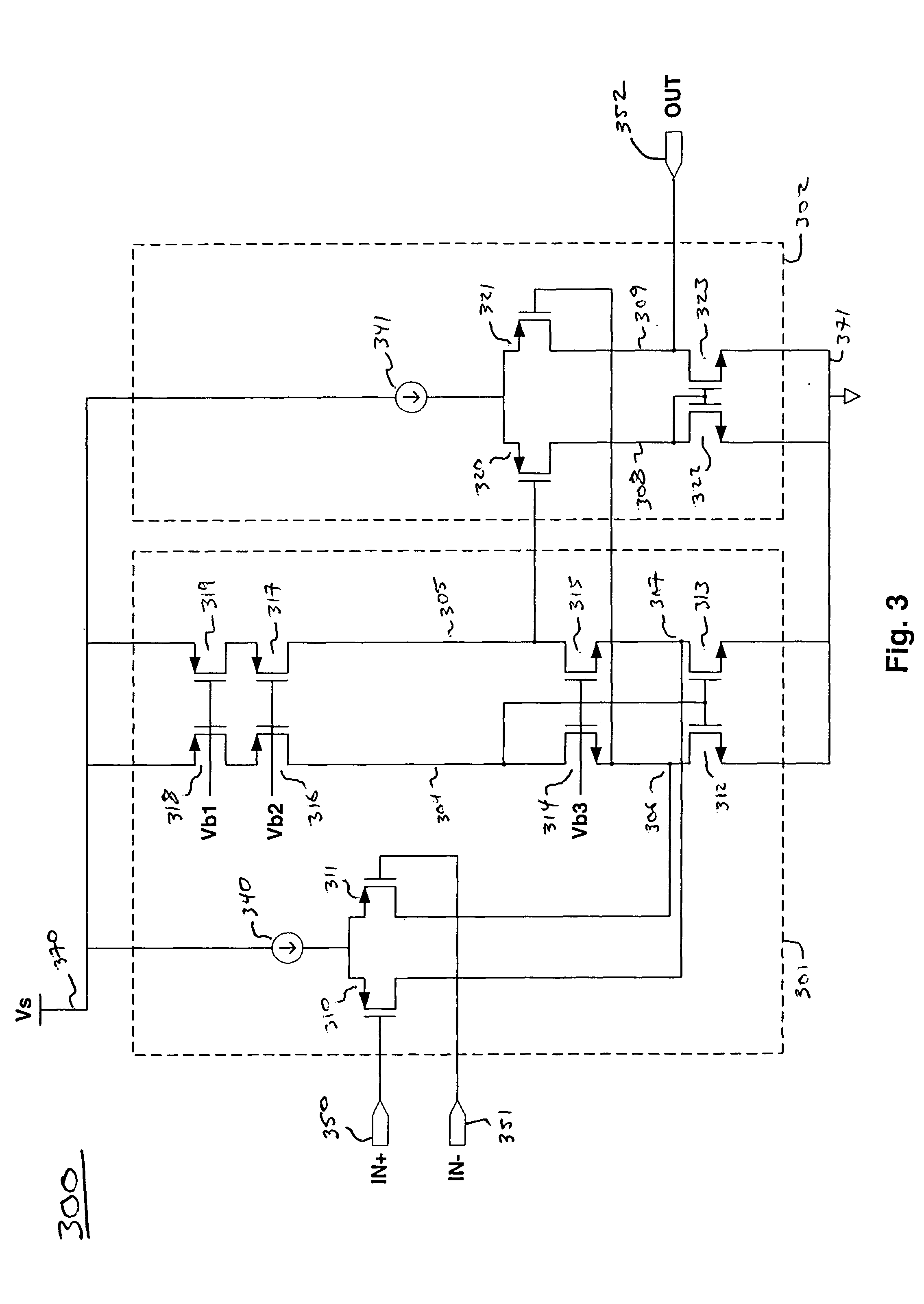

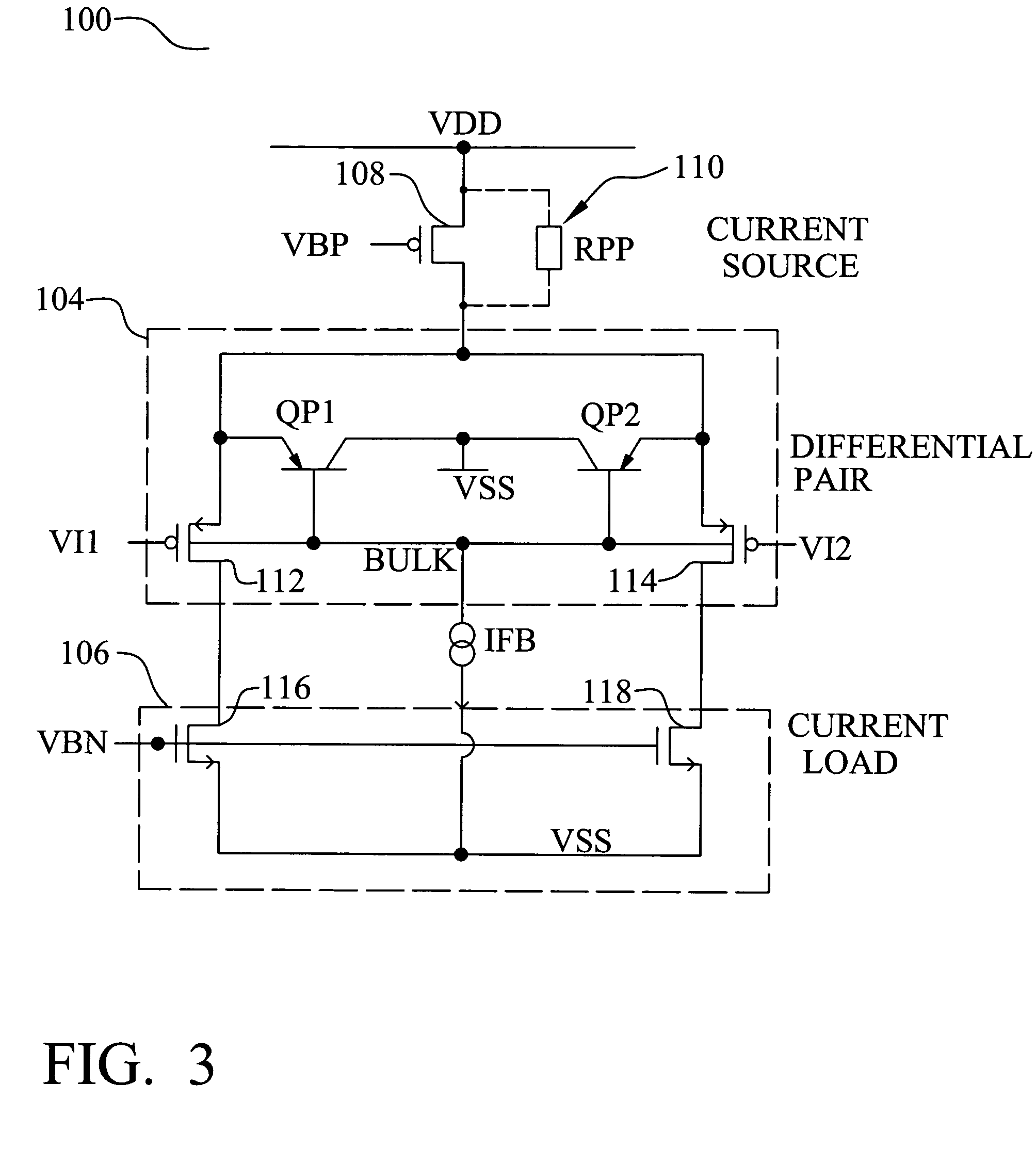

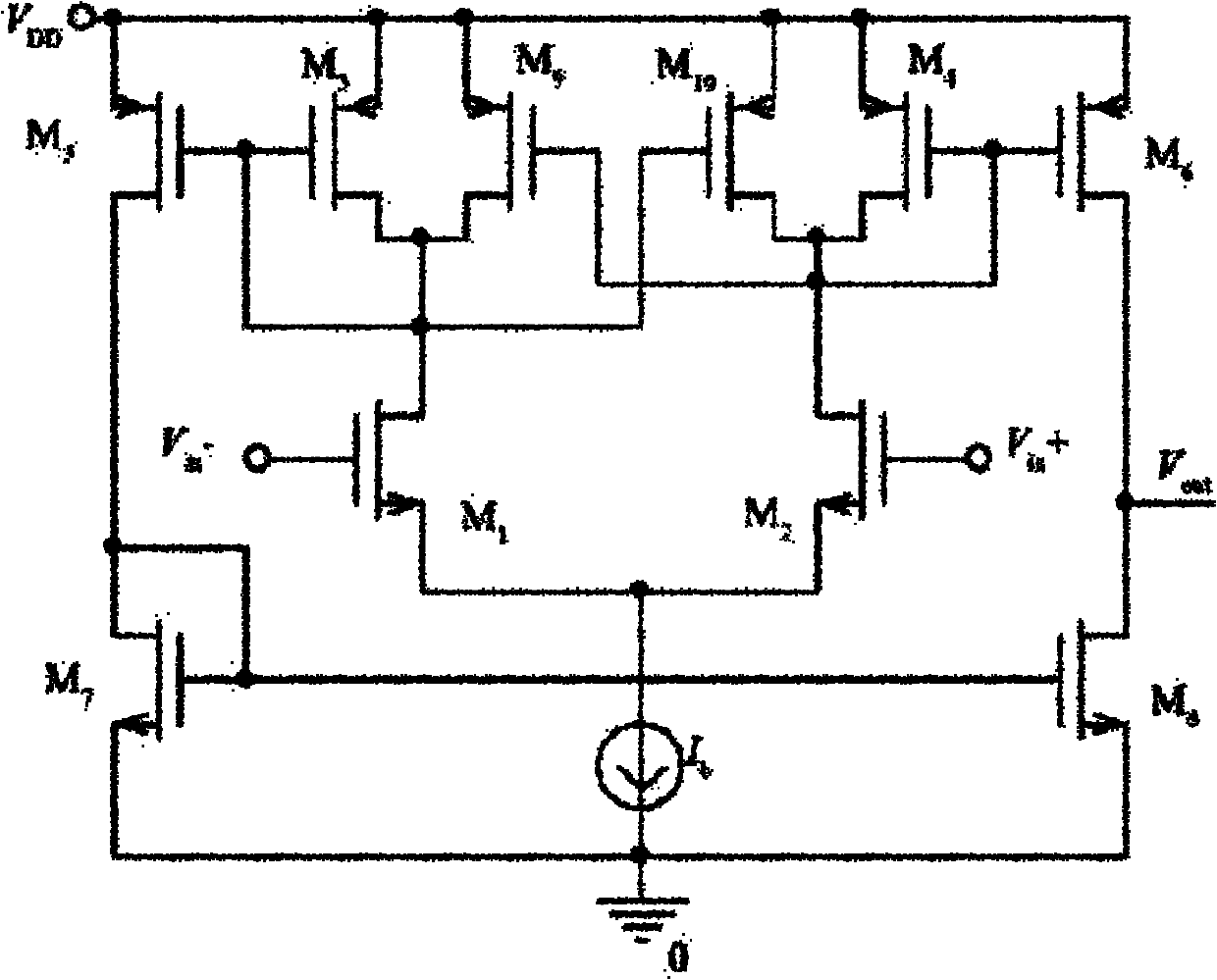

