Patents

Literature

32results about How to "Good low speed stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

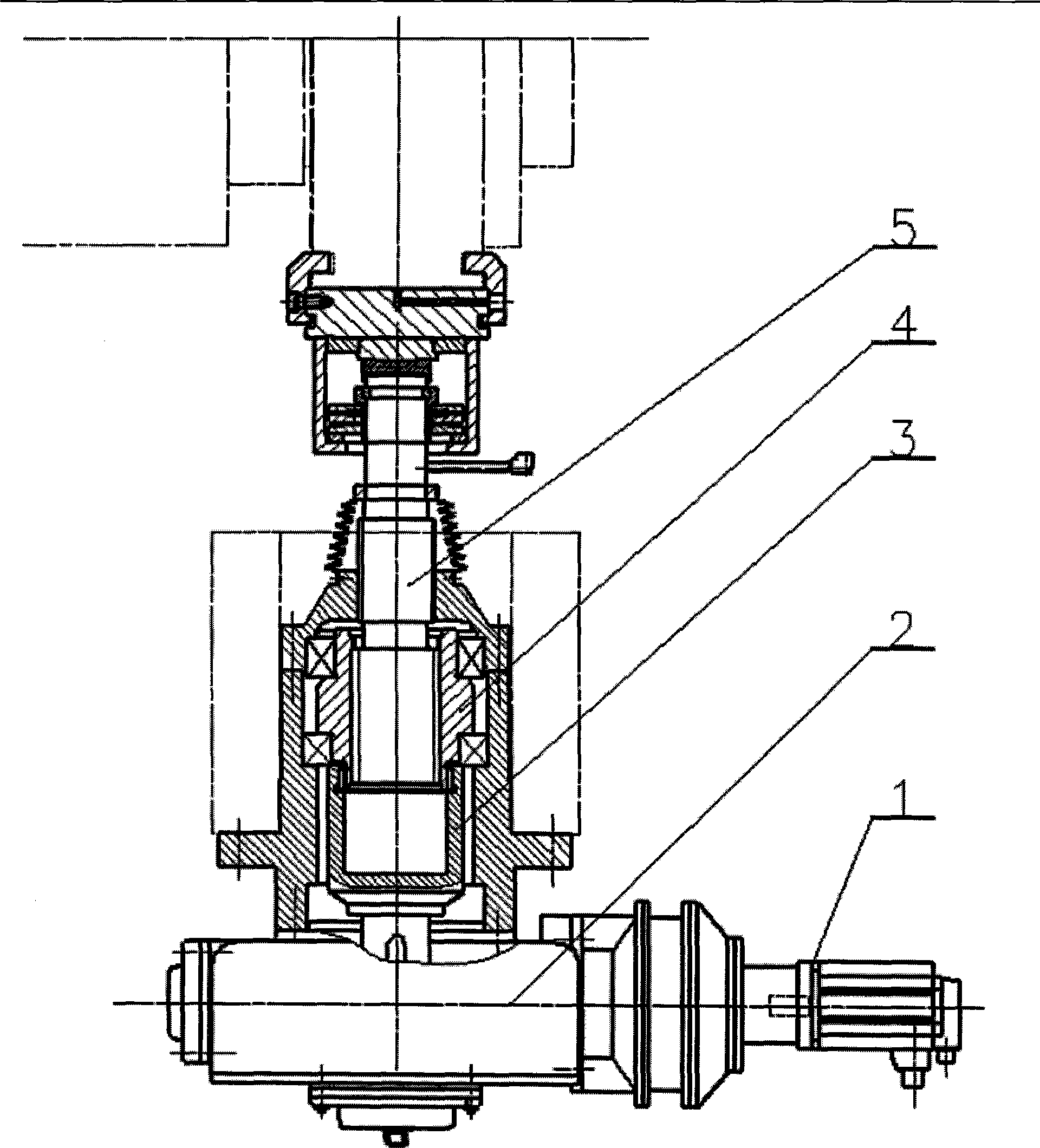

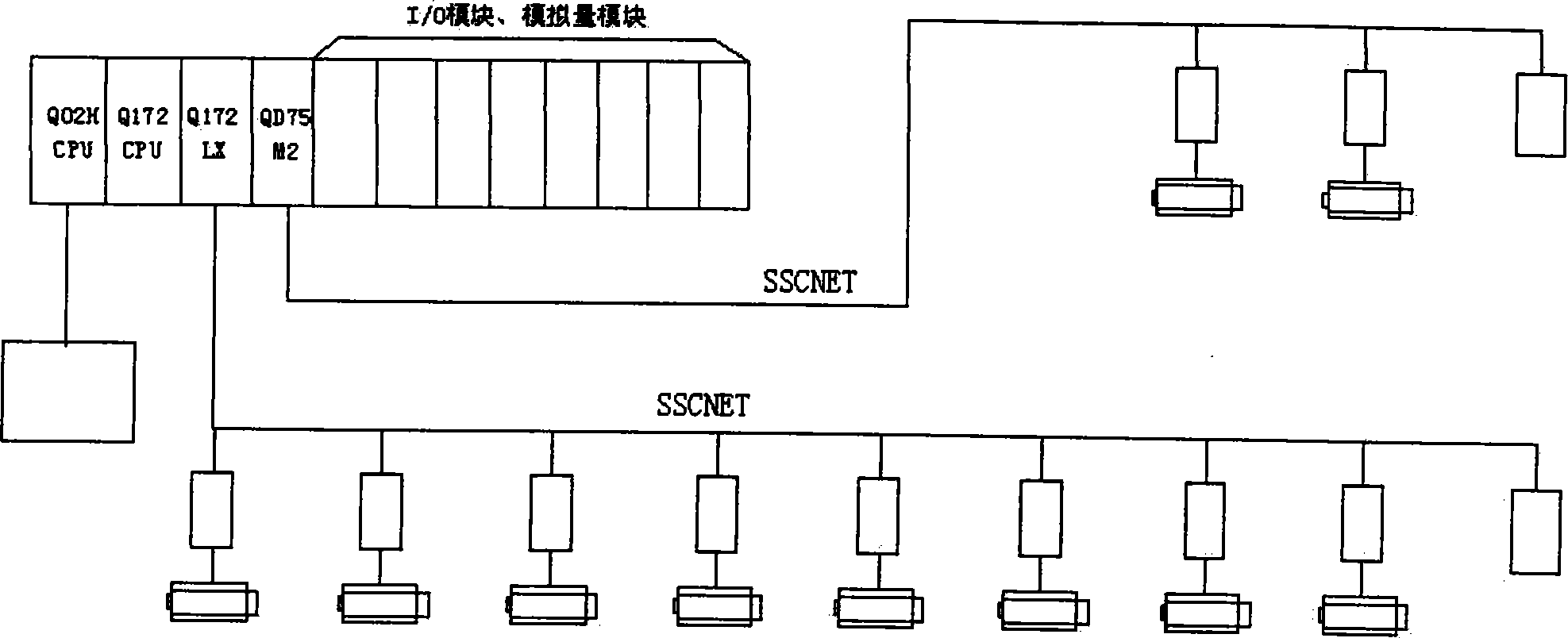

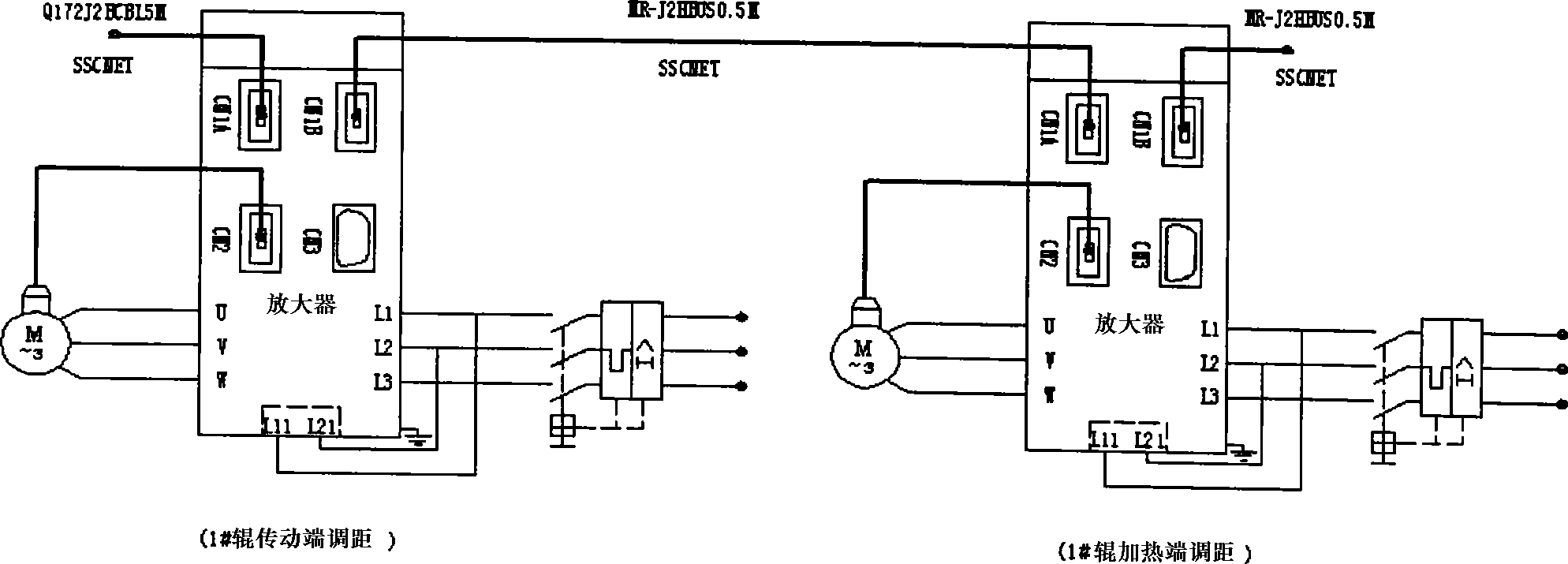

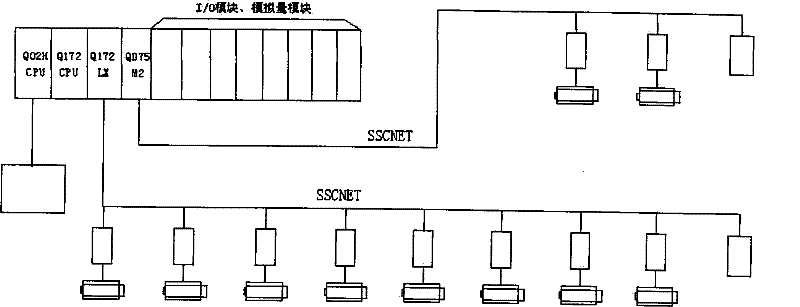

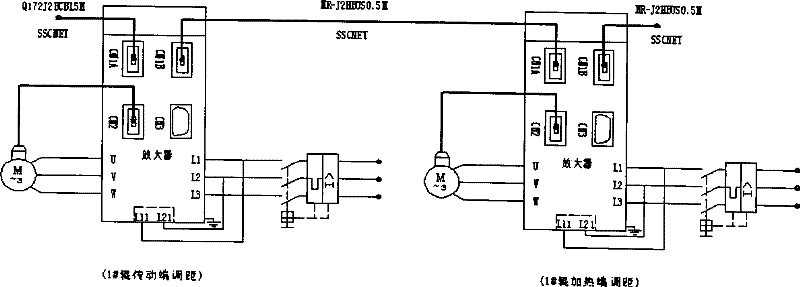

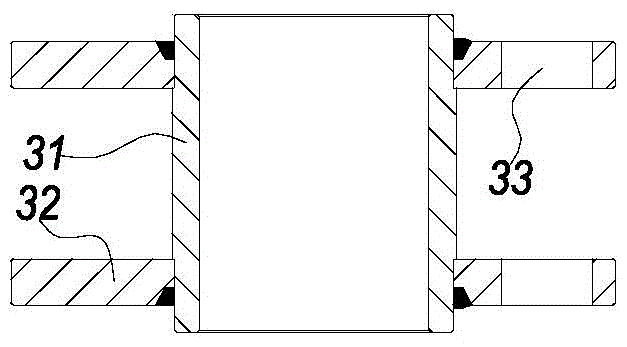

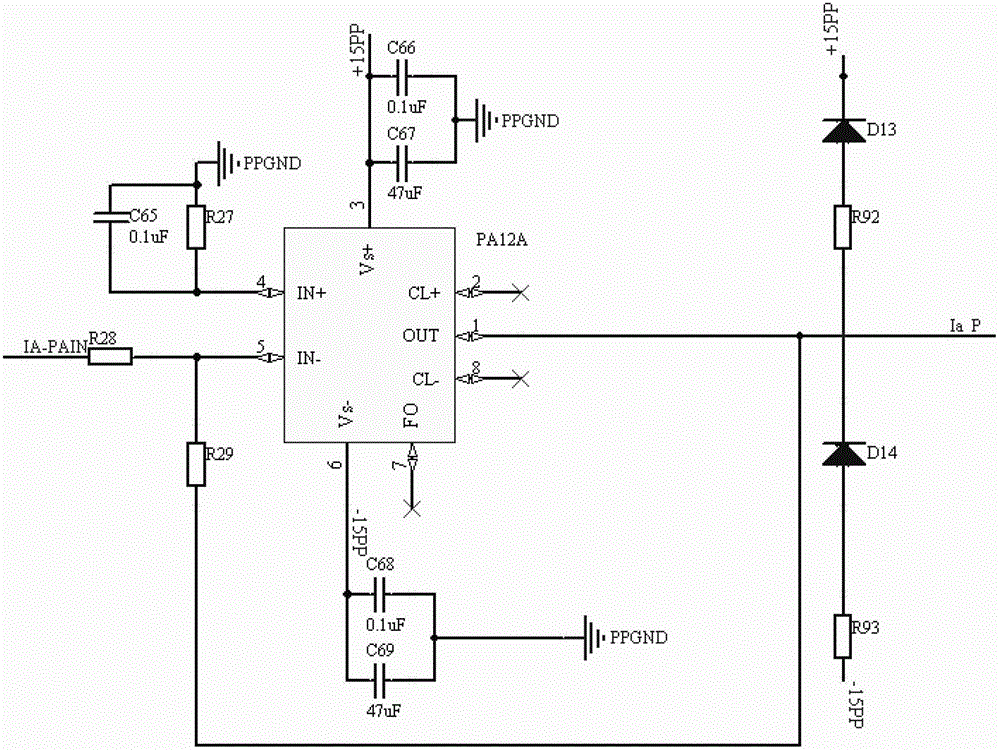

High-precision roller-spacing control system

The invention relates to an S typed four roller pressing extending line host computer distance adjusting system. A high precision roller distance control system consists of an distance adjusting part and a control part, wherein, the distance adjusting part drives a turbine box by a servo motor through a deceleration box, a worm gear drives a nut through inner and outer gear covers, the screw rod copulated with the nut does not rotate, the rotation of the nut drives the screw rod to move forward or backward in the radial direction, and the screw rod is connected with a bearing body; and the control part is a controller which sends command signals to a servo controller which controls a servo motor, the servo motor feeds back the data information to the servo controller through a coder, the servo controller carries out compare and calculation according to the current roller distance, afterwards the servo controller drives the servo motor to operate or stop, and a closed loop control is accomplished. The accurate fault detection function of the distance adjusting system eliminates mechanical fixed return difference through the procedures so as to ensure the positioning accuracy; the operational synchronization ensures the adjusting stability and synchronization of two ends in the roller canister; the automatic positioning of the roller distance is achieved, and the formula function of the roller distance is achieved.

