Double-channel plunger flow assignment electro-hydraulic actuator

An actuator and current distribution technology, applied in mechanical equipment, servo meter circuits, fluid pressure actuation devices, etc., can solve the problems of low volumetric efficiency, low-speed operation, instability, etc., and achieve simple and reliable systems and high oil volumetric efficiency. , the effect of high-precision positioning control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

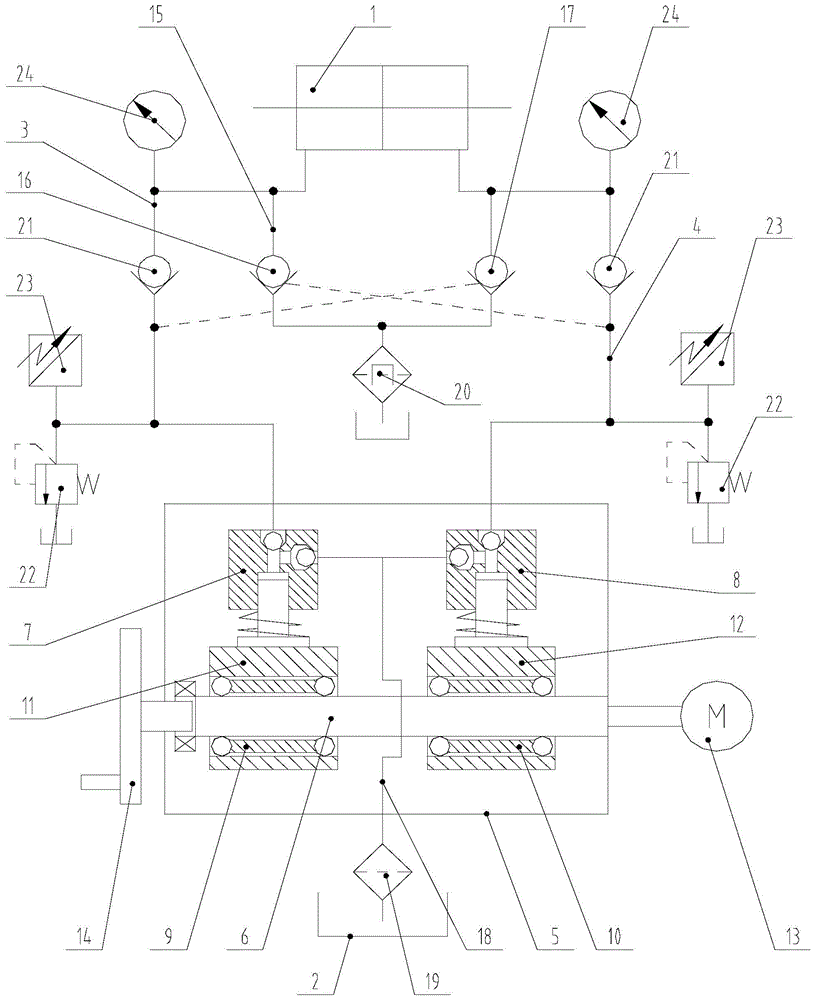

[0016] figure 1 It is a schematic diagram of the hydraulic structure of the present invention, as shown in the figure: the dual-channel plunger distribution electro-hydraulic actuator of this embodiment includes a bidirectional pump, a bidirectional oil cylinder 1, a fuel tank 2 and an oil circuit system; the bidirectional pump is provided with a forward rotation The first oil outlet for oil supply and the second oil outlet for reverse oil supply; the oil circuit system includes the first oil circuit 3 communicating with the first oil outlet and the left cavity of the two-way cylinder 1 and the second oil outlet port and the second oil passage 4 of the right chamber of the two-way oil cylinder 1, that is, when the two-way pump is rotating forward, the high-pressure oil is output through the first oil outlet, and when the two-way pump is in reverse, the high-pressure oil is output through the second oil outlet, and through the two-way pump The positive and negative rotation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com