Measurement device applied to online thickness detection and correction of stator or rotor

A thickness detection and measurement device technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of measurement accuracy influence, pass rate drop, temperature drift, etc., to improve stability and reliability, improve stability and reliability. Strength, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

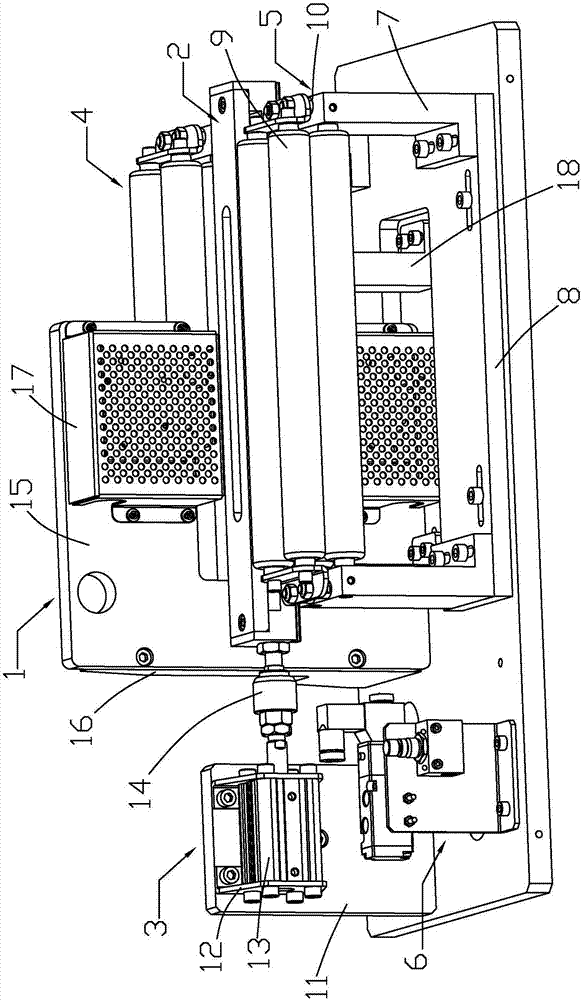

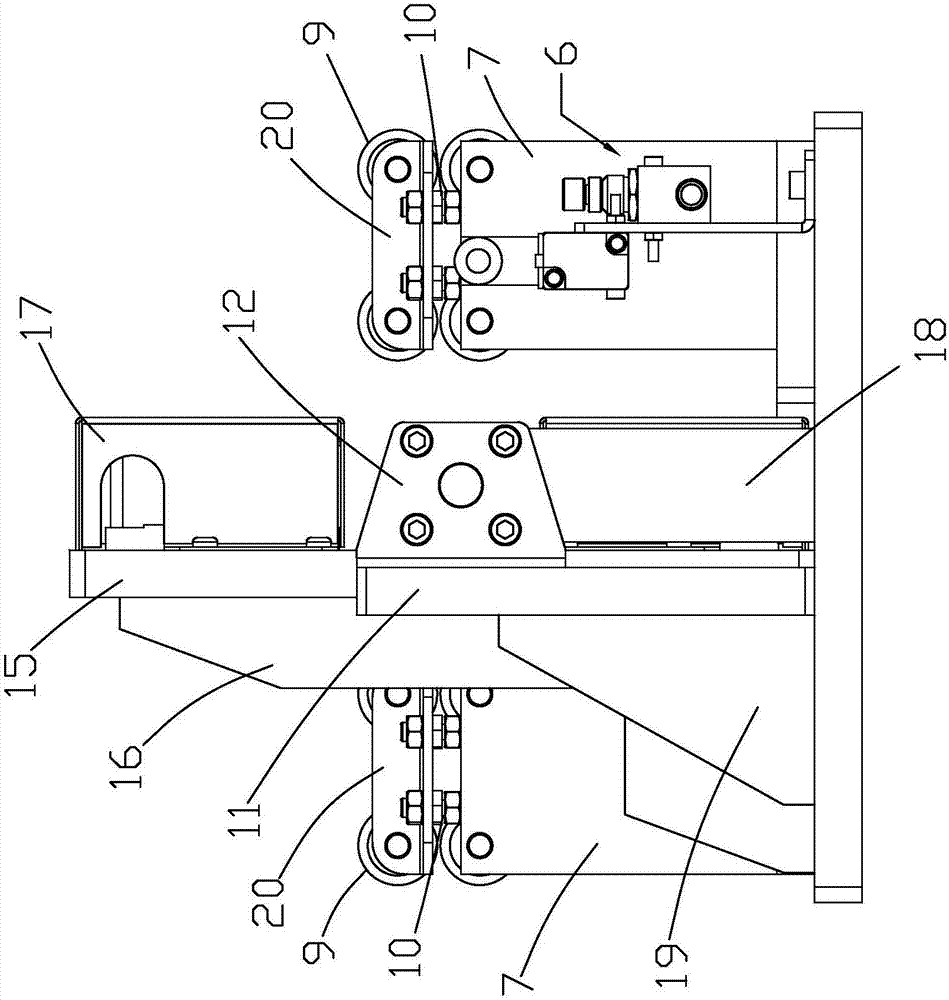

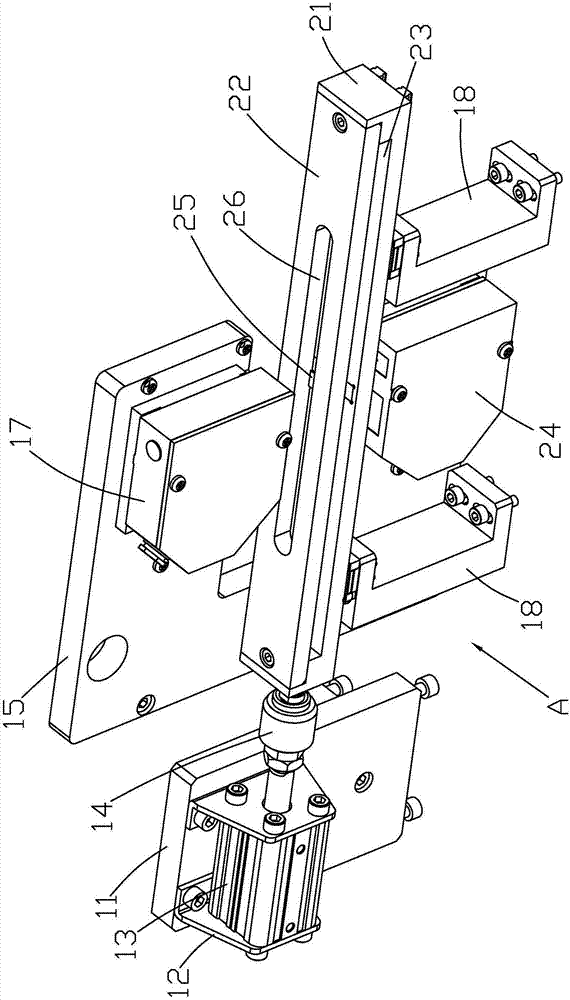

[0031] Such as Figure 1 to Figure 9 As shown, it is a measuring device applied to the online thickness detection and correction of the stator and rotor according to the present invention, including a laser adjustment mechanism 1, a gauge block adjustment mechanism 2, a cylinder movement mechanism 3, a solenoid valve installation assembly 6, and a first roller guide assembly 4 And the second roller guide assembly 5, the first roller guide assembly 4 and the second roller guide assembly 5 are located at the front and back sides of the laser adjustment mechanism 1, the first roller guide assembly 4 and the second roller guide assembly 5 are both Including the roller end mounting plate 7, the roller mounting bottom plate 8 and the unpowered roller 9, the two roller end mounting plates 7 are symmetrically arranged on the top surface of the roller mounting bottom plate 8, and the two unpowered rollers located below 9 are connected in parallel rotation between the two roller end mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com