Quick change device for stopper rod

A stopper and machine base technology, applied in the field of stopper quick change device, can solve the problems of limiting the service life of the tundish, increasing the replacement times of the tundish, affecting the output of the continuous casting machine, etc., achieving compact structure, improving adaptability, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

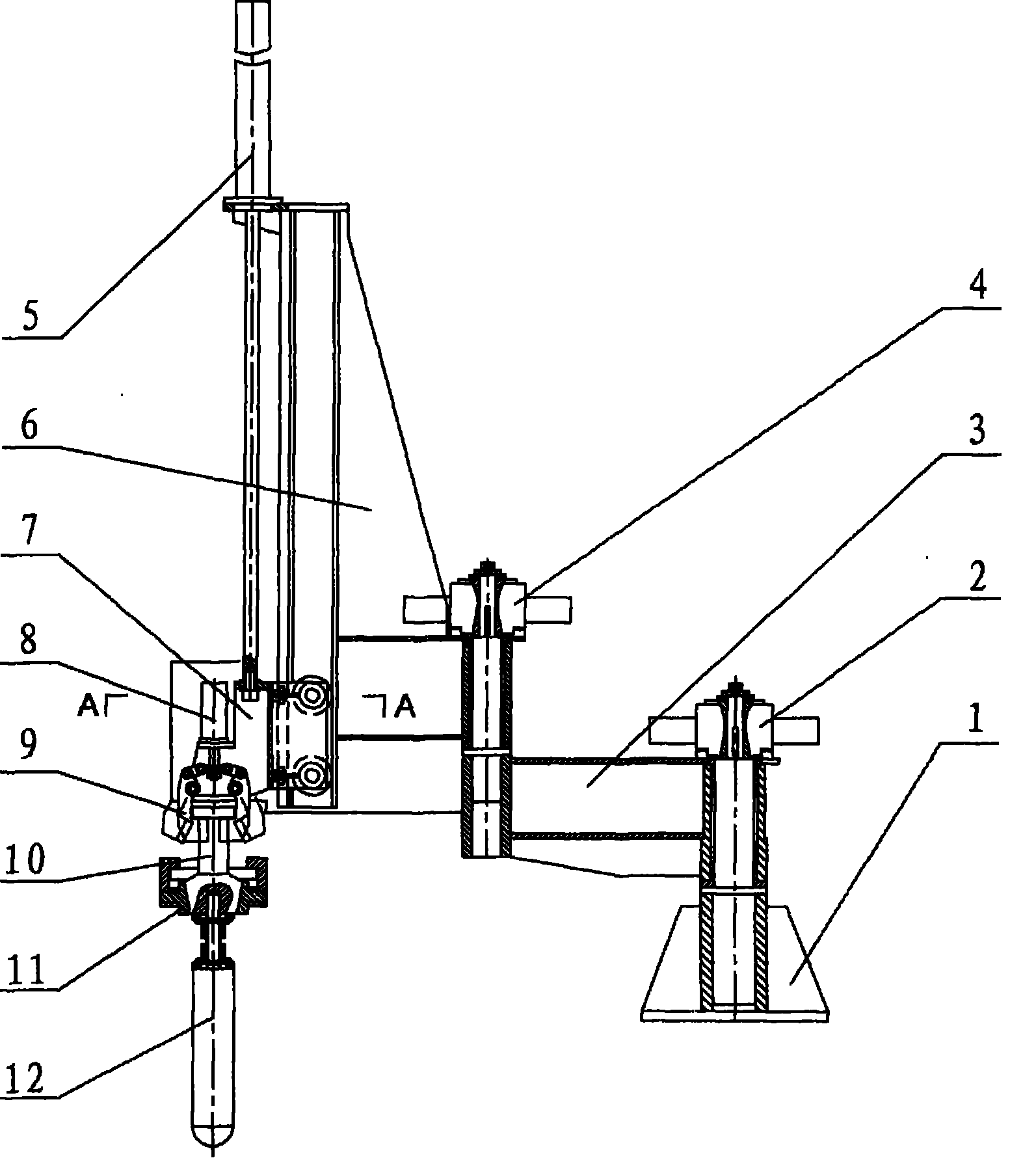

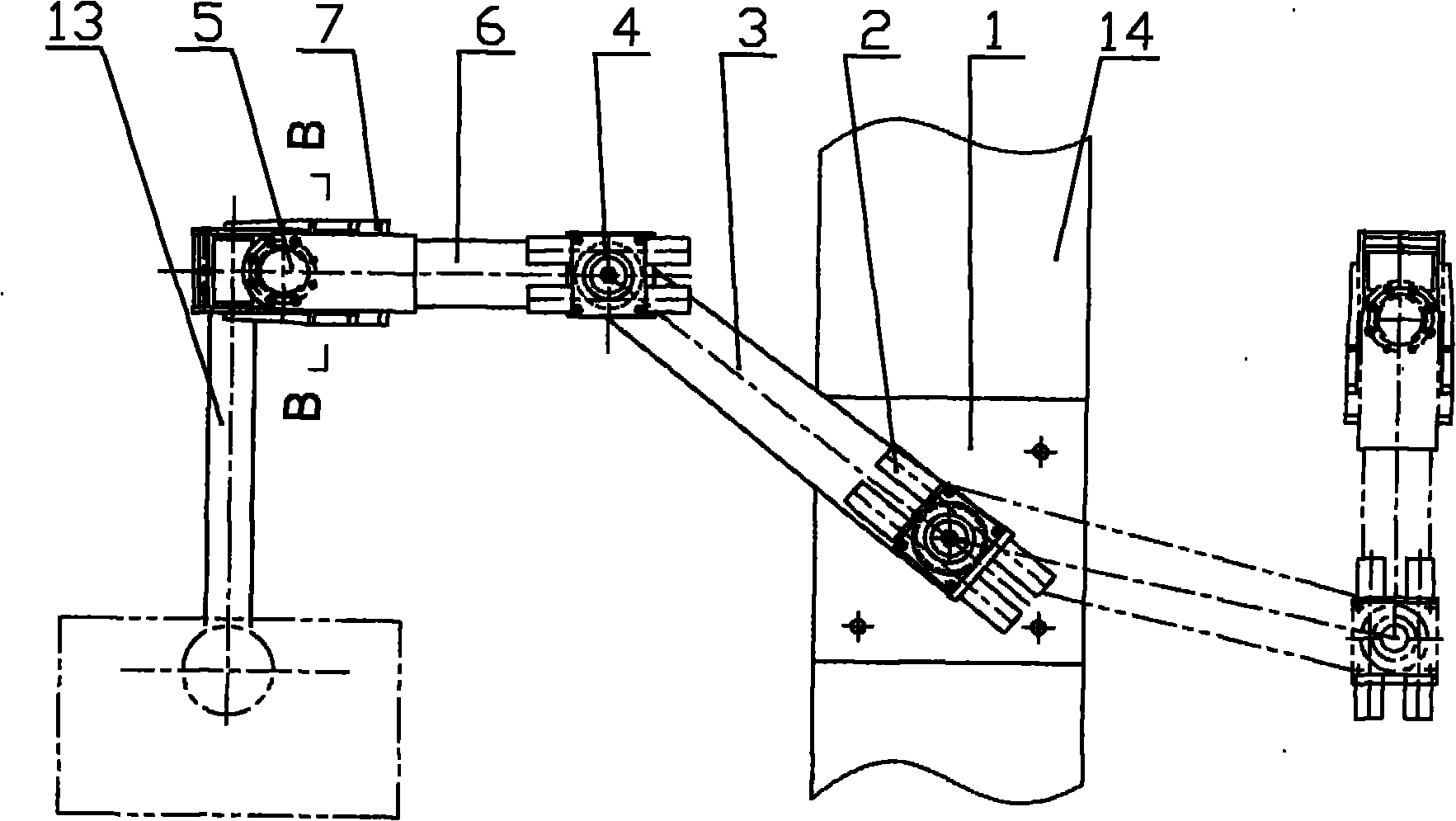

