Self-learning temperature precise control method

A precision control and precise technology, applied in the direction of temperature control using electric mode, auxiliary controller with auxiliary heating device, etc., can solve the difficulties in establishing mathematical models, PID control can not obtain ideal control effect, and difficulty in selecting optimal parameters And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

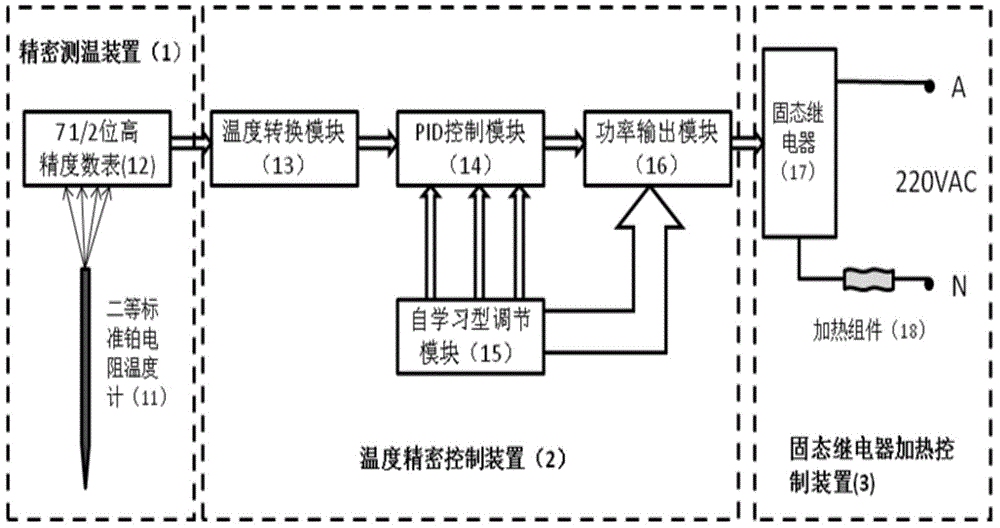

[0015] See figure 1 , a self-learning type temperature precision control method, the present invention is characterized in that the method is: a precision temperature measuring device, a temperature precision control device, and a solid state relay heating control device are sequentially connected to form; wherein:

[0016] 1) The precision temperature measuring device uses the second-class standard platinum resistance thermometer 11 to detect the temperature of the controlled object, and the second-class standard platinum resistance thermometer 11 outputs a resistance change signal corresponding to the temperature change. Serial output digital signal;

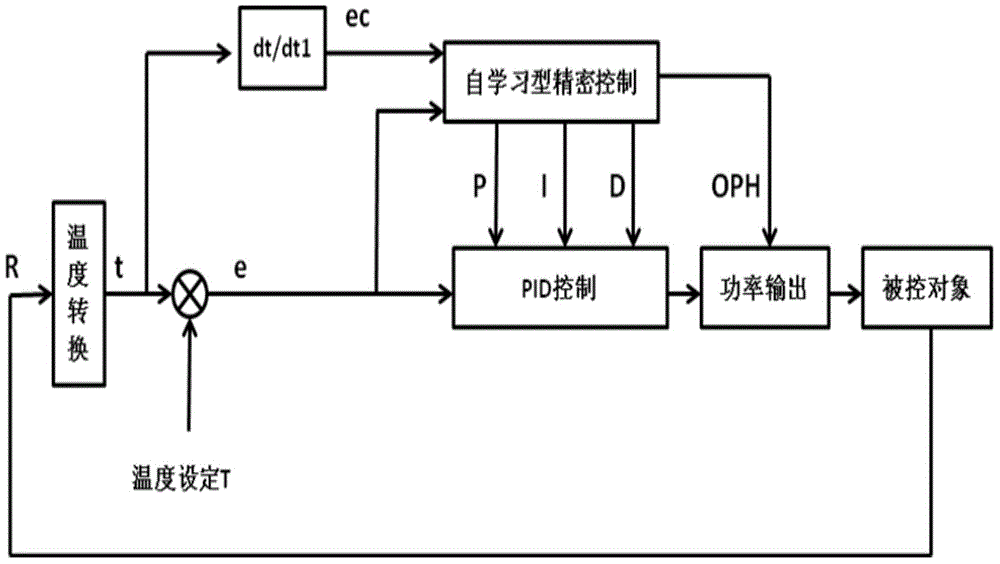

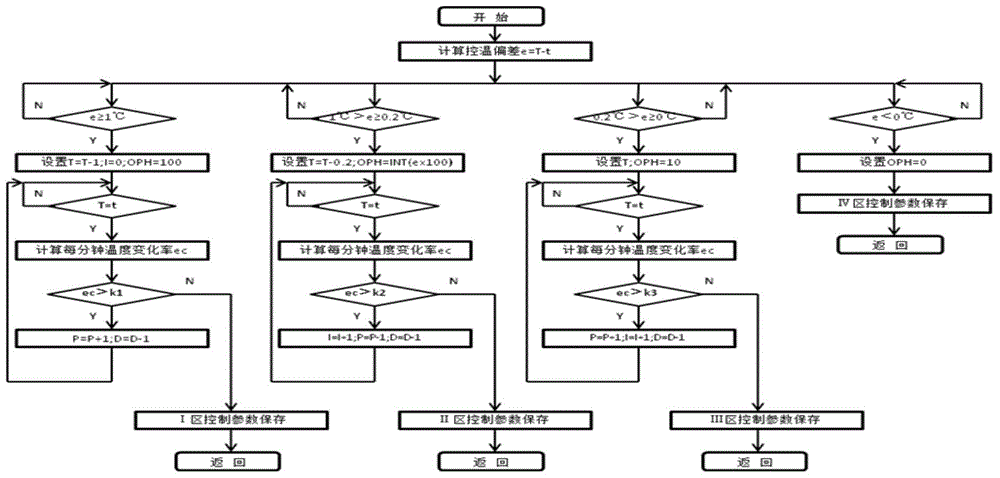

[0017] 2), the temperature precision control device is composed of a temperature conversion module, a PID control module, and a power output module connected in sequence; a self-learning adjustment module is respectively connected to the PID control module and the power output module; wherein the temperature conversion module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com