Positioning control mechanism of vertical load for double-acting cylinder

A double-acting cylinder, positioning control technology, applied to mechanical equipment, fluid pressure actuators, servo motors, etc., can solve problems such as rebound force, inconsistent lifting speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

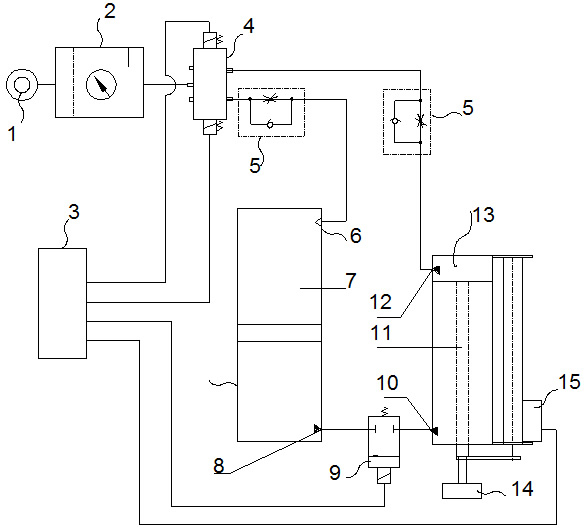

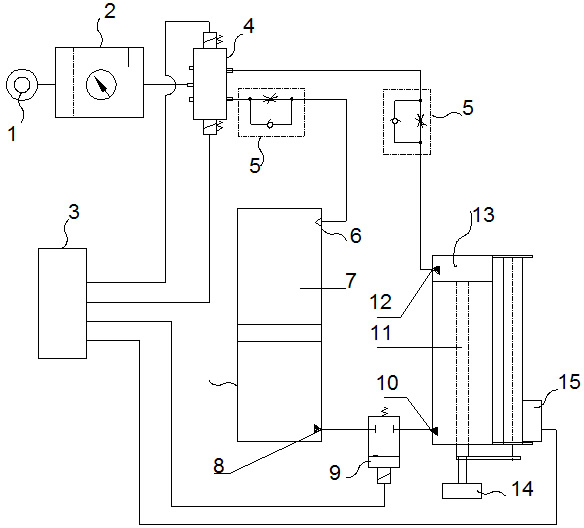

Embodiment 1

[0012] Embodiment one (see figure 1 ): a double-acting cylinder vertical load positioning control mechanism, which includes an air source 1 and an air source adjustment device 2, the air source adjustment device is connected to an air supply solenoid valve 4, and one end of the air supply solenoid valve 4 is connected to an adjustable flow The valve 5 and the inlet and outlet air hole 12 of the double-acting cylinder 13, the other end is connected with the adjustable flow valve 5 and the inlet and outlet air hole 6 of the gas-liquid converter 7, between the inlet and outlet 10 of the double-acting cylinder 13 and the inlet and outlet 8 of the gas-liquid converter 7 The electromagnetic valve 9 for stopping is connected between them, and the double-acting cylinder 13 is provided with a position sensor 15 for detecting the position of the piston 11 .

[0013] When the double-acting cylinder 13 loads the workpiece 14, it is not limited to installing the workpiece 14 below the cyli...

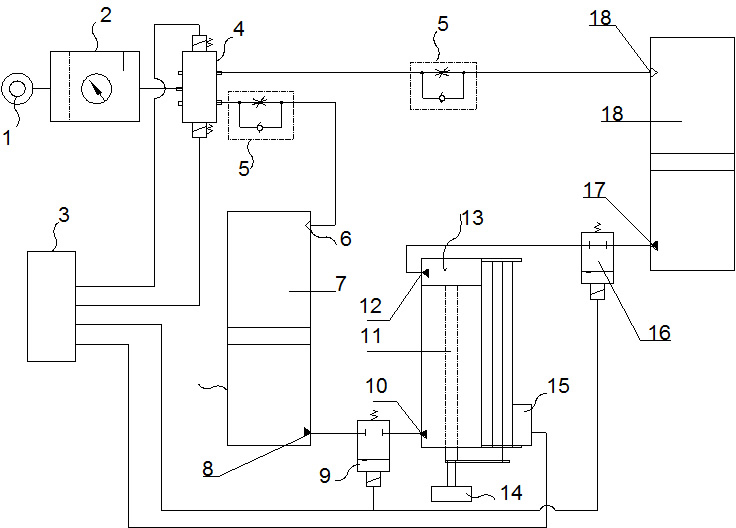

Embodiment 2

[0018] Embodiment two (see figure 2 ): The second embodiment of the positioning control device of the present invention is to increase a gas-liquid converter 18 and a stop solenoid valve 16 on the basis of the first solution to increase the stability of the movement of the piston 11 and better The stop and hold state, its electrical control method, the open and close state of each solenoid valve, the position sensor detection method, the workpiece installation method, etc. are all the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com