Patents

Literature

65results about How to "Precise positioning control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel control method of intelligent television

ActiveCN103281575ASolve the inconvenience caused by manipulationImprove human interaction experienceSubstation equipmentSelective content distributionControl systemHuman–computer interaction

The invention provides a novel control method of an intelligent television. According to the method disclosed by the invention, based on an intelligent touch control system, the intelligent television is remotely controlled through touch control on handheld computer equipment, so that the inconvenience caused by manipulating the intelligent television through a conventional remote controller is solved; a novel interaction manner brings about convenience for manipulating the intelligent television by a user and face-to-face interaction experiences of the intelligent television are improved; and the method is simple, low in cost and good in stability.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

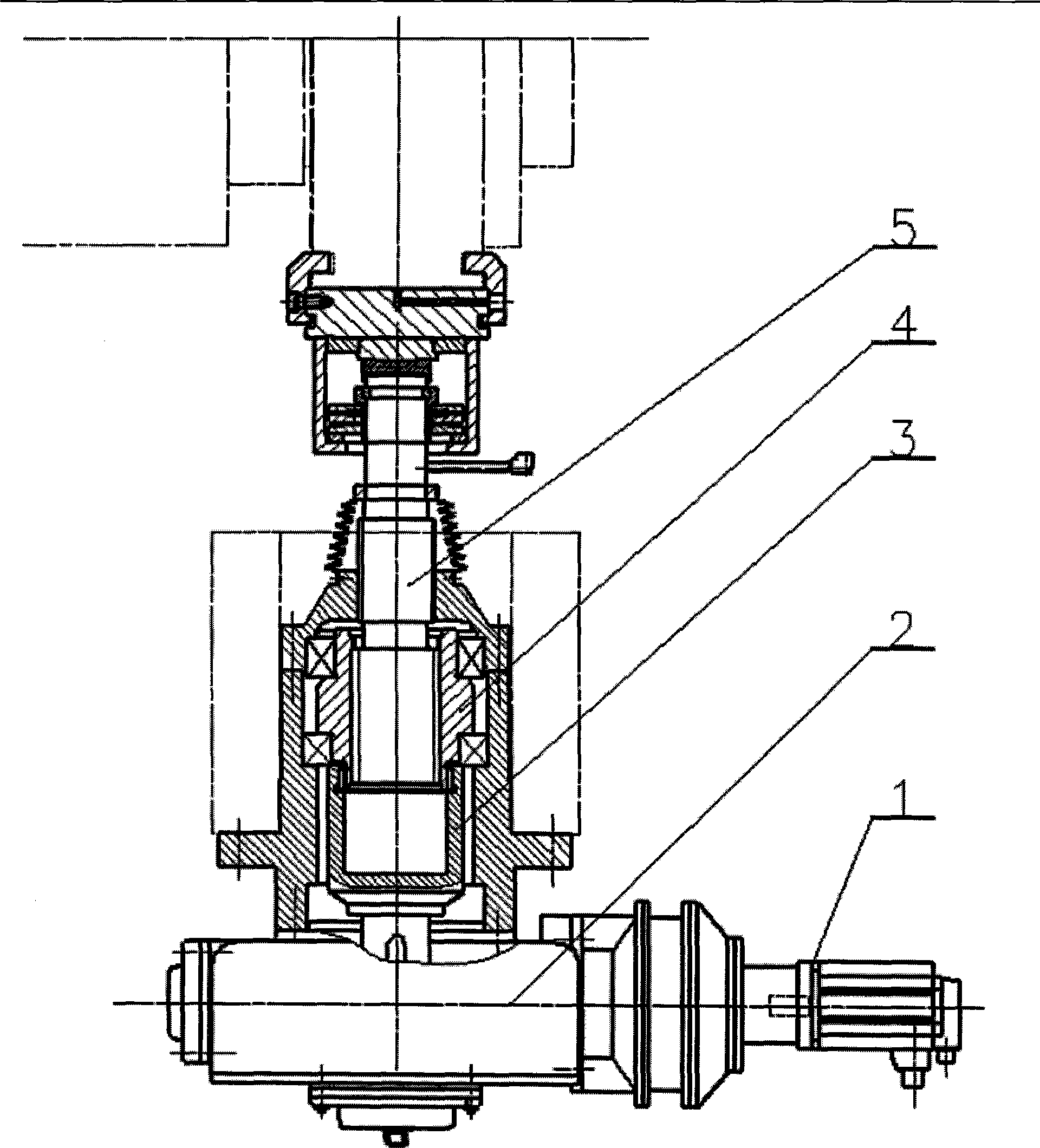

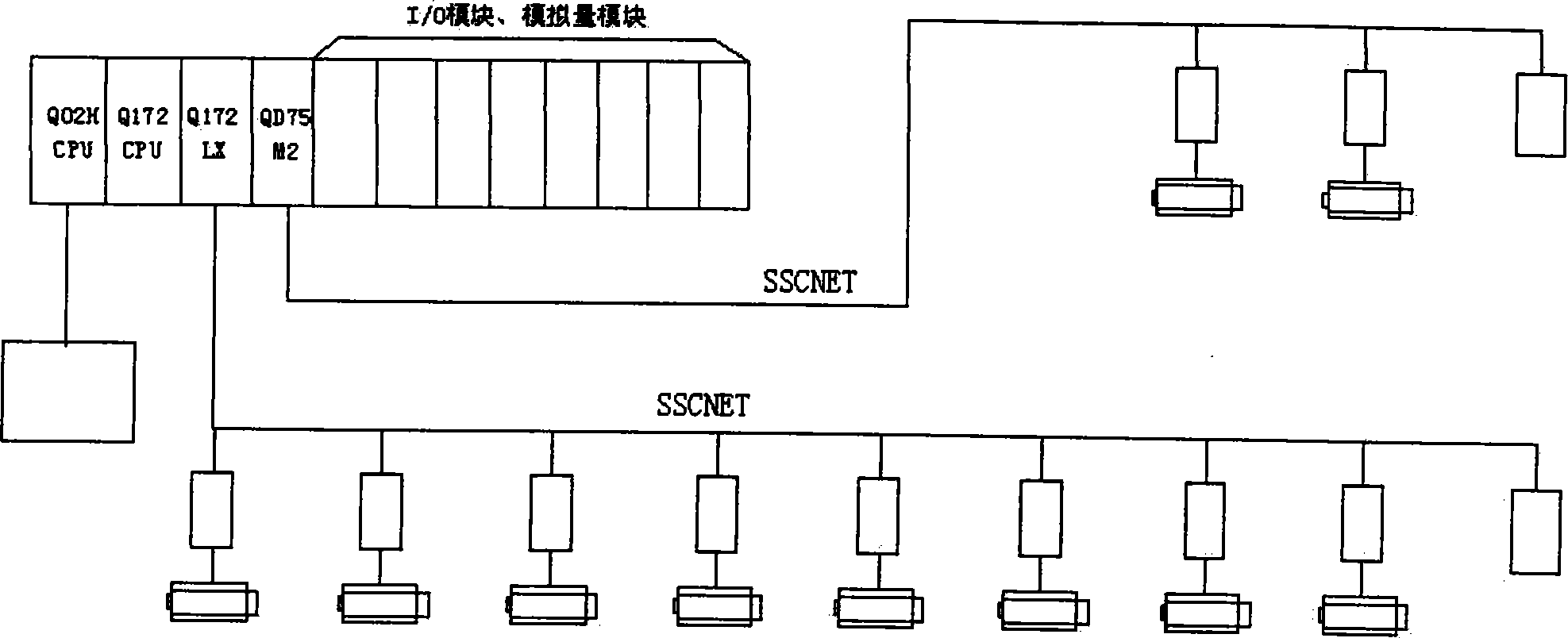

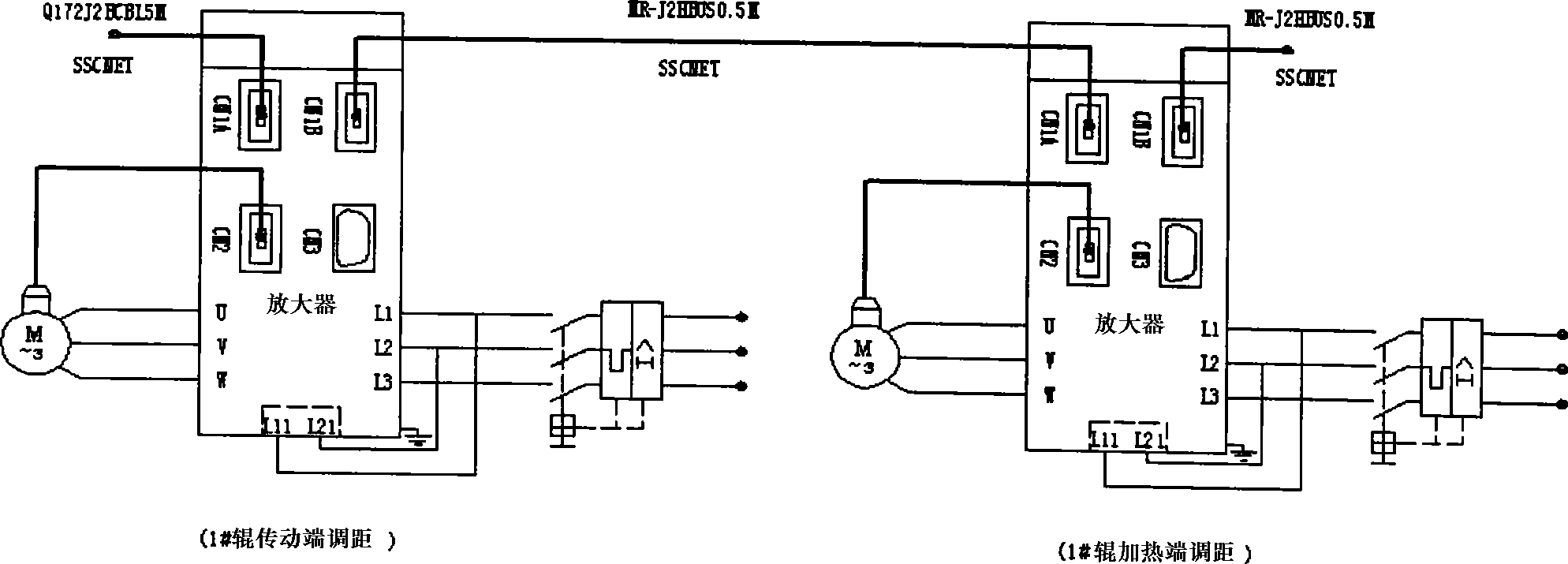

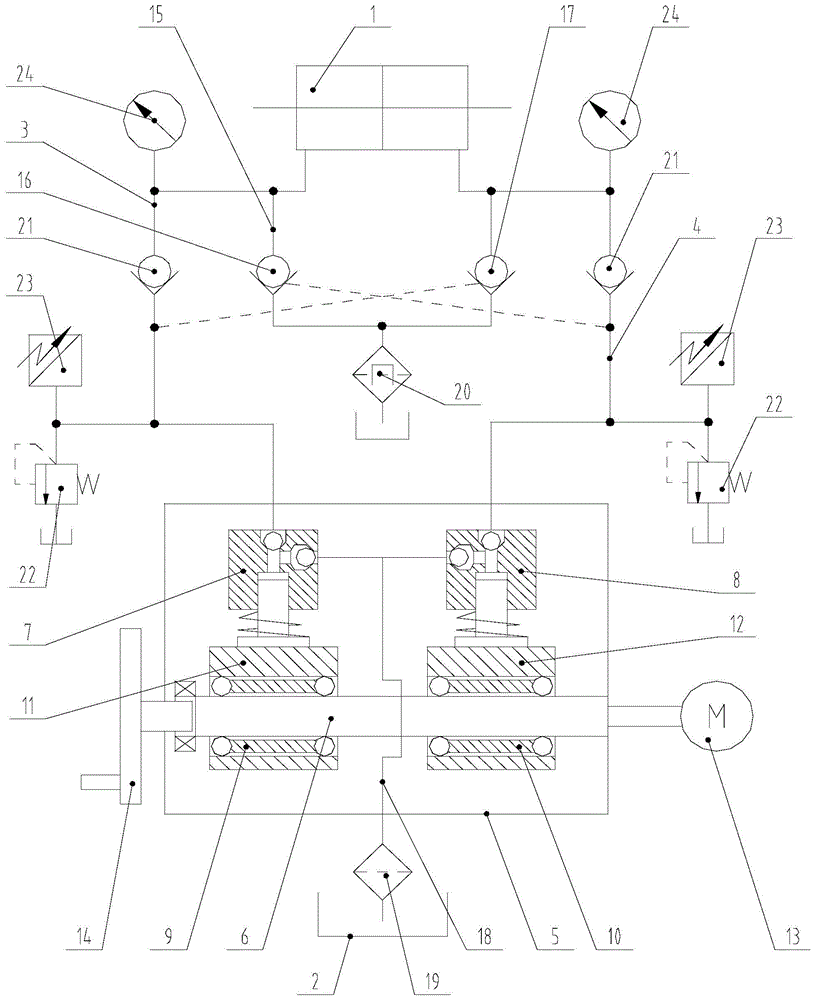

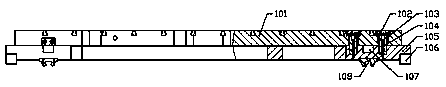

High-precision roller-spacing control system

The invention relates to an S typed four roller pressing extending line host computer distance adjusting system. A high precision roller distance control system consists of an distance adjusting part and a control part, wherein, the distance adjusting part drives a turbine box by a servo motor through a deceleration box, a worm gear drives a nut through inner and outer gear covers, the screw rod copulated with the nut does not rotate, the rotation of the nut drives the screw rod to move forward or backward in the radial direction, and the screw rod is connected with a bearing body; and the control part is a controller which sends command signals to a servo controller which controls a servo motor, the servo motor feeds back the data information to the servo controller through a coder, the servo controller carries out compare and calculation according to the current roller distance, afterwards the servo controller drives the servo motor to operate or stop, and a closed loop control is accomplished. The accurate fault detection function of the distance adjusting system eliminates mechanical fixed return difference through the procedures so as to ensure the positioning accuracy; the operational synchronization ensures the adjusting stability and synchronization of two ends in the roller canister; the automatic positioning of the roller distance is achieved, and the formula function of the roller distance is achieved.

Owner:大连橡胶塑料机械有限公司

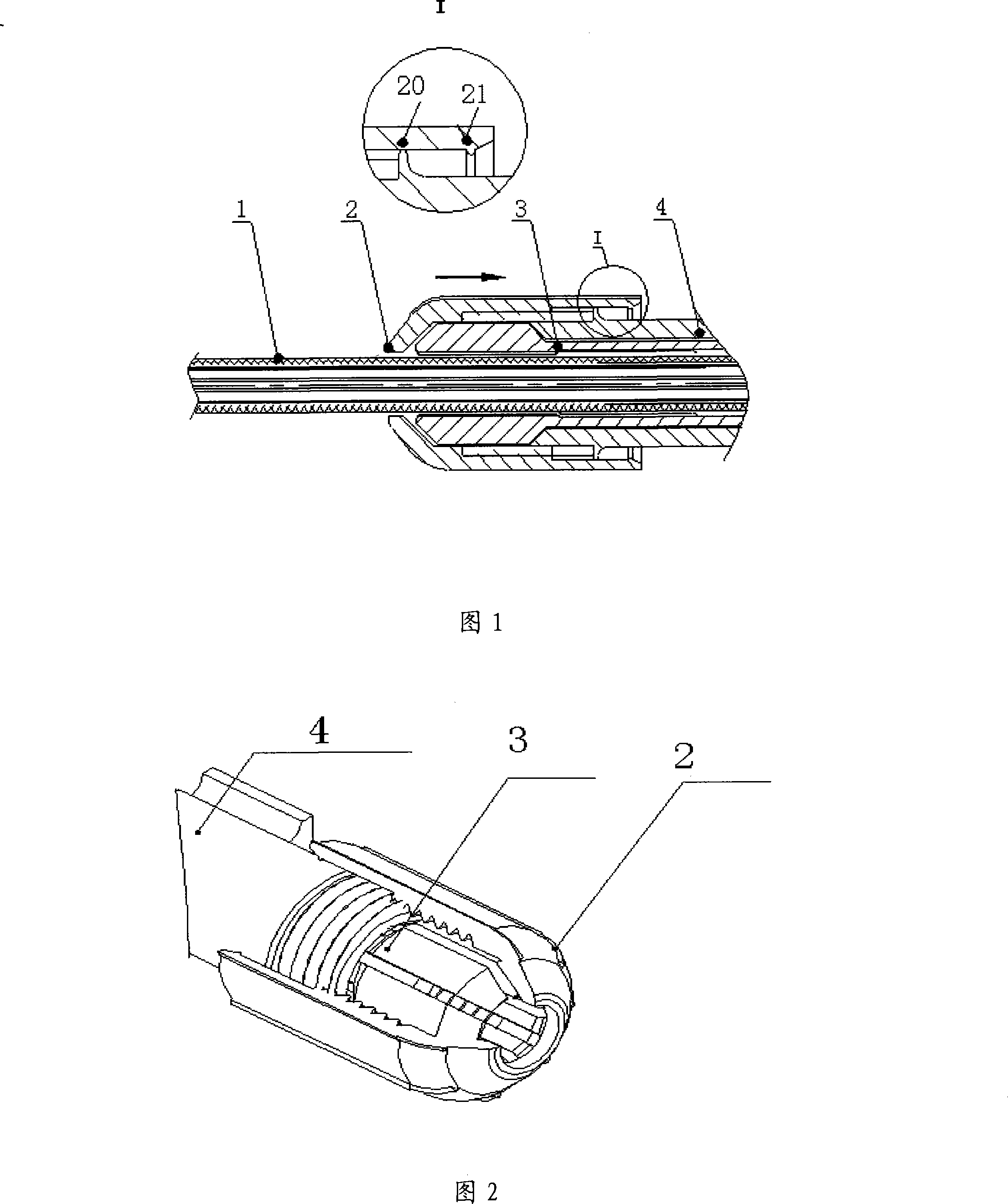

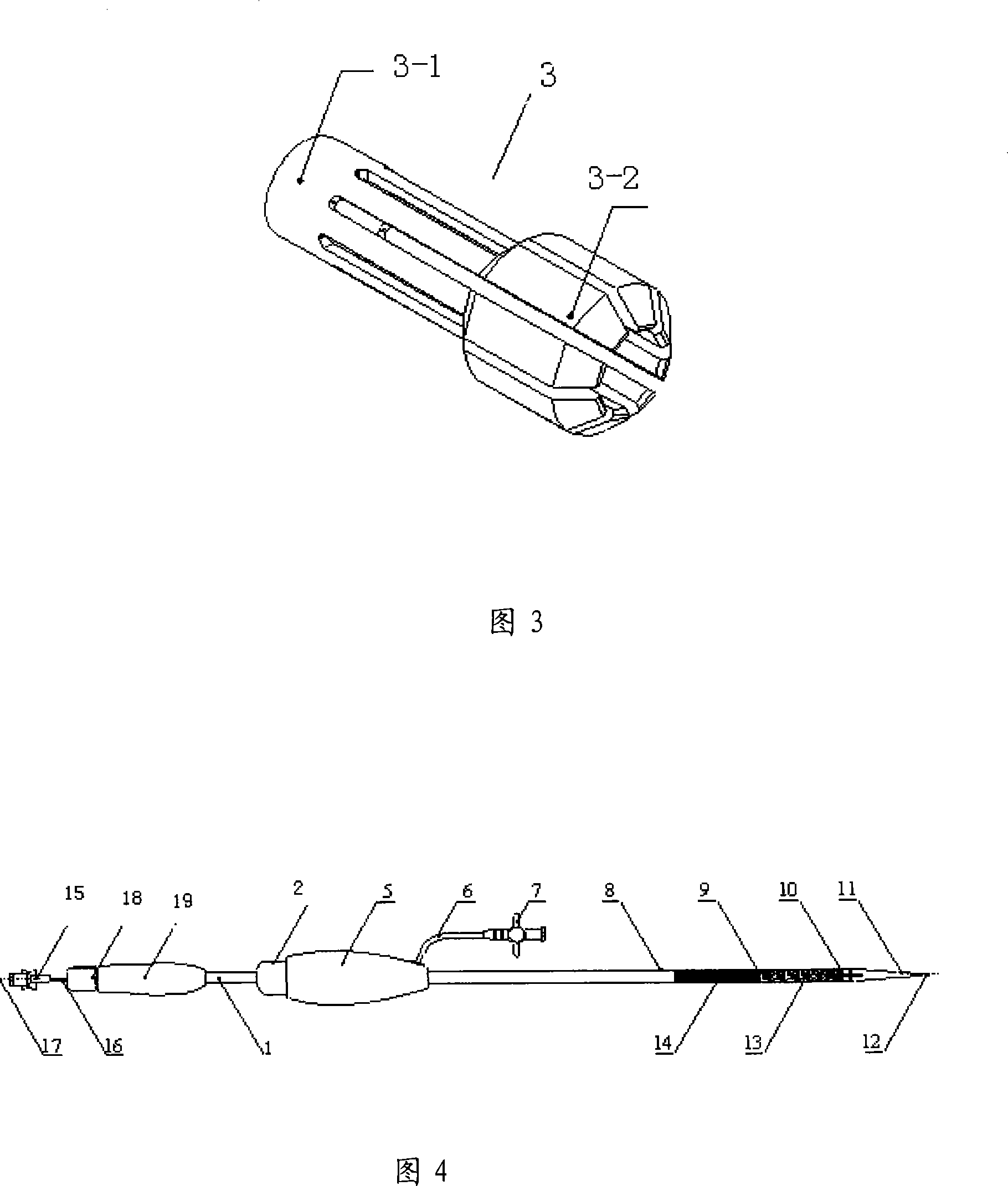

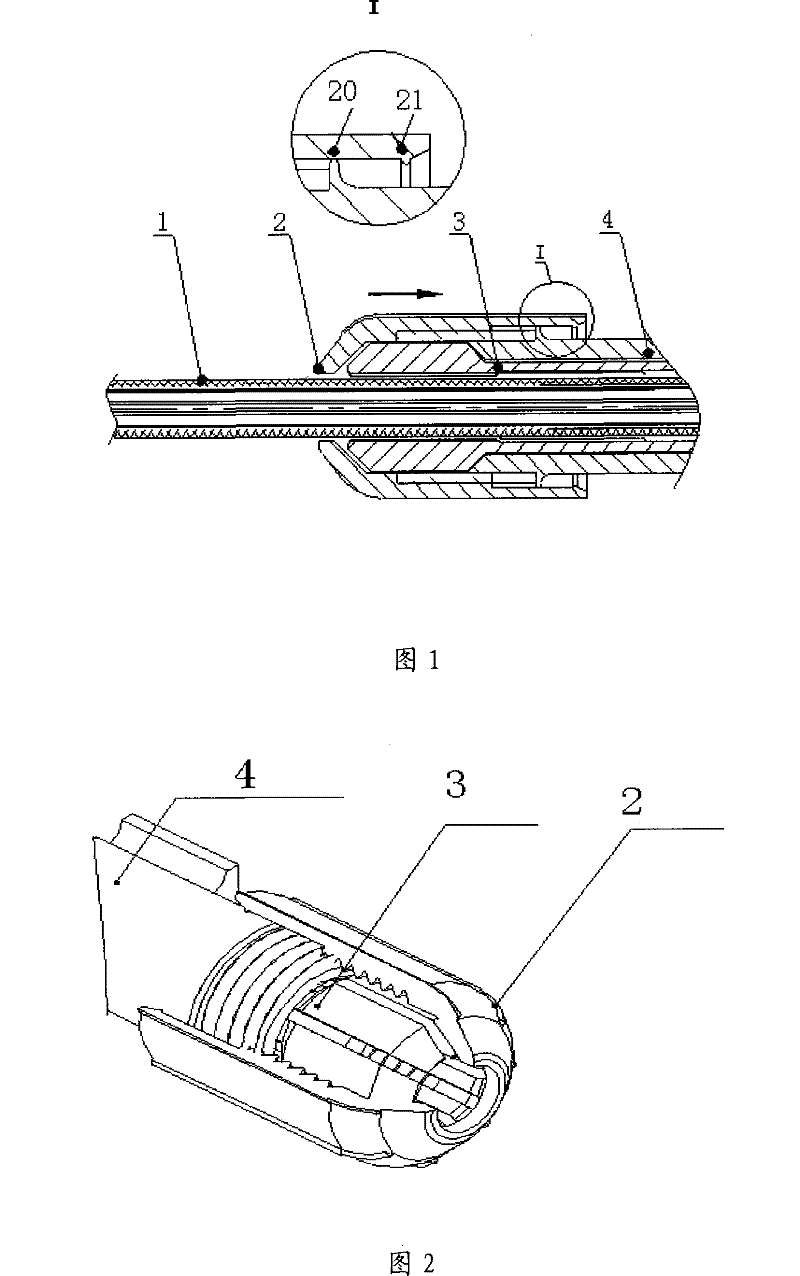

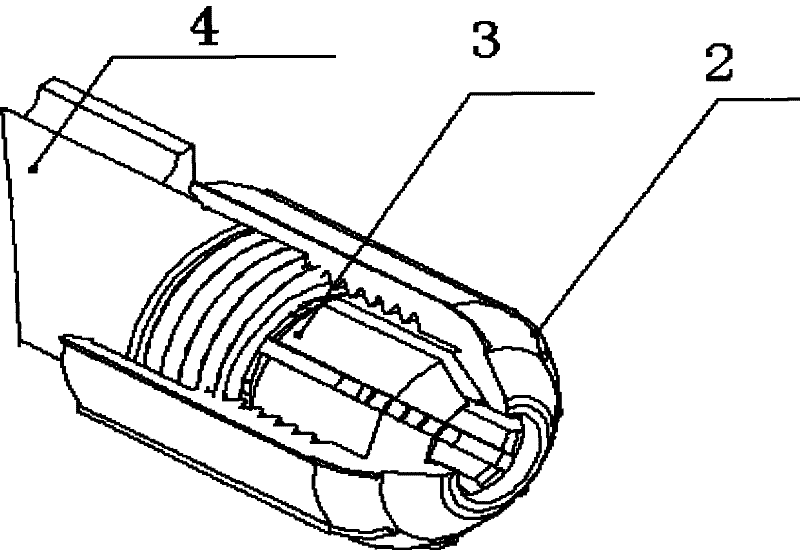

Locking device for human body medical appliance conveying system

The invention discloses a locking device which is used for a medical device transportation system in the human body, which is characterized in that the invention includes a locking head, a locking cap and a connection part which connects the locking head and the locking cap, wherein, one end of the locking head is sheathed in the connection part, and the other end thereof is sheathed in the locking cap. The invention can easily carry out the positioning control of a transportation duct of the transportation system by the matching of the locking cap and the locking head, the structure of the invention has simple design and easy operation, which can avoid the displacement of the transportation duct of the transportation system during using process, thus the medical device can be effectively released and positioned during installation process.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