Owner:大连橡胶塑料机械有限公司

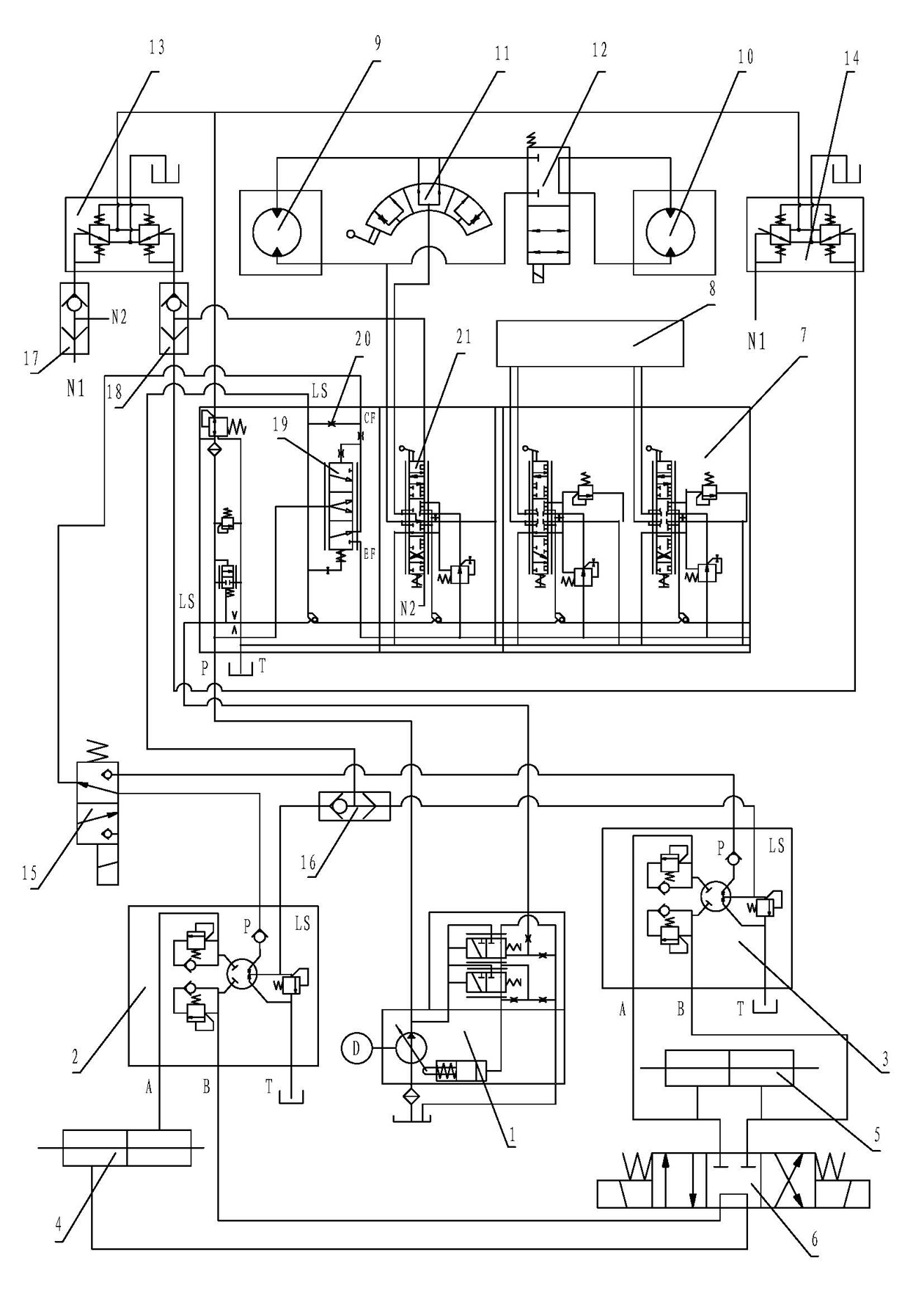

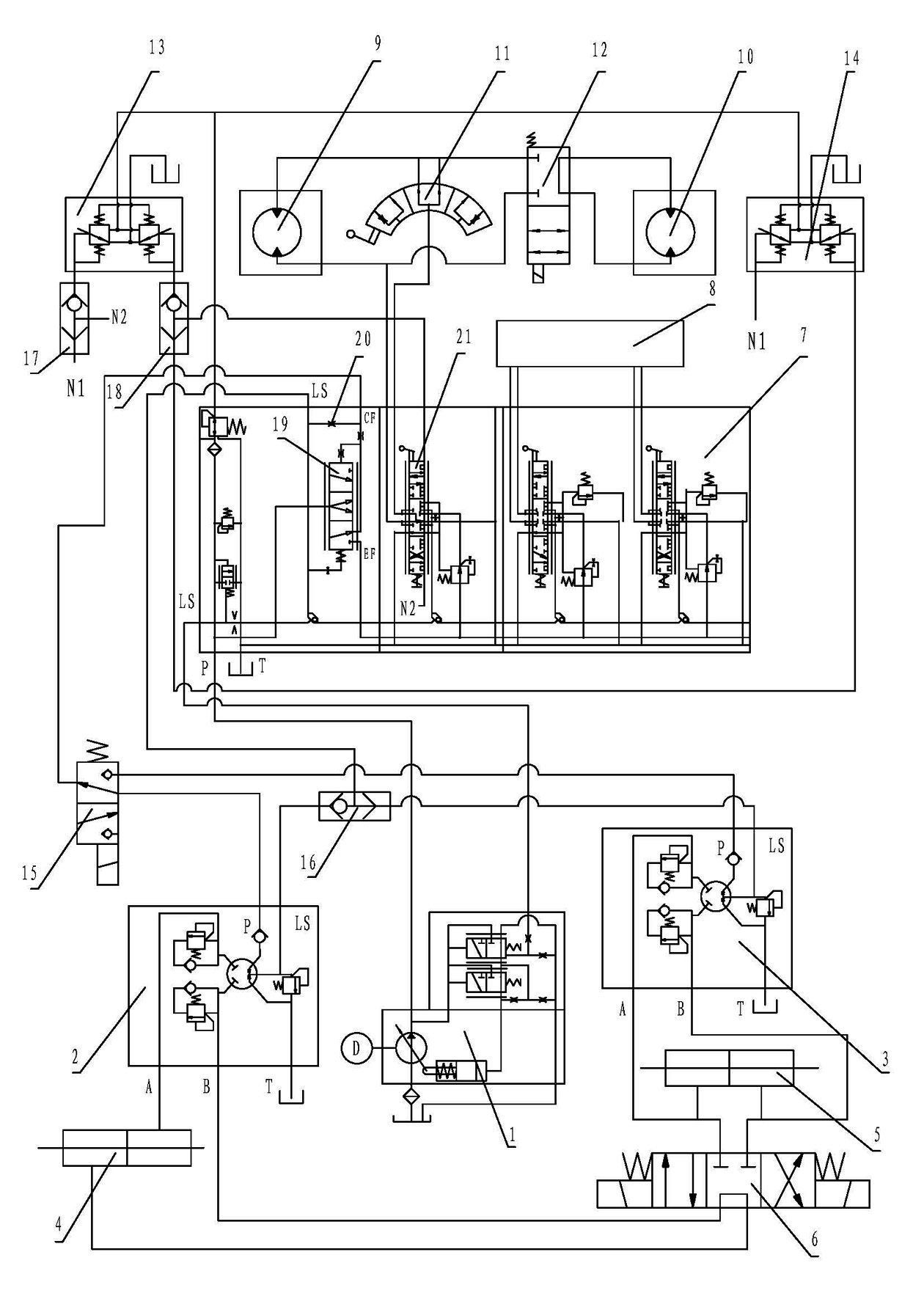

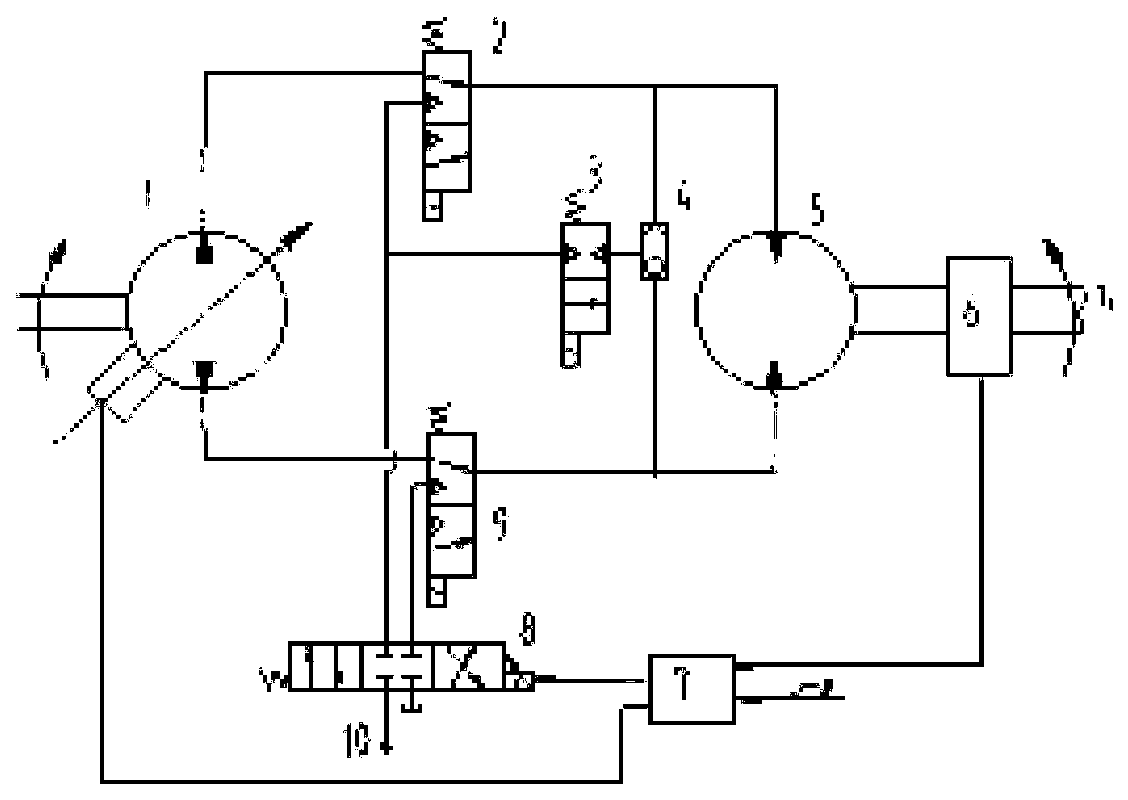

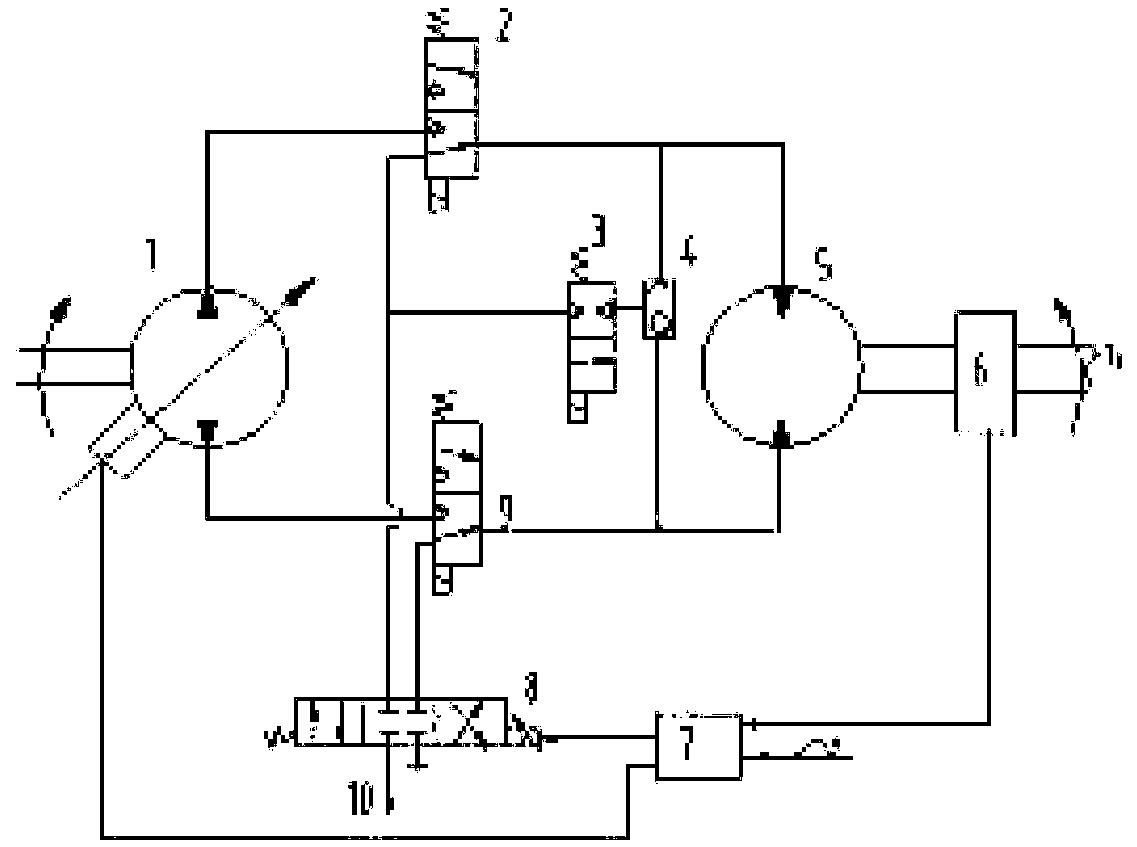

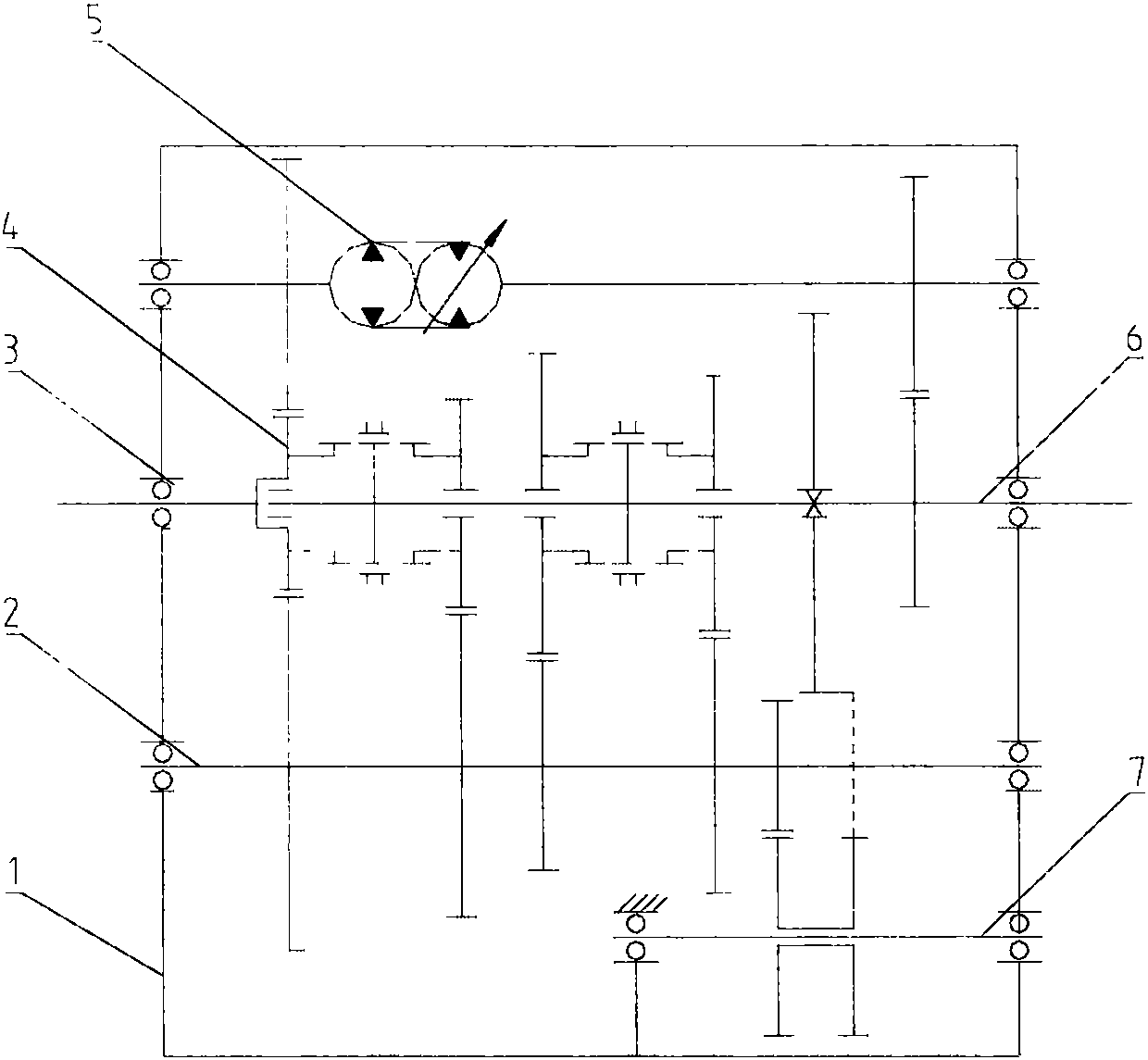

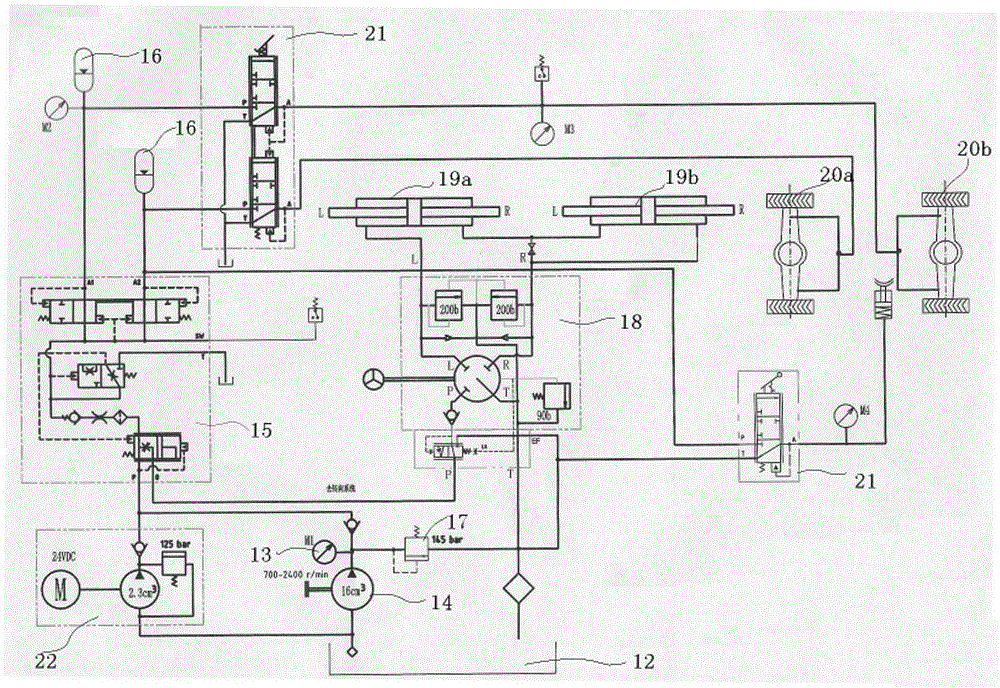

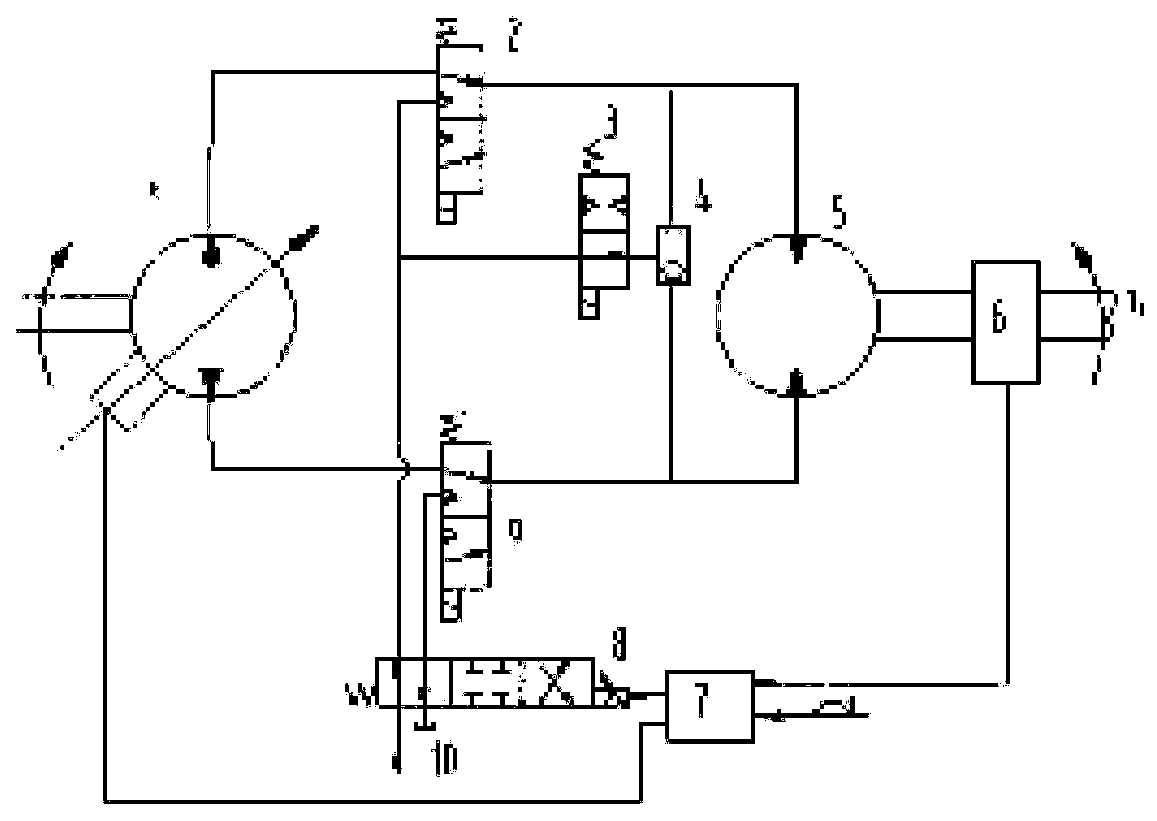

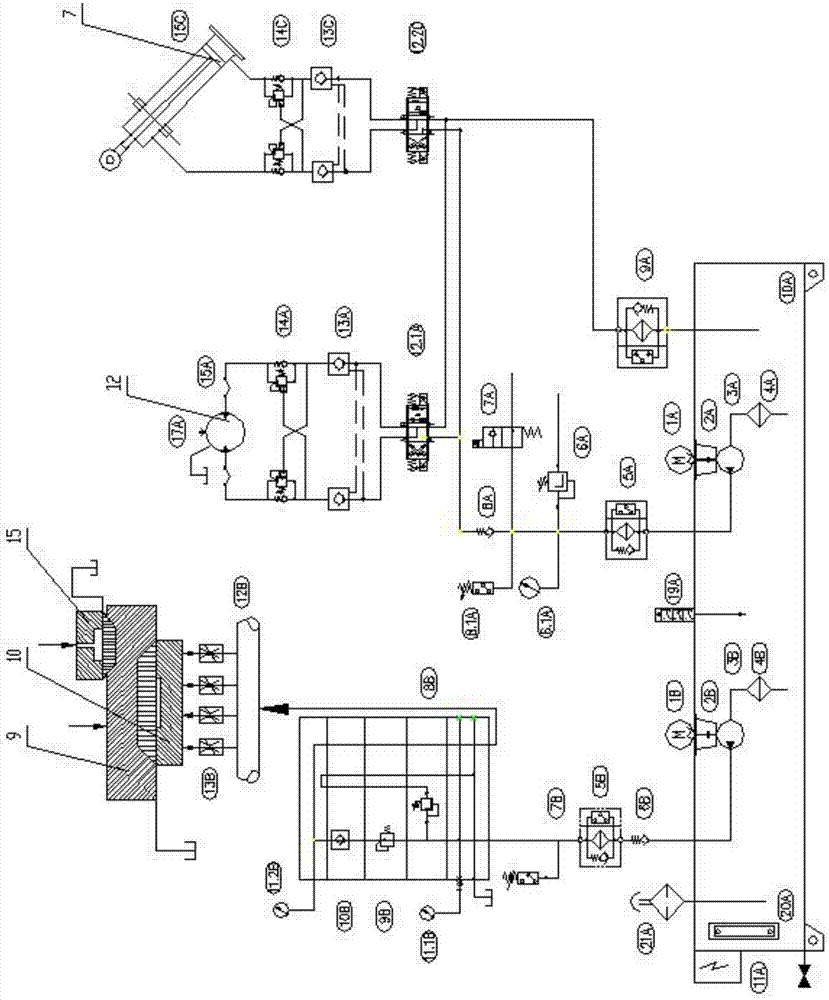

Multi-load hydraulic sensing system for single-power source and multi-system working

InactiveCN101954927AAchieve interlockRealize functionLifting devicesFluid steeringHydraulic motorLoad sensing

The invention relates to a multi-load hydraulic sensing system for single-power source and multi-system working, comprising a main liquid-control handle, an assistant liquid-control handle a load-sensitive variable pump, a load-sensing main steerer, a load-sensing assistant steerer, a front wheel steering oil cylinder, a back wheel steering oil cylinder, a front wheel hydraulic motor, a back wheel hydraulic motor and an operation actuating mechanism, wherein the load-sensitive variable pump is connected with a PVG multipath integrated valve, and the PVG multipath integrated valve is respectively connected with the main liquid-control handle and the assistant liquid-control handle, the front wheel steering oil cylinder and the rear wheel steering oil cylinder, and the operation actuating mechanism and also respectively connected with the load-sensing main steerer and the load-sensing assistant steerer through an anti-explosion two-position three-way electromagnetic valve; the load-sensing main steerer is connected with the front wheel steering oil cylinder, the load-sensing assistant steerer is connected with the back wheel steering oil cylinder, and the front wheel steering oil cylinder and the back wheel steering oil cylinder are connected through a three-position four-way electromagnetic valve; and a posture-adjusting valve and an anti-explosion two-position four-way electrohydraulic valve are arranged between the front wheel hydraulic motor and the back wheel hydraulic motor. The multi-load hydraulic sensing system can realize single-pump oil supply of a running system, a steering system and an operation actuating mechanism, and can also realize electric explosion prevention, two-way driving and all-around steering of the hydraulic system.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