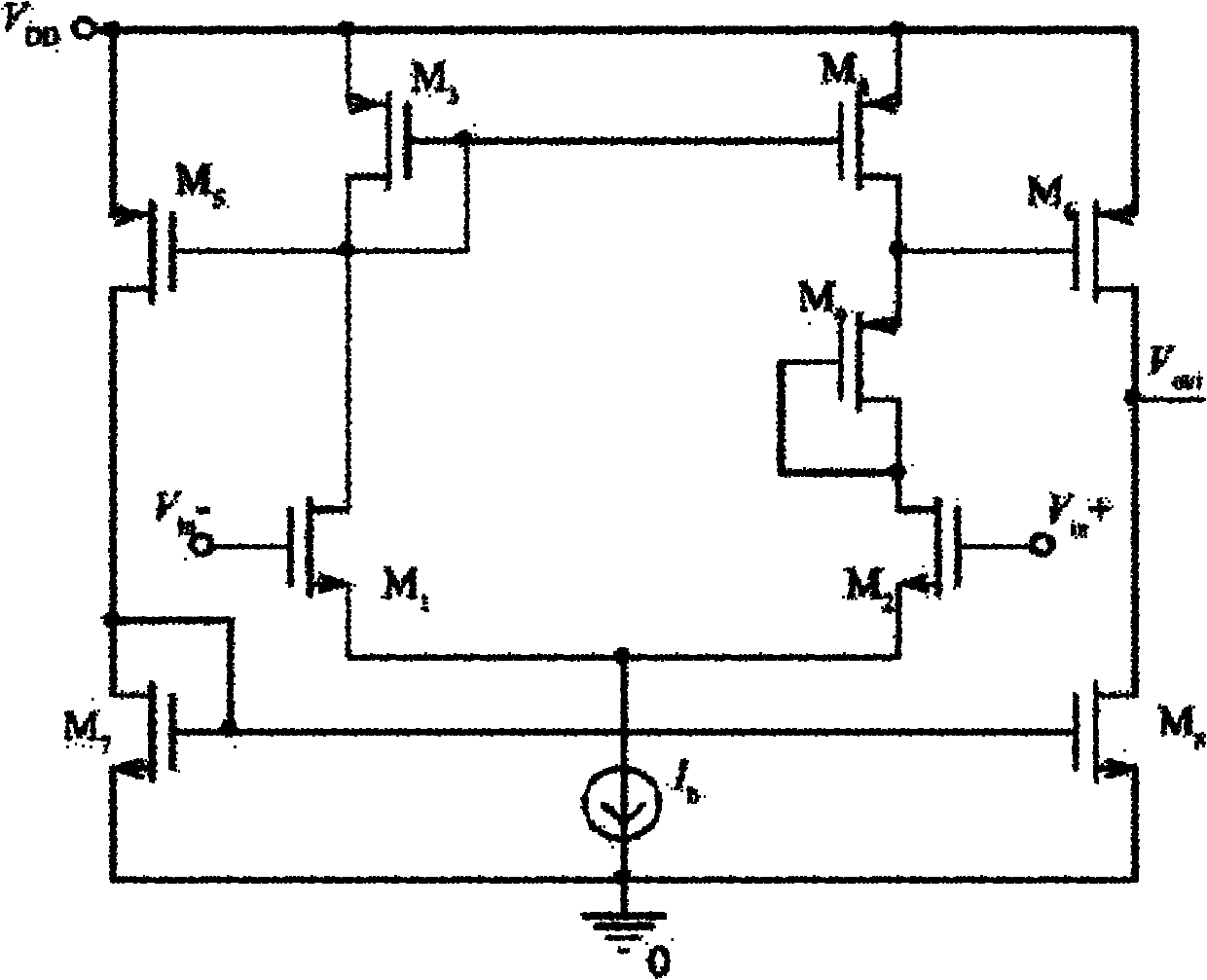

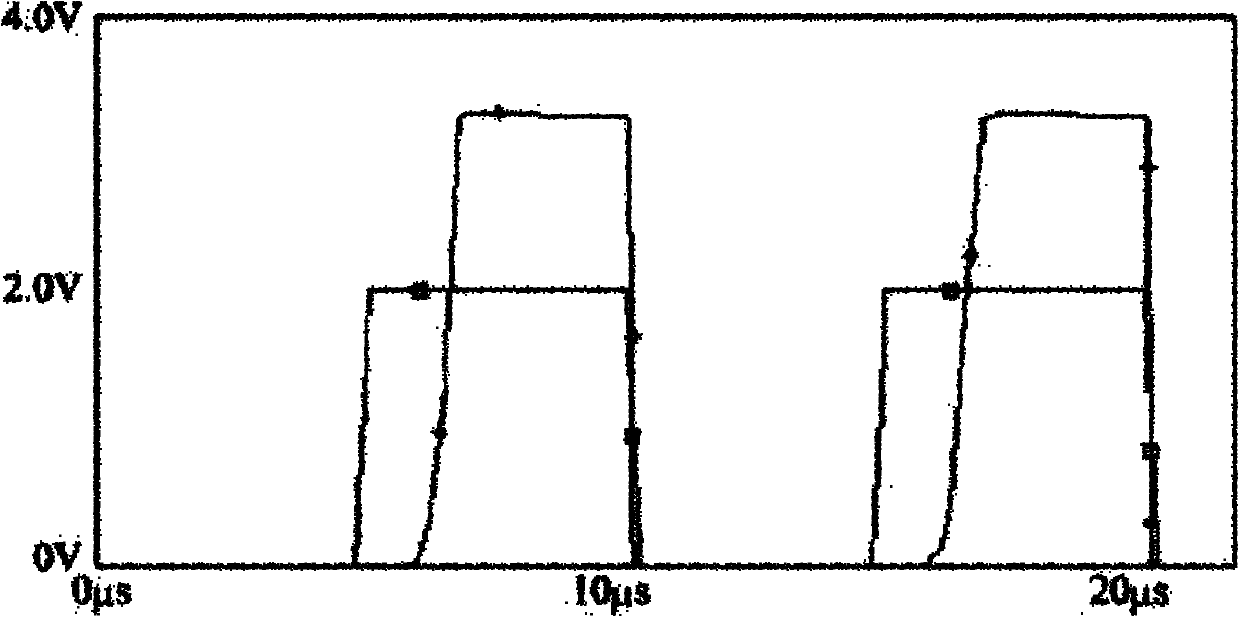

Differential gain stage for low voltage supply

InactiveUS7109794B2Lower performance requirementsReduce voltage gainDifferential amplifiersDc-amplifiers with dc-coupled stagesCurrent loadLow voltage