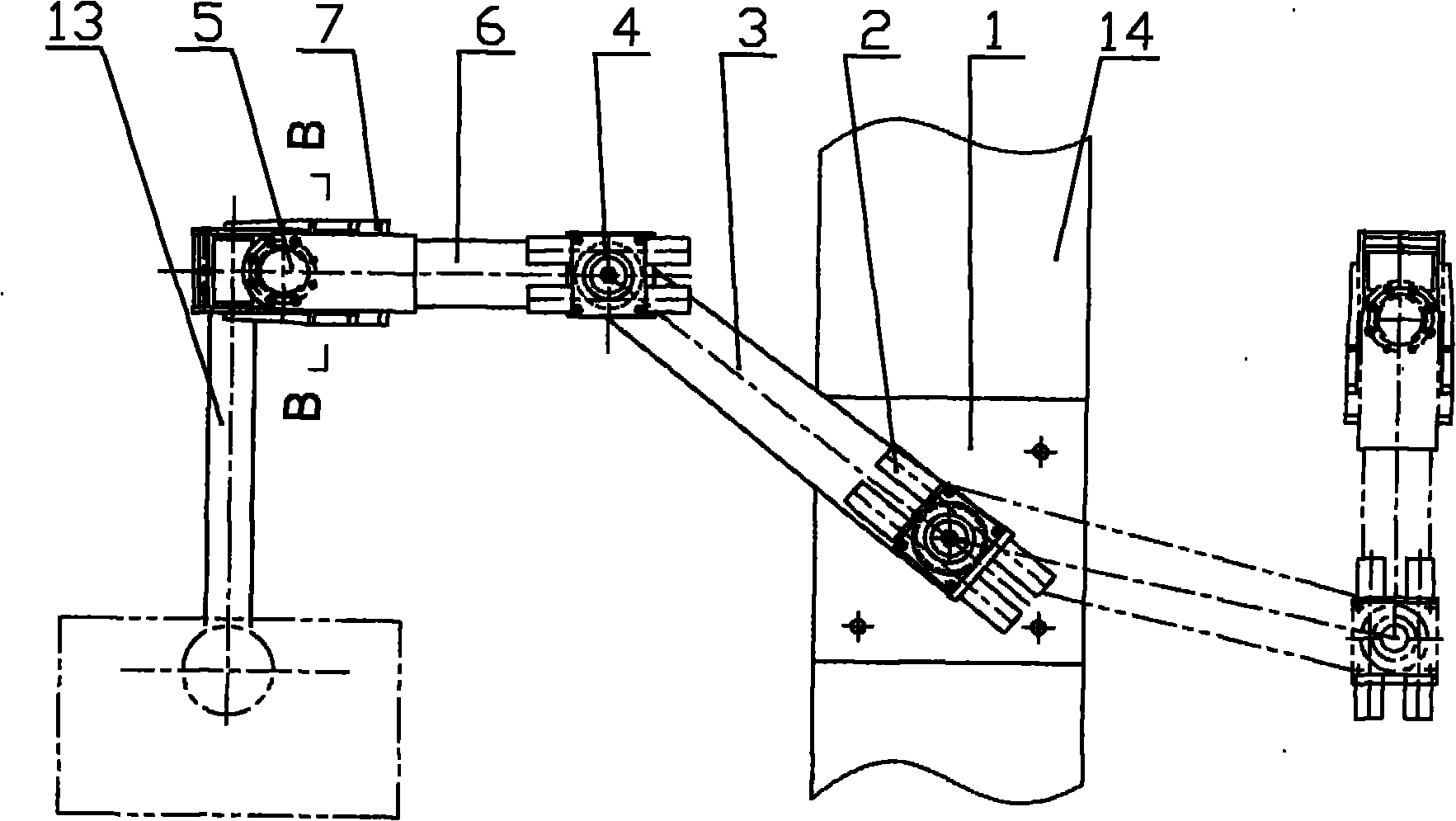

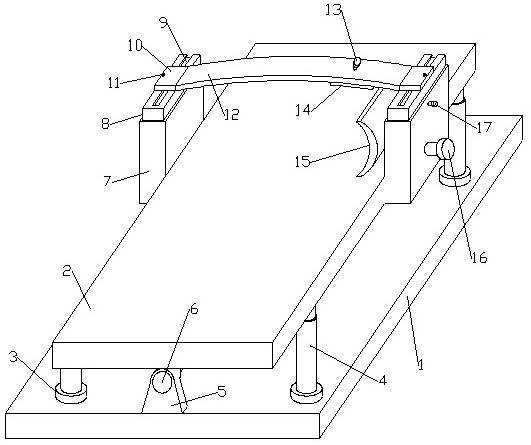

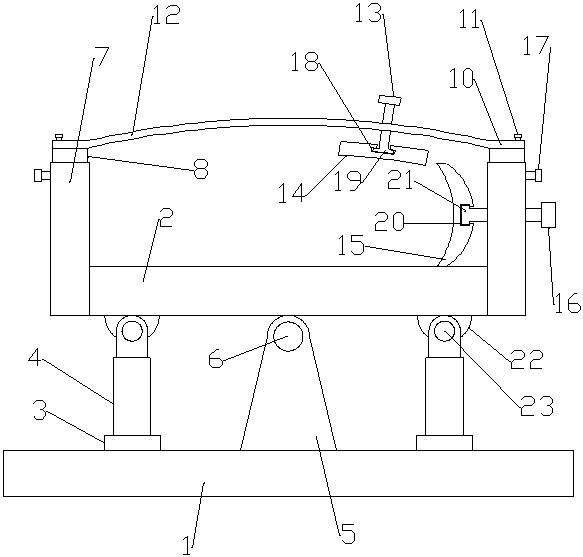

Metal wire bender

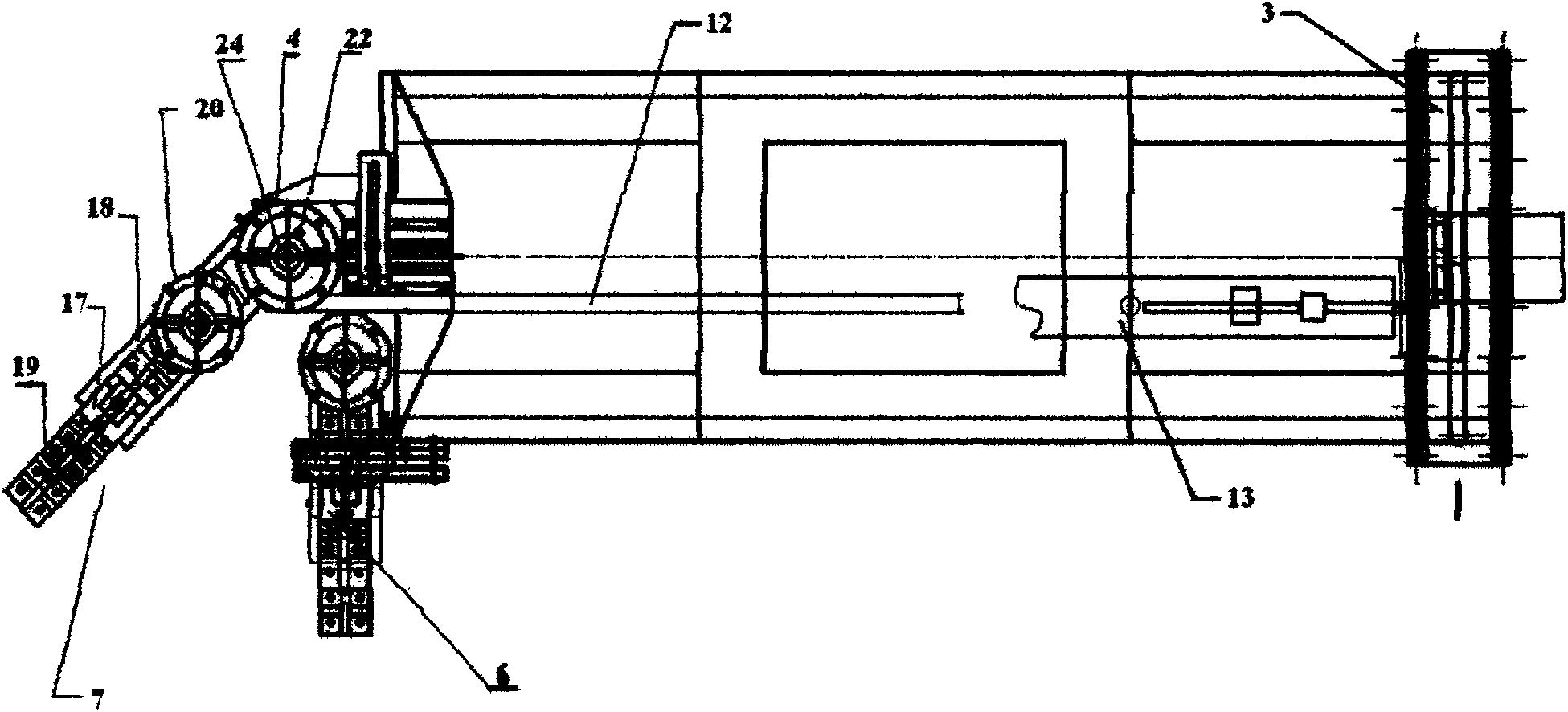

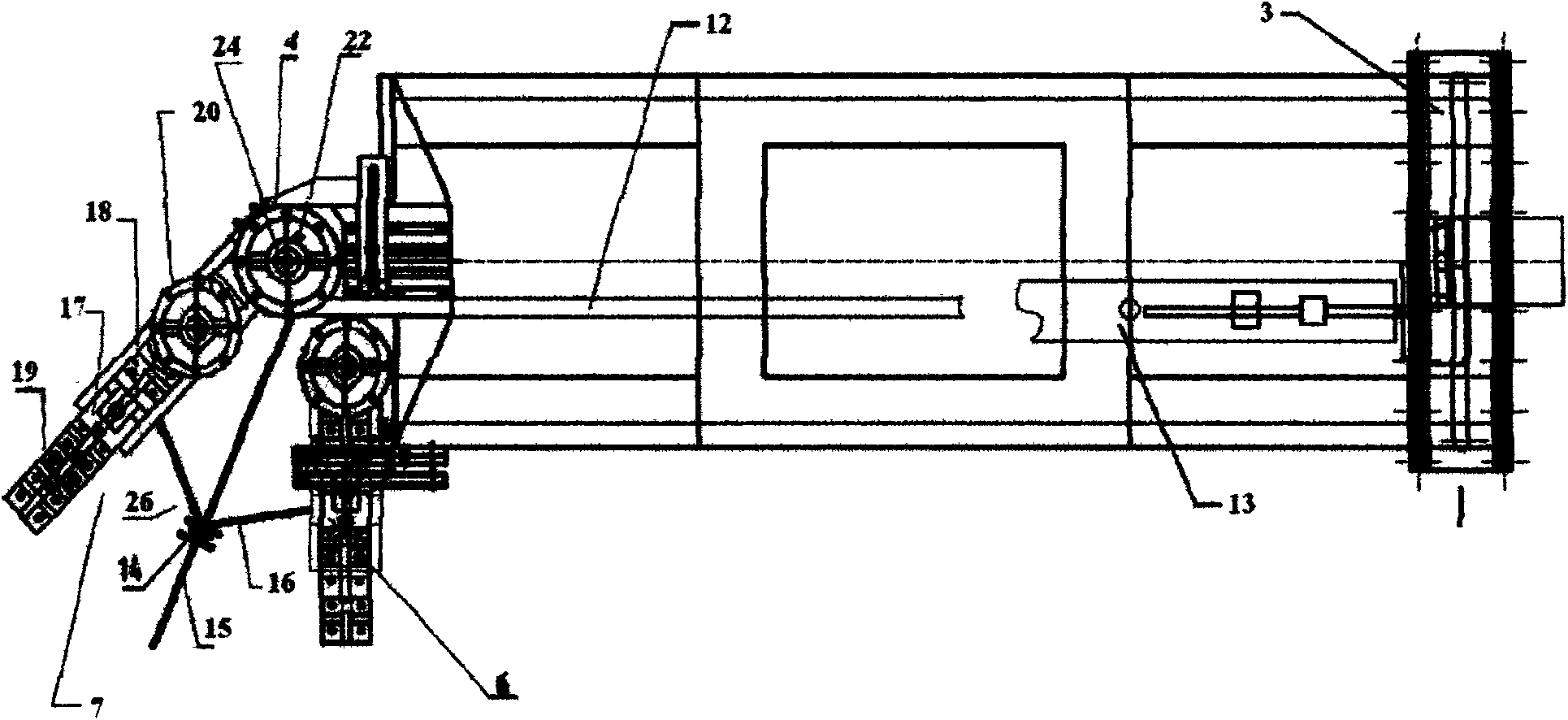

The invention provides a metal wire bender, which comprises a machine head, a machine body and a tail bed, wherein the machine bed is positioned at the front part of the bender and comprises a drivingdevice, a bending mould, a fixed rotating arm, a rotating arm and a rotating arm corner bracket. The fixed rotating arm is fixed on a bracket of the machine body; the rotating arm is fixed on a bearing seat, is powered by the driving device and is provided with a fixed bracket and a sliding bracket; the sliding bracket is provided with a sliding oil cylinder which can drive the sliding bracket tomove on the fixed bracket; an arm mould is arranged at one end of the sliding bracket and fixed on the sliding bracket through a fastening mechanism; the machine body comprises a guide rail mechanismand a bracket; the guide rail mechanism is arranged on the upper part of the bracket, one end of the guide rail mechanism is connected with the tail bed and the other end of the guide rail mechanismis connected with the machine through a guide rail groove contained in the guide rail mechanism; and after metal wires are put in the guide rail groove through the tail bed and fed forward by a feed device contained in the guide rail mechanism.

Owner:青岛富康源机械厂(普通合伙)

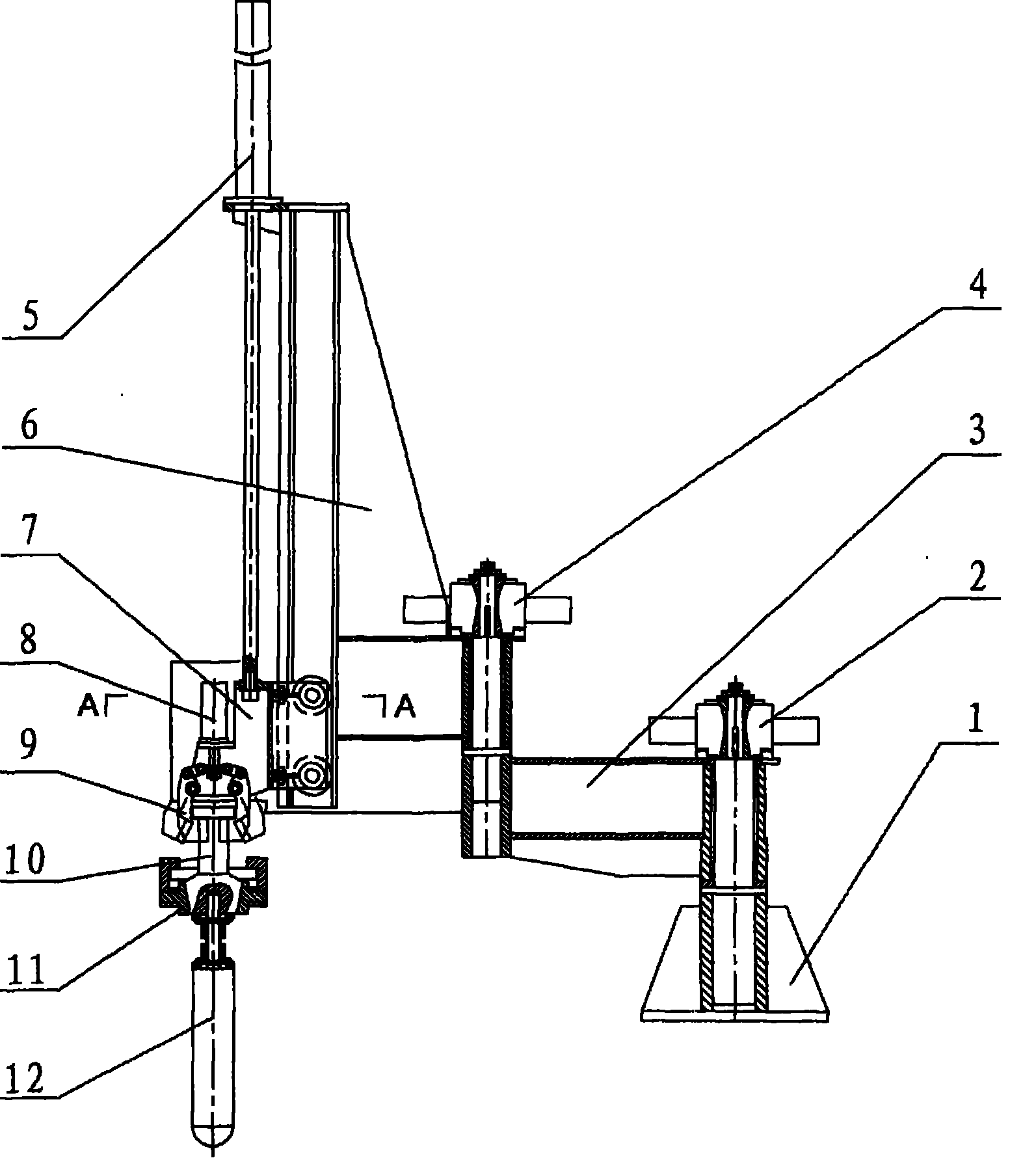

Quick change device for stopper rod

The invention provides a quick change device for a stopper rod for a tundish of a continuous casting machine, which belongs to the technical field of continuous casting machines. The quick change device for the stopper rod consists of a frame, a swing mechanism, a lifting mechanism, clamp forceps and a stopper rod clamping mechanism. The swing mechanism consists of a large-arm swing cylinder, a large arm, a small-arm swing cylinder and a small arm; the lifting mechanism consists of a movable rack, a transverse guide wheel, a longitudinal guide wheel and a lifting cylinder; and the stopper rod clamping mechanism consists of the stopper rod, a connecting head and a stopper rod seat. The stopper rod seat is provided with a locking arm, and the connecting head and the stopper rod seat are locked through the locking arm. When the locking is opened, the clamp forceps grip the connecting head for fixing the stopper rod, and quickly lift up and down or horizontally move to finish the change of the new and old stopper rods. The quick change device for the stopper rod has the advantages of simple motion, convenient operation, accurate stopper rod positioning and short change time, and can realize continuous casting and unstopped stopper rod change, improve the yield of the continuous casting machine and reduce the production cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

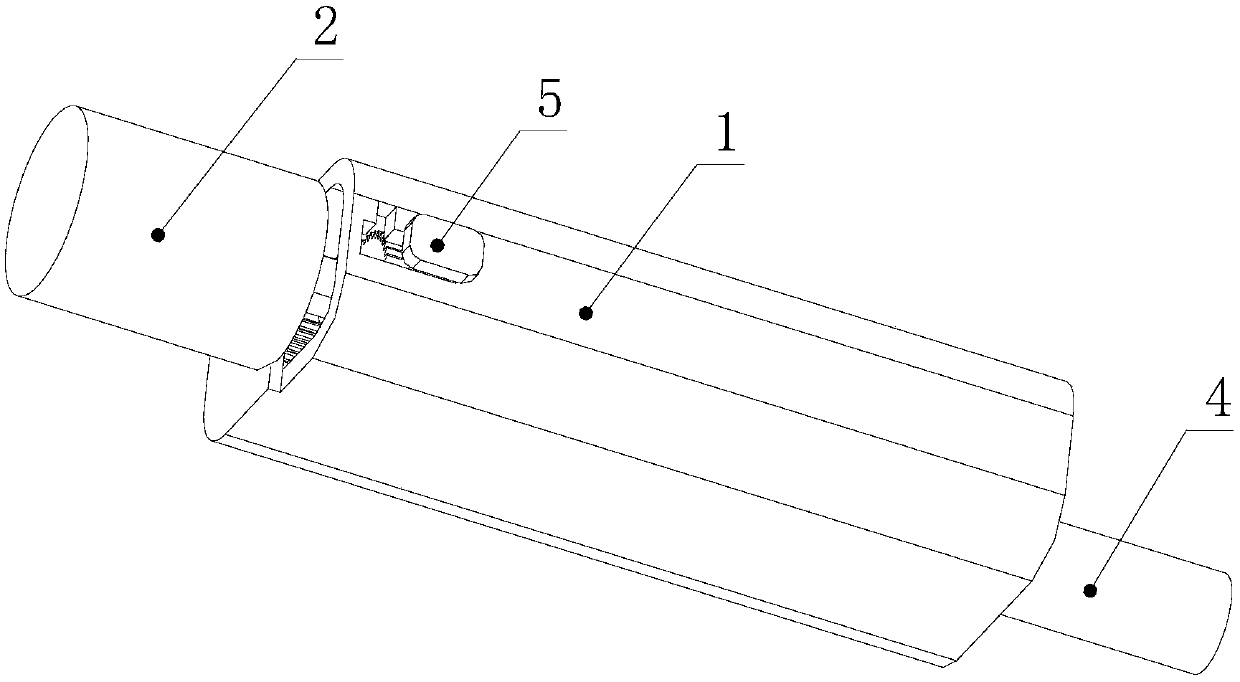

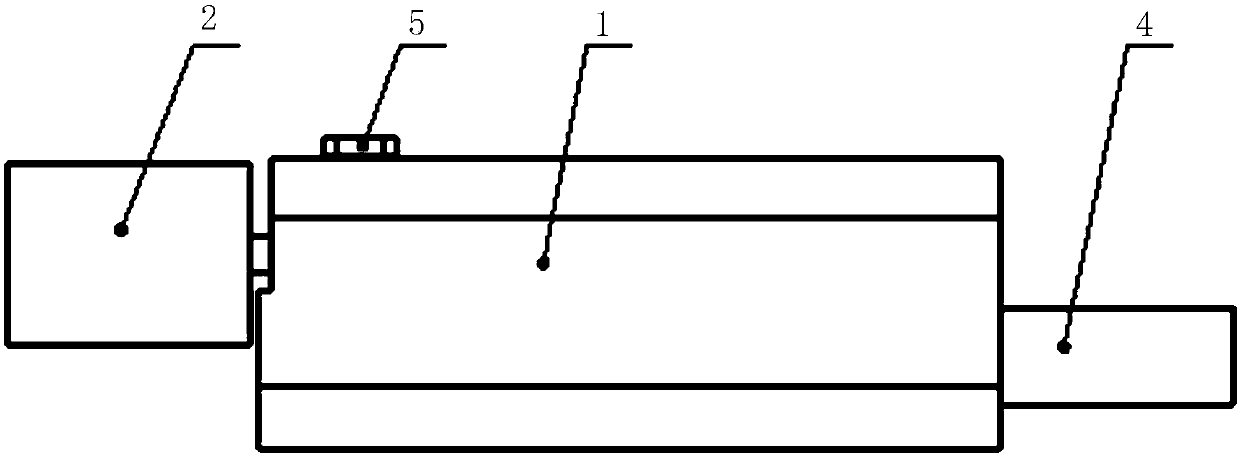

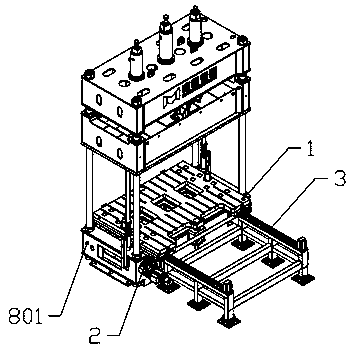

Device and method for discharging and forming cells

PendingCN108428923APrecise positioning controlPrevent shrinkage deformationAssembling battery machinesFinal product manufactureLocking mechanismPole piece

The invention discloses a device and a method for discharging and forming cells. A bare cell is wound on a winding needle. The device for discharging and forming the cells comprises a discharge movable platform and a locking mechanism. The locking mechanism is used for positioning the bare cell and comprises a lower positioning mechanism and an upper positioning mechanism, the lower positioning mechanism is used for positioning the lower portion of the inside of the bare cell, the upper positioning mechanism is used for positioning the upper portion, which is opposite to the lower portion, ofthe bare cell, and the upper positioning mechanism and the lower positioning mechanism are movably arranged on the discharge movable platform. The device and the method for discharging and forming thecells have the advantages that the device is simple in structure, the cells can be accurately positioned and controlled when automatically discharged, contraction deformation of the cells towards internal spaces of the cells can be prevented, accordingly, the purpose of controlling pole pieces to prevent displacement can be achieved, and the quality of the cells can be improved.