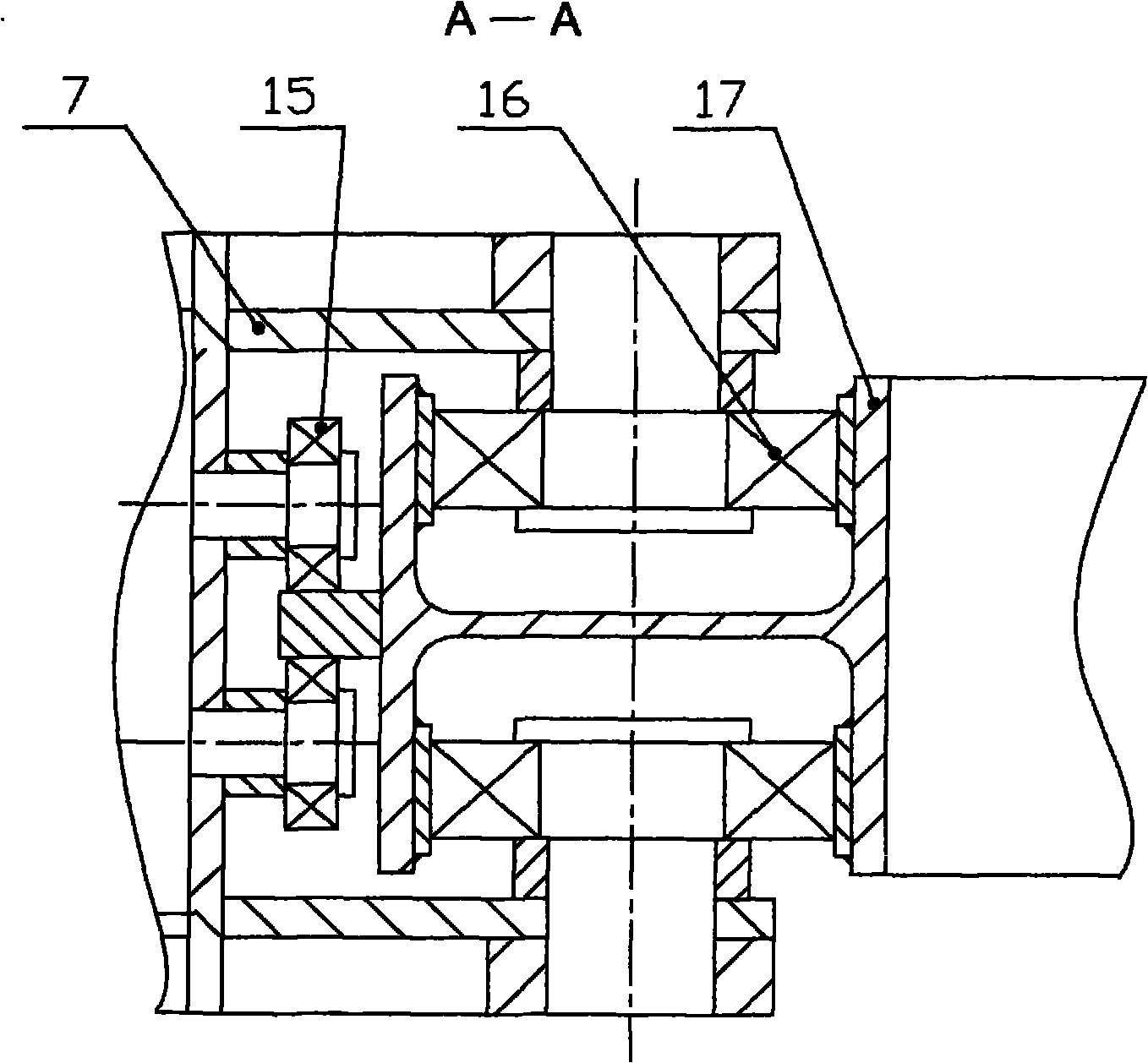

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] In the drawings, the machine base 1 is fixed on the crossbeam 14 of the tundish trolley with bolts, the base of the boom swing cylinder 2 is fixed on the boom 3 with bolts, and the stepped shaft of the machine base 1 is fixed in the shaft hole of the boom 3 At the same time, it cooperates with the output hole of the boom swing cylinder 2 and connects with a key to transmit torque to realize the rotation of the boom 3 relative to the base 1. The nut and the pressure plate at the shaft end can ensure the axial positioning of the boom 3. The stepped shaft of the boom 3 cooperates with the sliding bearing of the forearm 6, and at the same time cooperates with the output hole of the forearm swing cylinder 4 and is connected with a key to transmit torque to realize the movement of the forearm 6 relative to the forearm 3. The shaft end is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com