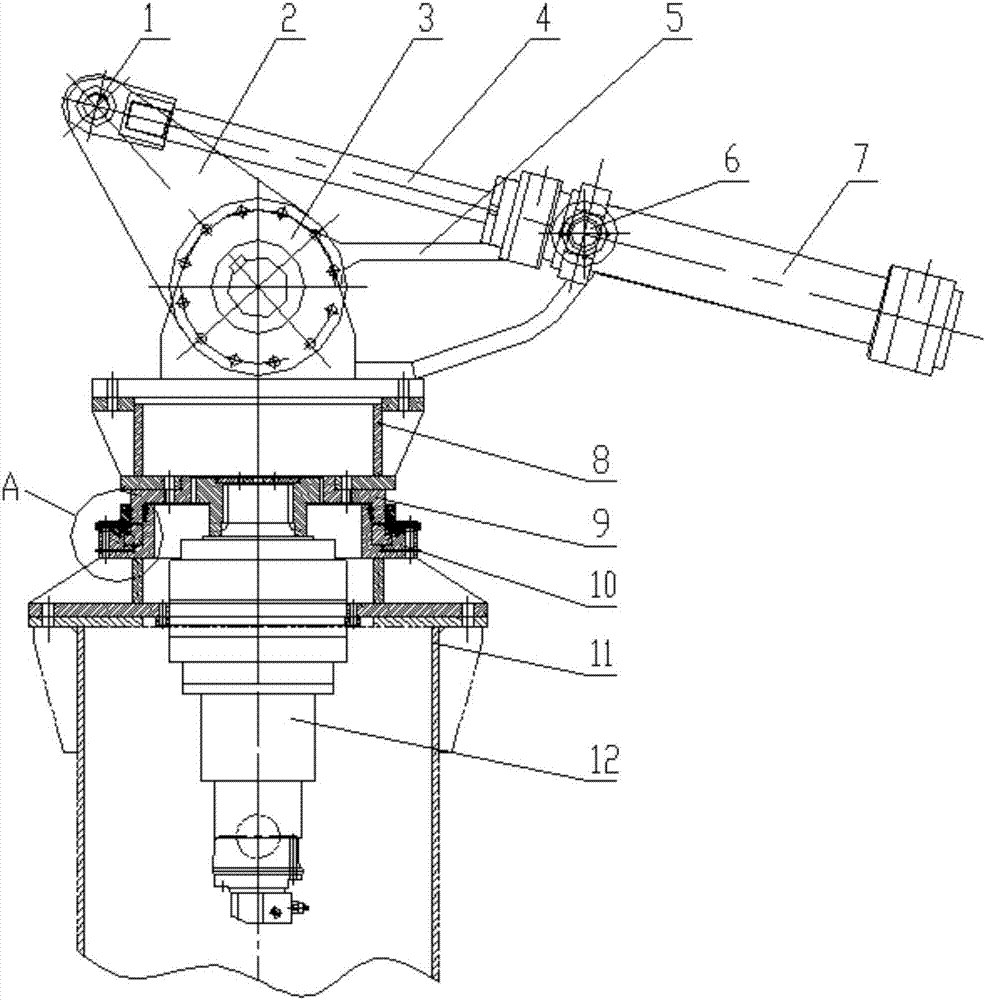

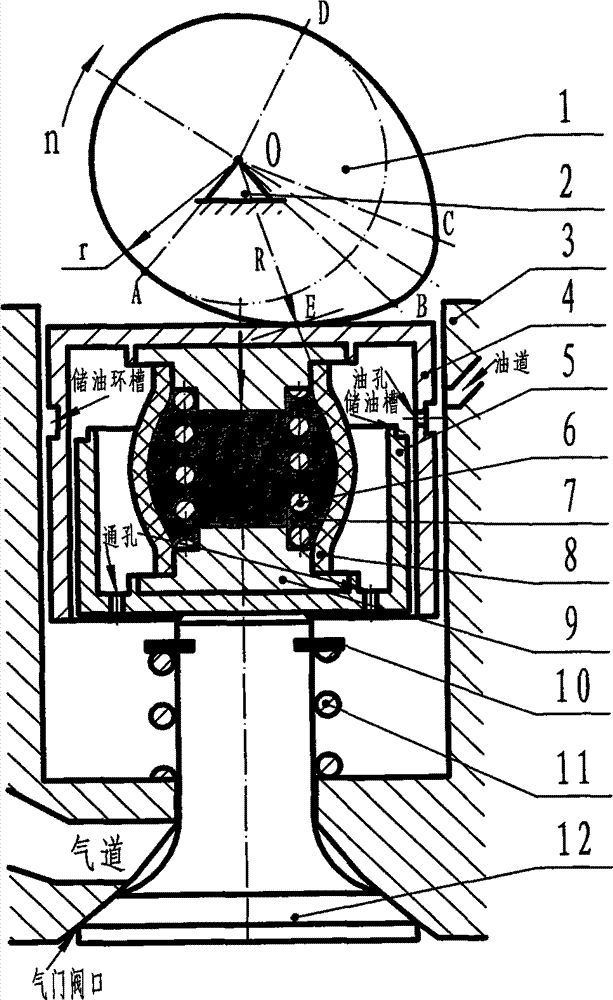

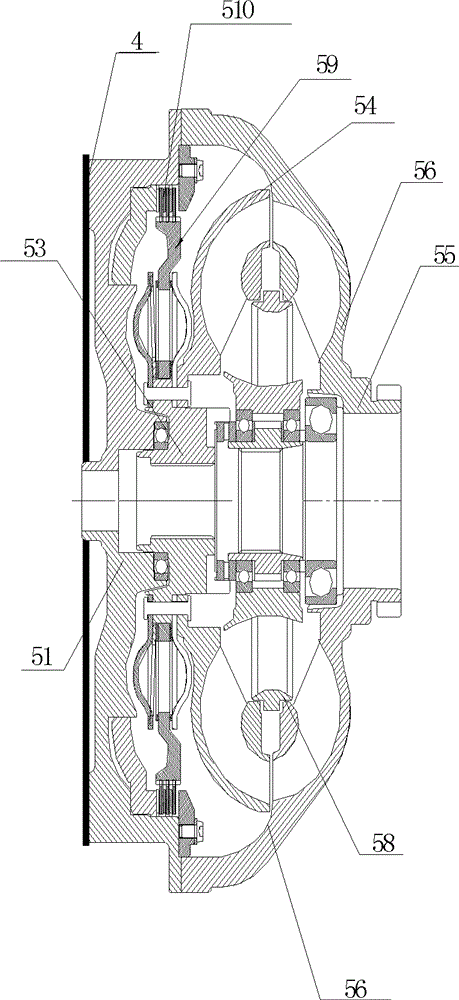

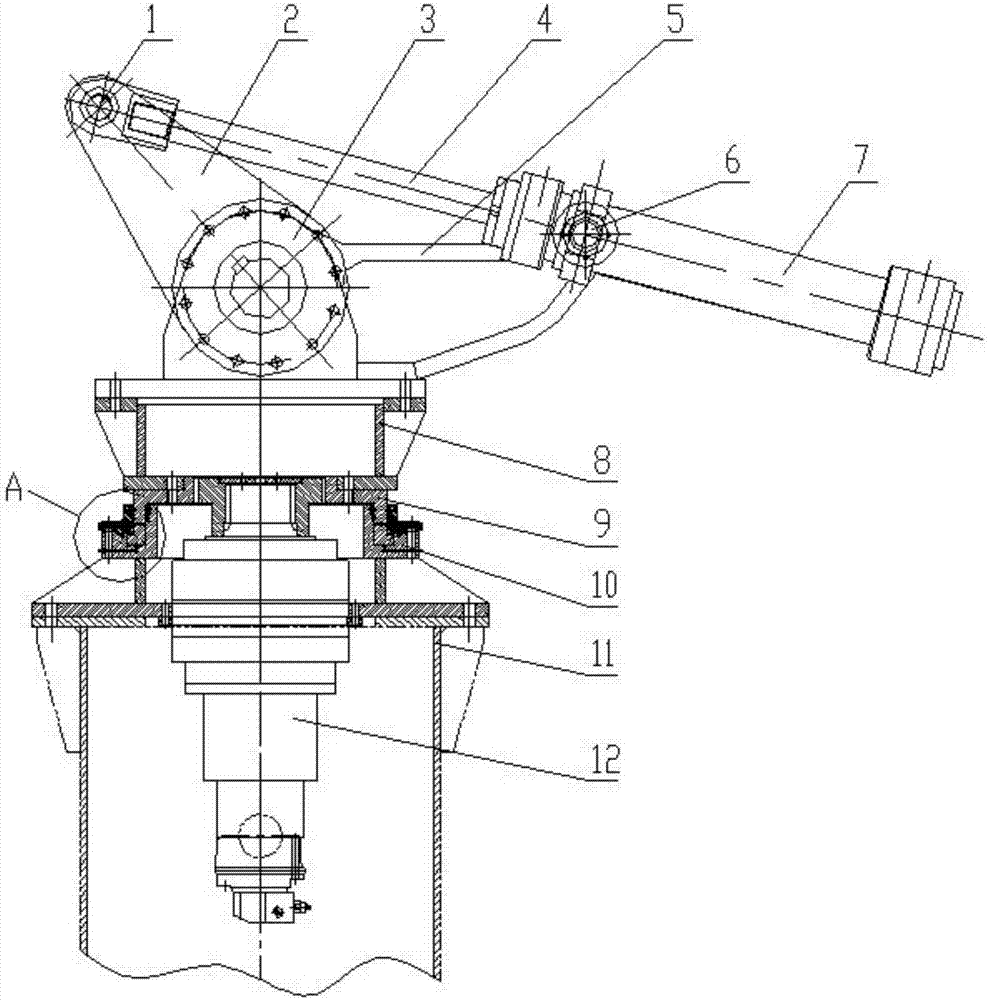

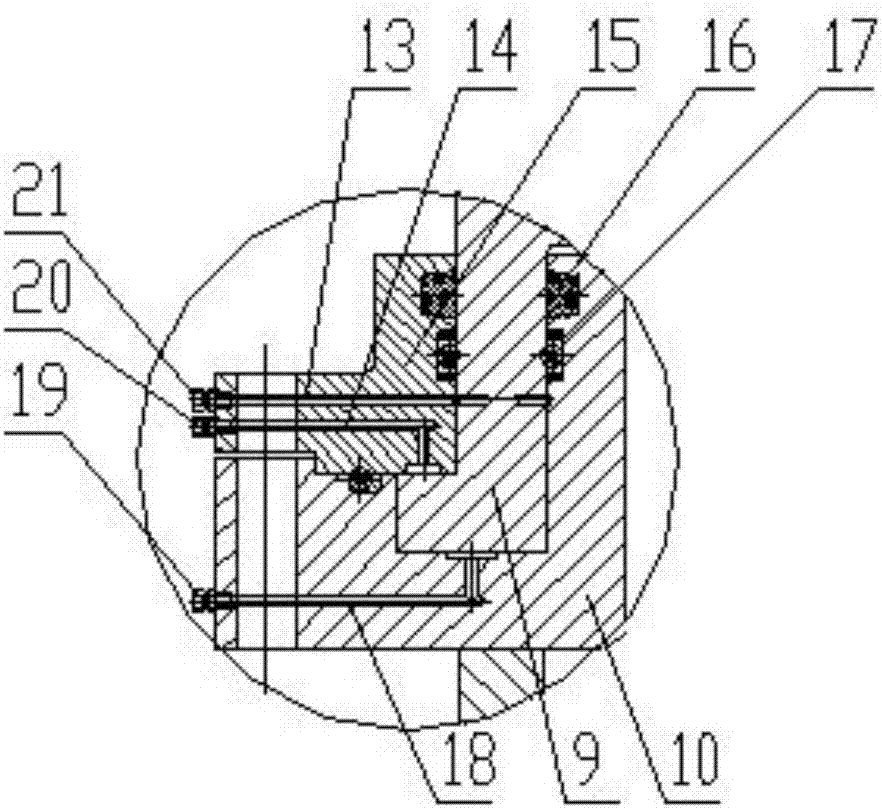

Azimuth rotation static-pressure support system of tower solar thermal power generation heliostat

ActiveCN106949106ASmall turning torqueLow costServomotor componentsServomotorsSupporting systemHydraulic motor

The invention relates to an azimuth rotation static-pressure support system of a tower solar thermal power generation heliostat. The tower solar thermal power generation heliostat includes a tower frame, a hydraulic motor speed reducer, an azimuth rotating unit and a pitching motion unit. The system designs chute and slide ring structures, and injects oil to the lower bottom end surface of a slide ring and the upper flat end surface of a chute through a pressure reducing valve, a one-way valve and a capillary throttling valve, so that the lubricating performance is greatly improved, the rotating torque of the tower heliostat azimuth is reduced by 70% compared with the torque of a mechanical drive, the azimuth rotation driving torque is largely reduced, the sizes of the driving device and the hydraulic motor are both largely reduced, and the cost of the azimuth driving device is correspondingly reduced.