Owner:苏州迈展自动化科技有限公司

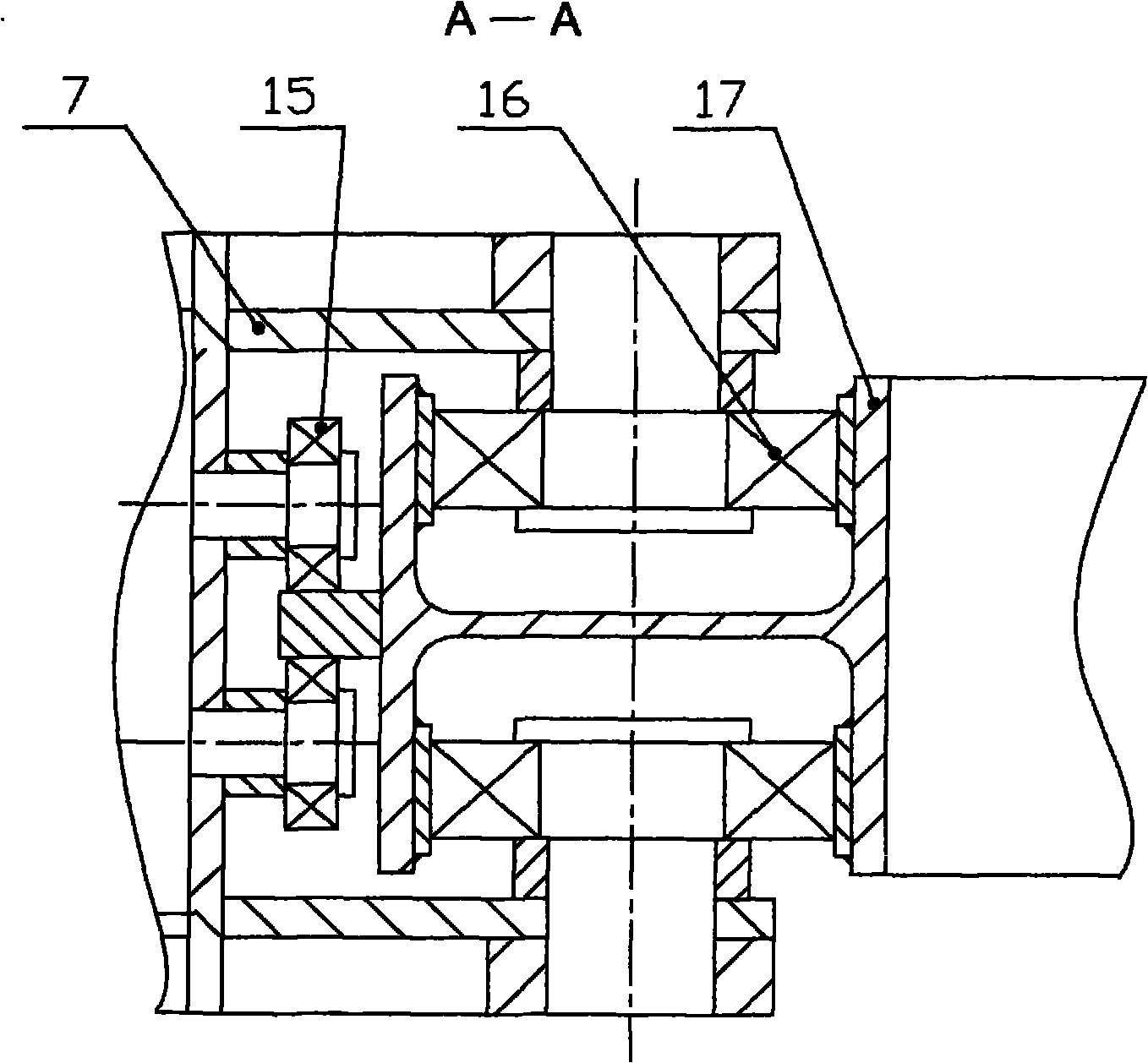

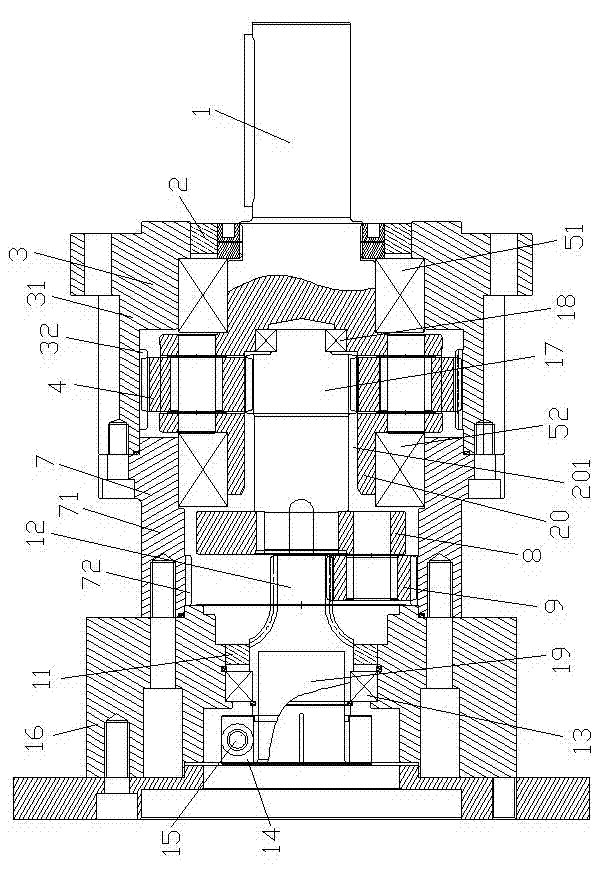

Double moduli high-accurate planet reducing mechanism

InactiveCN103089932AReasonable structural designSmooth runningToothed gearingsGearing detailsCouplingGear wheel

The invention relates to a double moduli high-accurate planet reducing mechanism. At present no high-accurate planet reducing mechanism is high in precision, compact in structure, small in meshing clearance and strong in bearing capability. The double moduli high-accurate planet reducing mechanism is characterized by comprising an output shaft, an output shaft oil sealing, a secondary gear ring shell body, a plurality of secondary planet gears, a primary gear ring shell body, an intermediate planet carrier, a plurality of primary planet gears, a primary sun gear, a coupling bearing, a simple-clamp type locking ring, a rear cover, a secondary sun gear, bearings, a coupling and a secondary planet carrier. The output shaft is installed inside a secondary gear case shell body through a front bearing, the secondary planet carrier is fixed at one end of the output shaft, the secondary planet gears are all installed on the secondary planet carrier, the secondary sun gear is installed in a secondary sun gear cavity of the secondary planet carrier, the primary planet gears are meshed with the primary gear ring, and the primary planet gears are all meshed with the primary sun gear. The double moduli high-accurate planet reducing mechanism is compact in structure, small in back lash, and high in concentric degree and repeated location.

Owner:浙江赛亚智能传动科技有限公司

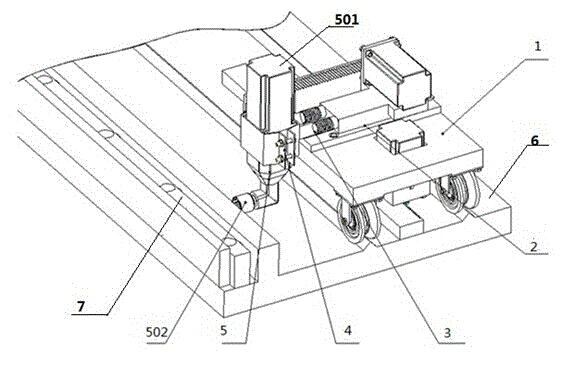

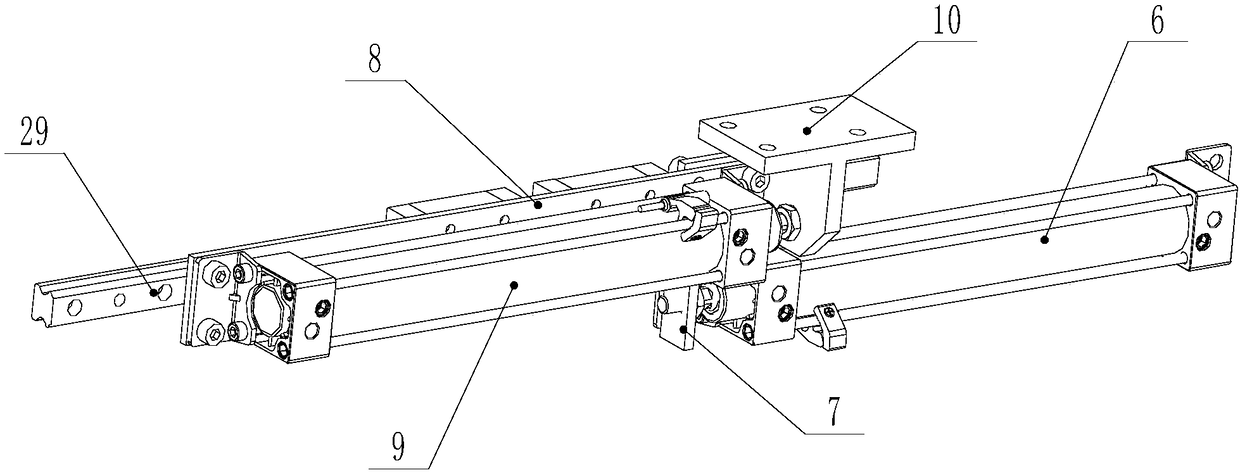

Automatic cutter deformation regulating device for ultra-large plate shearing machine

InactiveCN104439496AGuaranteed stabilityPlay a protective effectShearing machine accessoriesEngineeringWrench

The invention discloses an automatic cutter deformation regulating device for an ultra-large plate shearing machine. The automatic cutter deformation regulating device comprises a rail trolley, a feeding mechanism, spanner connecting mechanisms, a clamping mechanism and a spanner mechanism. V-shaped sheaves are adopted in the rail trolley so as to be matched with V-shaped guide rails, it is guaranteed that the trolley is operated smoothly, and meanwhile the trolley can not be disengaged from the rails or swing when receiving force perpendicular to the moving direction; gear and rack engagement is used for the rail trolley, servo motors are used for providing driving force, and localization of the walking direction of the rail trolley in the operation process is accurately controlled; the spanner feeding mechanism is used for feeding and retracting the spanner mechanism, the feeding mechanism receives force flexibly, and a sleeve of the spanner mechanism can be engaged with a regulating bolt under the condition that the spanner servo motor is ignited. According to the automatic cutter deformation regulating device, based on the fact that manual regulation is eliminated, regulation of the blade deformation can be greatly accelerated, and therefore work efficiency and operation accuracy are improved to a great extent.

Owner:JIANGSU UNIV

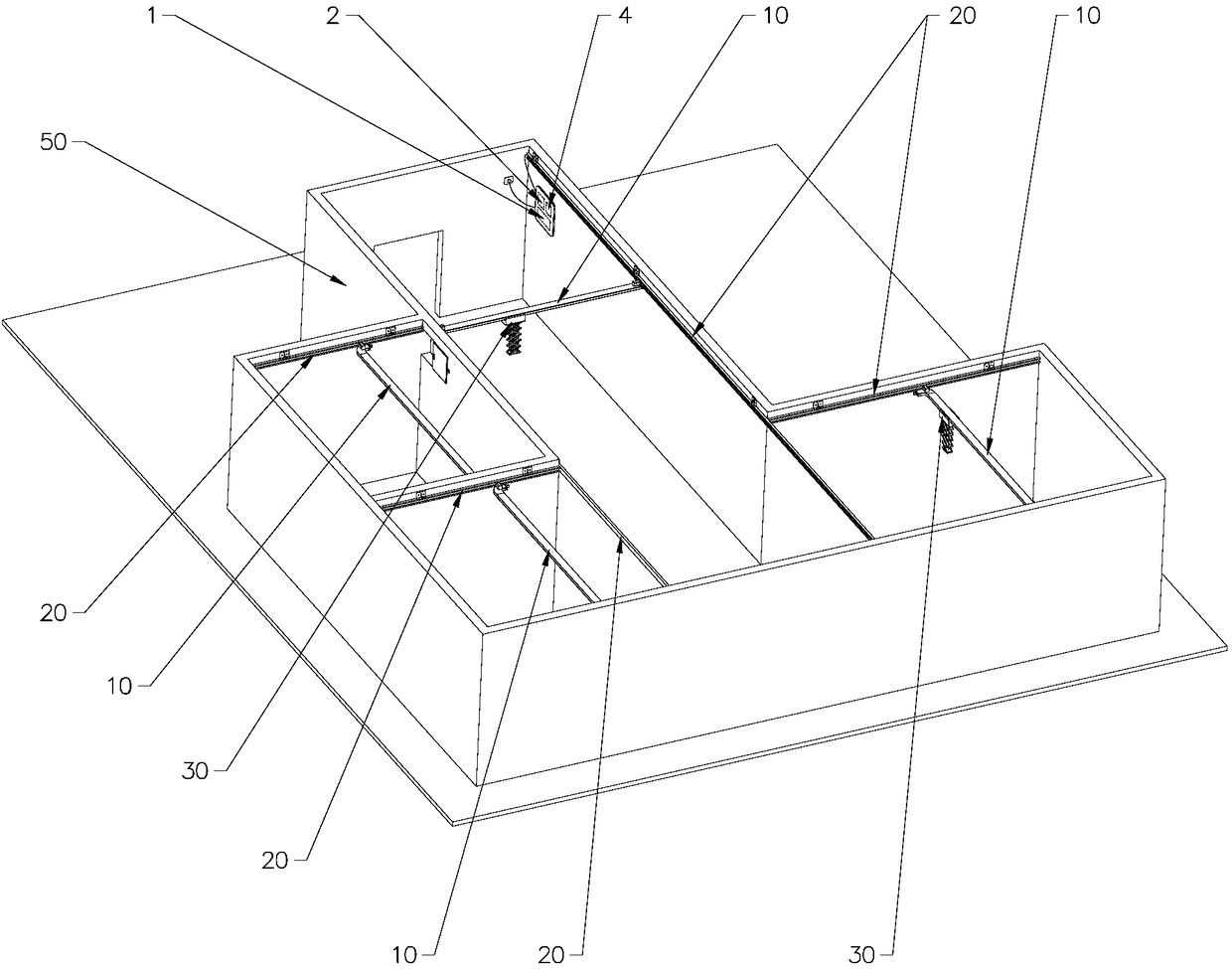

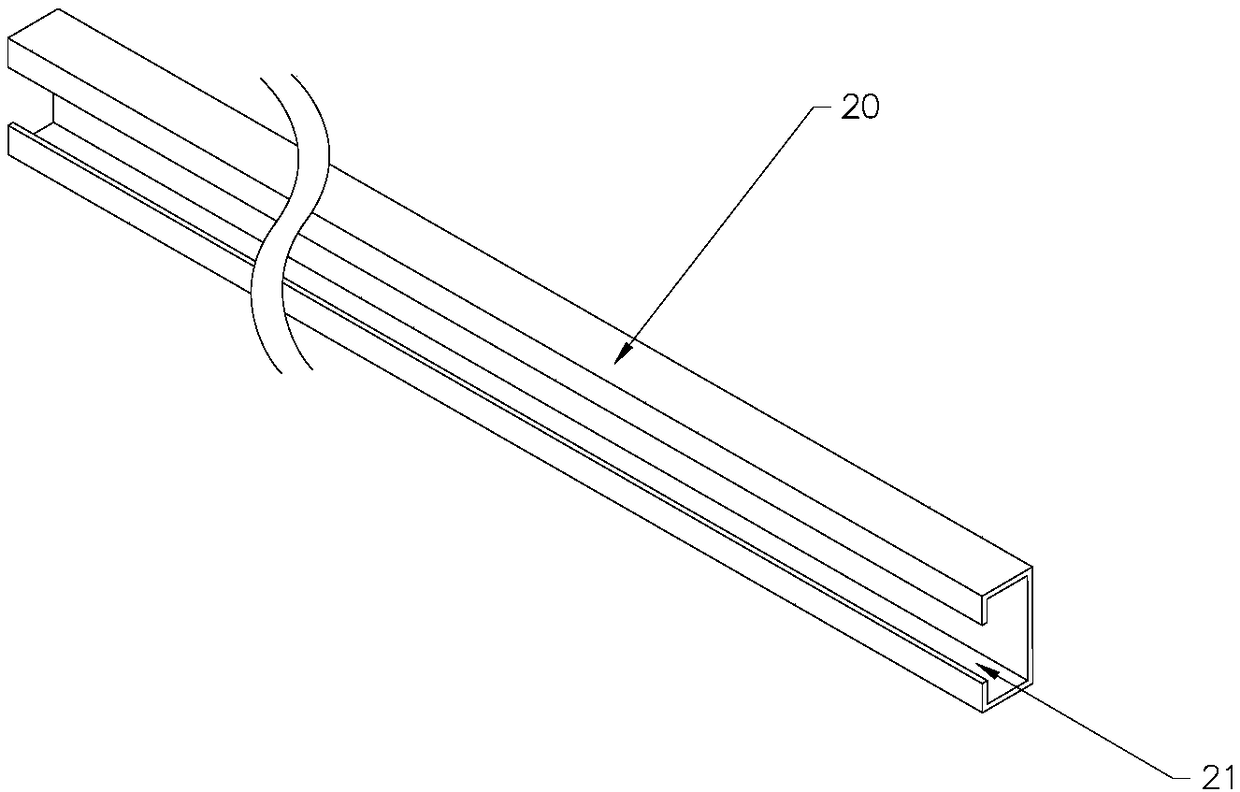

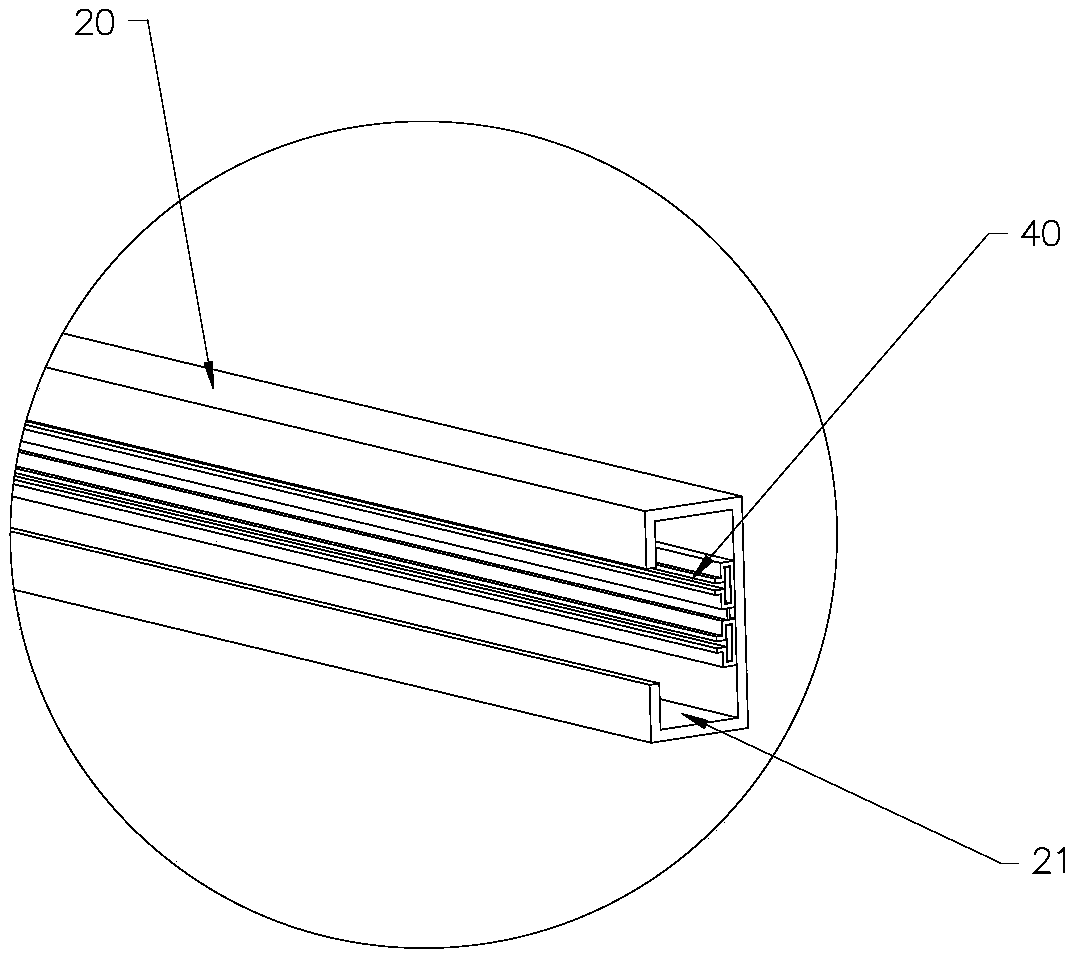

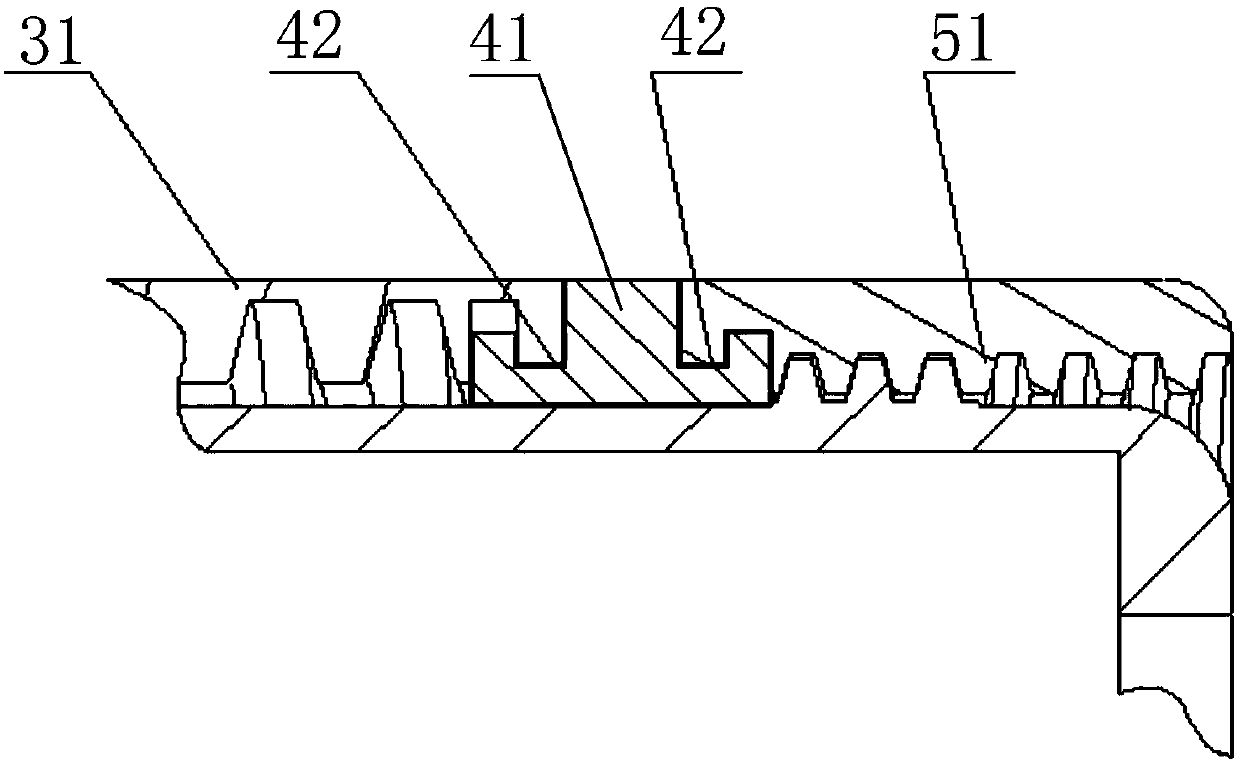

Hanger rail system capable of realizing trans-regional all-covering movement of hanging object

PendingCN108373103AAchieve freedom of movementMeet the needs of changing tracksTravelling gearRunwaysVehicle driving

The invention discloses a hanger rail system capable of realizing trans-regional all-covering movement of a hanging object. The hanger rail system comprises travelling crane rails for supplying movingrails I to a hanger rail vehicle, wherein the hanger rail vehicle is provided with a hanger rail vehicle driving motor for driving the hanger rail vehicle to move; two adjacent travelling crane railsare respectively correspondingly provided with a first connecting end and a second connecting end, support rails for supplying supports and moving rails II to the travelling crane rails are respectively arranged at two ends of at least one travelling crane rail in the two adjacent travelling crane rails, a travelling crane rail driving motor for driving the travelling crane rails to move is further arranged at the travelling crane rail with two ends respectively provided with support rails; and the travelling crane rails are movably arranged above or below the supporting rails, the two adjacent travelling crane rails are communicated through the butting cooperation of the first connecting end and the second connecting end, and then the hanger rail vehicle can move through one of the two adjacent travelling crane rails so as to step over one of the two adjacent travelling crane rails, thereby realizing the trans-regional all-covering movement of the hanger rail vehicle and objects carried by the hanger rail vehicle in a multi-region site.

