Framework oil seal automatic pressing machine

A skeleton oil seal and press-fitting machine technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in ensuring vertical press-in of the oil seal, high labor intensity of the operator, and large fluctuations in press-fitting pressure. Precise and controllable assembly position, saving tooling and mold change time, and the effect of multi-point precise positioning control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

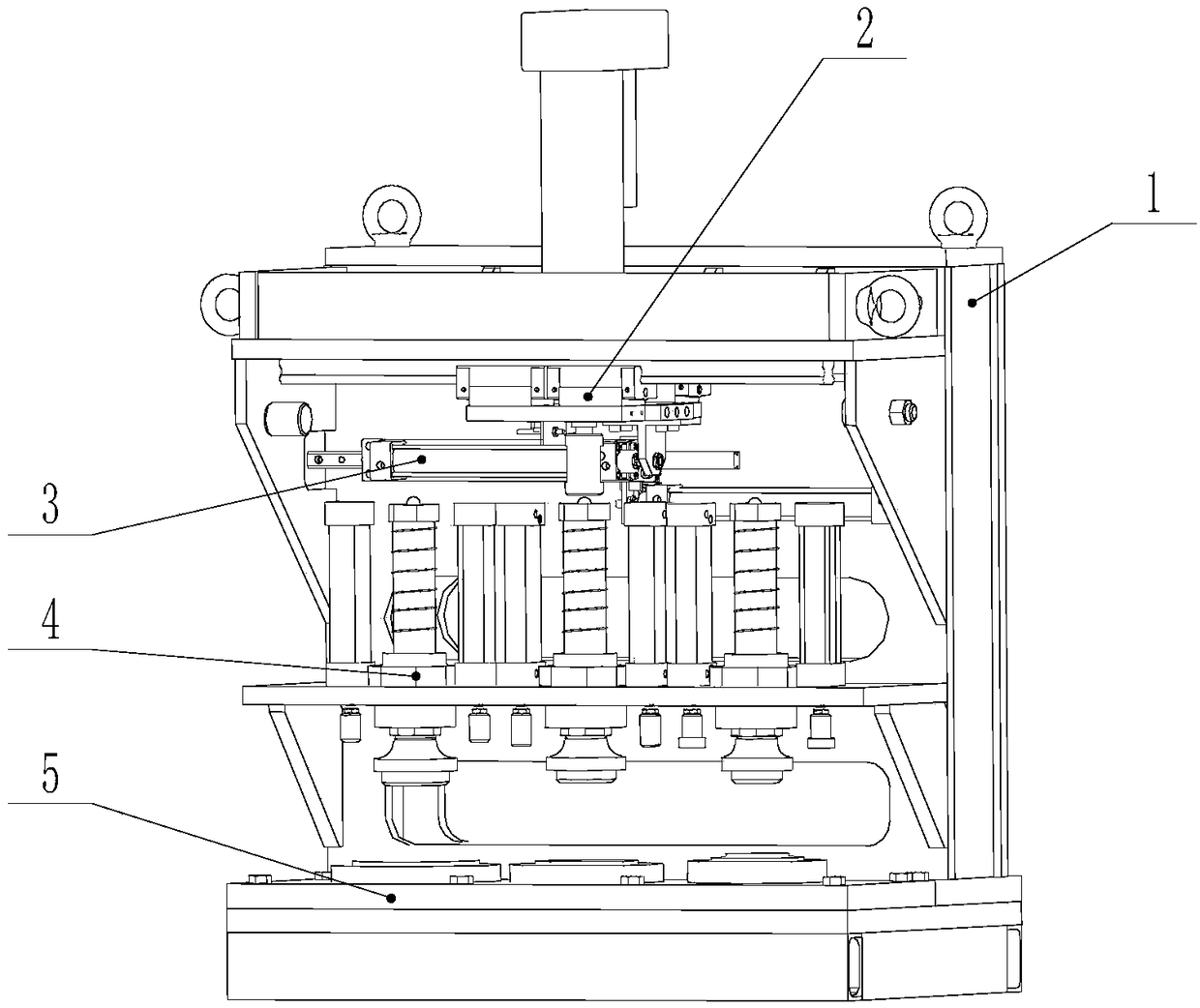

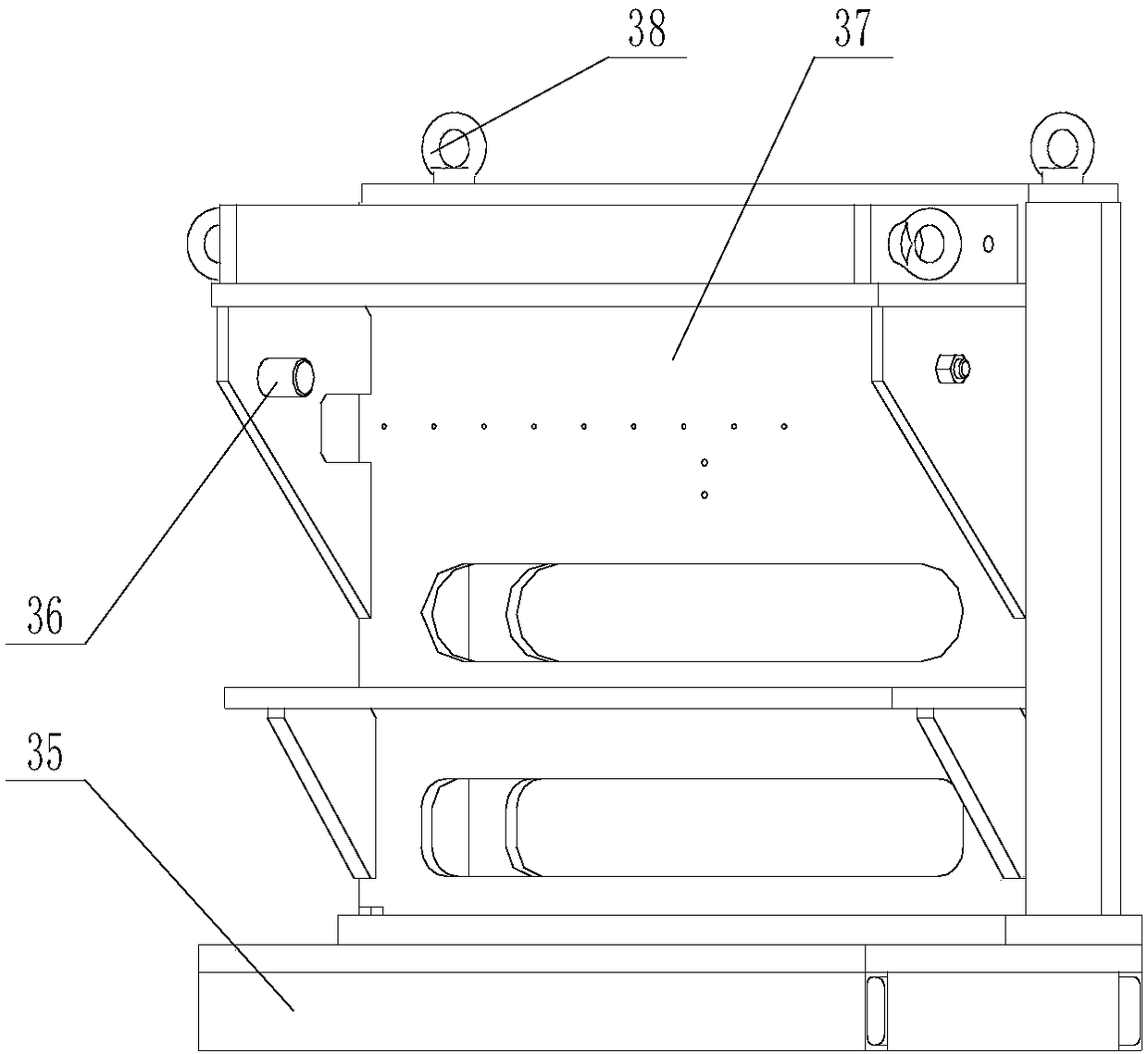

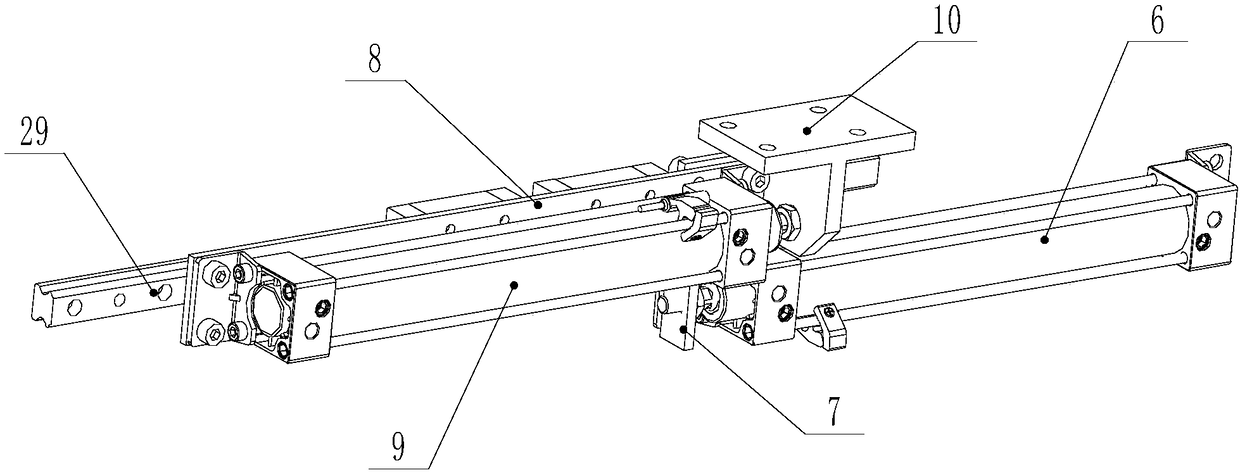

[0028] The frame oil seal automatic press-fitting machine includes a frame 1, on which a press-fitting station quick change device 3, an actuator 2, a guiding and pressing device 4, and an axial positioning device 5 are provided in cooperation with each other, The press-fitting station quick-change device 3 is fixed on the frame by linear guide rail Ⅱ29. The press-fitting station quick change device 3 includes a horizontally fixed cylinder I6 and a horizontally movable cylinder II9. The piston rod of the horizontally fixed cylinder I6 passes through the first connecting plate. 