Owner:TIANJIN OULU HEAVY MACHINERY MFG

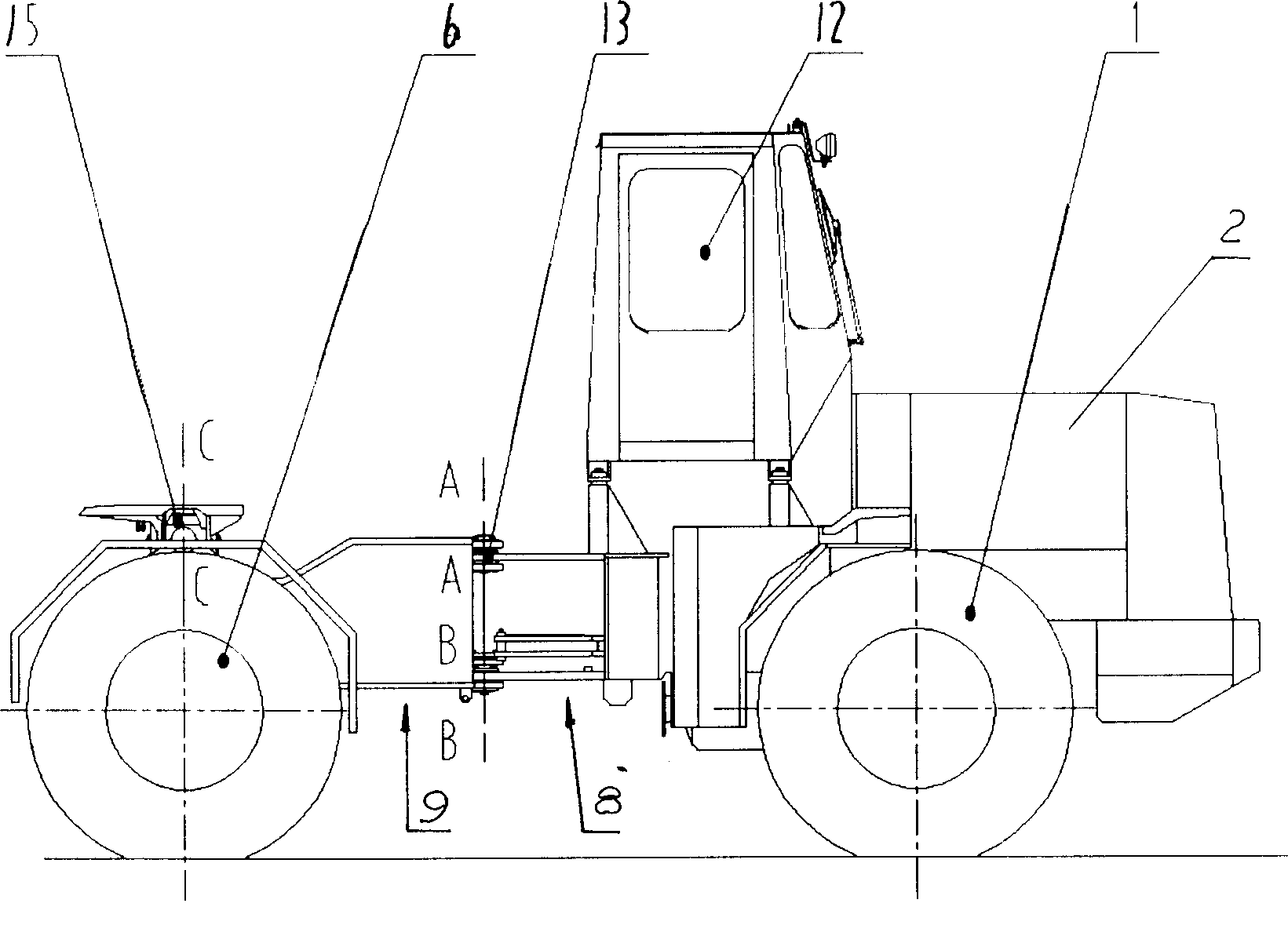

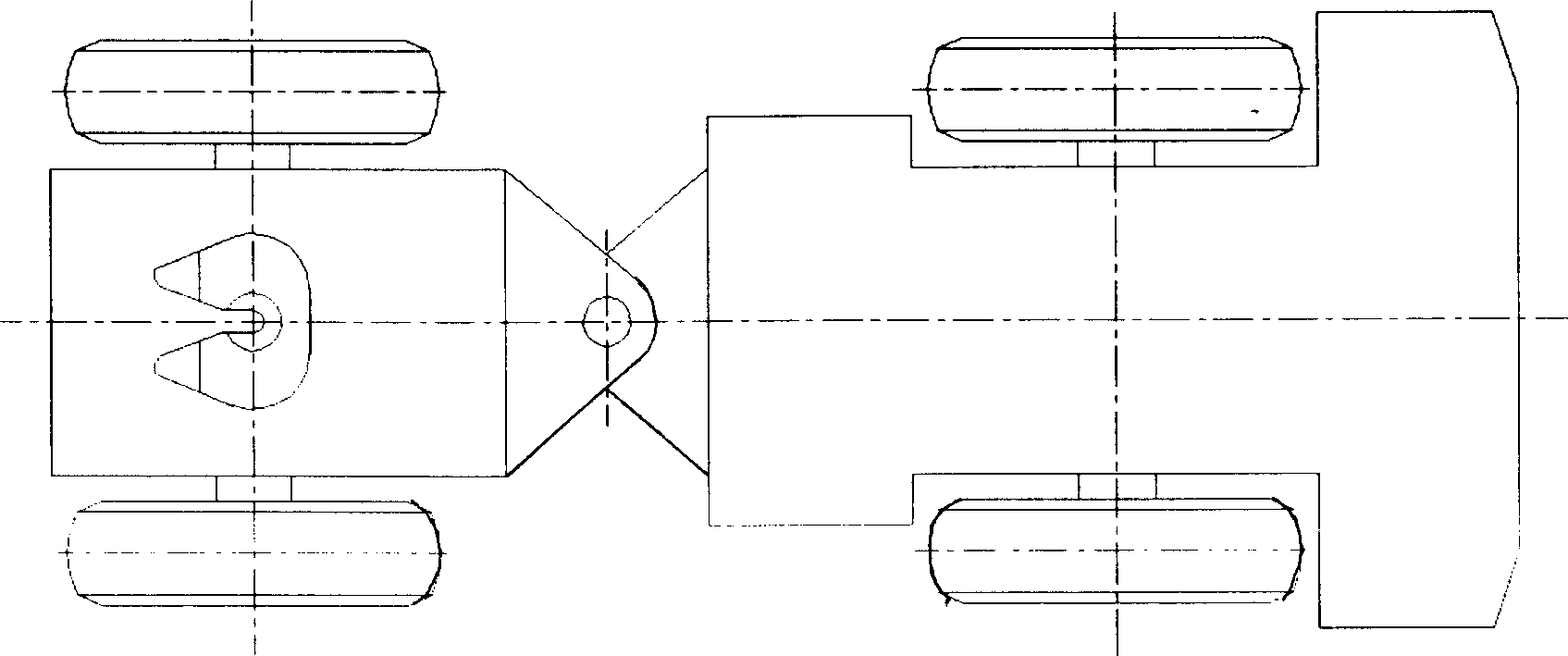

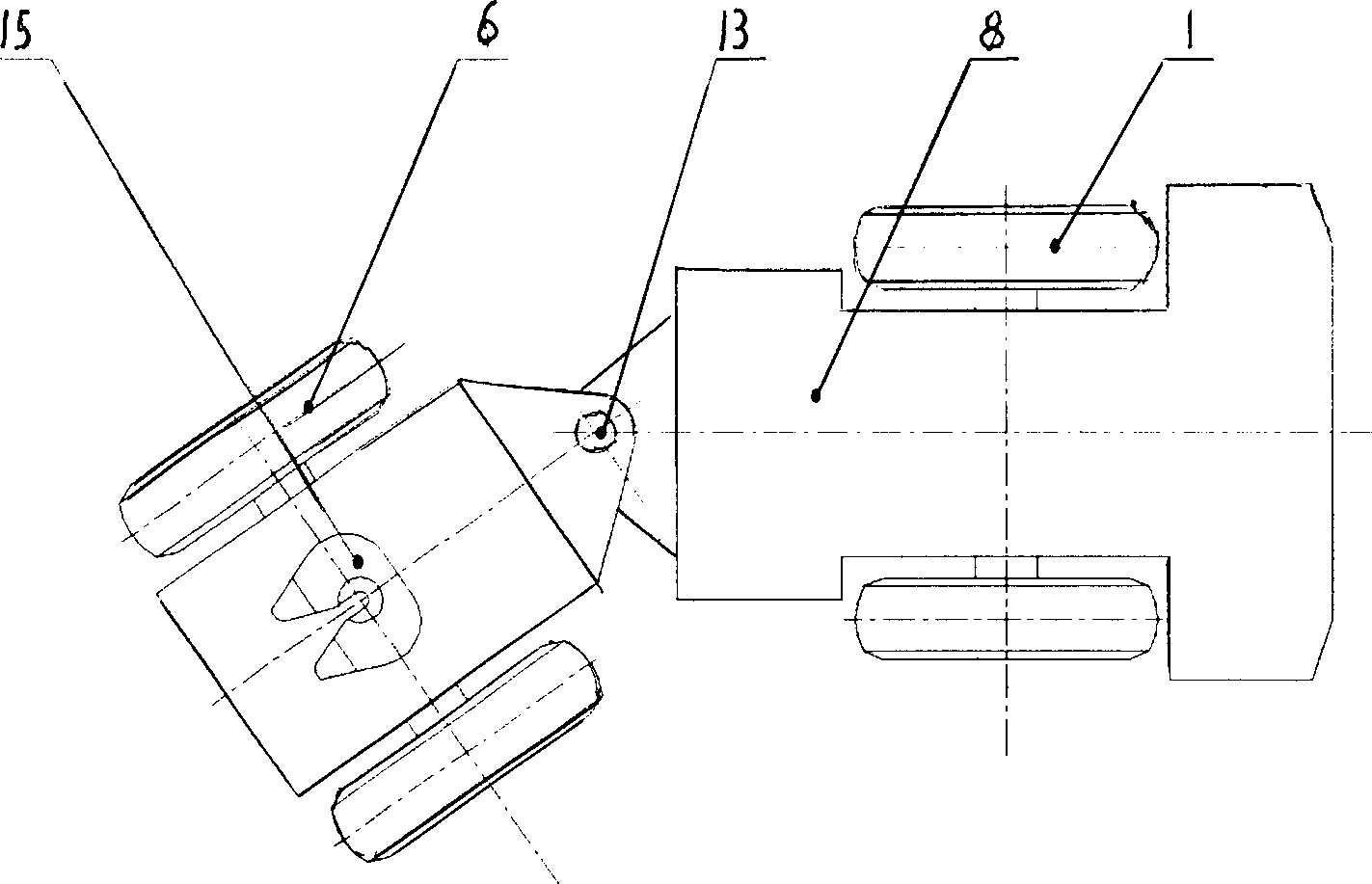

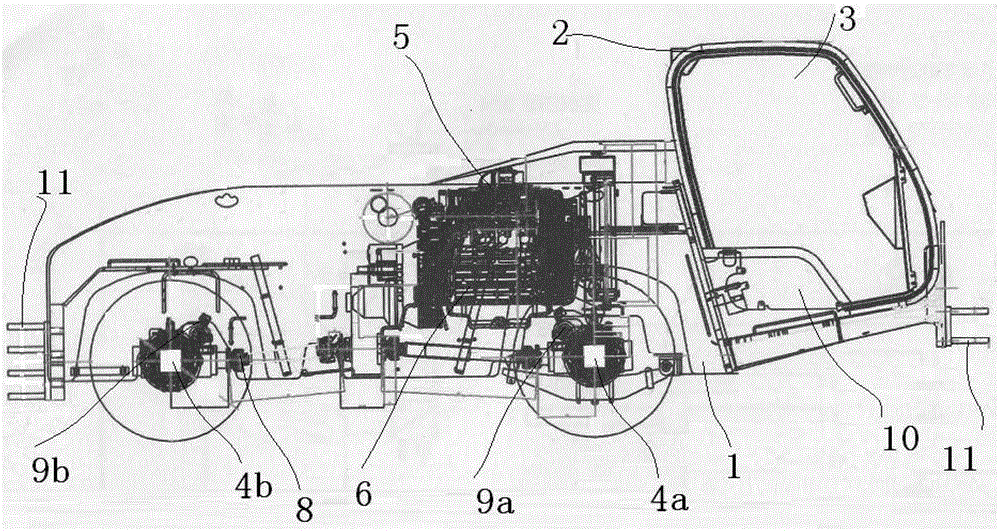

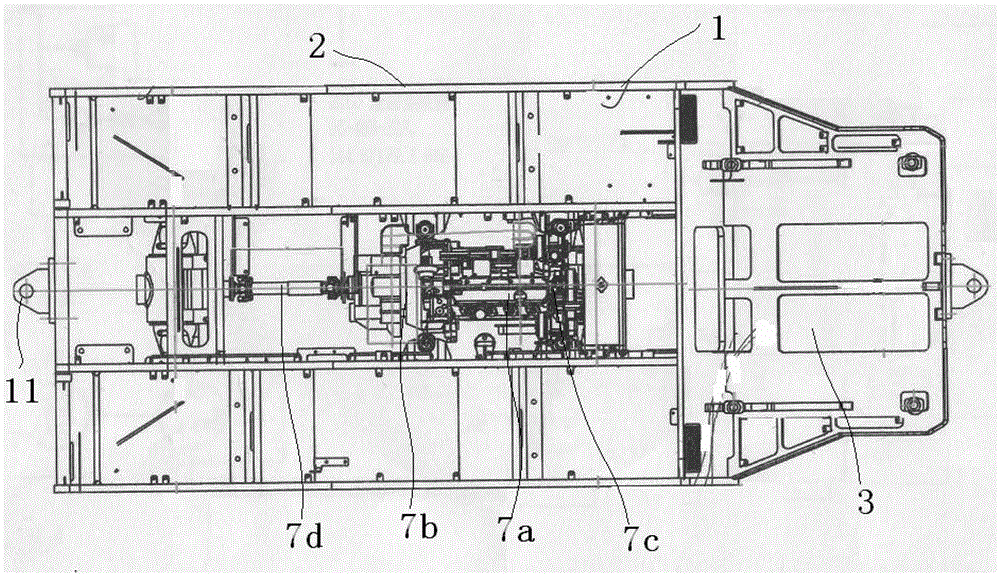

Great-tonnage low-speed tractor

InactiveCN1432501AIncreased turning radiusGood low speed stabilityTractorsControl devicesVehicle frameLow speed

The great-tonnage low-speed tractor includes chassis with front drive axle, back drive axle, driver cab and engine, the engine is connected via hydraulic torque converter to gear box, the gear box isconnected to front and back drive axles via the transmission shaft, and the chassis includes the front chassis and the back chassis hinged together. The tractor has high low speed stability, good heavy load starting characteristic, smooth gear shift, all-wheel drive, great traction, disc brack suitable for frequency braking, light and flexible steering and small turn radius. It is suitable for iron and steel works and other enterprise to perform low-speed short-distance great-tonnage transportation in narrow space.

