Numerical control device

A numerical control device and data technology, applied in the direction of automatic control device, program control, feeding device, etc., can solve problems such as inability to perform accurate positioning, and achieve the effect of high-precision positioning control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

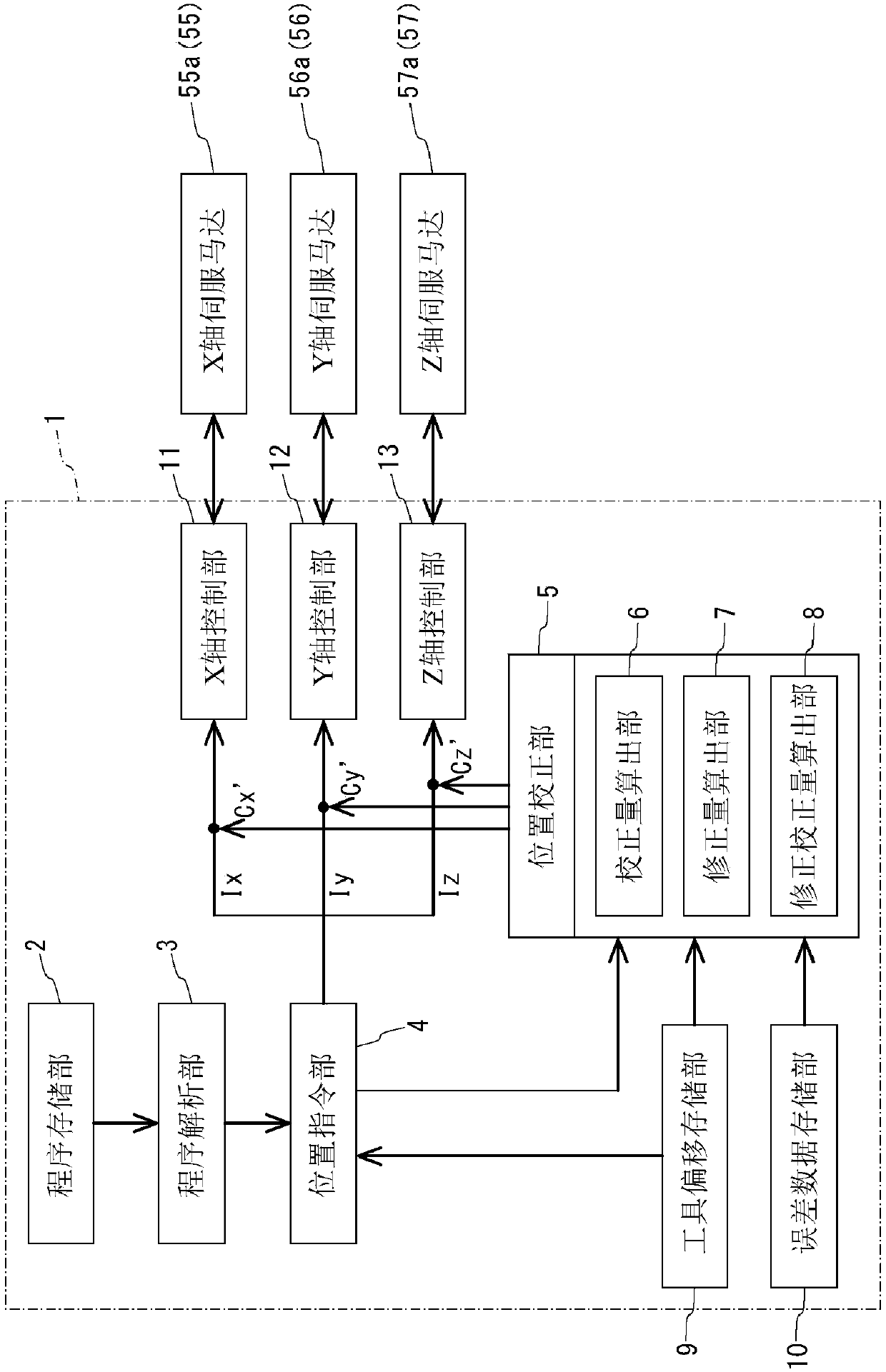

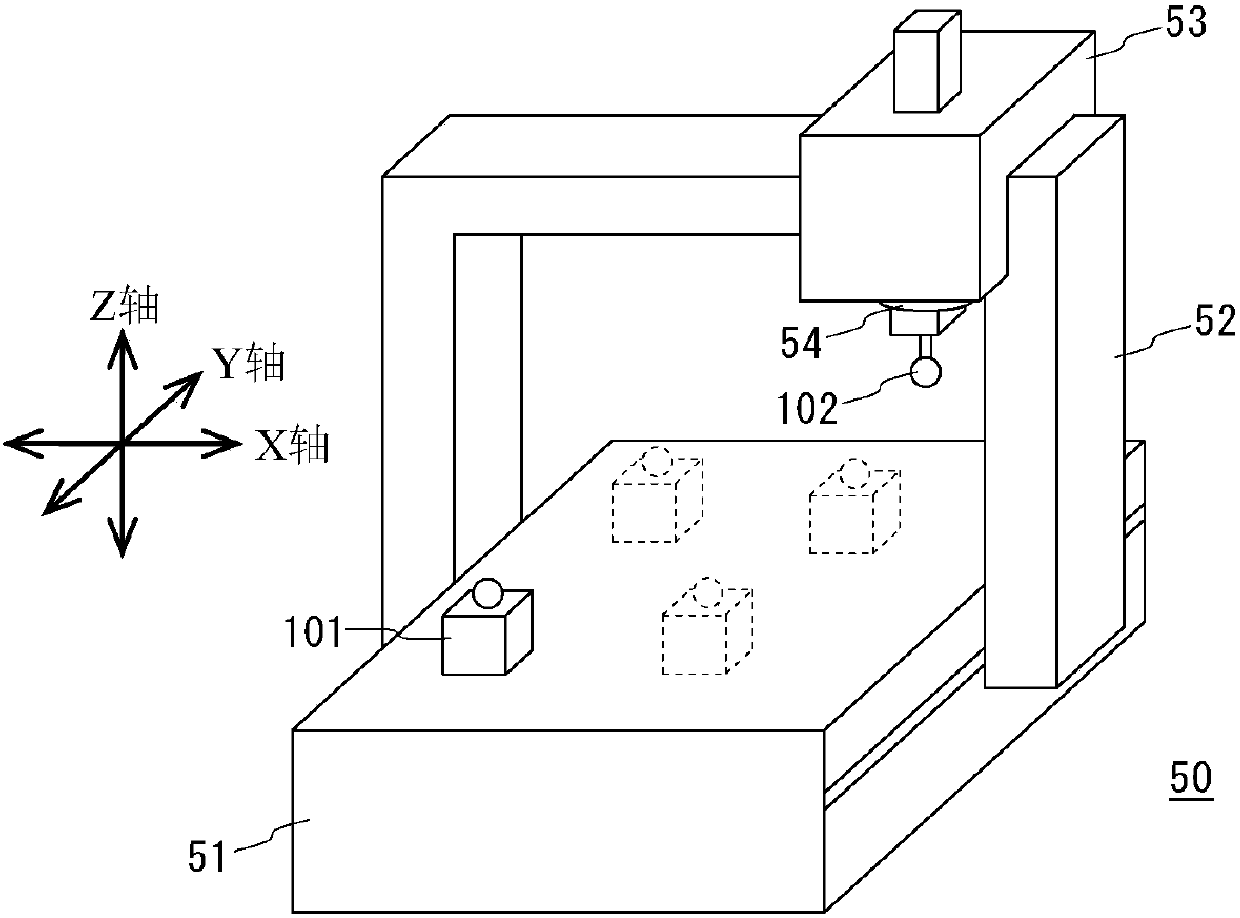

[0049] Below, while referring to the attached Figure 1 Specific embodiments of the present invention will be described. exist figure 1 A schematic configuration of a numerical control device according to an embodiment of the present invention is shown in figure 2 An example of a machine tool controlled by this numerical controller is shown in .

[0050] Such as figure 2 As shown, the machine tool 50 of this example includes a base 51 whose upper surface is a workpiece placement surface (so-called table), a door-shaped frame 52 , and a saddle 53 . The frame 52 is arranged so that its horizontal portion is above the base 51 , and its two vertical portions are respectively engaged with the side portions of the base 51 , so that the frame 52 can move in the Y-axis direction as a whole. In addition, the saddle 53 is engaged with a horizontal portion of the frame 52 and is movable in the X-axis direction along the horizontal portion. Furthermore, the saddle 53 holds the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com