Owner:蔡德贤

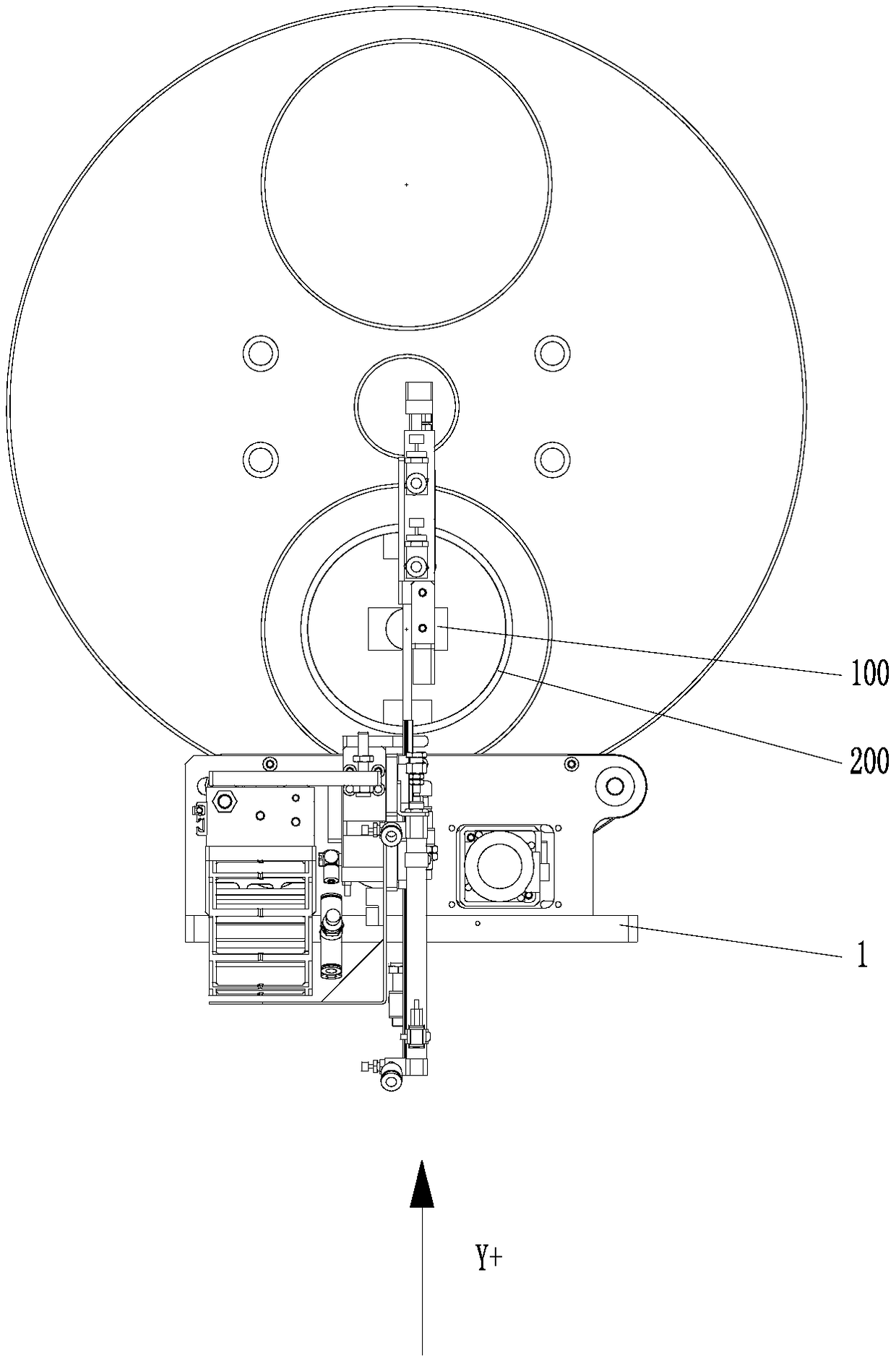

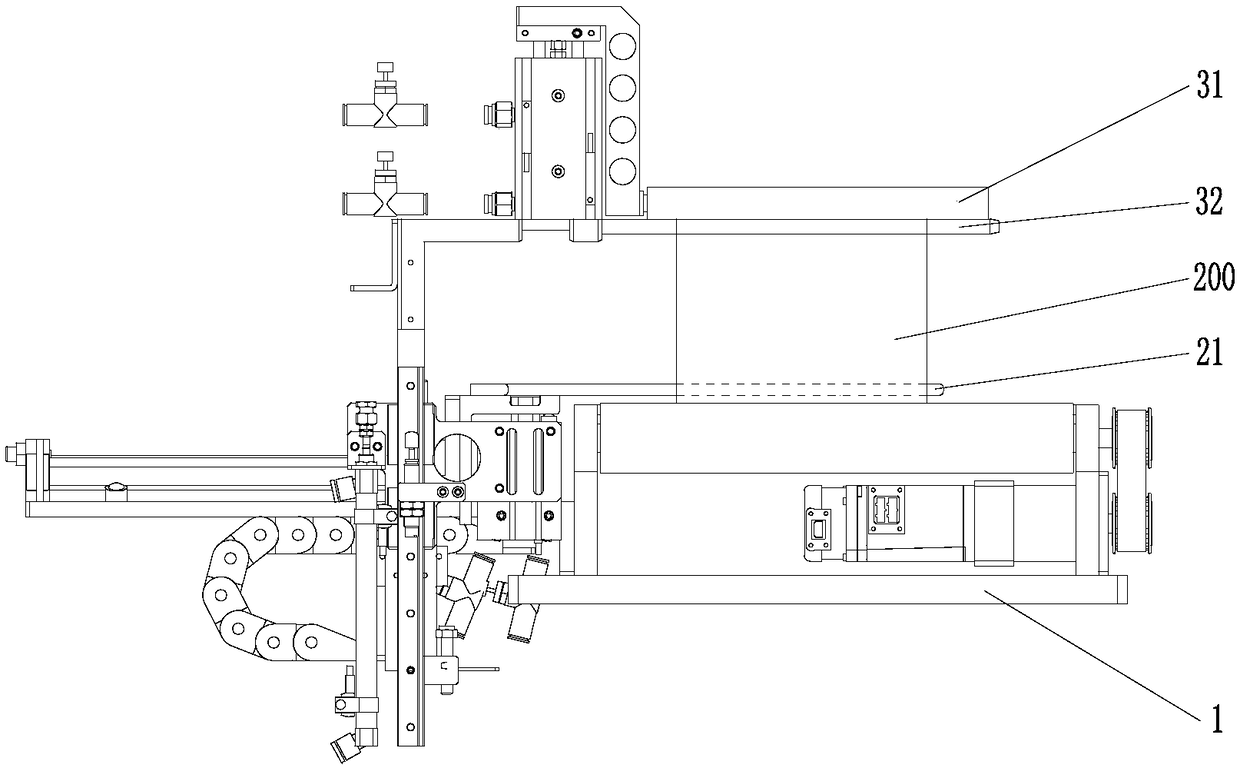

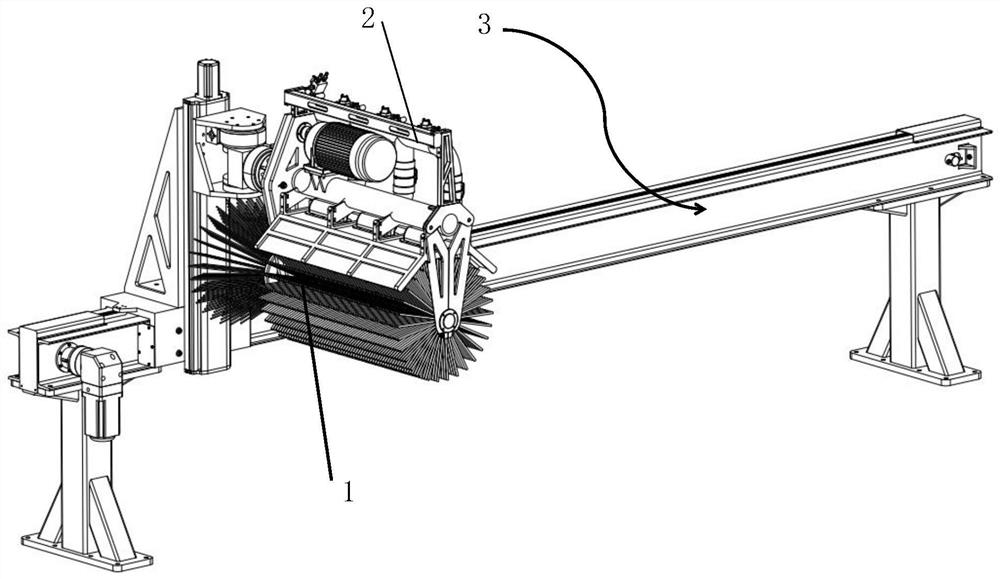

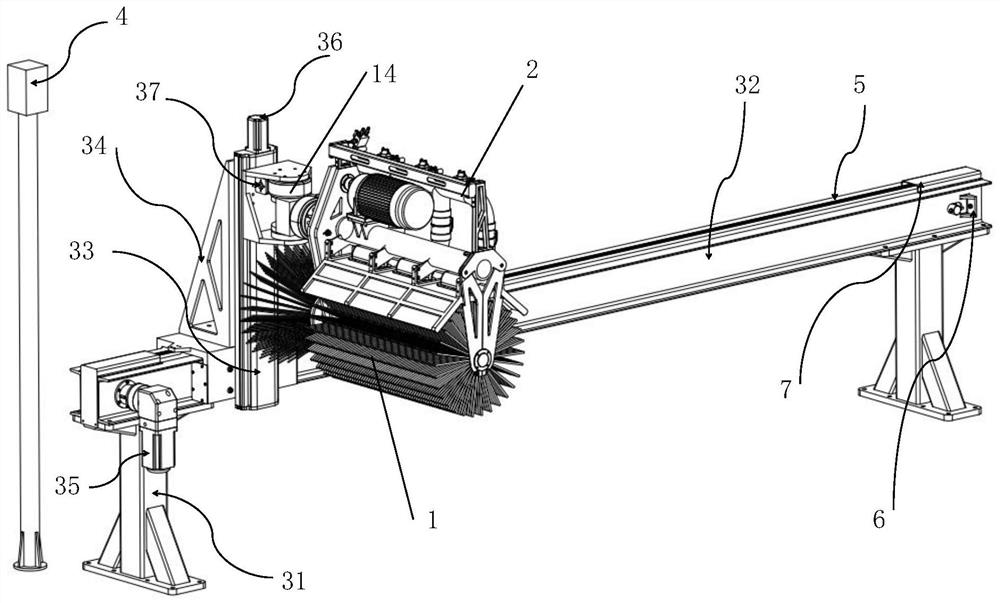

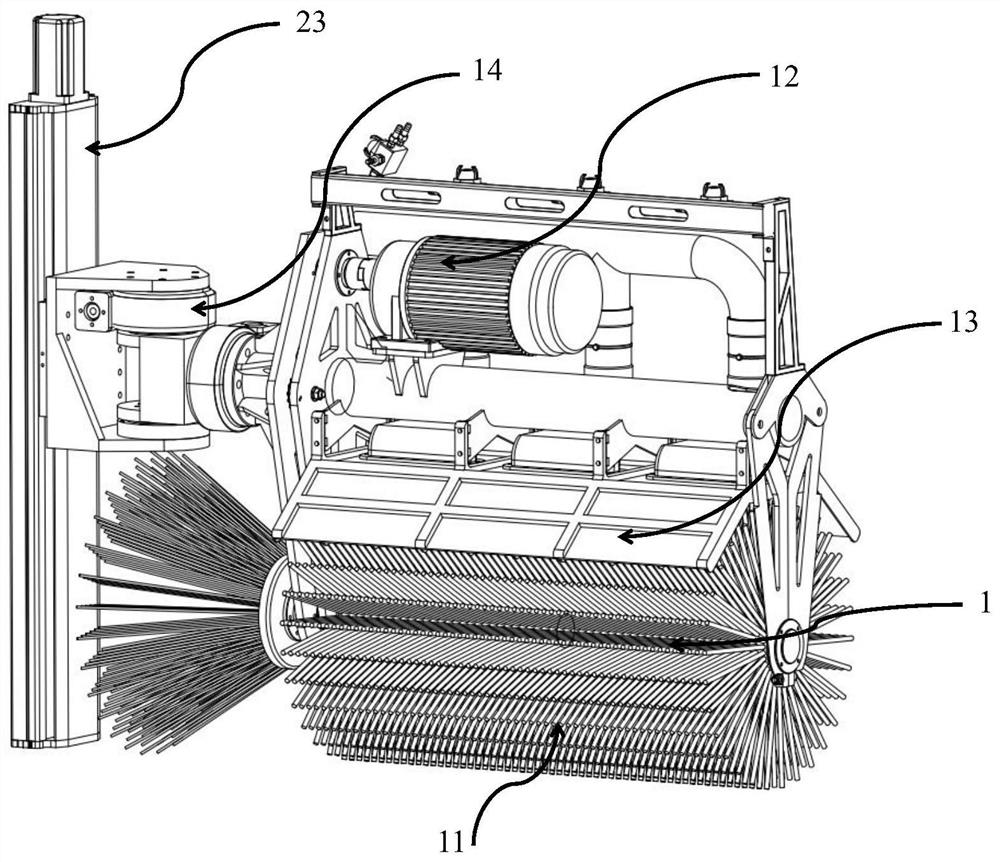

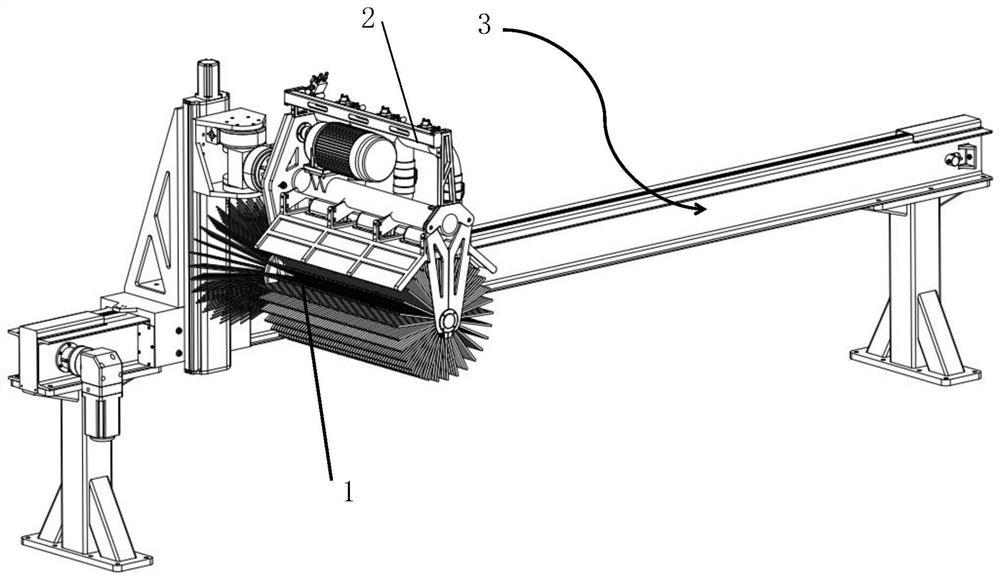

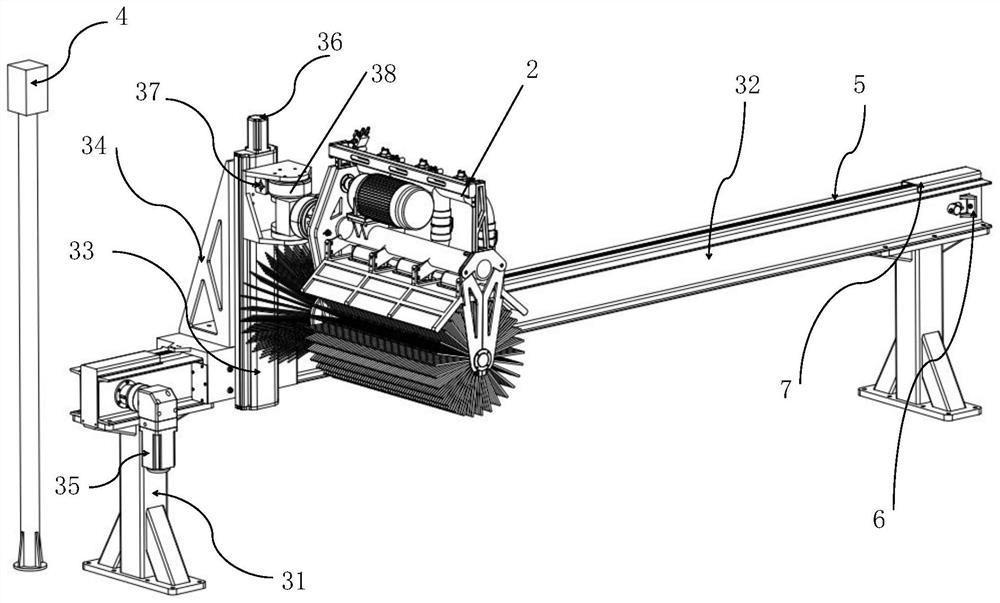

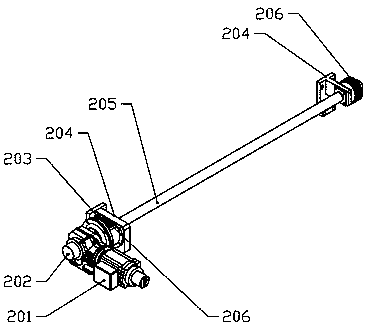

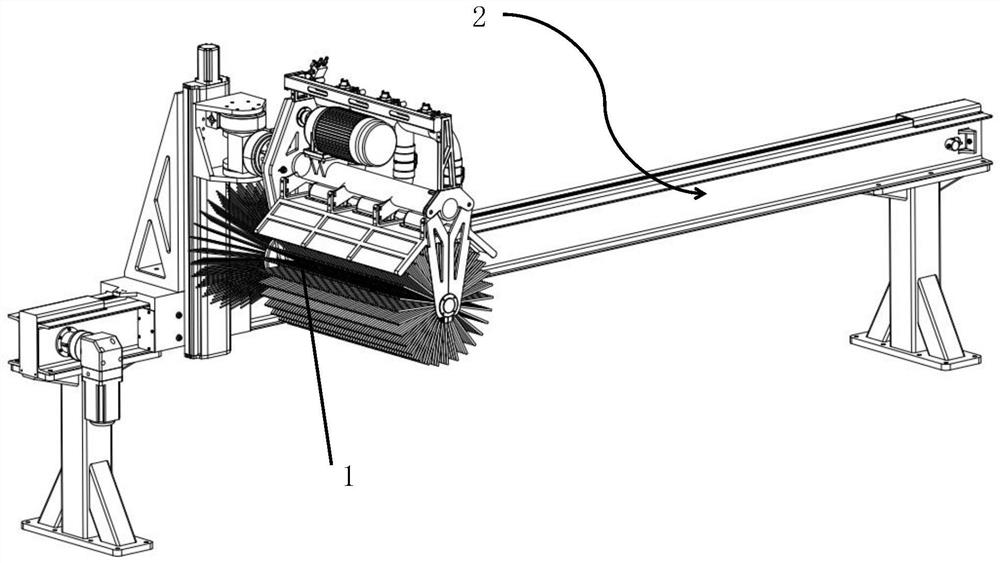

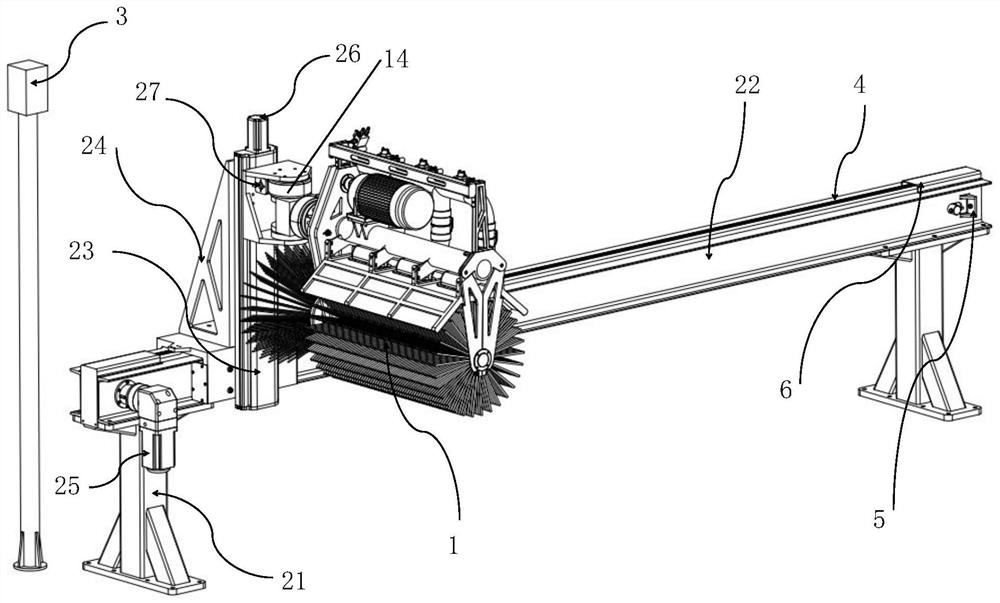

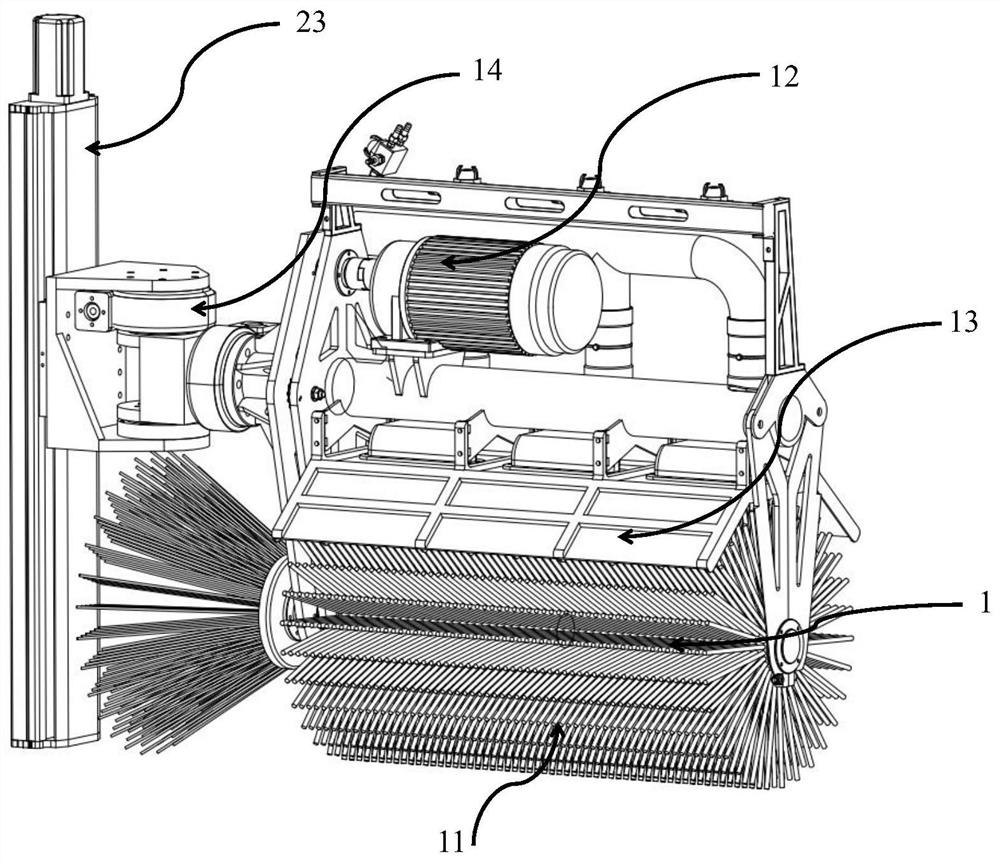

Automatic release agent clearing and spraying equipment for shield segment mould

PendingCN111805712APrecise positioning controlRealize automatic start and stopAuxillary shaping apparatusCleaning using toolsControl systemControl engineering

The invention provides automatic release agent clearing and spraying equipment for a shield segment mould, belongs to the technical field of shield segment automatic production equipment, and particularly relates to a device for clearing and spraying a release agent of a shield segment mould. The equipment comprises a control system, a clearing mechanism, a spraying mechanism and a moving mechanism. The clearing mechanism is installed on the moving mechanism. The spraying mechanism is installed on the clearing mechanism. The control system is connected with the clearing mechanism, the sprayingmechanism and the moving mechanism. The equipment has the beneficial effects that an X-direction moving module drives the clearing mechanism or the spraying mechanism to move transversely, a Z-direction moving module drives the clearing mechanism or the spraying mechanism to move vertically and cooperates with a rotation driver, thus the clearing mechanism or the spraying mechanism can do curvilinear motion along the motion trail, and then automatic clearing and spraying to an arc-shaped inner cavity of the mould can be completed. The equipment solves the problems that for a current domesticshield segment mould, due to manual release agent clearing and spraying, a shield segment generates flaws easily, precision is reduced, and efficiency is low.