Owner:长沙凯瑞重工机械有限公司

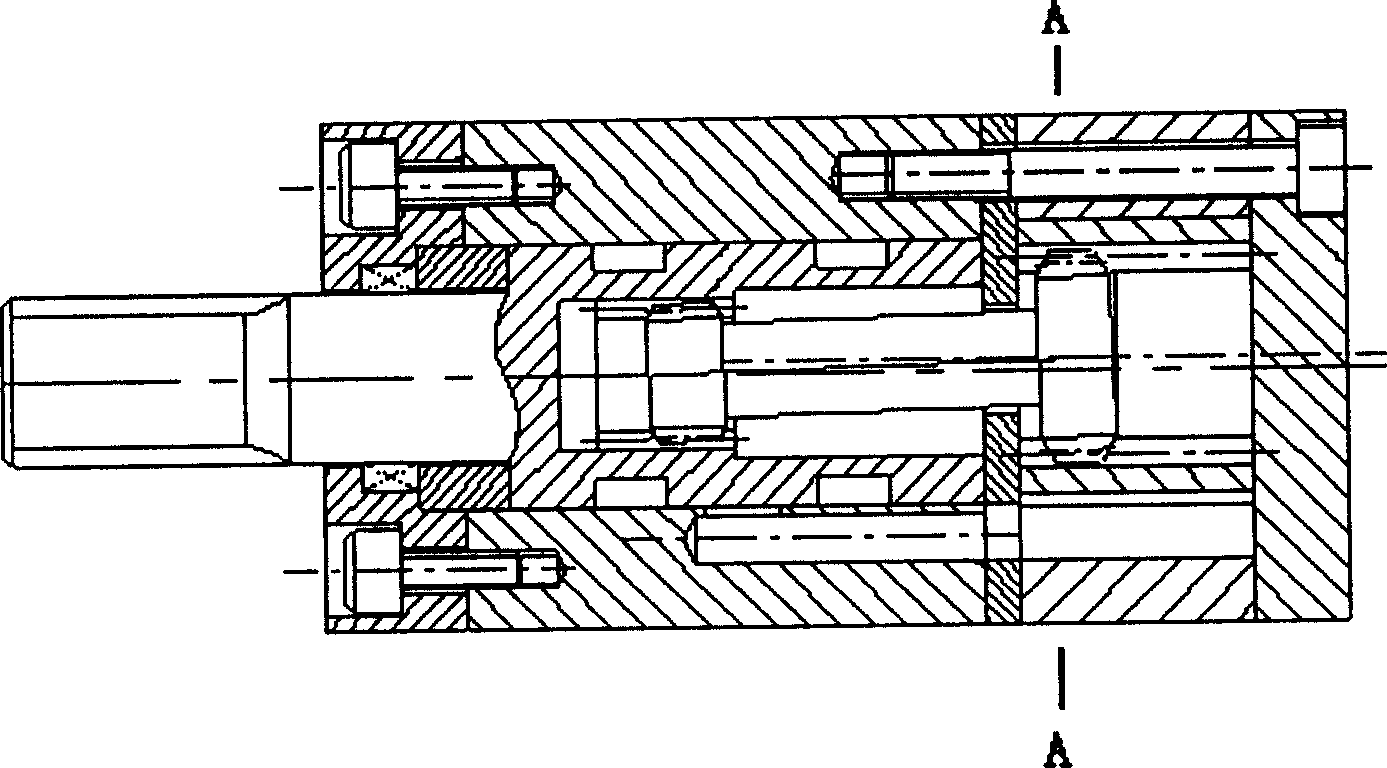

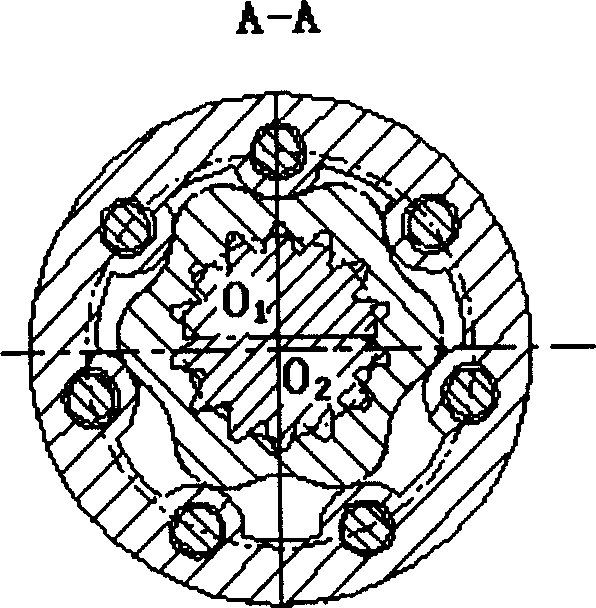

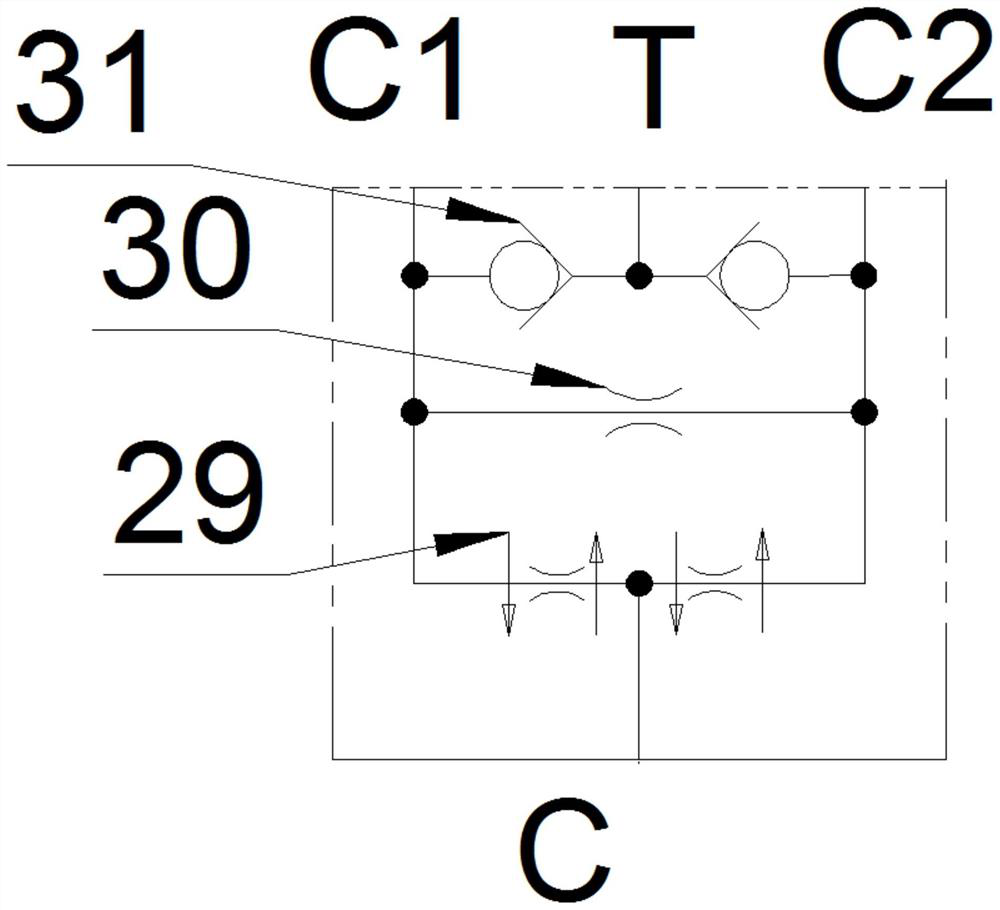

Dual cycloid hydraulic motor

InactiveCN1862032ALarge oil dischargeHigh output torqueFluid-pressure actuatorsRotary piston enginesCentre of rotationEngineering

A double-cycloid hydraulic motor comprises a output shaft, front and back end caps, a distributing valve, a motor base, internal and external rotors and several pin teeth. The output shaft is connected with the internal rotor each other. The pin teeth disposed between the external and internal rotors are engaged with the external and internal rotors at the same time. Between the internal and external rotors and the pin teeth are formed several independent enclosed tooth cavities, which are in communication with the distributing valve separately and then in communication with the fuel inlet and outlet through the distributing valve.

Owner:SHANGHAI NORMAL UNIVERSITY

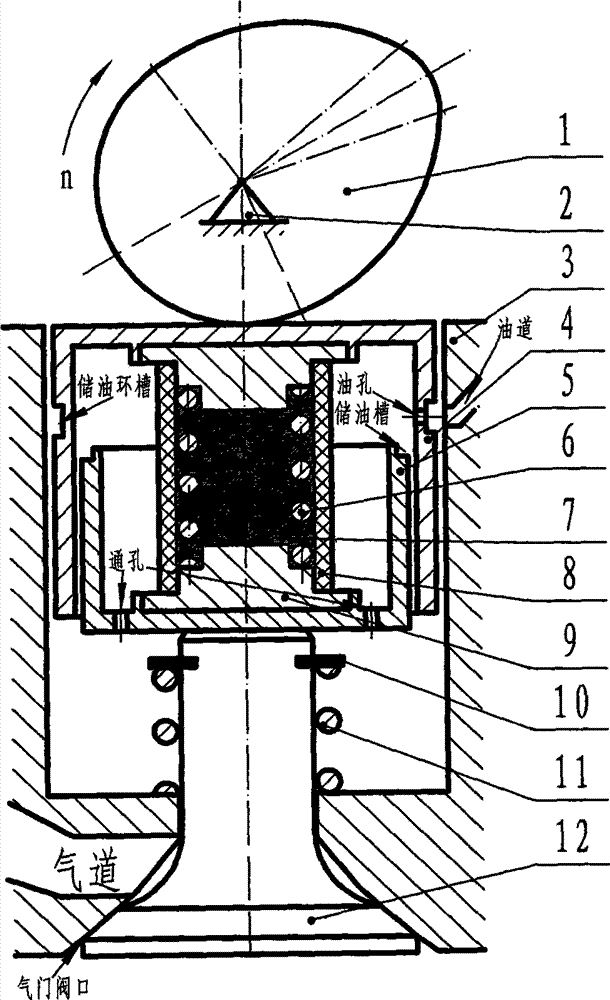

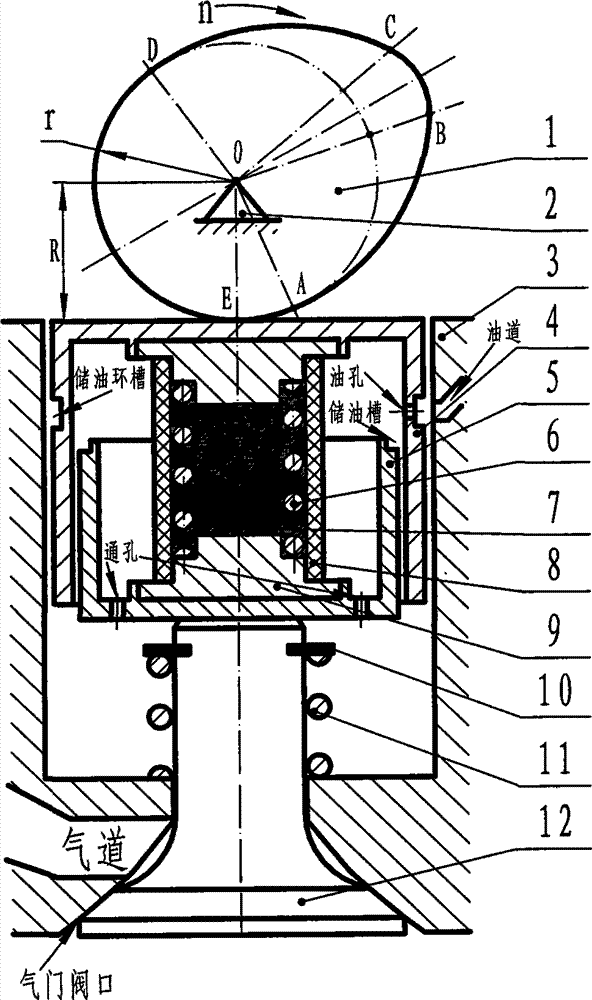

Piston engine valve timing and variable lift driving system

ActiveCN104121054AAvoid damageAvoid failureValve arrangementsMachines/enginesLow speedEffective length

The invention discloses a piston engine valve timing and variable lift driving system. On the basis of the shear thickening fluid critical speed phase change characteristic and the cam speed change curve driving rule, the effective length of a shear thickening tappet changing in the same direction as change of rotation speed of a cam is adaptively obtained according to the change of the rotation speed of the cam (or the rotation speed of an engine), the opening advance angle, the lift and the closing delay angle of a valve are automatically adjusted, and thus the dynamic property, the strengthening degree, the low temperature startability, the low speed stability, the economical efficiency and the exhaust cleanliness of the engine are improved. According to the technical scheme, the system is free of electronic control, simple in mechanical structure, reliable in work, convenient to arrange, low in cost, easy to maintain, smooth in engine power output and capable of being widely applied to driving valves of various piston engines.

