Epitaxial structure of near-infrared VCSEL laser and manufacturing method thereof

An epitaxial structure and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problem that it is difficult to meet the application requirements of near-infrared sensors, the design of the MQW structure in the active region is unreasonable, and the carrier gain in the active region is not large enough. and other problems, to achieve the effect of reducing leakage loss, increasing differential gain, and increasing recombination probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

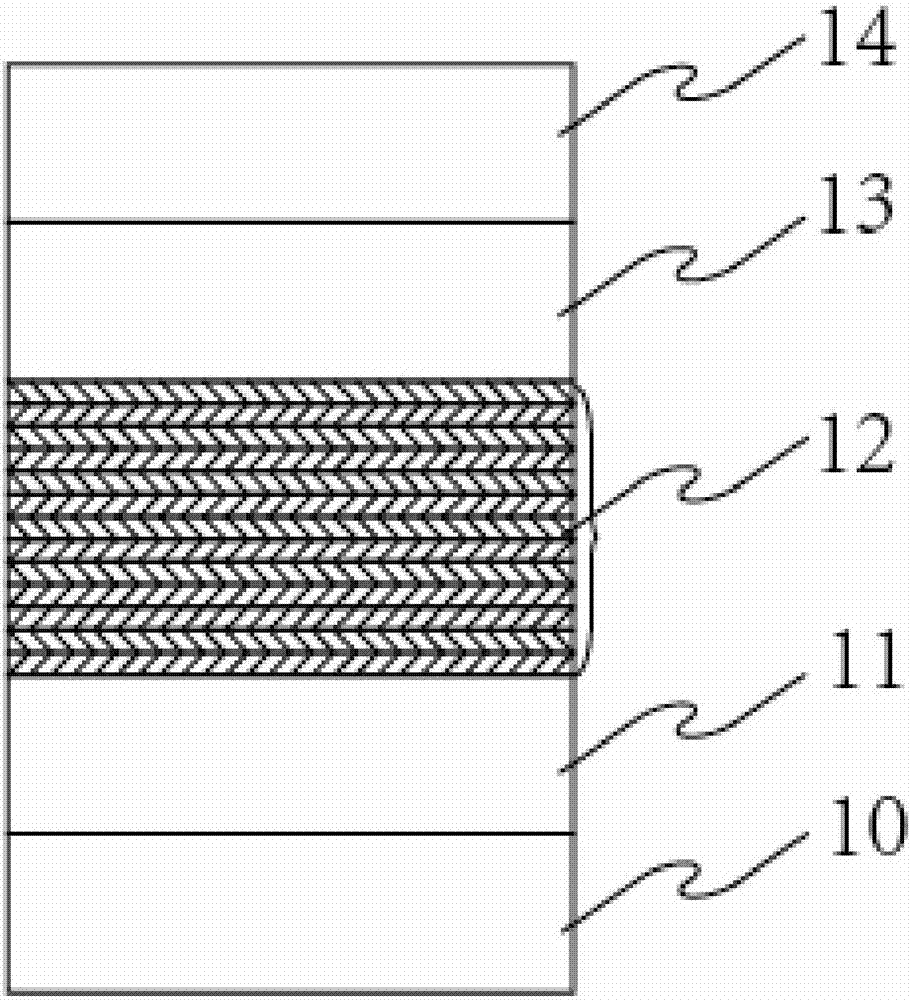

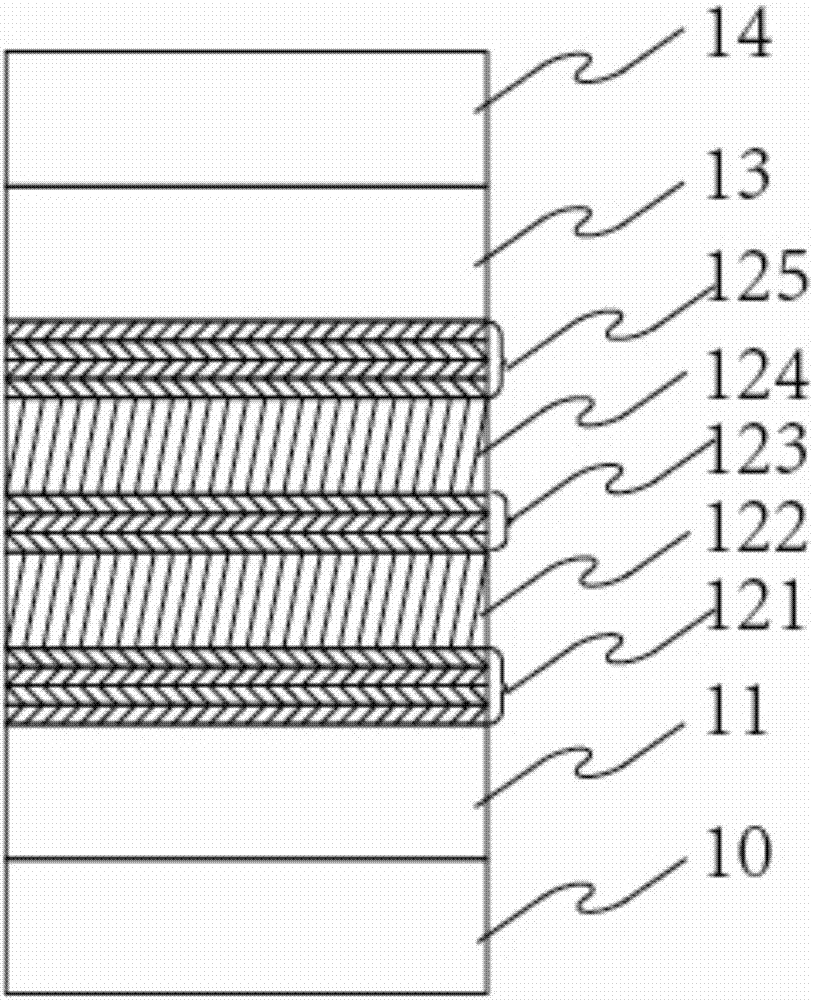

[0036] Such as Figure 4 As shown, the difference between the structure of this embodiment and the first embodiment lies in the structural design of the active region 12, and the active region of this embodiment is composed of the following epitaxial layers:

[0037] Layer 10: 45nm Al 0.90 Ga 0.10 As restriction layer;

[0038] Layer 11: 30nm Al 0.60 Ga 0.40 As to Al 0.10 Ga 0.90 A waveguide layer with a graded As composition;

[0039] Layer 12: Multiple Groups by In 0.12 Ga 0.88 As well and Al 0.10 Ga 0.90 Quantum wells composed of As barriers;

[0040] In the structure of the present invention, the quantum well 12 includes a first quantum well layer 1210, a first thick barrier layer 1220, a second quantum well layer 1230, a second thick barrier layer 1240 and a third quantum well layer 1250, the first quantum well Layer 1210 includes 3nmIn 0.12 Ga 0.88 As well, 6nm Al 0.10 Ga 0.90 As barrier, 3nmIn 0.12 Ga 0.88 As well, the first thick barrier layer 1220 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com