Owner:中电建成都混凝土制品有限公司

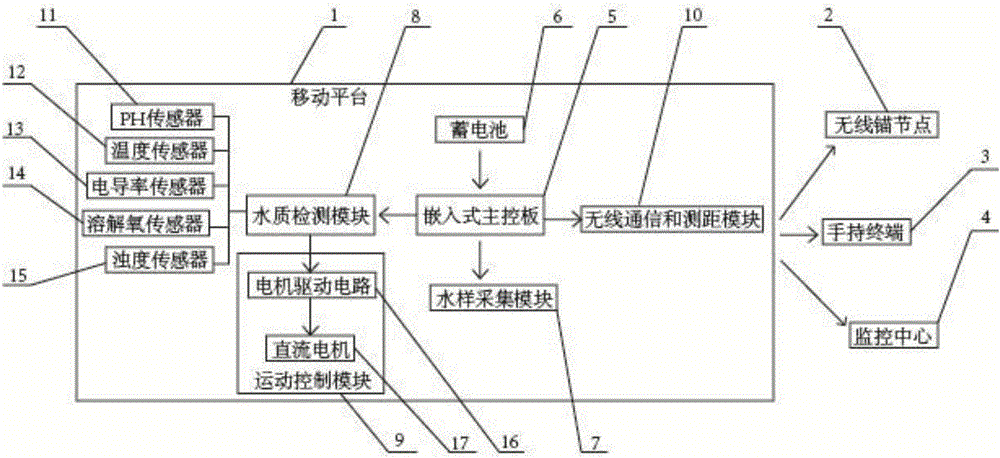

Movable water quality monitoring system

The invention relates to a movable water quality monitoring system. The system comprises a mobile platform, a wireless anchor node, a hand-held terminal and a monitoring center, the mobile platform comprises an embedded main control board, a storage battery, a water sample collecting module, a water quality detection module, a movement control module, and a wireless communication and range finding module, the water quality detection module comprises a pH sensor, a temperature sensor, a conductivity sensor, a dissolved oxygen sensor and a turbidity sensor, the movement control module comprises a motor driving circuit and two direct current motors, the direction is controlled the direction is controlled through controlling the speeds of the direct current motors, and the wireless communication and range finding module is communicated with the hand-held terminal or the monitoring center and cooperates with the wireless anchor node to complete a range finding function. The system has the advantages of low cost, small size, flexible and convenient operation, and suitableness for being promoted.

Owner:天津盛优宝网络科技有限公司

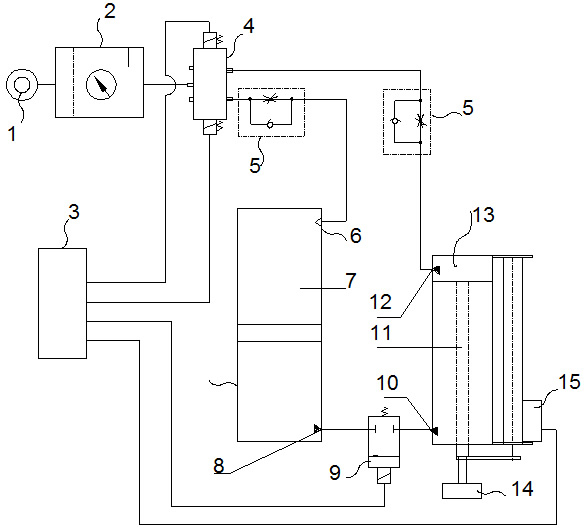

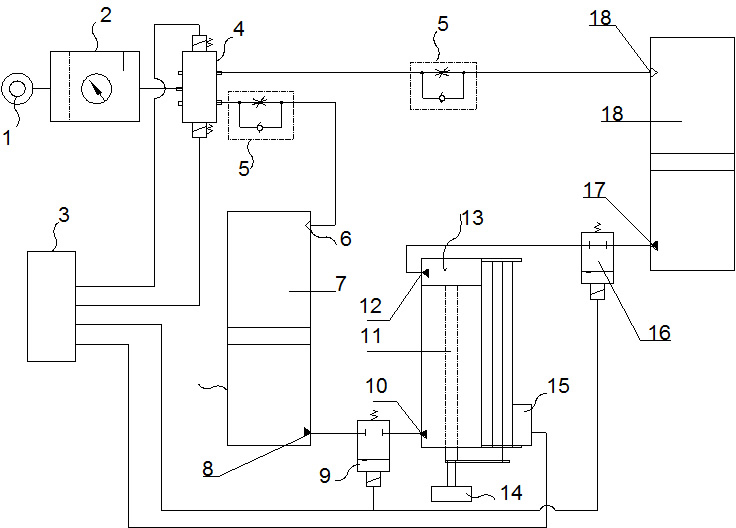

Positioning control mechanism of vertical load for double-acting cylinder

InactiveCN102606562ASolve the speed problemPrecise positioning controlServomotorsFluid-pressure actuator componentsElectrical controlVertical load

The invention aims at providing a positioning control mechanism of a vertical load for a double-acting cylinder (13). A three-position five-way electromagnetic valve for air supply (4) is connected to an air inlet and outlet opening (6) of an air-liquid converter (7) and an air inlet and outlet opening (12) of a double-acting cylinder, and a stopping electromagnetic valve (9) is connected between a liquid inlet and outlet opening (8) of the air-liquid converter and a liquid inlet and outlet opening (10) of the double-acting cylinder. The control mechanism is provided with a position sensor (15) for detecting the position of a cylinder piston and an electrical control system (3), wherein the electrical control system (3) controls the opening and the closing of the electromagnetic valves according to the piston position (11) detected by the position sensor (15), and stably moves the cylinder piston to the target position, so that the cylinder piston is stopped and kept at the stopping position.

Owner:王凡

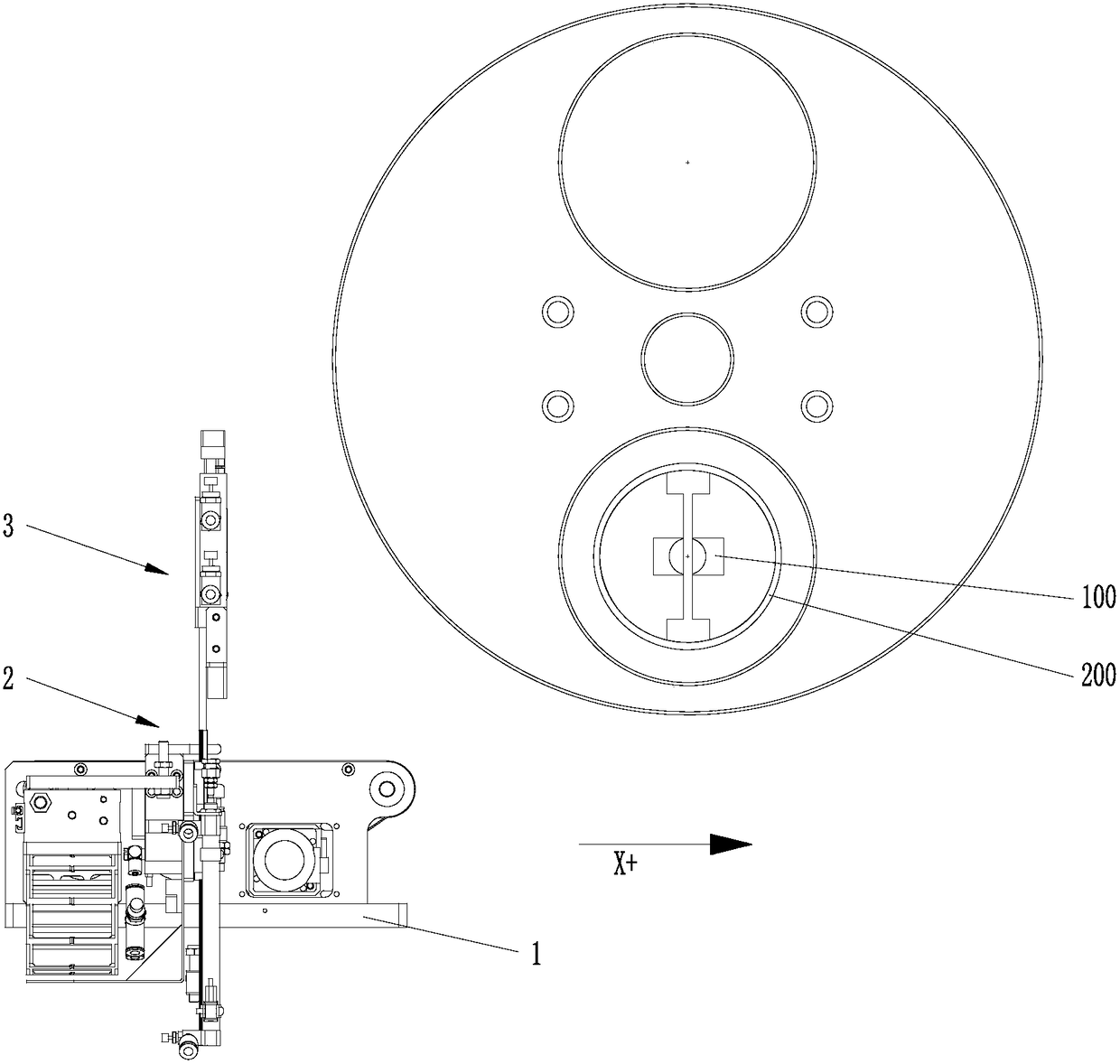

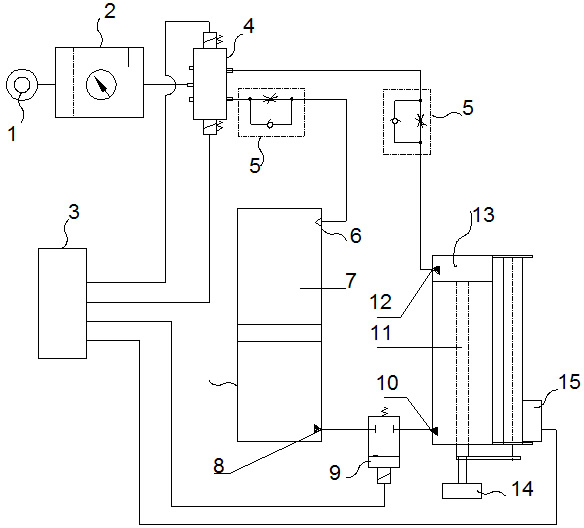

Framework oil seal automatic pressing machine

ActiveCN108381147ACompact structureHigh degree of automationMetal working apparatusMass ConsistencyPiston rod

The invention discloses a framework oil seal automatic pressing machine, and belongs to the technical field of framework oil seal pressing. According to the framework oil seal automatic pressing machine, the problems that in the prior art, the working efficiency is low, and the pressing quality is poor in consistency are solved. The framework oil seal automatic pressing machine comprises a rack; the rack is provided with a pressing station quick-changing device, an executing mechanism, a guiding compressing device and an axial positioning device which are mutually matched; the pressing stationquick-changing device is fixed to the rack through a linear guiding rail II; the pressing station quick-changing device comprises a transverse fixed air cylinder I and a transverse movable air cylinder II; and a piston rod of the transverse fixed air cylinder I is connected with a fixing plate through a first connecting plate, the transverse movable air cylinder II is fixed to the fixing plate, apiston rod of the transverse movable air cylinder II is connected with a second connecting plate, and the fixing plate can slide along the linear guiding rail II. The framework oil seal automatic pressing machine is mainly used for pressing operation of a framework oil seal and a sealing cover.

Owner:SHANDONG LINGONG CONSTR MACHINERY

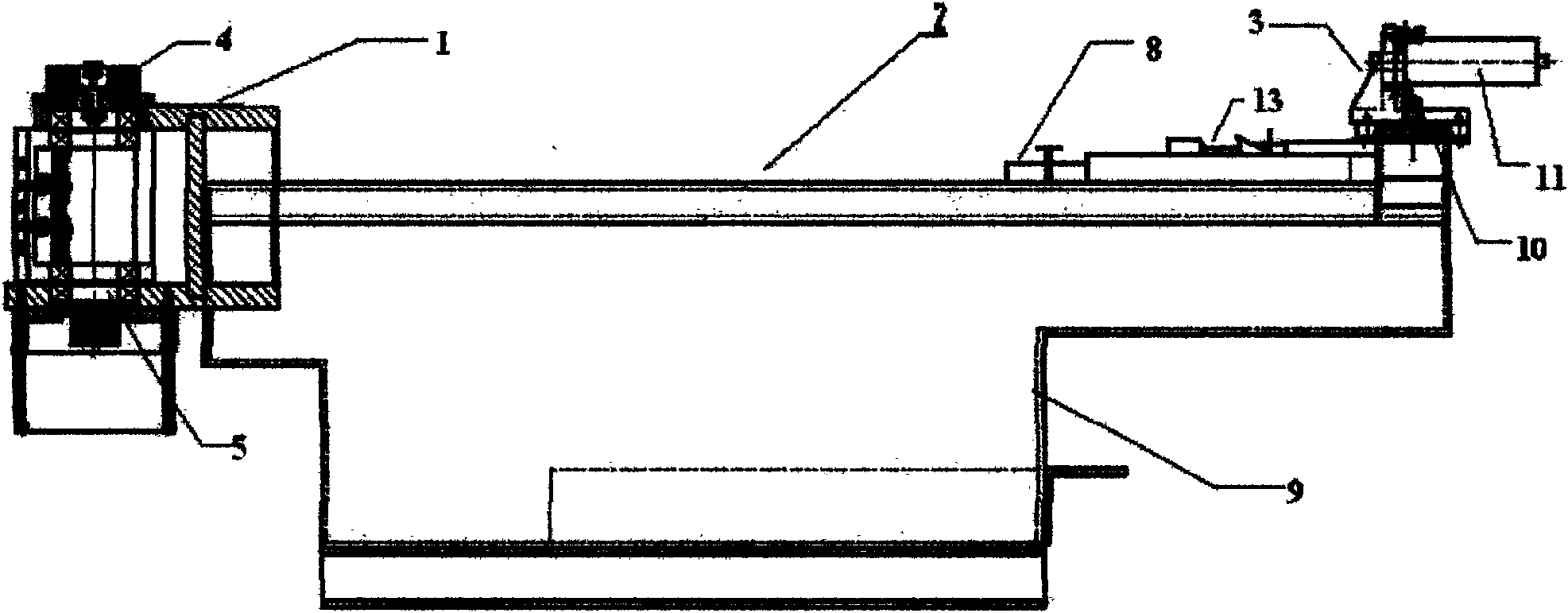

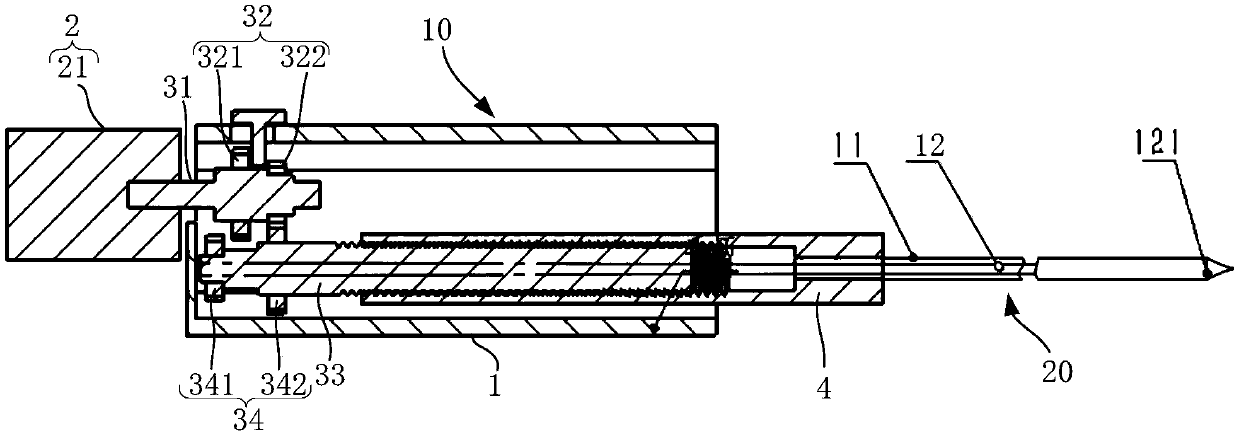

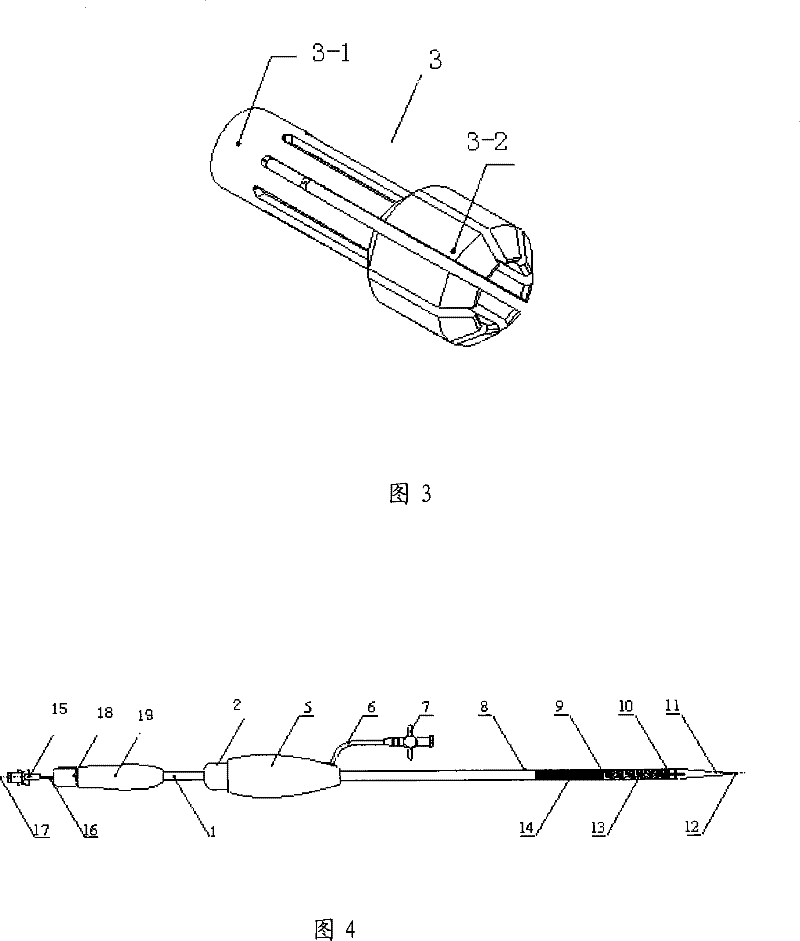

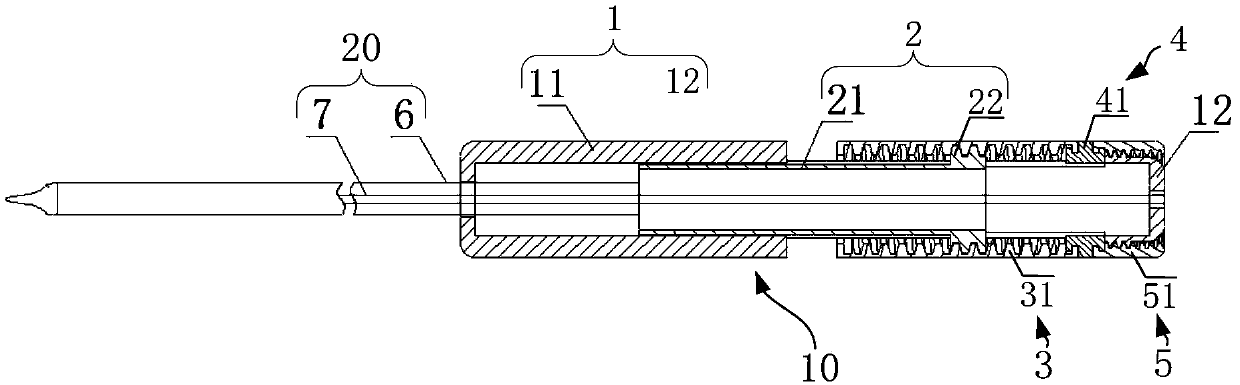

Conveying system for conveying implant and driving handle

PendingCN111557764APrecise positioning controlEfficient surgical operationHeart valvesGear driveGear wheel

The invention relates to a conveying system for conveying an implant and a driving handle. A sheathing canal for conveying the implant can be controlled to move at a high speed or a low speed. The driving handle comprises a shell, a fixing piece, a first driving mechanism and a gear transmission mechanism, the gear transmission mechanism is arranged in the shell, the input section of the gear transmission mechanism is connected with the first driving mechanism, and the output section of the gear transmission mechanism is connected with the fixing piece and used for being driven by the input section to rotate; the first driving mechanism is used for driving the gear transmission mechanism to drive the fixing part to move along the axis of the driving handle, and the gear transmission mechanism is used for outputting multiple transmission ratios and selectively driving the fixing part to move through one of the multiple transmission ratios. The conveying system comprises the driving handle, an outer pipe and an inner pipe assembly. The inner pipe assembly is arranged in the outer pipe in a penetrating manner, is used for fixing the implant and keeps static relative to the shell; theouter pipe is connected with the fixing piece, and the fixing piece is used for driving the outer pipe to axially move relative to the inner pipe assembly.

Owner:SHANGHAI MICROPORT CARDIOFLOW MEDTECH CO LTD

Parking auxiliary device and method

InactiveCN109532783AEasy and quick parkingSolution to short lifeVehicle cleaning apparatusGear wheelParking space

The invention discloses a parking auxiliary device which comprises a support, movable wheels, a buffer frame, a telescopic frame, an ultrasonic probe, an alarm device, an ECU, planet gear speed reduction motors and fork frames. The top of the support is connected with the buffer frame through a spring. The buffer frame is connected with the telescopic frame. The cross section of the support is ofan arc-shaped structure. The two ends of the support are connected with the fork frames respectively. The fork frames are internally provided with the movable wheels. The movable wheels are provided with the planet gear speed reduction motors respectively. The movable wheels are in transmission connection with the planet gear speed reduction motors. The movable wheels on the same sides of the supports are in transmission connection through belts. Tension wheels are arranged between the belts and the supports. The parking auxiliary device is reasonable in structural design and ingenious and novel in concept, vehicles can be conveniently and rapidly parked in parking spaces when needing to be parked on the sides, repeated backup troubles are omitted, probable vehicle scratching is avoided, the parking space is reduced when the parking difficulty is lowered, and the utilization rate of a parking lot is increased.