A new method and a circuit to improve the low voltage performance of a differential gain stage is achieved. The method comprises a monitoring stage and a differential stage. The monitoring stage comprises a differential transistor pair having first and second differential inputs, an upper current input, and a lower current output. In addition, a current source is connected to the upper current input, and a current load is connected to the lower current output. The differential stage comprises a differential transistor pair having first and second differential inputs, an upper current input, and first and second lower current outputs. In addition, a current source is connected to the upper current input, and first and second current loads are connected to the first and second lower current inputs. A current is forced through the monitoring stage current source. The current through the monitoring stage current source is mirrored in the differential stage current source. Current through the monitoring stage current load is mirrored through the differential transistor stage first and second current loads.

Owner:DIALOG SEMICONDUCTOR GMBH

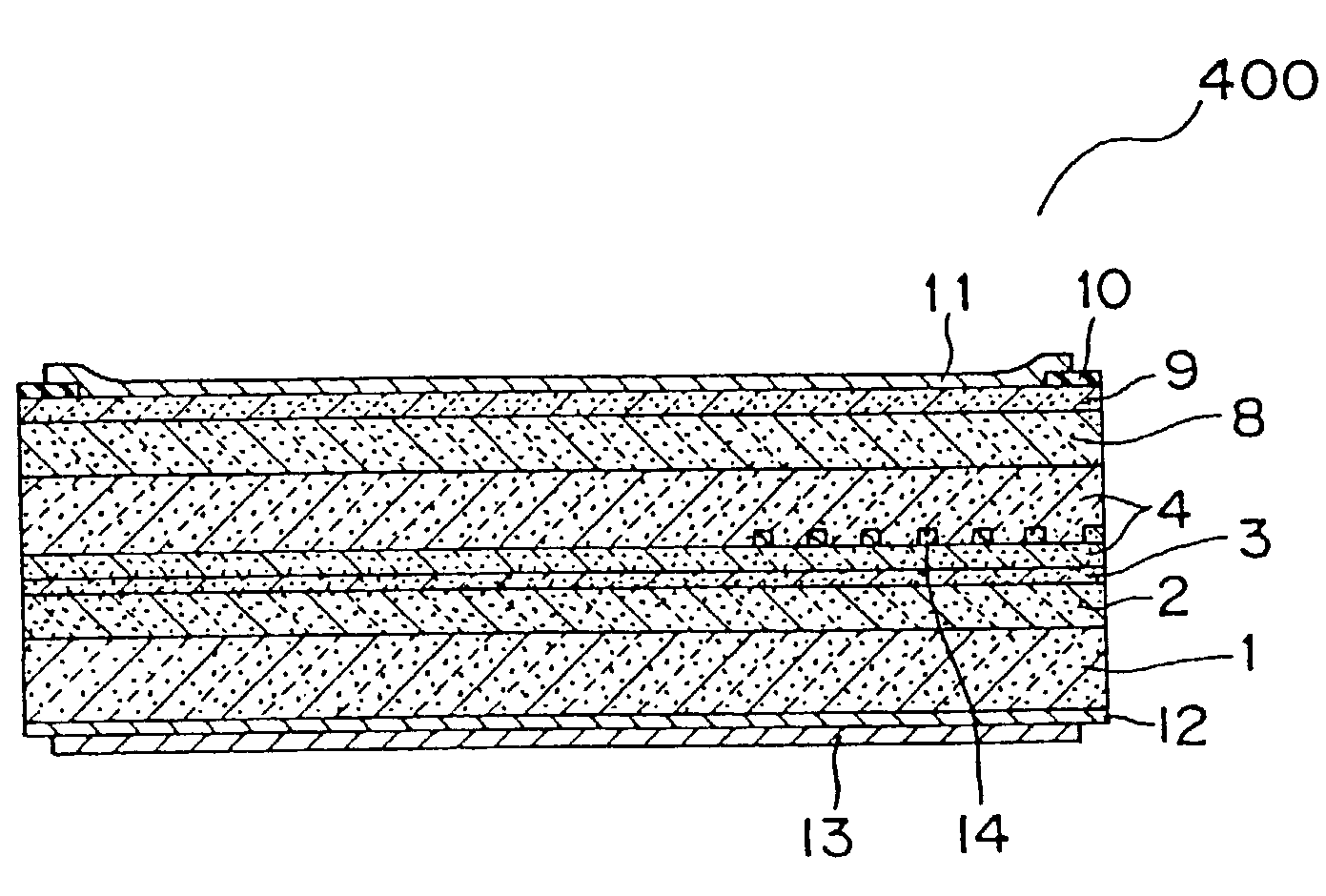