Owner:范永建

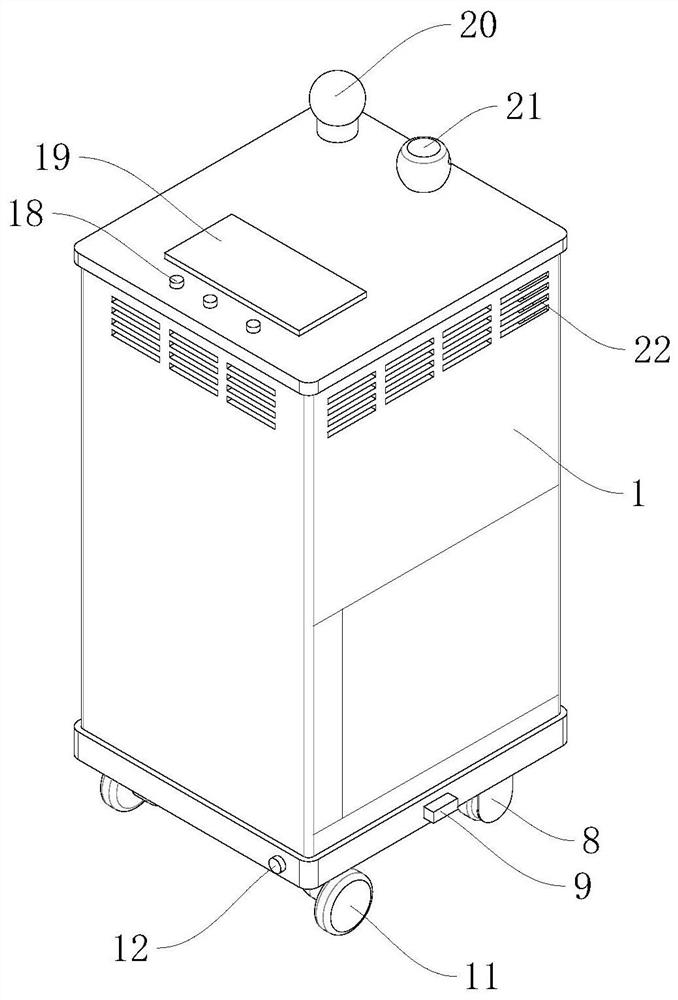

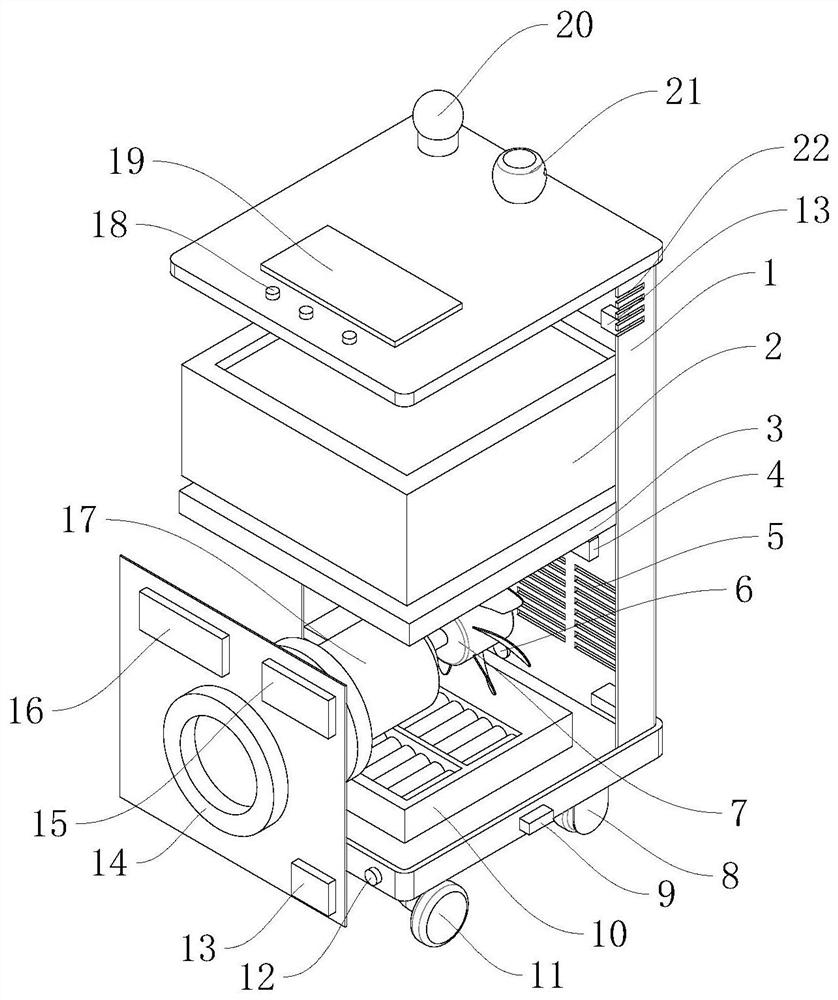

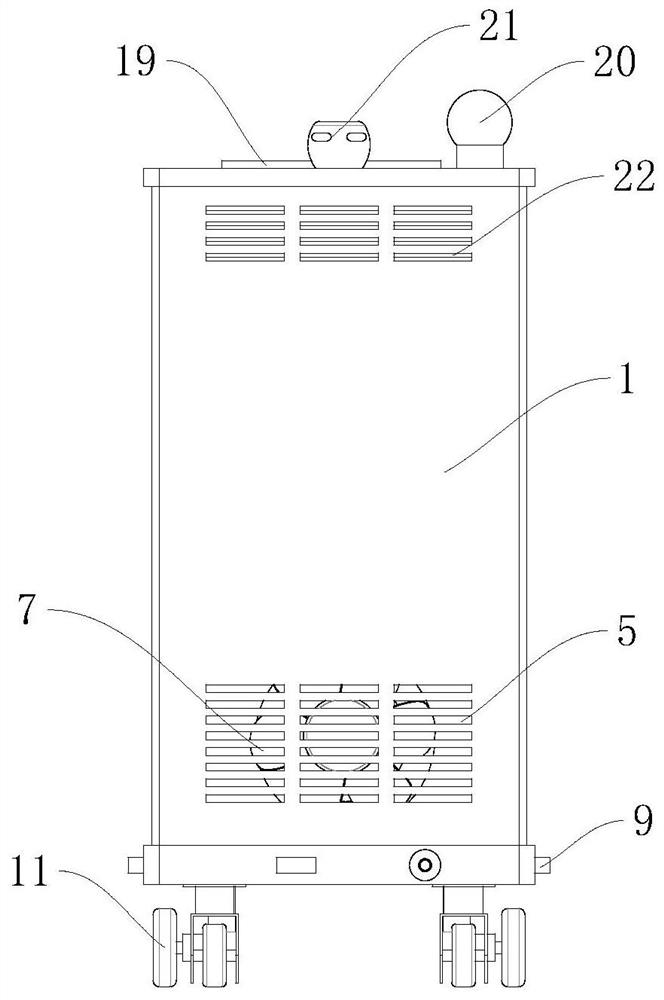

Movable plasma sterilizer

InactiveCN112902368AControl speedAchieve steeringMechanical apparatusLighting and heating apparatusDrive wheelEngineering

The invention discloses a movable plasma sterilizer, and belongs to the technical field of disinfection and sterilization devices. The movable plasma sterilizer comprises a mounting shell, wherein a mounting base is fixedly connected to the bottom end of the mounting shell, universal wheels are fixedly mounted at the front end of the bottom face of the mounting base, driving wheels are fixedly mounted at the rear end of the bottom face of the mounting base, falling sensors are fixedly connected to the side wall and the front wall face of the mounting base, and the front wall surface of the mounting base is also fixedly connected with an ultrasonic sensor; a power interface is embedded in the rear wall surface of the mounting base, and the power interface is electrically connected with the battery pack. The problems that in an existing design, only air sterilization work can be carried out at a fixed point, and effective air purification and germ sterilization effects cannot be carried out on air in places with large people flow, dense people and large space are effectively solved.