Owner:陈勇

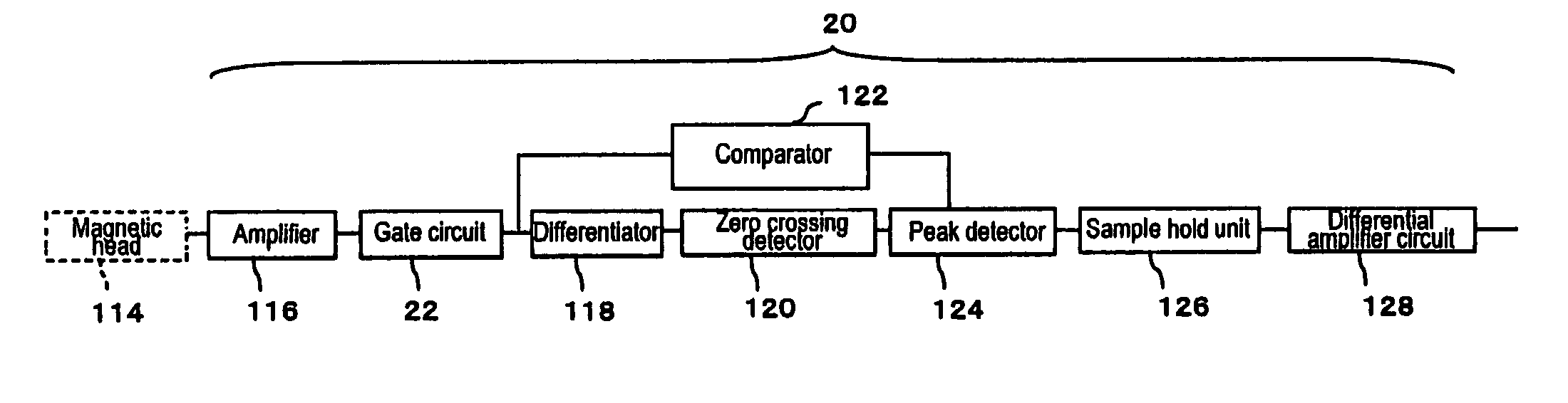

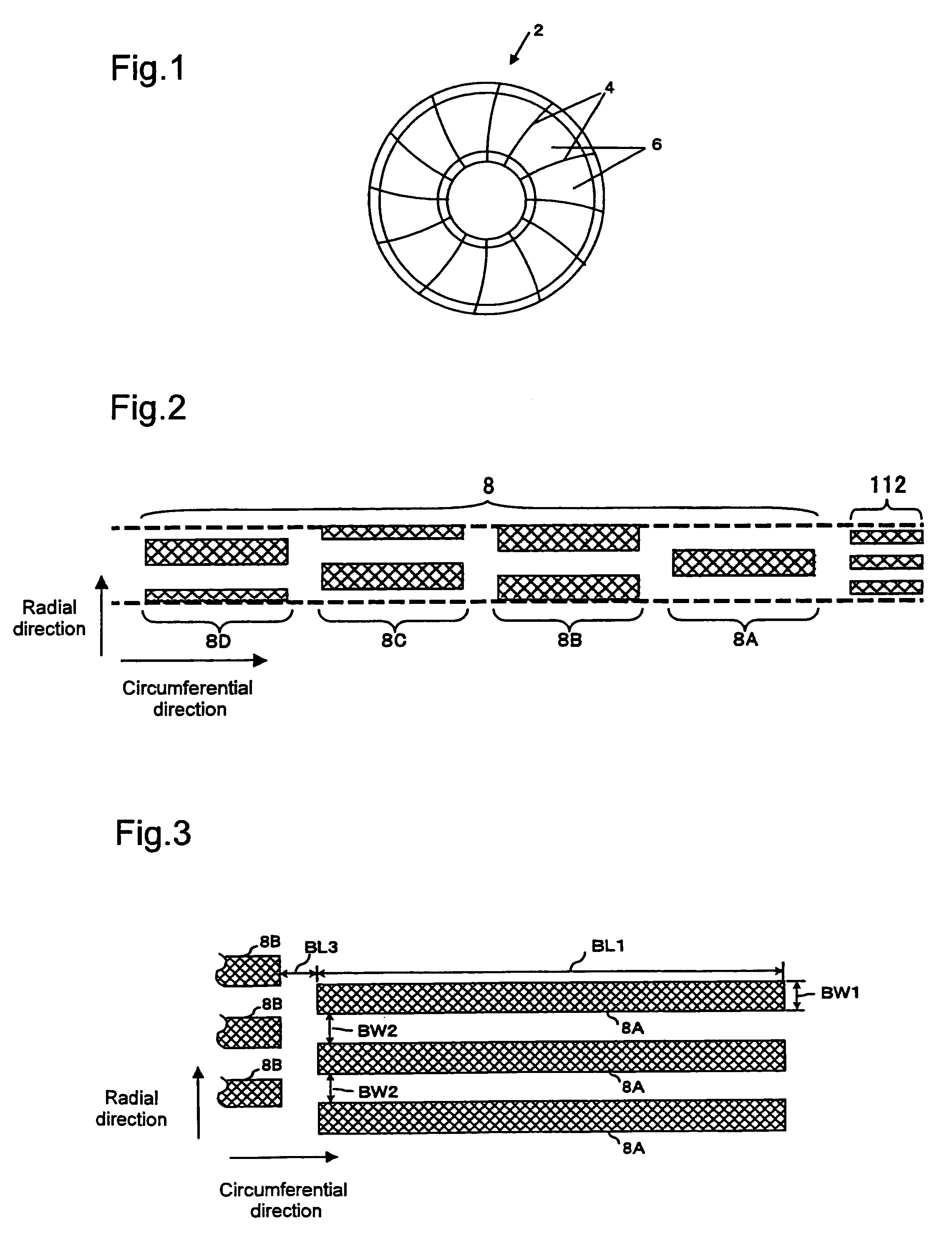

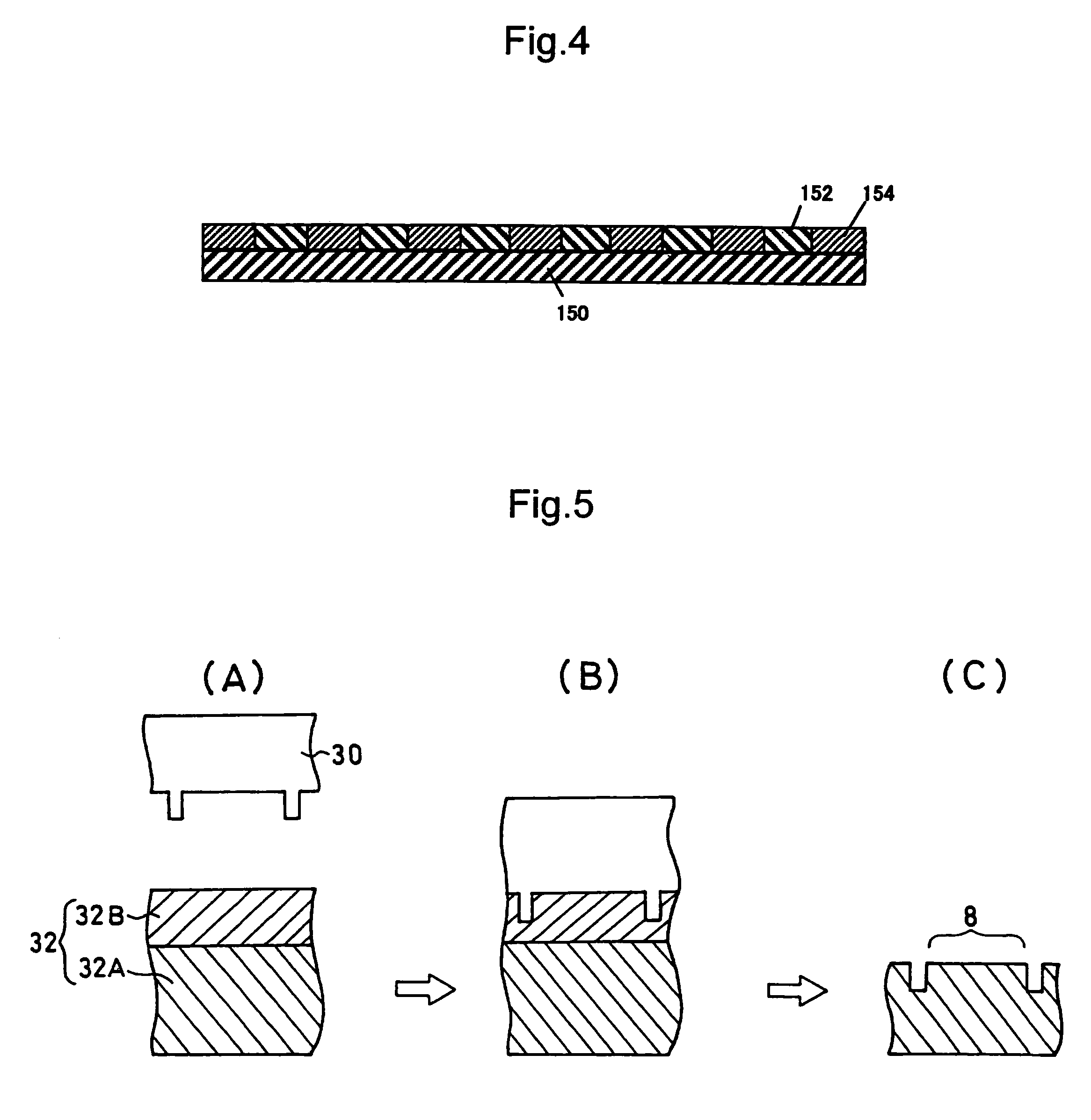

Magnetic recording and reproducing apparatus, method of controlling the same, magnetic recording medium, and stamper for manufacturing magnetic recording medium

InactiveUS7333289B2Increase productionPrecise positioning controlRecord information storageAlignment for track following on disksIntegratorEngineering

A magnetic recording and reproducing apparatus and a method of controlling the same, capable of increasing the output of a position control signal and performing a precise positioning control of a magnetic head. The magnetic recording and reproducing apparatus has: a magnetic recording medium on which a positional information is recorded in the form of burst signal groups each consisting of either one of a single concave portion and a single convex portion of a predetermined concavo-convex pattern formed of a magnetic layer; a gate circuit; and an integrator for calculating a area integral of a reproduced signal corresponding to each of the burst signal groups.

Owner:TDK CORPARATION

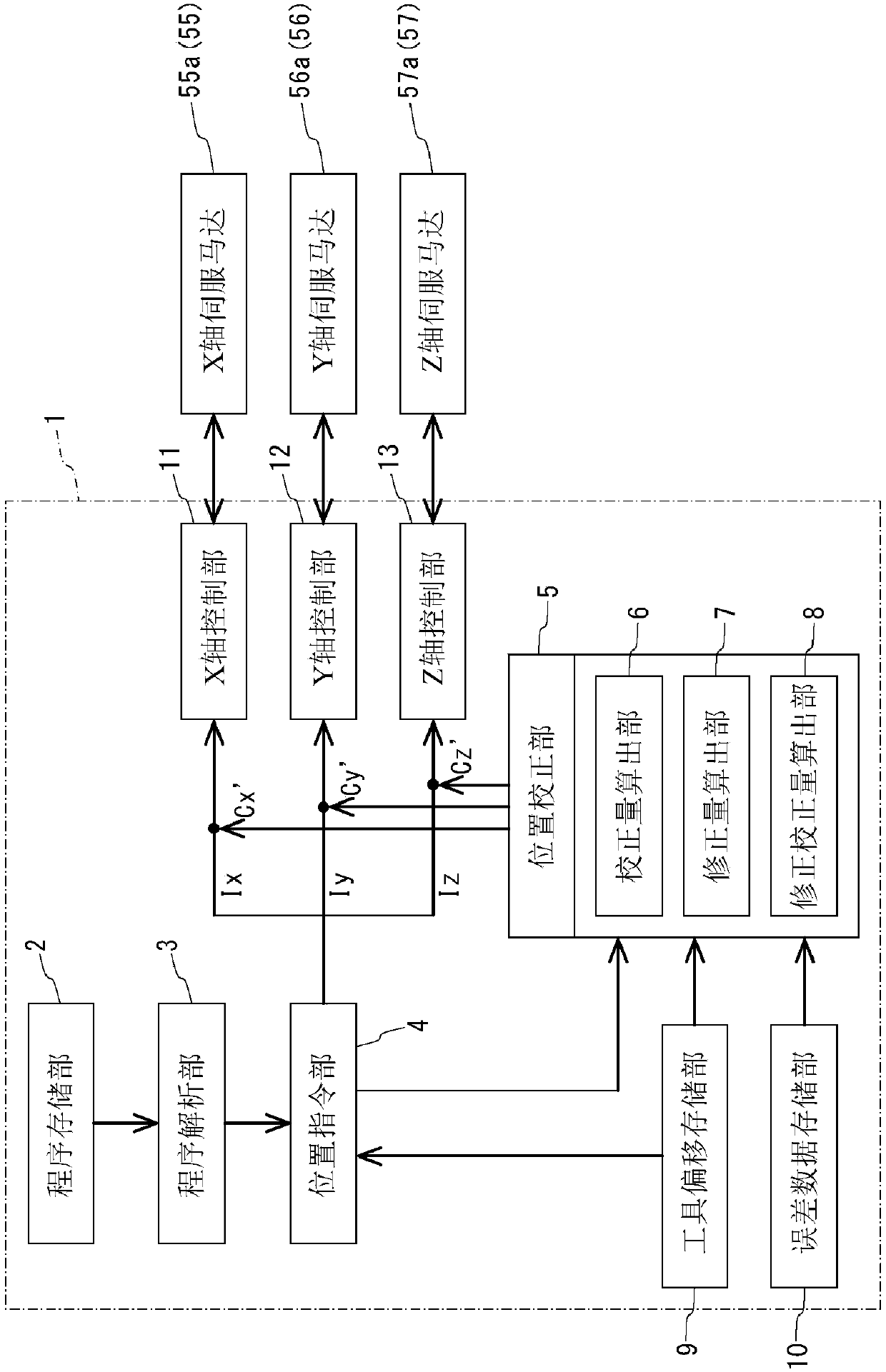

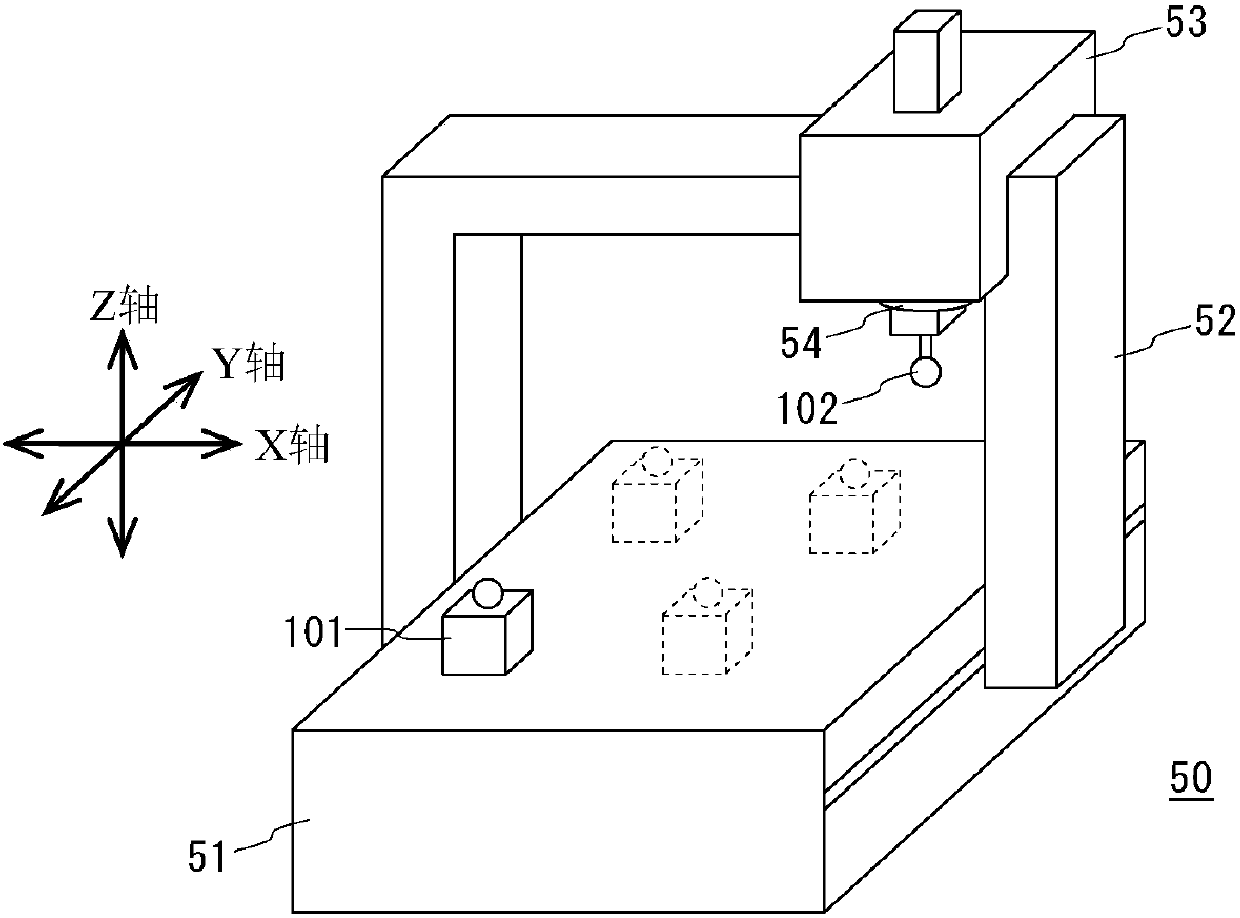

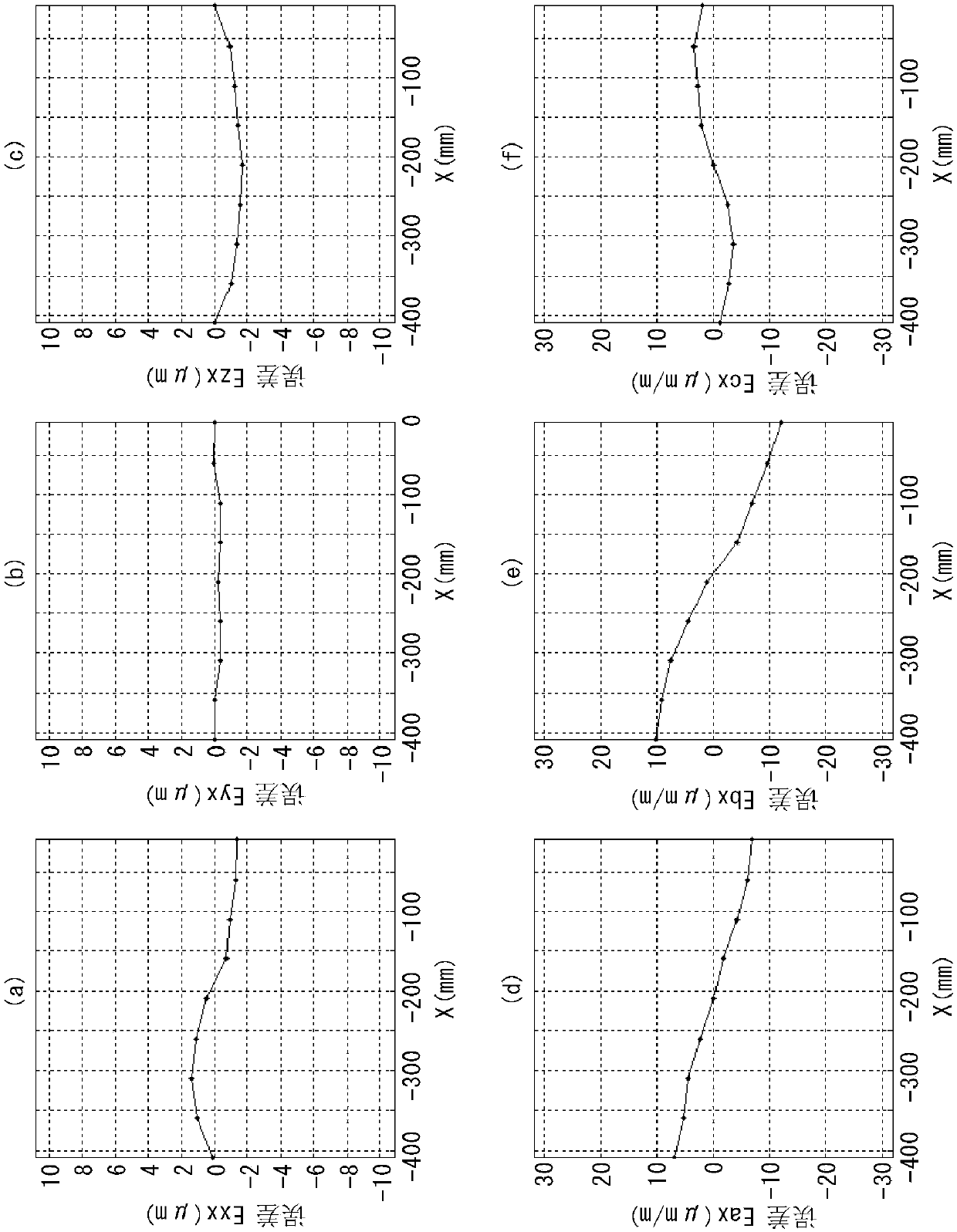

Numerical control device

InactiveCN108027601ACompensate for motion errorsCorrect movement errorProgramme controlAutomatic control devicesNumerical controlThree-dimensional space

Provided is a numerical control device with which the tip position of a tool can be positioned with high precision in a three-dimensional space. This numerical control device (1) is equipped with a position correction unit (5) and an error data storage unit (10). The error data storage unit (10) stores error data for the X-, Y-, and Z-axes, that is, data pertaining to the angular error (Eax, Eay,Eaz) around the X-axis, the angular error (Ebx, Eby, Ebz) around the Y-axis, and the angular error (Ecx, Ecy, Ecz) around the Z-axis. The position correction unit (5) calculates a revision amount (Mx,My, Mz) in accordance with the tool length, on the basis of a command position (Ix, Iy, Iz), the error data, and tool length data for the tool being used, revises a correction amount (Cx, Cy, Cz) forthe command position (Ix, Iy, Iz), and uses the revised correction amount to correct the command position (Ix, Iy, Iz).

Owner:DMG MORI CO LTD

Double-channel plunger flow assignment electro-hydraulic actuator

InactiveCN104564864AThe system is stable and reliableHigh oil volumetric efficiencyServomotor componentsServomotorsOil supplyFuel tank

The invention discloses a double-channel plunger flow assignment electro-hydraulic actuator. The actuator comprises a two-way pump, a two-way oil cylinder, an oil tank and an oil channel system. A forwarding oil supplying first oil outlet and a reversing oil supplying second oil outlet are formed in the two-way pump. The oil channel system comprises a first oil channel communicated with the first oil outlet and a left chamber of the two-way oil cylinder and a second oil channel communicated with the second oil outlet and a right chamber of the two-way oil cylinder. By means of the actuator, two pressure oil is produced through forward and reverse rotation of the two-way pump to be output independently through two channels, and accordingly, the oil cylinder reciprocating is achieved, a traditional solenoid directional valve is not needed, the actuator is simple and reliable, the two-way oil cylinder volume efficiency is high, 'packeted oil' is prevented, oil can be pumped in the low rotation speed, and high-accuracy location control of the pump control system is achieved.