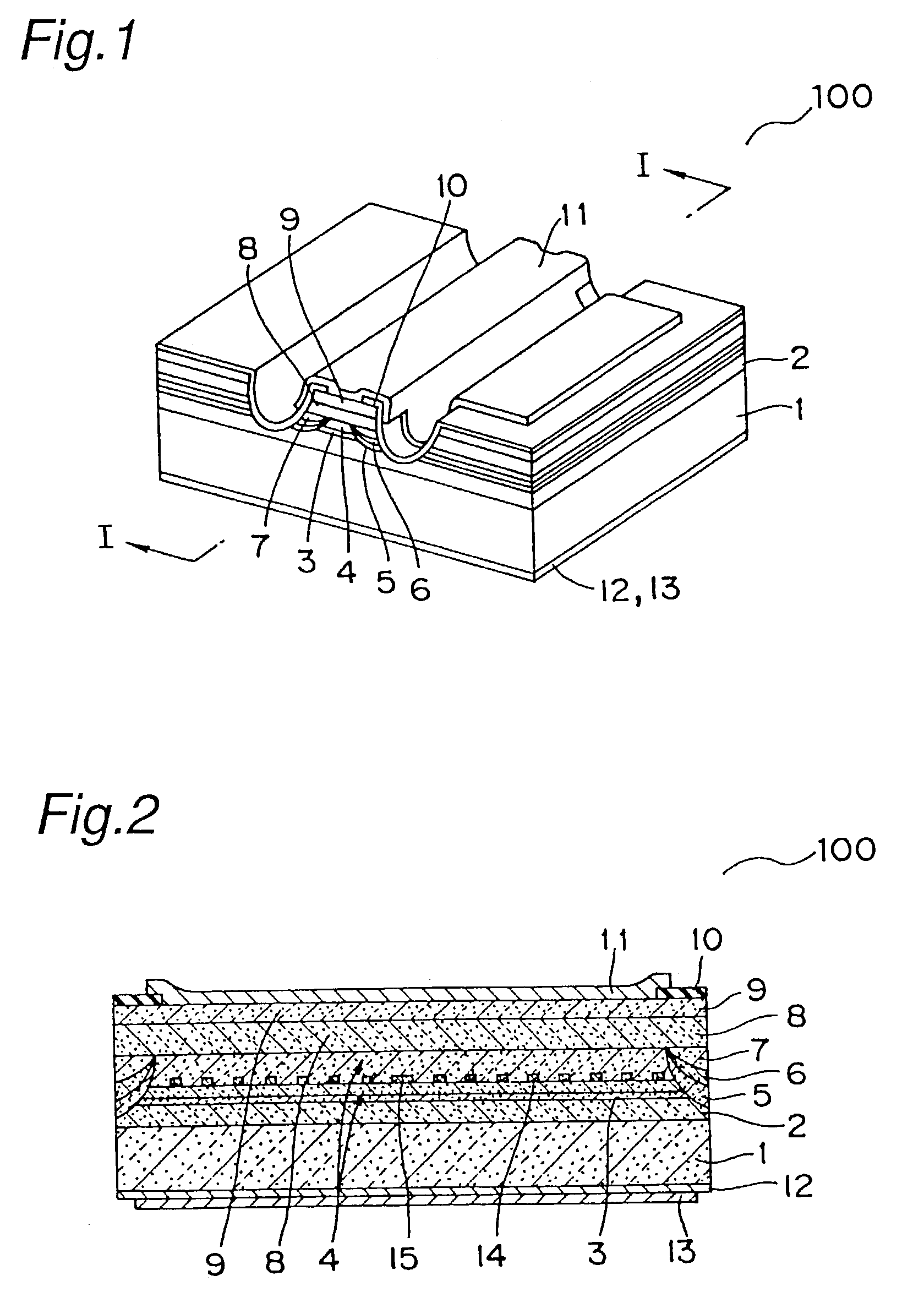

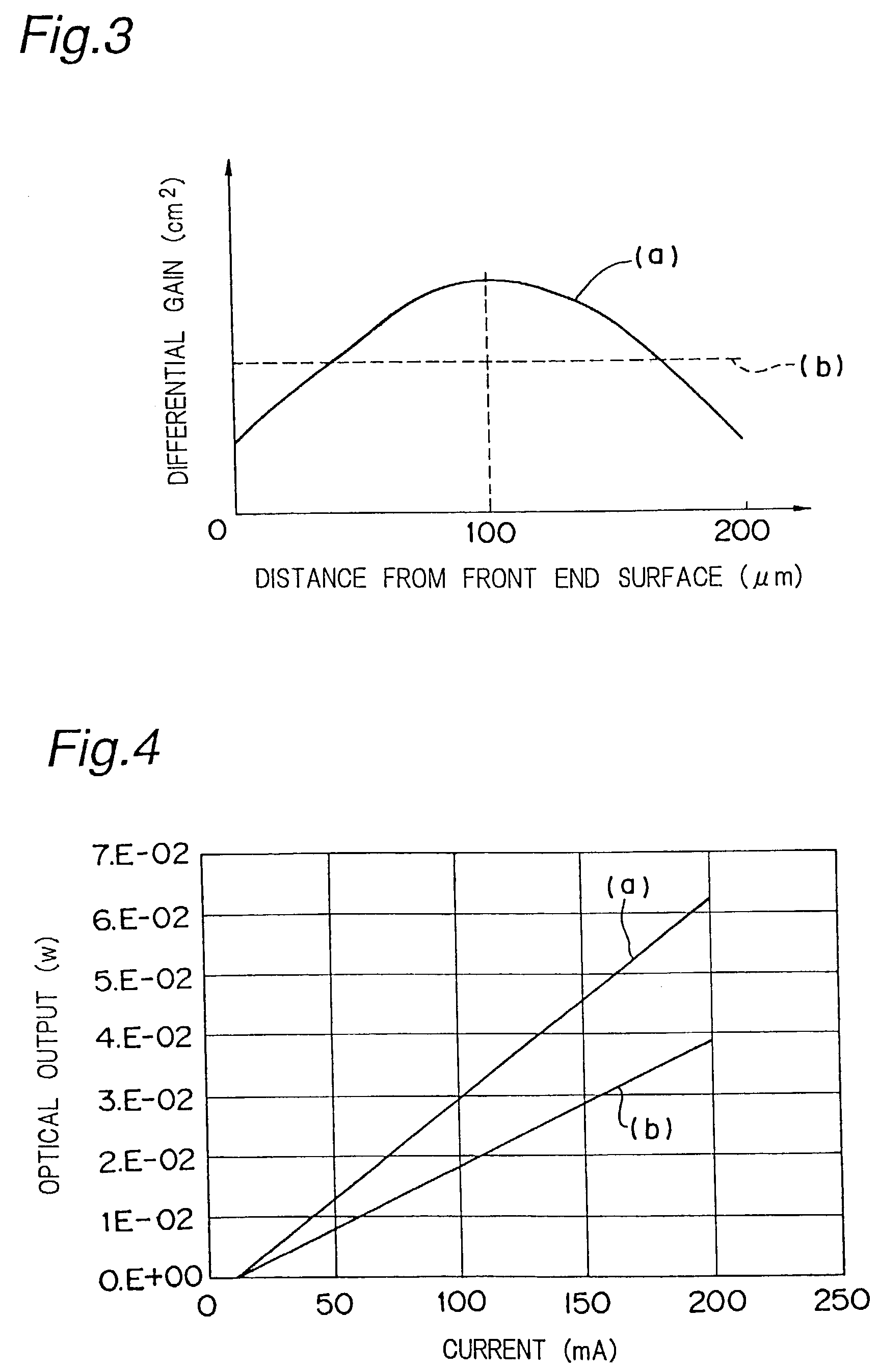

Semiconductor optical device

InactiveUS6999485B2Reduce variationLow refractive indexLaser optical resonator constructionLaser active region structureRefractive indexLight beam

A kink-free semiconductor optical device stabilizing laser oscillation and producing a high optical performance. The semiconductor optical device includes a beam waveguide extending in a longitudinal direction between a pair of end surfaces. The beam waveguide includes an active layer having a quantum well structure with at least one well layer and two barrier layers, and a pair of cladding layers sandwiching the active layer. The active layer has first and second regions in the longitudinal direction, the photon density in the first region being larger than in the second region. The first region has a differential gain greater than the second region so that variation of refractive index across the beam waveguide is reduced.

Owner:MITSUBISHI ELECTRIC CORP

Voltage comparator

InactiveCN102571044AReduce bias currentLower latencyMultiple input and output pulse circuitsElectric variable regulationSub thresholdComputer module

The invention provides a voltage comparator, which comprises a current source, a differential gain module and a conversion module, wherein the current magnitude of the current source is of nanoampere level; the differential gain module comprises a first transistor, a second transistor, a third transistor and a fourth transistor; the first transistor and the second transistor are connected with the current source respectively; the third transistor and the fourth transistor form a current mirror structure; the third transistor is connected with the first transistor; and the fourth transistor is connected with the second transistor through a ninth transistor for forming asymmetric differential gain. According to the voltage comparator provided by the invention, since the transistor which works in a sub-threshold region has higher transconductance-to-current ratio Gm / Ib than the transistor which works in a saturation region, the power consumption is lower; and in order to reduce the power consumption, the bias current in the voltage comparator provided by the embodiment is low, and the time delay of the voltage comparator is also low.