Owner:HEFEI UNIV OF TECH

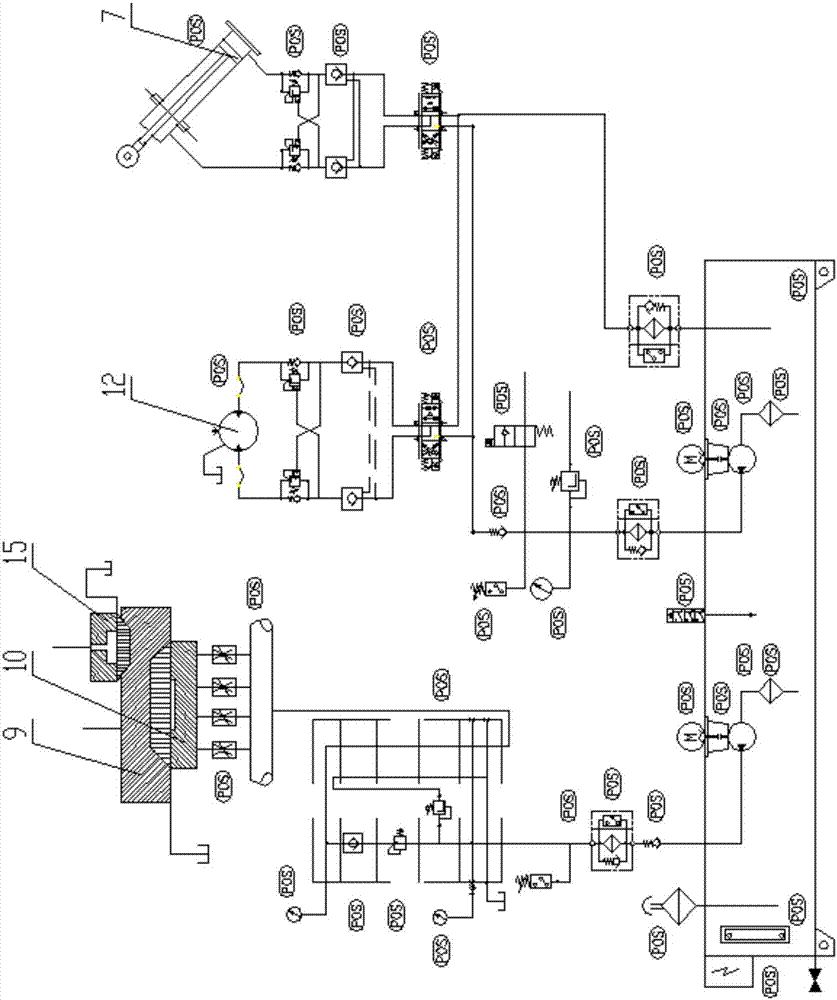

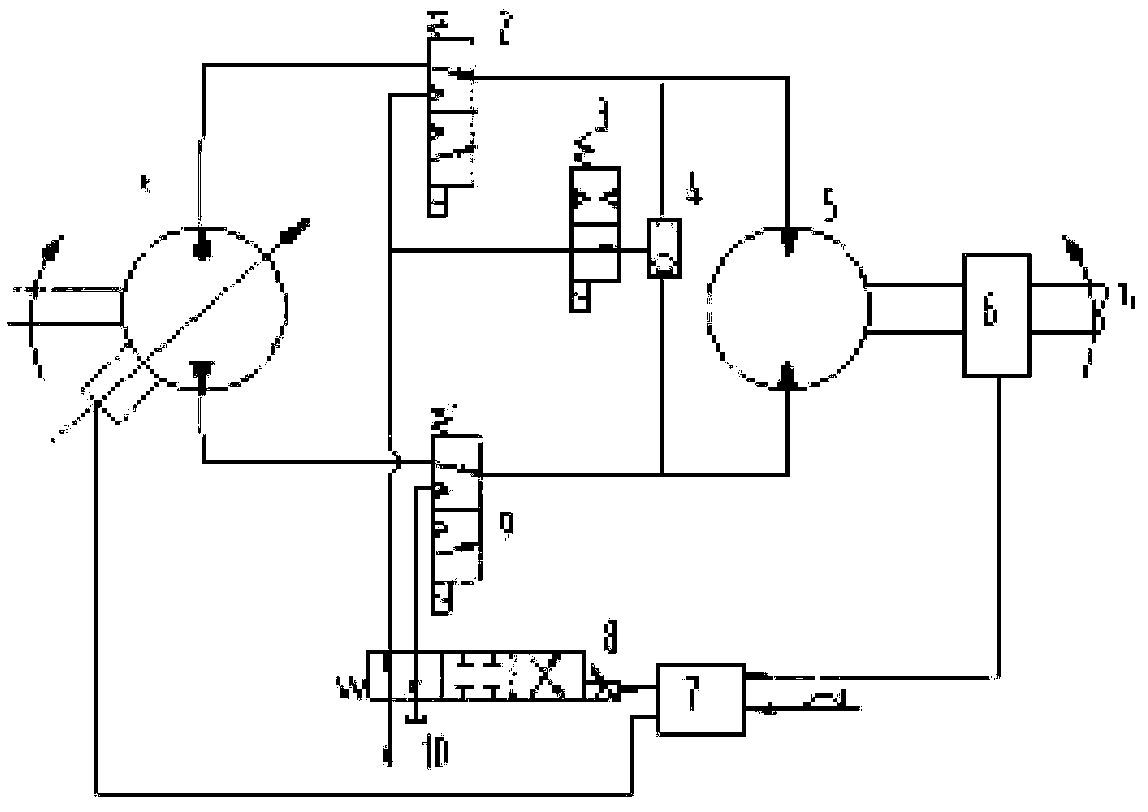

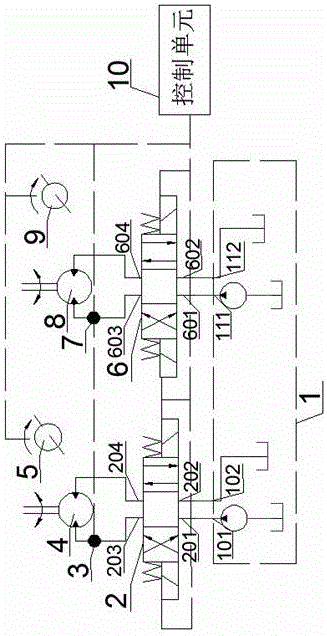

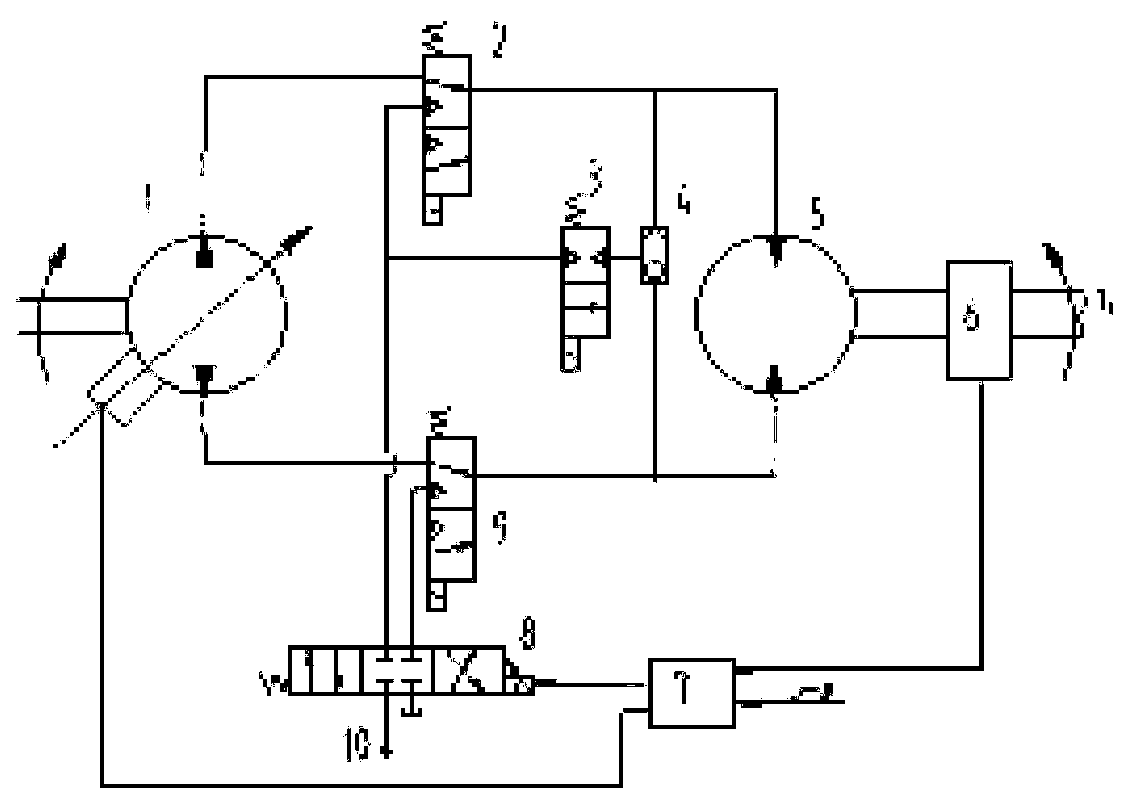

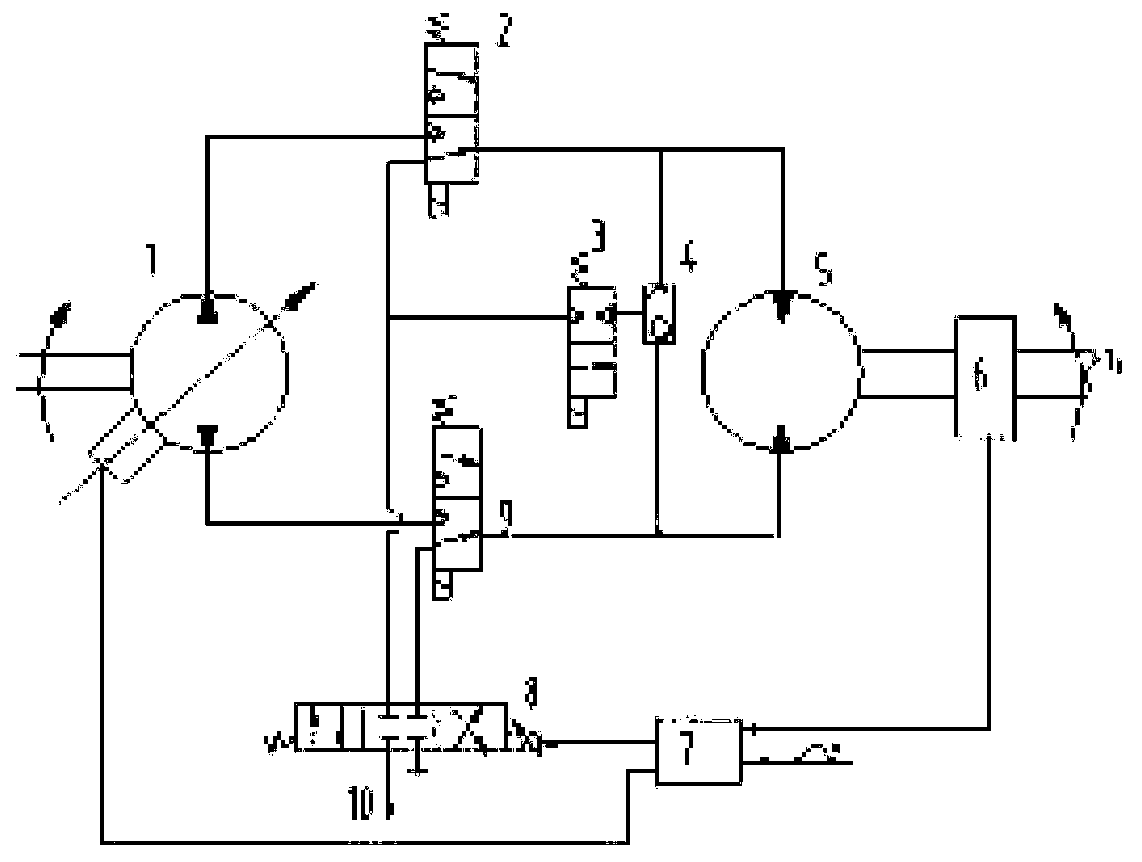

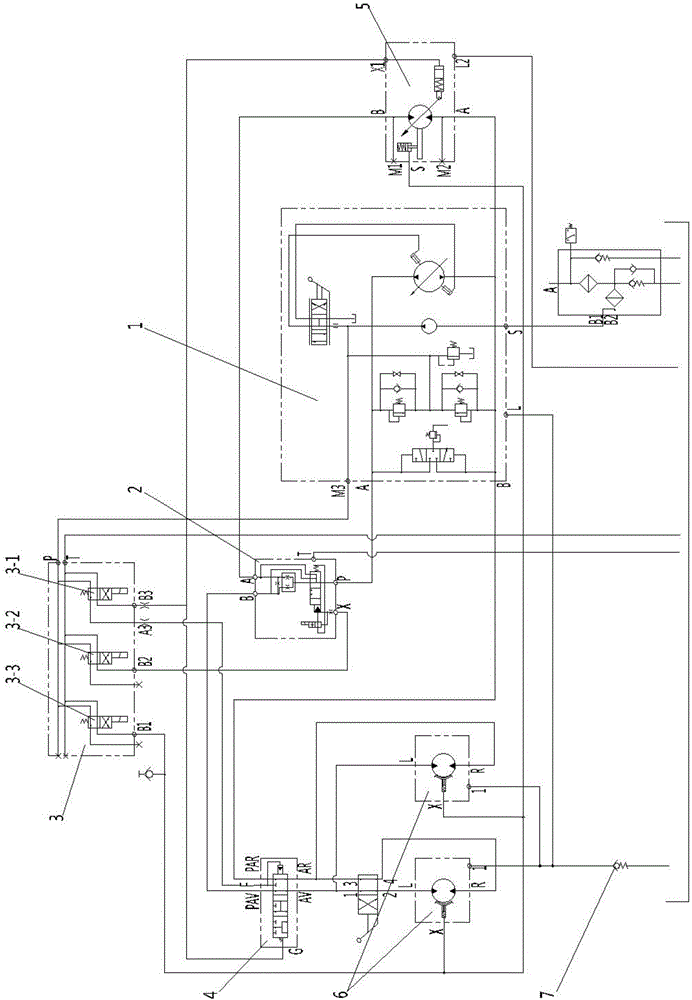

Valve-pump combined multi-mode hydraulic control system and control method thereof

ActiveCN108397447ATaking into account efficiencyVarious forms of controlServomotor componentsServomotorsClosed loopMode selection

The invention relates to a valve-pump combined multi-mode hydraulic control system and a control method thereof. The multi-mode hydraulic system comprises a pump control motor main loop, a valve control branch circuit, a mode switching unit and a control unit, wherein the valve control branch circuit is connected with the pump control motor main loop in parallel through the mode switching unit. The control method is characterized in that a controller has two layers of control strategies, wherein the first layer of control strategy is a mode selection strategy, and the system can be in variousworking modes such as the valve control mode, pump control mode and valve-pump combined control mode by controlling the mode switching unit; and the second layer of control strategy is a flow controlstrategy, one circuit is used for controlling the displacement of a proportional variable pump so as to adjust the flow in the pump control mode, the other circuit is used for controlling an opening of a proportional reversing valve so as to adjust the flow in the valve control mode, and finally, the rotating speed of a hydraulic motor is controlled through a closed loop. The valve-pump combined multi-mode hydraulic control system can be used for hydraulic power devices with obvious speed regulation processes, such as a hydraulic elevator and an engineering machinery rotary table, different working modes are adopted in different speed regulation stages, so that the comprehensive speed regulation performance of the system is improved.

Owner:CHINA UNIV OF MINING & TECH

Hydraulic walking mechanism for tunnel lining working jumbo and control method

ActiveCN106274922AImprove performanceImprove efficiencyRotary prime mover transmissionHydraulic motorDrive wheel

The invention discloses a hydraulic walking mechanism for a tunnel lining working jumbo and a control method. Hydraulic motors on the left side and the right side of a hydraulic oil driver of a hydraulic pump station are connected and then connected with drive wheel axles on the left side and the right side through couplers, so the jumbo is driven to walk; in order to make the jumbo advance or retreat, bidirectional quantitative hydraulic motors are adopted as the hydraulic motors, and the hydraulic motors are rotated forward or backward by changing the flowing direction of hydraulic oil in the hydraulic motors; in order to synchronously control a left drive wheel and a right drive wheel of the jumbo, through signals of pressure sensors between a proportional electromagnetic valve and the hydraulic motors and encoders on driven wheels, the proportional electromagnetic valve is controlled so as to control the rotating speed of the hydraulic motors; a drive mechanism adopted by the hydraulic walking mechanism is simple in structure, high in reliability and convenient to control.