Owner:CHONGQING CHUANYI AUTOMATION

Locking device for human body medical appliance conveying system

The invention discloses a locking device which is used for a medical device transportation system in the human body, characterized in that the invention includes a locking head, a locking cap and a connection part which connects the locking head and the locking cap, wherein, one end of the locking head is sheathed in the connection part, and the other end thereof is sheathed in the locking cap; the connection part is connected with the locking cap through threads; the contact surface of the locking head and the locking cap is all conical surface; the locking head has a hollow structure for allowing a transportation conduit of the medical device transportation system in the human body, and a shrinkage structure which is in particular a shrinkable multi-petal structure, and each petal of the multi-petal structure is uniformly distributed in the circumference; the wall thickness of a proximal end of the multi-petal structure is less than that of a distal end; the connection part and the locking cap are provided with buckles preventing from separating. The invention has simple design in the structure and easy operation, which can avoid the displacement of the transportation conduit of the transportation system during using process, thus the medical device can be effectively released and positioned during installation process.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

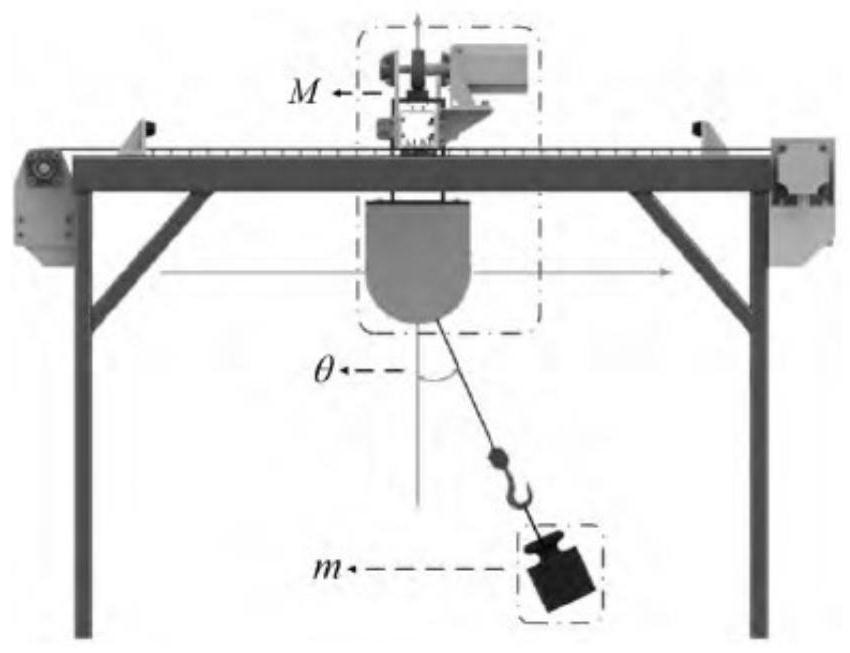

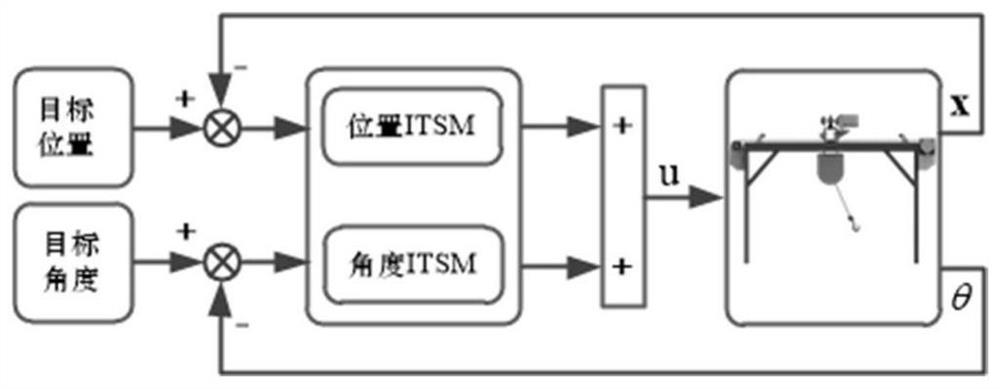

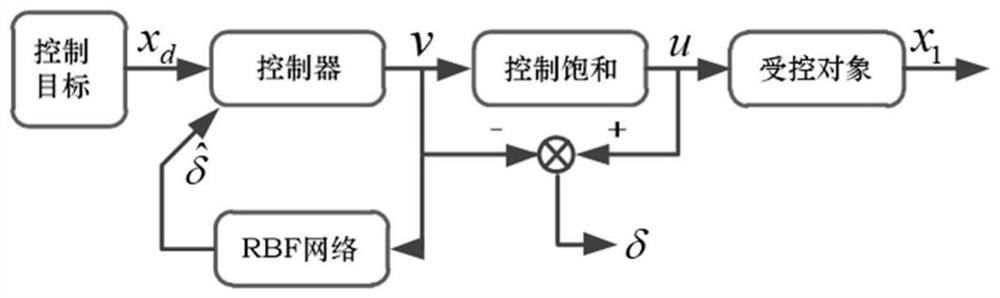

Finite time sliding mode control system and method for bridge crane system under limited control input

ActiveCN112363398APrecise positioningStrong robustnessAdaptive controlControl systemControl objective

The invention provides a finite time sliding mode control system and method for a bridge crane system under a limited control input. The method comprises the following steps: 1, determining a controltarget of a two-dimensional under-actuated bridge crane system; step 2, according to the control target obtained in the step 1, constructing a total sliding mode surface of the system in combination with a hierarchical sliding mode theory; 3, constructing a total control law of the system according to the total sliding mode surface of the system obtained in the step 2; and 4, constructing a control-limited fast terminal sliding mode controller according to the total control law of the system obtained in the step 3. The method provided by the invention has two control effects, can provide a basis for rapid anti-swing and accurate and effective positioning control of the bridge crane system under various complex conditions, and enables the bridge crane system to be better applied to variousindustrial fields.

Owner:中国人民解放军火箭军工程大学

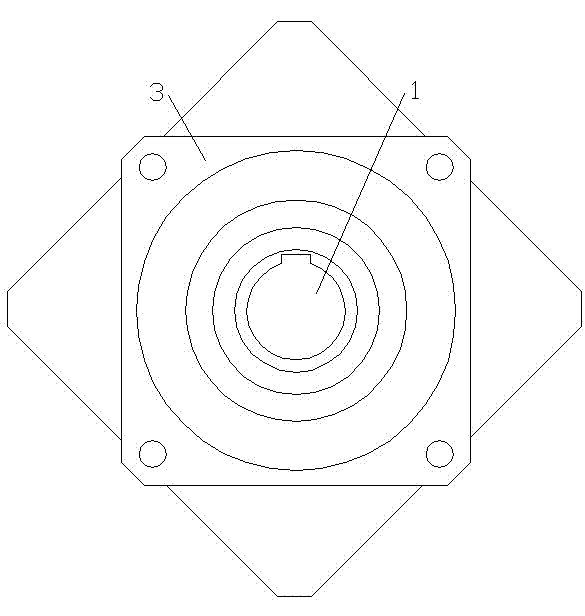

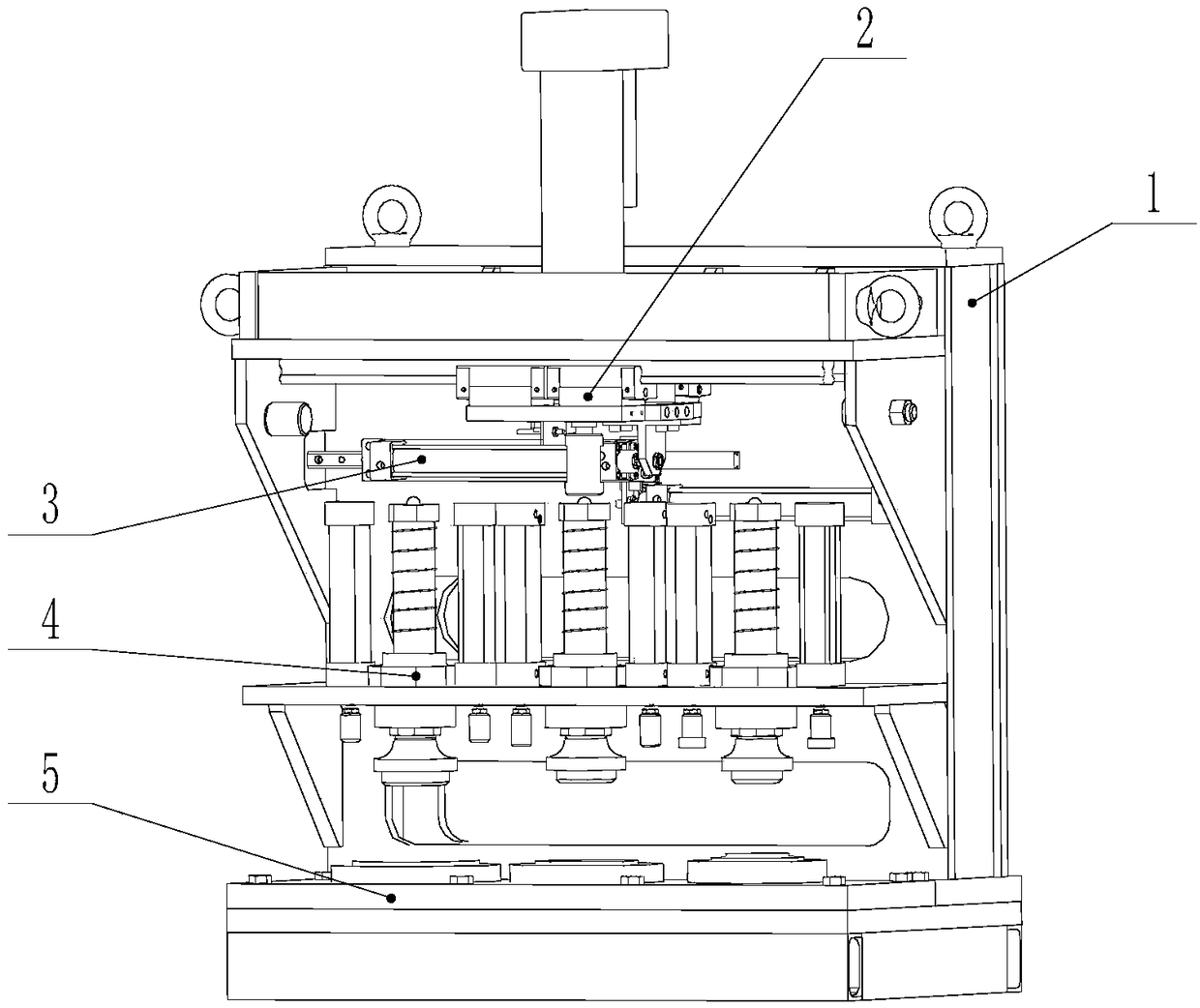

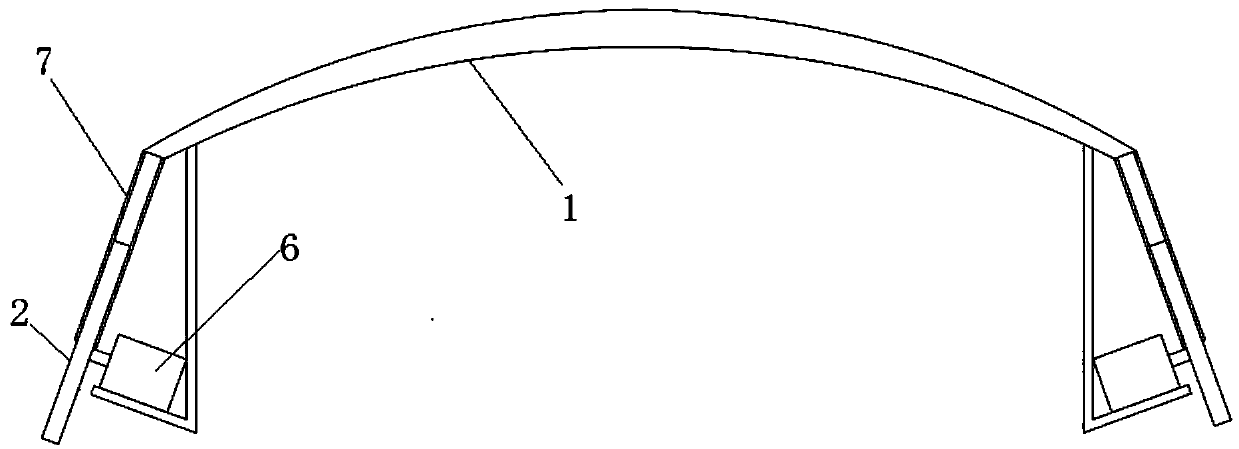

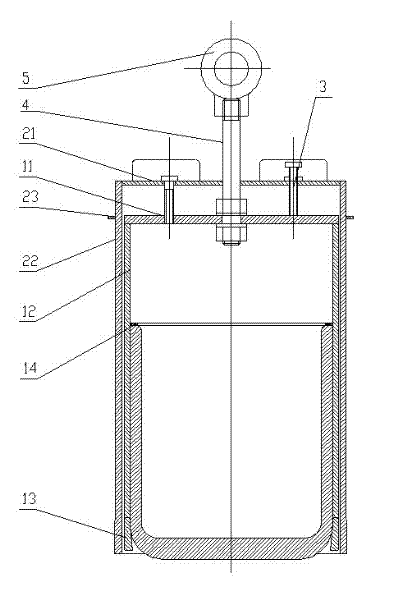

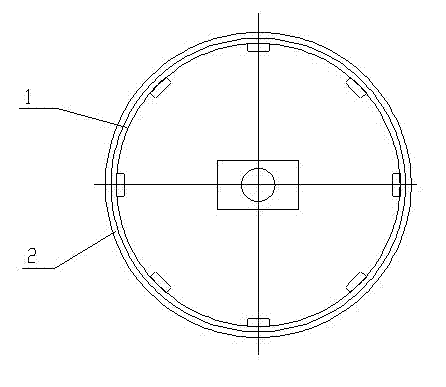

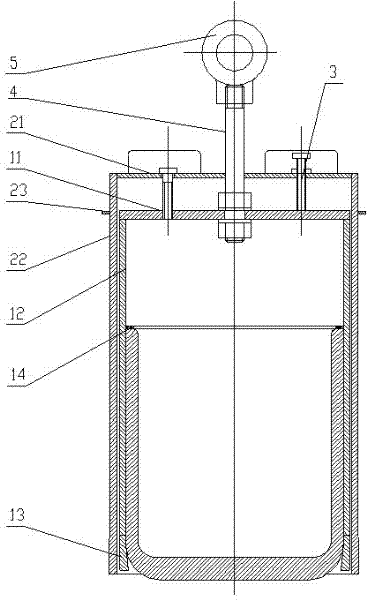

Tungsten crucible double-sleeve hoisting frame

ActiveCN102418141ALong runGuaranteed uptimePolycrystalline material growthBy pulling from meltCrucibleEngineering

The invention relates to a tungsten crucible double-sleeve hoisting frame, which is characterized by comprising an inner sleeve (1) and an outer sleeve (2), wherein the inner sleeve (1) comprises a plurality of circular-arc plates (12) arranged on the same circumference and a lifting plate (11) connected to the top of the circular-arc plates (12); inward hook claws (13) are arranged at bottoms of the circular-arc plates (12); inner sleeve positioning rings (14) are fixed to inner walls on upper parts of the circular-arc plates (12); the outer sleeve (2) comprises a cylinder (22) and a support plate (21) which is fixedly connected to the top of the cylinder (22); an outer sleeve positioning ring (23) is fixedly connected to the outer wall on the upper part of the outer sleeve (2); and the lifting plate (11) is connected with the support plate (21) by a compression bolt (3). The tungsten crucible double-sleeve hoisting frame can be precisely positioned and controlled, and is difficult to crush, raw materials filled into a crucible still can be hoisted, the operation can be performed reliably for a long time, and the tungsten crucible can be better protected to ensure that a sapphire furnace runs safely and efficiently for a long time.

Owner:SHUANGLIANG NEW ENERGY EQUIP

Compression fixing device after cardiac pace-making operation and compression fixing method of compression fixing device

ActiveCN111759392ARelieve stressPrevent looseningNursing bedsInstruments for stereotaxic surgeryRotational axisSlide plate

The present invention relates to a compression fixing device after a cardiac pace-making operation and a compression fixing method of the compression fixing device. A chest limiting adjustment bracketis fixedly arranged between two support sliding plates, an upper surface of one end of the chest limiting adjustment bracket is provided with a compression bolt hole, a compression bolt is movably arranged in the compression bolt hole, a bottom part of the compression bolt is connected with a compression plate arranged at a bottom part of the chest limiting adjustment bracket, a lateral positionlimiting plate is arranged at an inner side of a longitudinal limiting groove seat close to the compression plate, an outer end of the lateral position limiting plate is connected with a lateral position adjusting bolt positioned and arranged on the longitudinal limiting groove seat, a rotating shaft is fixedly arranged at a middle position of a bottom part of a fine adjustment plate, two ends ofthe rotating shaft are movably arranged in rotating shaft brackets, and bottom parts of the rotating shaft brackets are fixedly arranged on a bottom part supporting plate. When the device is used integrally, positioning of a pressurizing position is accurately controlled, a user is limited between the chest limiting adjustment bracket and the support sliding plates, and phenomena of falling, pressure changes, etc. do not occur by utilizing a bolt compression structure.

Owner:河南弘辉医疗科技有限公司

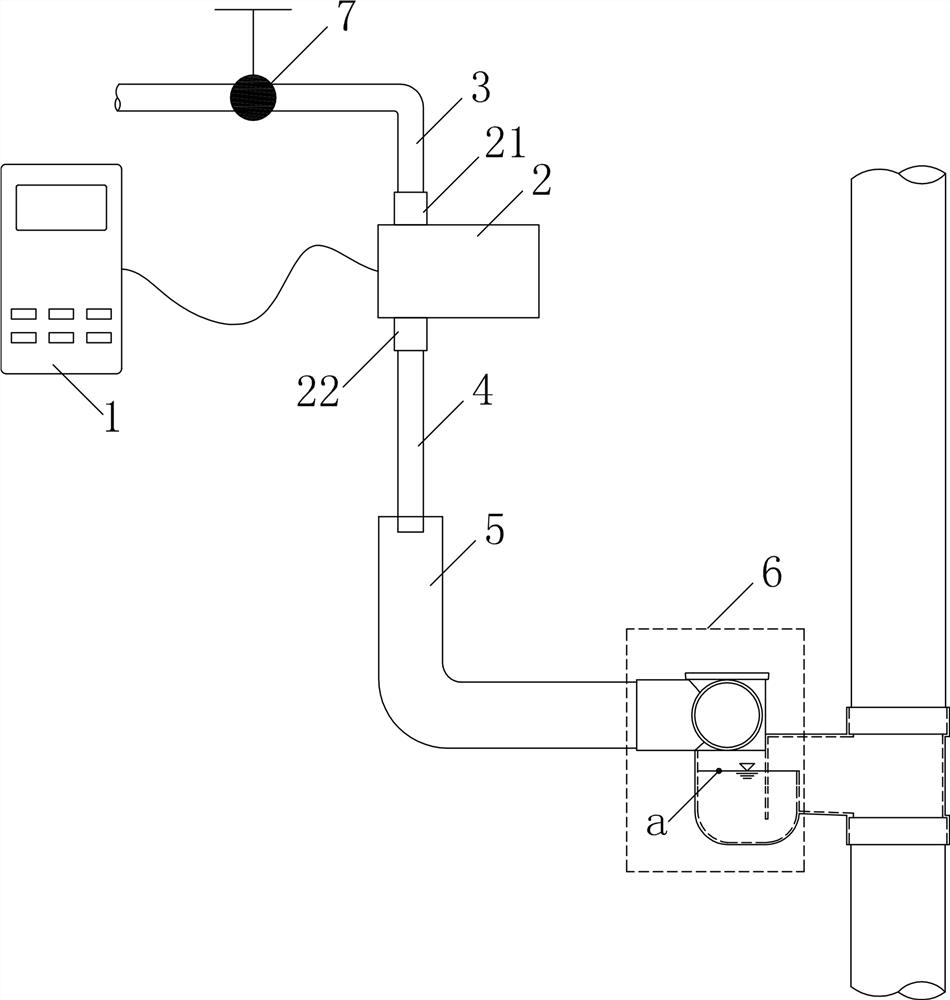

Automatic water-seal water supplementing device and method

PendingCN112878442APrecise positioning controlSize is not too much requirementDomestic plumbingPathogenic bacteriaEnvironmental engineering

The invention discloses an automatic water-seal water supplementing device and method. A power controller is electrically connected with an electric control valve, a water inlet and a water outlet are formed in the electric control valve, a water inlet pipe is connected with the water inlet, a water supplementing pipe is connected with the water outlet, the water supplementing pipe is connected with a water draining branch pipe in a non-closed mode, the water draining branch pipe communicates with a water seal body, and an outlet of the water supplementing pipe is higher than the highest point of a water seal. The invention further discloses the automatic water-seal water supplementing method. The automatic water-seal water supplementing device and method can achieve the technical effect of automatic water supplementing of the water seal in a building, the device is simple, reliable, economical and applicable, the water seal does not lose efficacy and water stored in the water seal is replaced, bad smell in a pipeline system is prevented from diffusing into a room, the problem of bad smell caused by drying of the water seal in the building is solved, and the risk that pathogenic bacteria are spread through the water seal losing efficacy can be effectively reduced.

Owner:KUNMING QUNZHIYING TECH

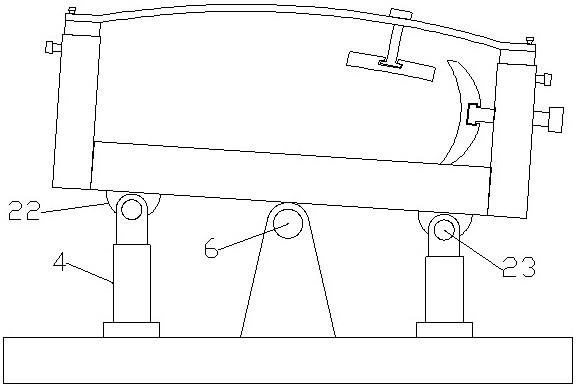

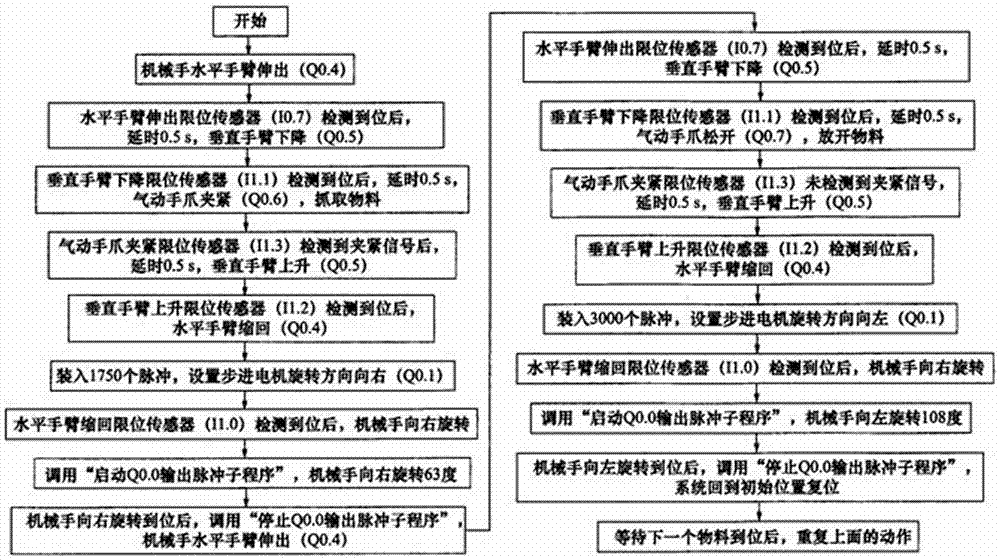

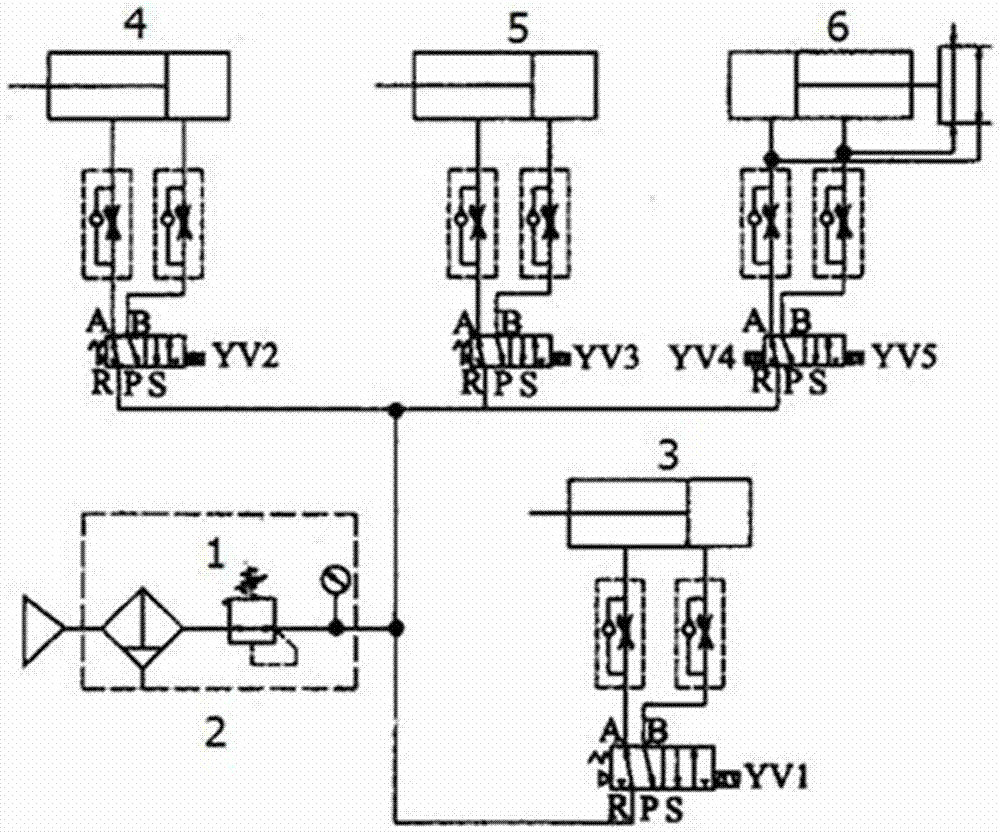

Precision positioning and controlling system for material carrying of pneumatic manipulator

InactiveCN106863291AEasy to controlEasy to operateProgramme-controlled manipulatorProgrammable logic controllerMotor control

A precision positioning and controlling system for material carrying of a pneumatic manipulator is mainly composed of a programmable logic controller (PLC) control module, a horizontal manipulator arm, a vertical manipulator arm, manipulator pneumatic claws, a manipulator rotary shaft, a stepping drive module, a pneumatic control module and the like. Rotation, grabbing and releasing of the pneumatic manipulator are controlled by applying the PLC technology and the stepping motor control technology, and precision positioning and control over material carrying of the manipulator are achieved. The system is simple in control, convenient to operate, reliable in operation, accurate in positioning and good in using effect. A method, principles and technologies of the precision positioning and controlling system can be expanded to the industries including machinery, metallurgy, chemical engineering, electronics, medicine, food processing, printing, delivery centers and ports, and broad application prospects are achieved.