Owner:CSMC TECH FAB1 +1

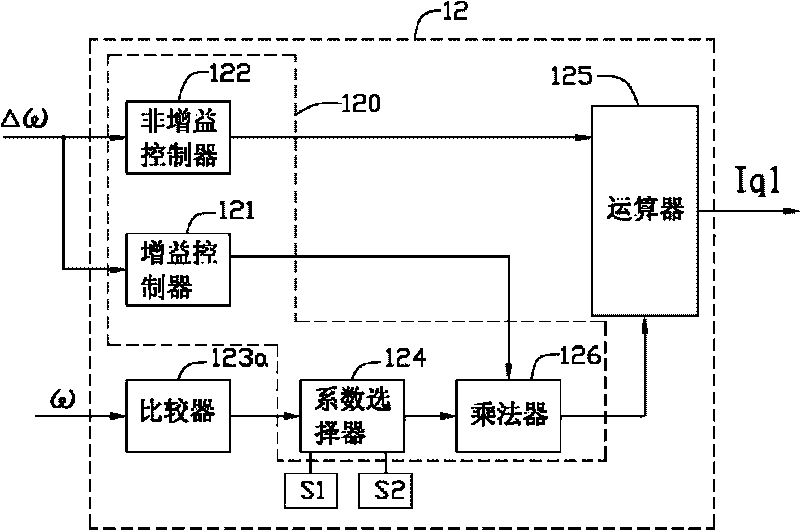

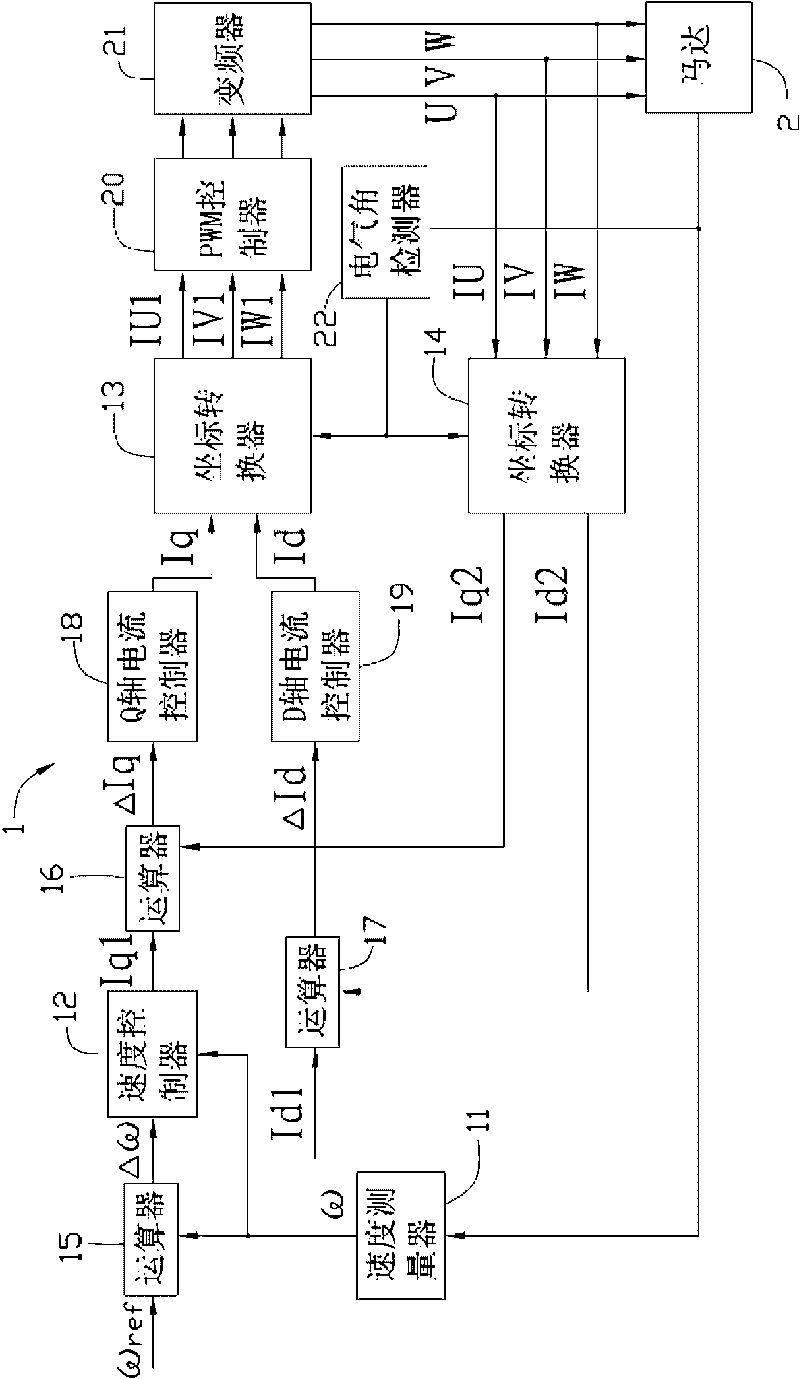

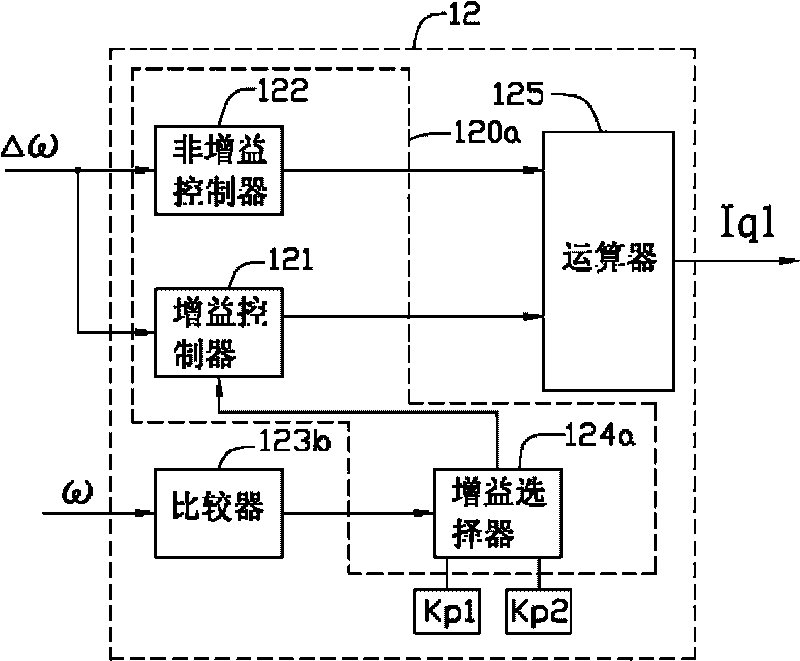

Speed controller

The invention discloses a speed controller, which is used in a motor control circuit. The speed controller comprises a comparator, a processing module and a computing device, the input end of the processing module receives a speed differential value of a control circuit, i.e. the difference between a command speed and a measured speed of a motor, and the comparator receives the measured speed or the command speed and compares the measured speed or the command speed with an internal critical speed value. When the speed value received by the comparator is larger than the critical speed value, the comparator outputs a first signal to the processing module, and when the speed value received by the comparator is smaller than the critical speed value, the comparator outputs a second signal to the processing module. When the comparator outputs the first signal, the processing module outputs a first speed differential gain to the computing device, and when the comparator outputs the second signal, the processing module outputs a second speed differential gain smaller than the first speed differential gain to the computing device. The computing device computes the received gain value and then outputs a command current to the control circuit. The speed controller can also reduce the vibration and noise of the motor.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