7 is connected to the fixed plate 8. The horizontally movable cylinder II 9 is fixed on the fixed plate 8, and the piston rod of the horizontally movable cylinder II 9 is connected with the second connecting plate 10, and the fixed plate 8 can slide along the linear guide II 29.

Embodiment 2

[0030] The frame oil seal automatic press-fitting machine includes a frame 1, on which a press-fitting station quick change device 3, an actuator 2, a guiding and pressing device 4, and an axial positioning device 5 are provided in cooperation with each other, The press-fitting station quick-change device 3 is fixed on the frame by linear guide rail Ⅱ29. The press-fitting station quick change device 3 includes a horizontally fixed cylinder I6 and a horizontally movable cylinder II9. The piston rod of the horizontally fixed cylinder I6 passes through the first connecting plate. 7 is connected to the fixed plate 8. The horizontally movable cylinder II 9 is fixed on the fixed plate 8, and the piston rod of the horizontally movable cylinder II 9 is connected with the second connecting plate 10, and the fixed plate 8 can slide along the linear guide II 29.

[0031] The actuator 2 includes a power press-fitting device 11, a fixed seat 14, and a limit block 12. The power press-fit device...

Embodiment 3

[0035] The frame oil seal automatic press-fitting machine includes a frame 1, on which a press-fitting station quick change device 3, an actuator 2, a guiding and pressing device 4, and an axial positioning device 5 are provided in cooperation with each other, The press-fitting station quick-change device 3 is fixed on the frame by linear guide rail Ⅱ29. The press-fitting station quick change device 3 includes a horizontally fixed cylinder I6 and a horizontally movable cylinder II9. The piston rod of the horizontally fixed cylinder I6 passes through the first connecting plate. 7 is connected with the fixed plate 8, the horizontally movable cylinder II 9 is fixed on the fixed plate 8, the piston rod of the horizontally movable cylinder II 9 is connected with the second connecting plate 10, and the fixed plate 8 can slide along the linear guide rail II 29.

[0036] The actuator 2 includes a power press-fitting device 11, a fixed seat 14, and a limit block 12. The power press-fit dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com