Owner:魏莹

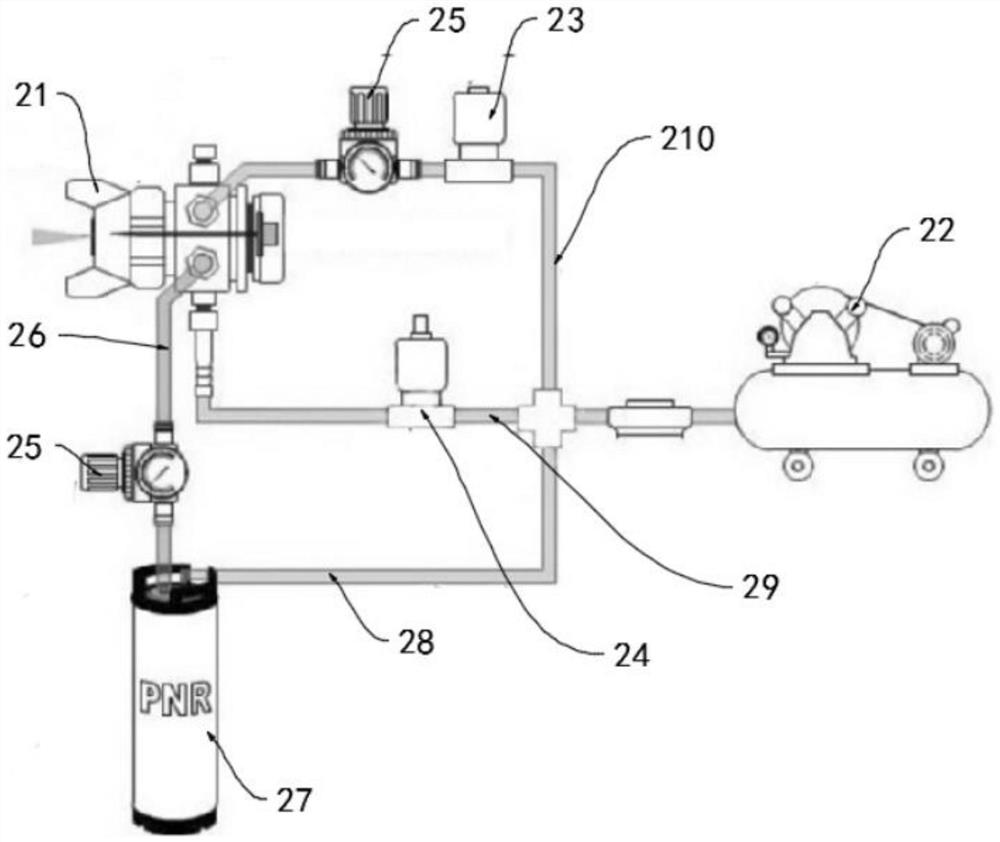

Automatic mould release agent spraying equipment for shield segment mould

PendingCN111804461APrecise positioning controlRealize automatic start and stopLiquid spraying apparatusControl systemProcess engineering

The invention discloses automatic mould release agent spraying equipment for a shield segment mould, which belongs to the technical field of automatic shield segment production equipment, and particularly relates to equipment for automatically spraying a mould release agent to the shield segment mould. The equipment comprises a control system, a spraying mechanism and a moving mechanism, wherein the spraying mechanism is mounted on the moving mechanism; the control system is separately connected to the spraying mechanism and the moving mechanism; the spraying mechanism comprises a spray head,a feeding tube, an air compressor and a mould release agent raw material barrel; a plurality of interfaces are arranged on the spray head; the air compressor is separately connected to a first gas inlet tube, a second gas inlet tube and a third gas inlet tube; the mould release agent raw material barrel is connected to the first gas inlet tube; and the first interface of the spray head communicates with the mould release agent raw material barrel through the feeding tube. The automatic mould release agent spraying equipment has the beneficial effects that: an X-direction moving module drives the spraying mechanism to transversely move, a Z-direction moving module drives the spraying mechanism to vertically move, and can be matched with a rotary driver, so that the spraying mechanism can perform curve motion along motion track to accomplish automatic spraying for an arc-shaped inner cavity of the mould.

Owner:中电建成都混凝土制品有限公司

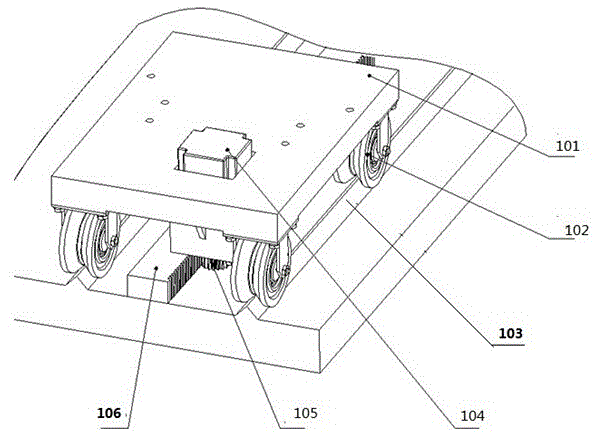

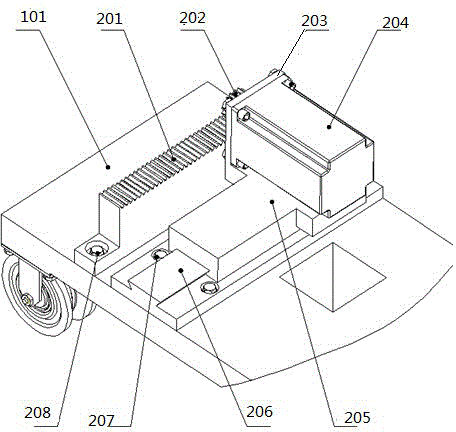

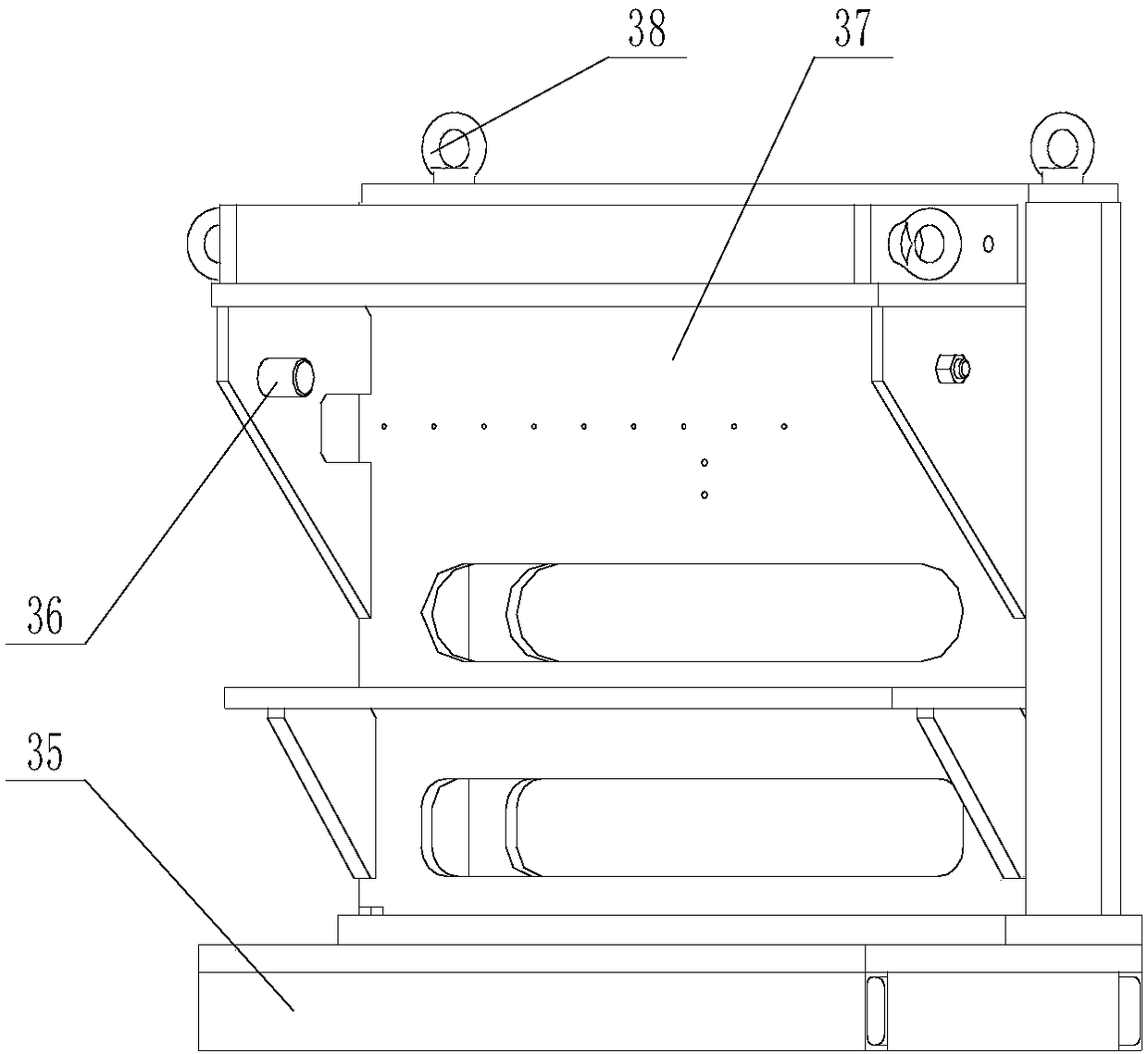

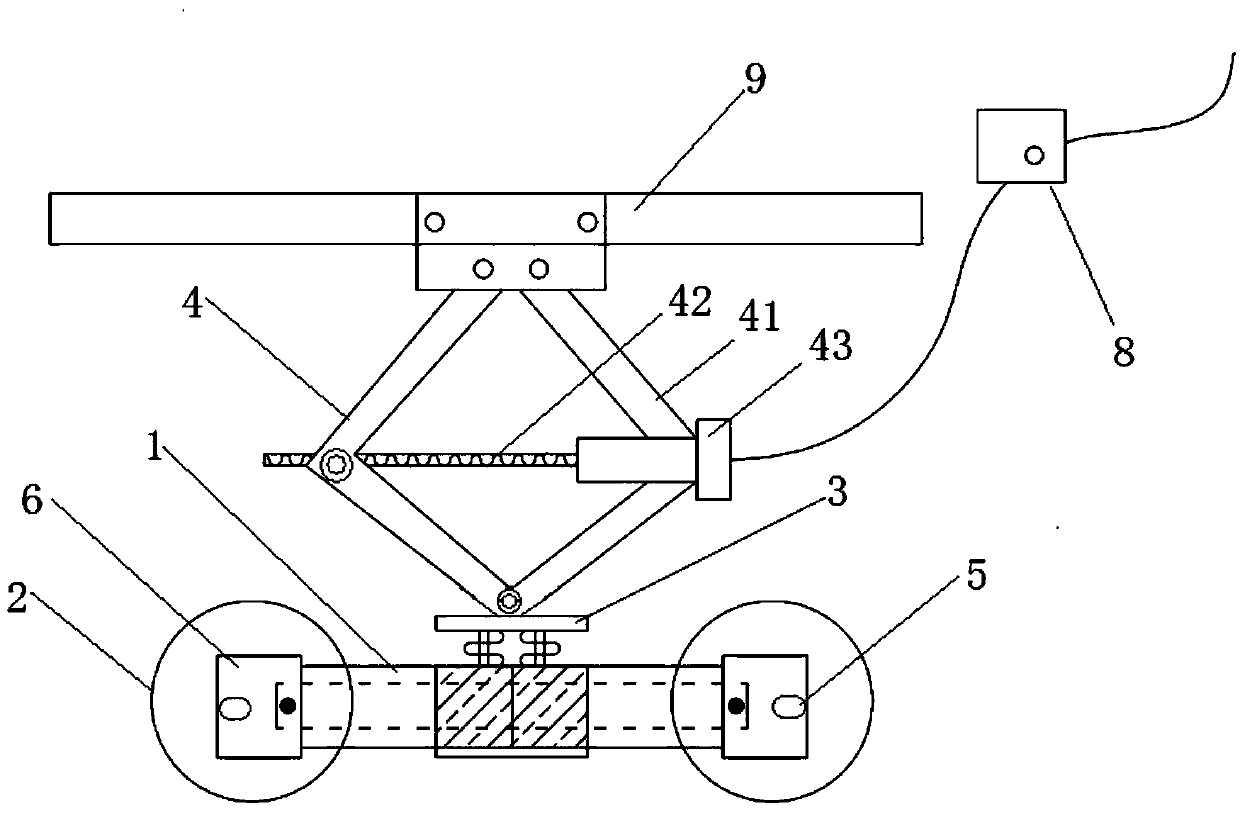

Passive take-off and landing type high-speed mobile workbench of hydraulic machine

PendingCN110303716AGood manufacturing precision and structural stabilityImprove work efficiencyPressesFlangeMachining system

The invention discloses a passive take-off and landing type high-speed mobile workbench of a hydraulic machine. The platform mainly comprises a moving platform, a driving device, a linear rail deviceand the like. The moving platform comprises a main table plate, an end cover, a guide sleeve, a cylindrical guide pin, a dragging side plate, a rack, a spring lifting device, a linear rail sliding block and the like, wherein the driving device comprises a servo motor, a speed reducer, a flange, a bearing seat, a transmission shaft, a gear and the like, and the linear rail device comprises a linearrail, a bracket, a shift-out collision block, a shift-in collision block and the like. According to the passive take-off and landing type high-speed mobile workbench of the hydraulic machine, a driving mechanism specially used for controlling the lifting and descending of a mobile workbench and power input are not required, thus simplifying a hydraulic machine system, reducing malfunction pointsand saving energy; in addition, the friction resistance is small, so that high-speed shift-in and shift-out and accurate repeated positioning is achieved, and the waiting time of lifting, lowering andother auxiliary actions can be avoided, thus greatly improving the working efficiency of a mobile refueling type hydraulic machine.

Owner:NANTONG METALFORMING EQUIP

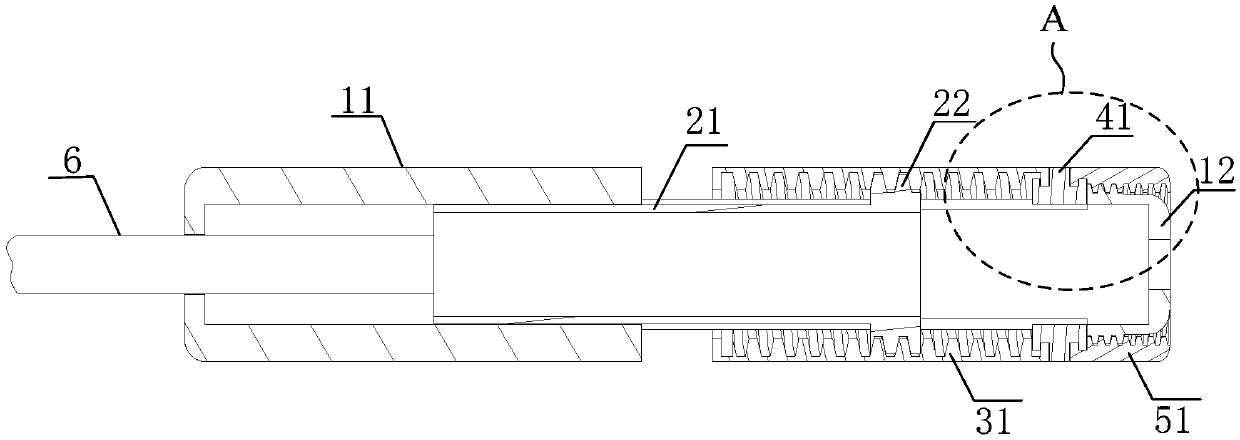

Driving handle and conveying system for conveying implant

PendingCN111214310AFast loadingPrecise positioningHeart valvesSurgeryPhysical medicine and rehabilitationEngineering

The invention provides a driving handle and a conveying system for conveying an implant. The driving handle can drive an outer tube which is used for conveying the implant to perform variable motion,namely, the handle controls motion of the outer tube at different speeds according to requirements of actual operation, thereby improving operation efficiency and reducing operation difficulty. The driving handle specifically comprises a hand-held sleeve, a fixed sleeve, a first driving mechanism, a second driving mechanism and a transmission mechanism; at least one part of the fixed sleeve movably penetrates through the hand-held sleeve; the first driving mechanism, the second driving mechanism and the transmission mechanism are all movably arranged on the hand-held sleeve; the first drivingmechanism is connected with the fixed sleeve, and is configured to directly drive the fixed sleeve to move along the axis of the driving handle at a first speed under action of external force; the second driving mechanism is configured to push the transmission mechanism under action of external force; and the transmission mechanism drives the first driving mechanism and the fixed sleeve to synchronously move along the axis of the driving handle at a second speed, wherein the second speed is not equal to the first speed.

Owner:SHANGHAI MICROPORT CARDIOFLOW MEDTECH CO LTD

Automatic clearing device of shield segment mold

PendingCN111805713APrecise positioning controlIncrease productivityCeramic shaping apparatusCleaning using toolsControl systemControl engineering

The invention belongs to the technical field of automatic shield segment production devices and particularly relates to an automatic clearing device of a shield segment mold. The automatic clearing device of the shield segment mold comprises a control system, a clearing mechanism and a moving mechanism. The clearing mechanism is installed on the moving mechanism. The control system is connected with the clearing mechanism and the moving mechanism. The moving mechanism comprises a support, an X-direction moving module and a Z-direction moving module. The X-direction moving module is installed at the upper end of the support. The Z-direction moving module and the X-direction moving module are connected. A rotation driver is installed on the Z-direction moving module. The automatic clearing device of the shield segment mold has the beneficial effects that the X-direction moving module and the Z-direction moving module cooperate with the rotation driver to enable the clearing mechanism toconduct curvilinear motion along a motion path, and then automatic clearing of an arc inner cavity of the mold can be completed; and in this way, the production efficiency is greatly improved, the production cost is lowered, and the problem that manual clearing enables the shield segment to generate flaws, lowers precision is low in efficiency is solved.

Owner:中电建成都混凝土制品有限公司

Bag opening and positioning tool of packaging machine

InactiveCN105129140ASimple structureEasy to operate and controlPackagingMaster controllerEngineering

The invention discloses a bag opening and positioning tool of a packaging machine. The tool comprises a fixed seat, a lifting mechanism fixed to the fixed seat and a bag opening clamp which is connected to the top end of the lifting mechanism and is in bilateral symmetry; the lifting mechanism comprises a lifting driving air cylinder and a lifting rod, wherein the lifting driving air cylinder is fixed to the bottom end of the fixed seat, and the lifting rod is connected with the lifting driving air cylinder; the bag opening clamp comprises a U-shaped mounting frame fixed to the top end of the lifting rod, a movable guide rail fixed to the top end of the U-shaped mounting frame, two clamping plates which are mounted on the movable guide rail in a sliding manner and provided with opposite inner end faces and a clamping plate driving air cylinder connected with the clamping plates; and the lifting driving mechanism and the clamping plate driving air cylinder are both connected with a master controller.

Owner:ANHUI ZENGRAN PACKAGING SCI & TECH

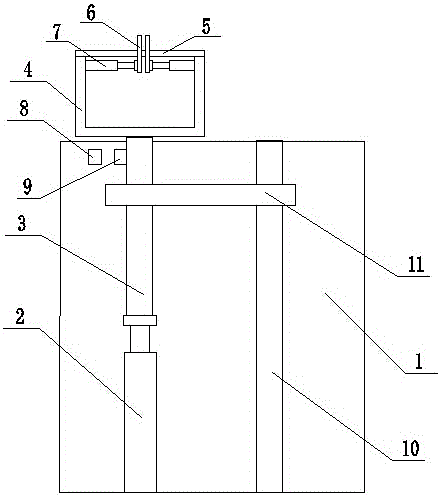

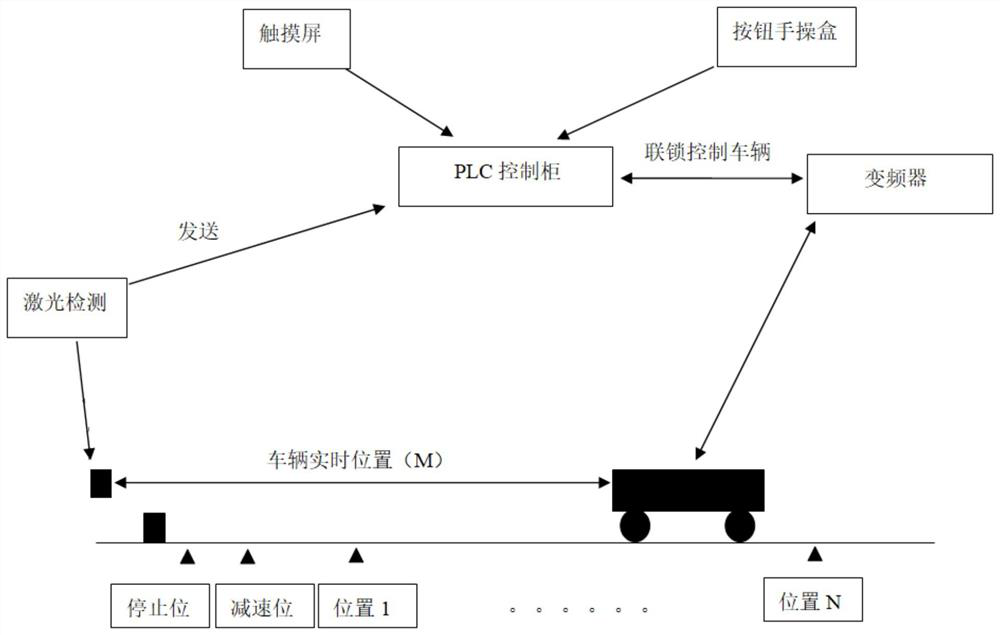

Metallurgical vehicle position detection control system

PendingCN111830997AImprove securityPrecise positioning controlPosition/course control in two dimensionsVehiclesFrequency changerControl system

The invention discloses a metallurgical vehicle position detection control system. The metallurgical vehicle position detection control system comprises a laser limiting detection instrument, a PLC control cabinet, a frequency converter and a metallurgical vehicle, wherein the laser limiting detection instrument is connected with the PLC control cabinet and is used for detecting the position of the metallurgical vehicle in real time and sending a detection result to the PLC control cabinet, a man-machine interaction operation system is embedded in the PLC control cabinet and used for achievingprecision positioning and acceleration and deceleration control over the metallurgical vehicle through an algorithm, and the PLC control cabinet is connected with the frequency converter and used forcontrolling the metallurgical vehicle in an interlocking mode. According to the metallurgical vehicle position detection control system, accurate positioning and position detection functions of the metallurgical vehicle are achieved, meanwhile, two-place visual operation of equipment is achieved, labor intensity of posts is reduced, and an operation mode is simplified; and safety performance in the use process is further greatly improved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com