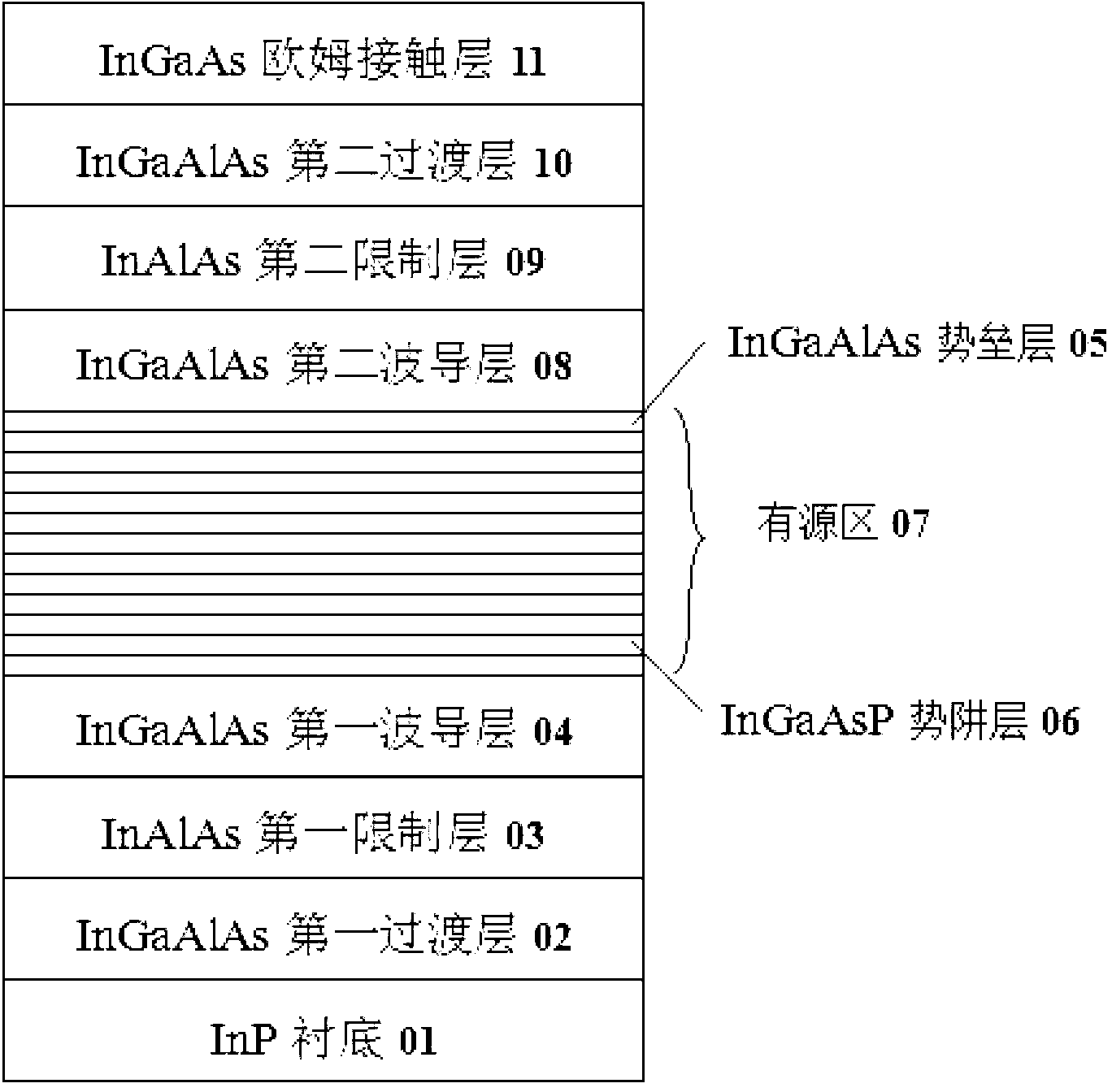

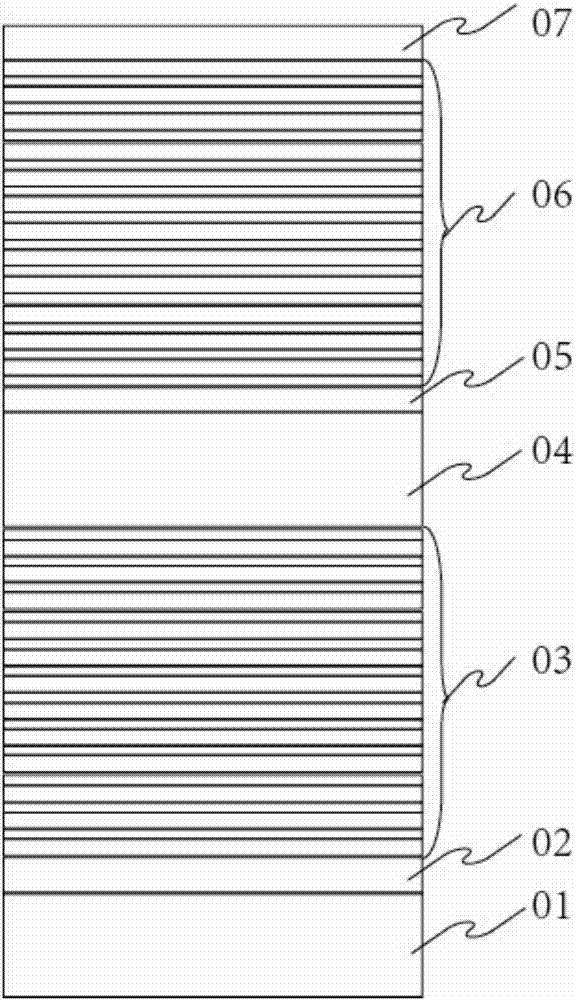

Epitaxial structure of near-infrared VCSEL laser and manufacturing method thereof

InactiveCN107093841AIncreased Radiation PowerImprove response rateLaser detailsLaser active region structureOhmic contactActive layer

The invention provides an epitaxial structure of a near-infrared VCSEL laser. The structure comprises a GaAs substrate. A GaAs buffer layer, an N-type doped DBR, an active layer, an oxidation limiting layer, a P-type doped DBR and an ohmic contact layer are successively deposited on the GaAs substrate. The active layer successively comprises a limiting layer, a waveguide layer, a quantum well, a symmetrical waveguide layer and a symmetrical limiting layer. The quantum well is formed by multiple groups of quantum well layers. A thick barrier layer is arranged between the two adjacent groups of quantum well layers. A thickness of the thick barrier layer is greater than 50nm. In the epitaxial structure of the near-infrared VCSEL laser, through inserting the plurality of thick barrier layers in an active area quantum well, leakage losses of a carrier are reduced, a compound probability of an active area carrier is increased, a differential gain of the active area is improved and radiation power of the VCSEL laser is increased. Simultaneously, a limiting factor of active area photon is increased and a response rate of the VCSEL laser is improved.

Owner:张永

High-side current sense circuit with common-mode voltage reduction

ActiveUS20080284403A1Reduce common mode voltageCurrent/voltage measurementDigital storageEngineeringGain stage

A high-side current sense circuit comprises a sense resistance Rsense connected in series with a signal having an associated current to be measured I, which develops voltages V1 and V2 on either side of Rsense. A differential gain stage powered by supply voltages VCC and VEE produces an output voltage which varies with the difference between its input signals. To keep the common mode portion of the input signal between voltages VCC and VEE, a voltage modification circuit subtracts or adds a common mode voltage to or from V1 and V2 to produce modified voltages V1′ and V2′, which are coupled to the gain stage inputs. The voltage modification circuit is arranged to ensure that VEE≦V1′ and V2′≦VCC.

Owner:ANALOG DEVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com