Owner:NANTONG TIEJUN MACHINERY CO LTD

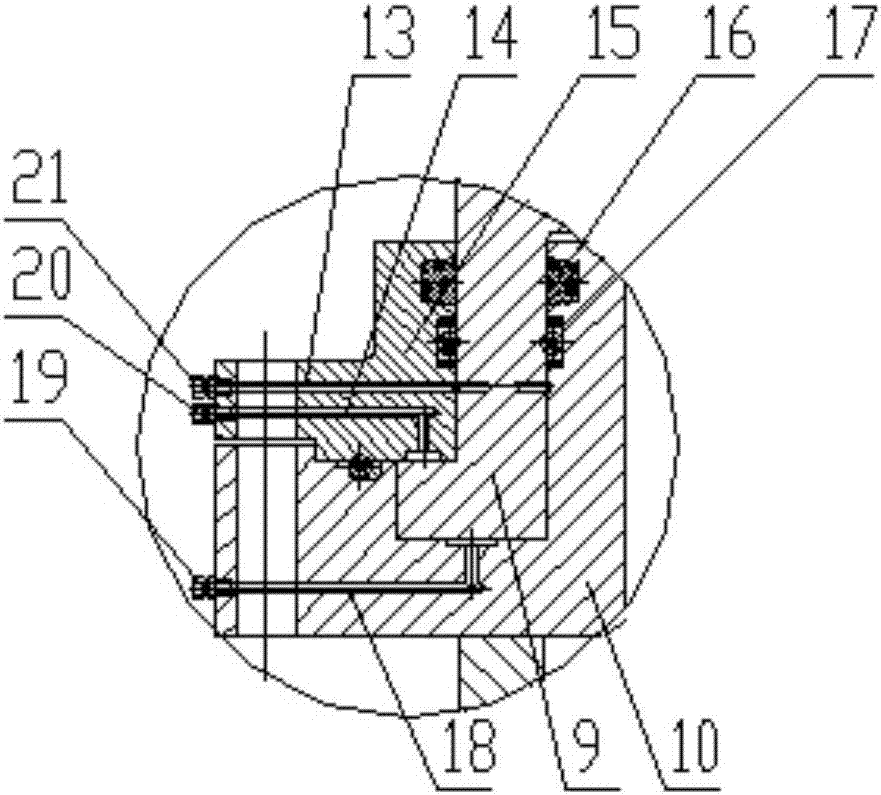

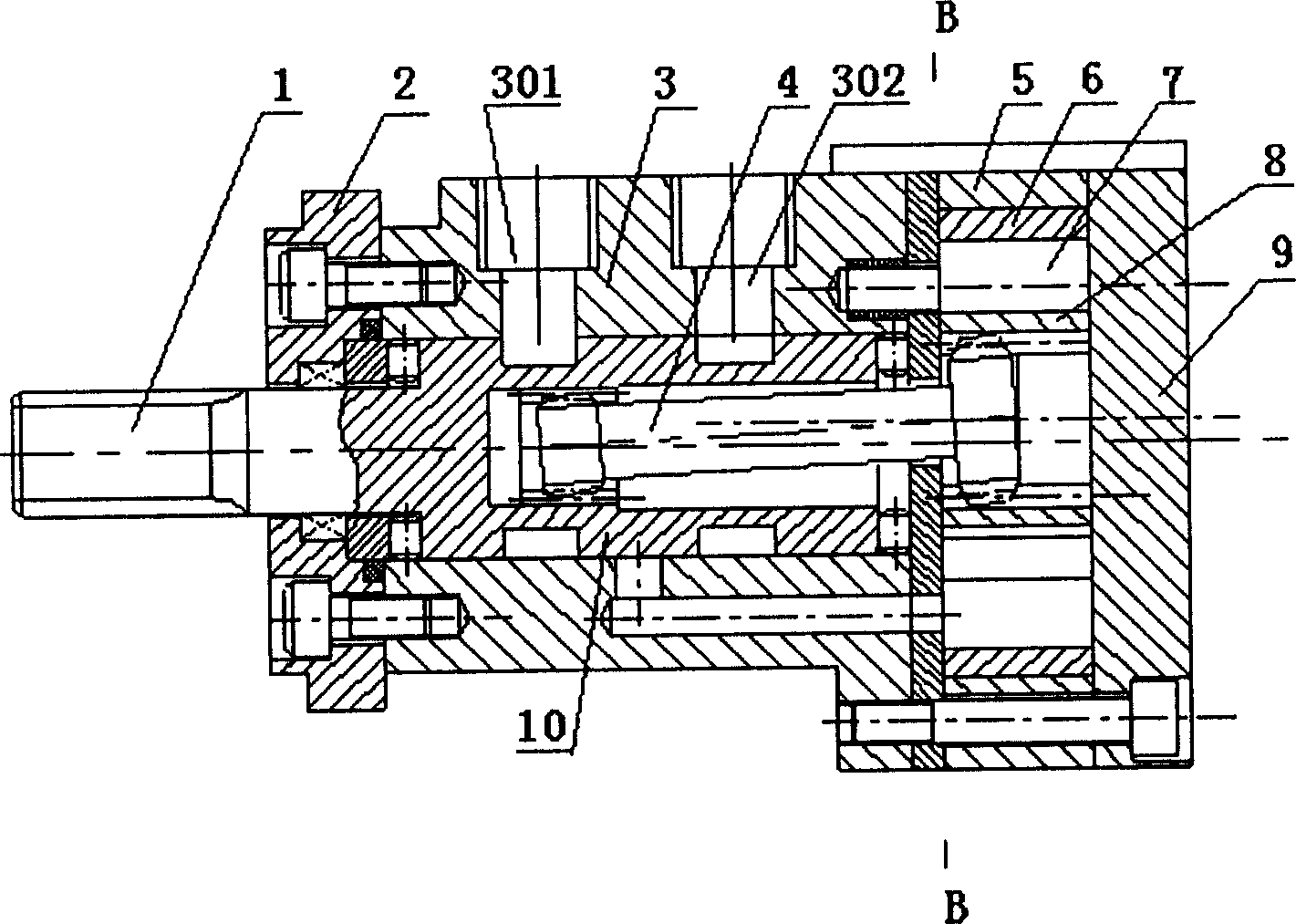

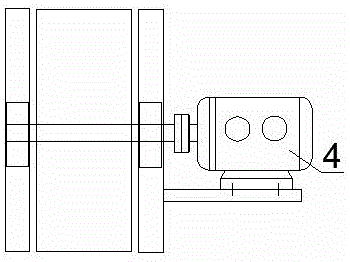

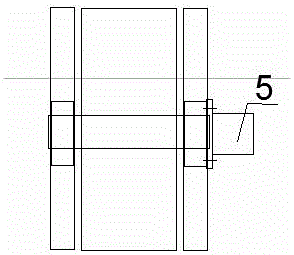

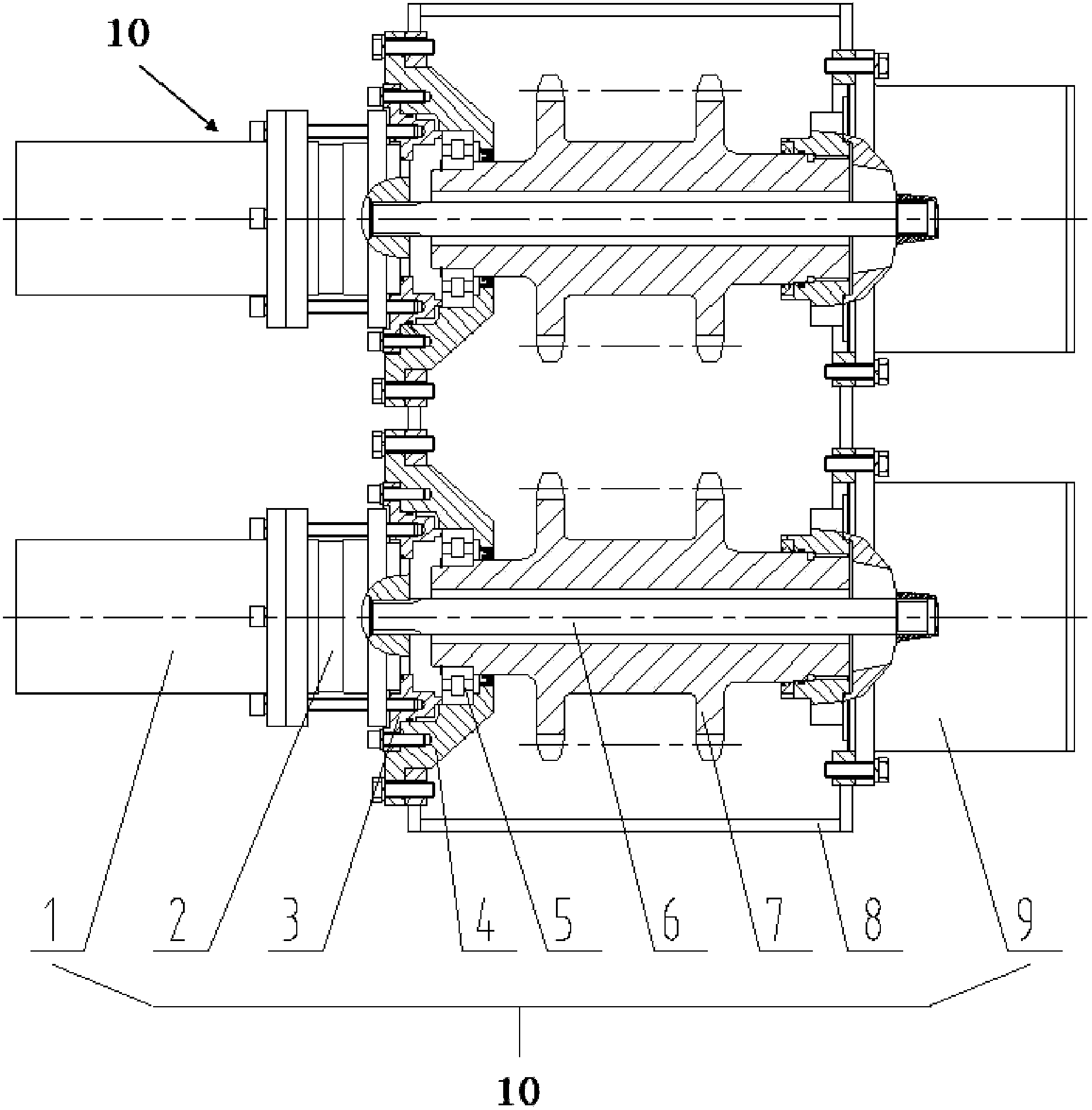

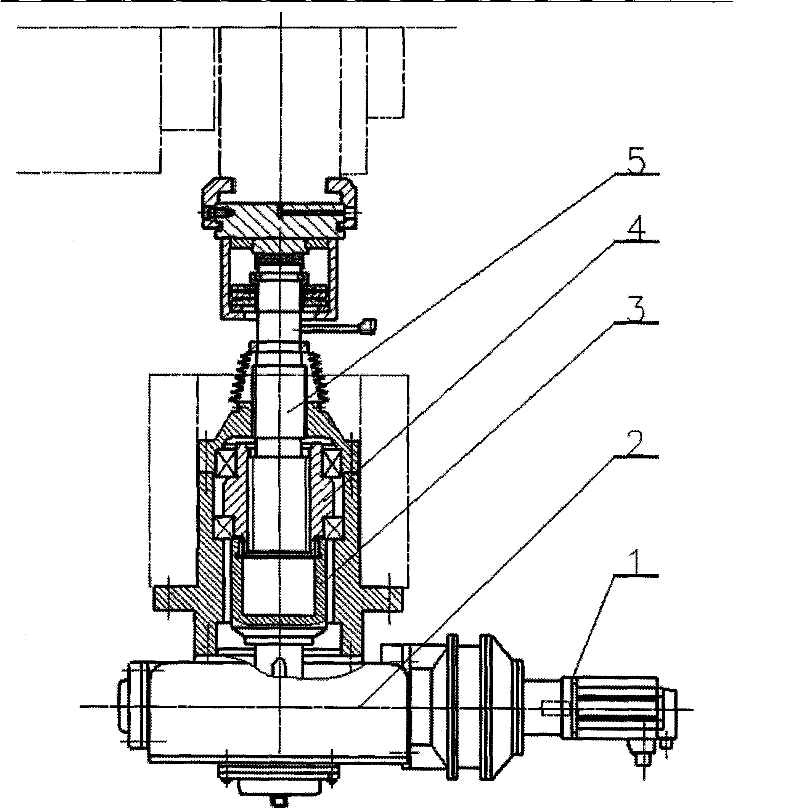

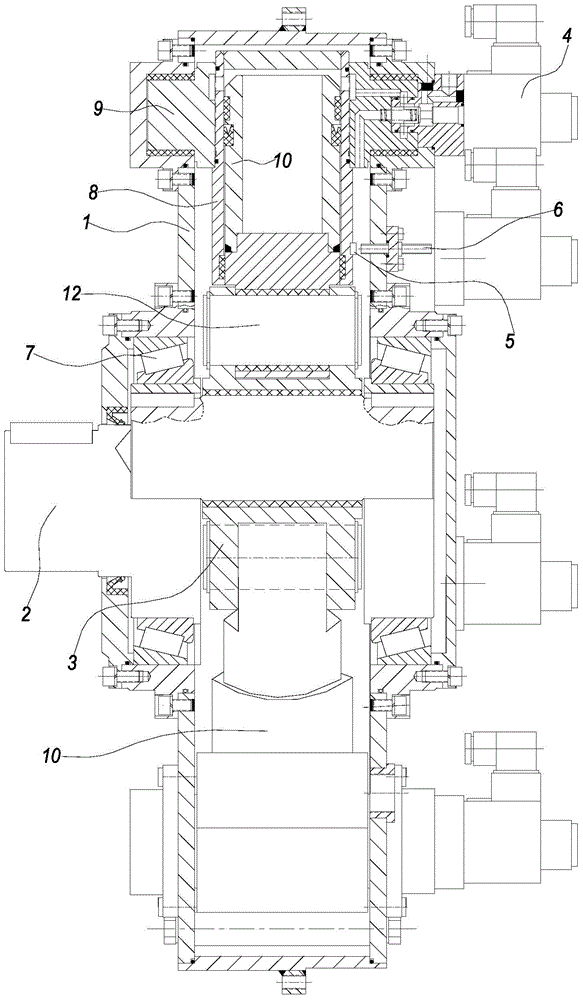

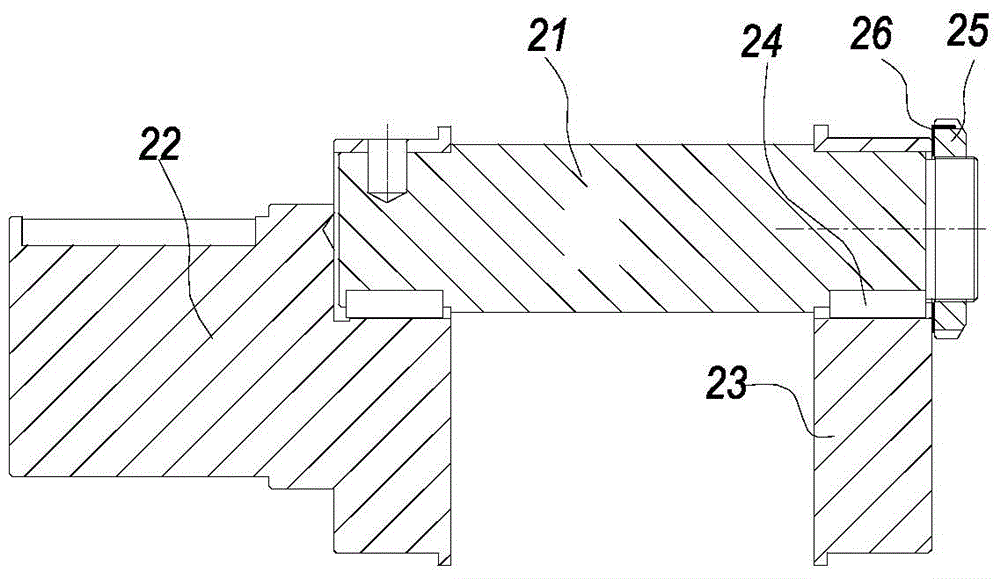

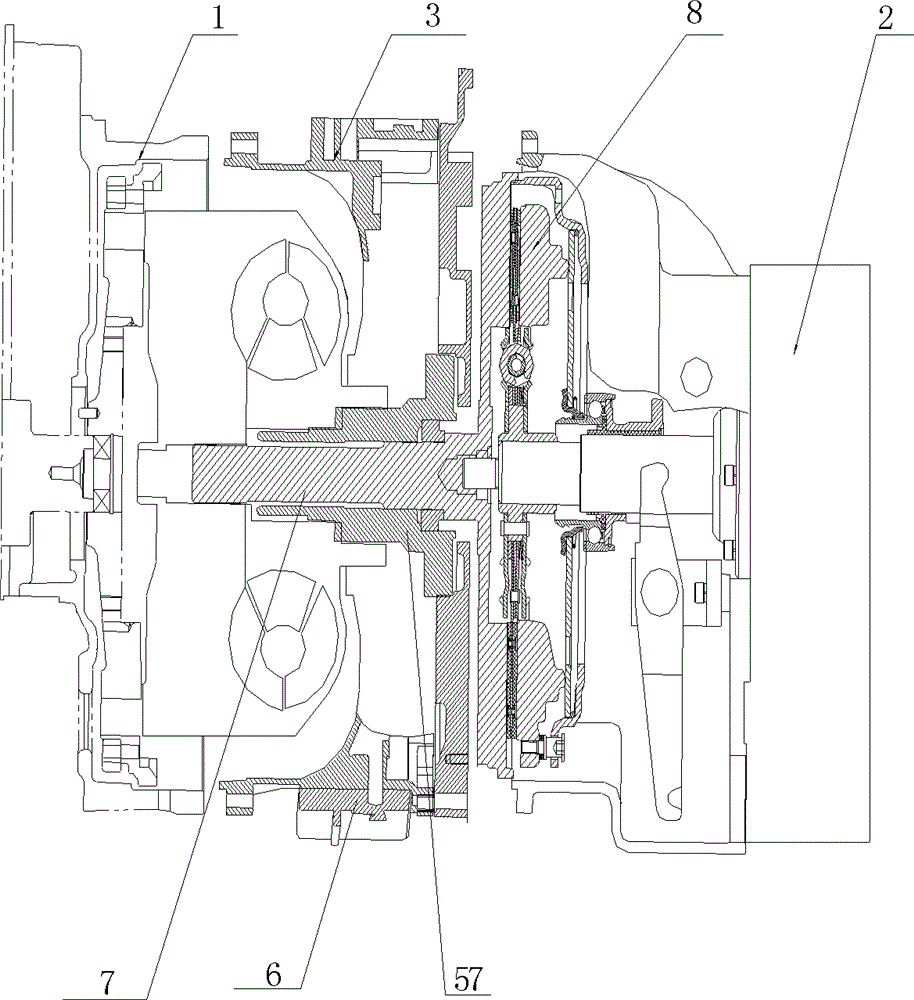

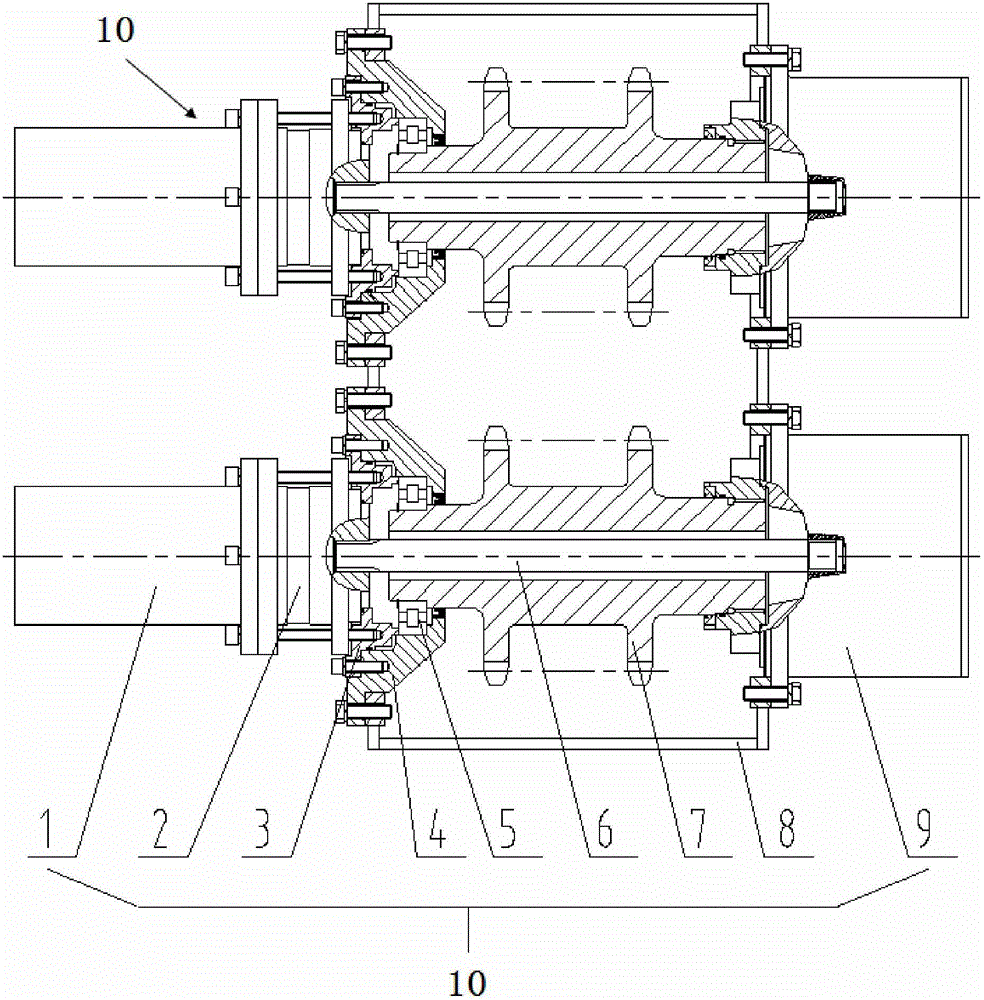

Injection head driving device for coiled tubing

ActiveCN103510891AEasy to installEfficient use ofDrilling rodsDrilling casingsHydraulic motorCoiled tubing

The invention discloses an injection head driving device for coiled tubing, and belongs to the field of petroleum. The injection head driving device for the coiled tubing comprises two sets of hydraulic motor driving mechanisms arranged in an injection head box body, and each set of hydraulic motor driving mechanism comprises a hydraulic motor, a hydraulic brake device, a connecting disc, a bearing block, a planetary reducer, a bearing, a sprocket shaft and a central shaft. The hydraulic motors and the planetary reducers are mounted on the two sides of the injection head box body respectively, the sprocket shafts are hollow shafts, the central shafts penetrates through the sprocket shafts, one end of each central shaft is connected with the output end of each hydraulic motor, and the other end of each central shaft is connected with the input end of each planetary reducer. The injection head driving device for the coiled tubing has the advantages of being compact and symmetrical in structure, good in balance performance, easy to lift, operate and mount, high in driving efficiency and good in low speed stability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

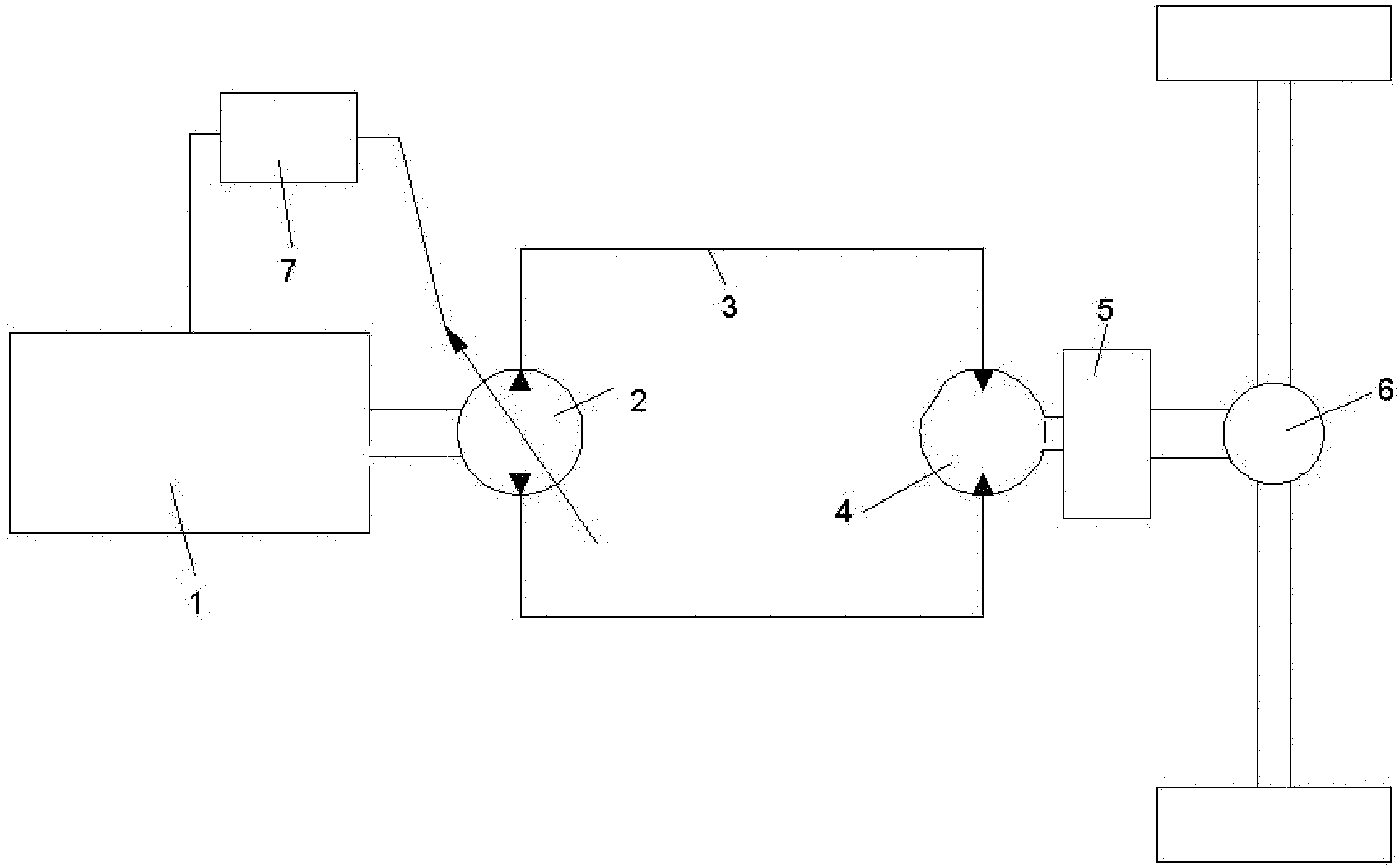

Walking transmission system for airport equipment

InactiveCN102101436AImprove controllabilityIncreased operating comfortControl devicesHydraulic motorEngineering

The invention provides a walking transmission system for airport equipment, which ensures the speed controllability and comfortableness of the airport equipment, can realize continuous variable transmission and ensures operating comfortableness. The system comprises an input shaft and a variable pump which is connected with the flywheel end of an engine, wherein the oil inlet and the oil outlet of the variable pump are communicated with the oil outlet and the oil inlet of a hydraulic motor through hydraulic pipelines respectively.

Owner:江苏嘉捷特种车辆制造有限公司

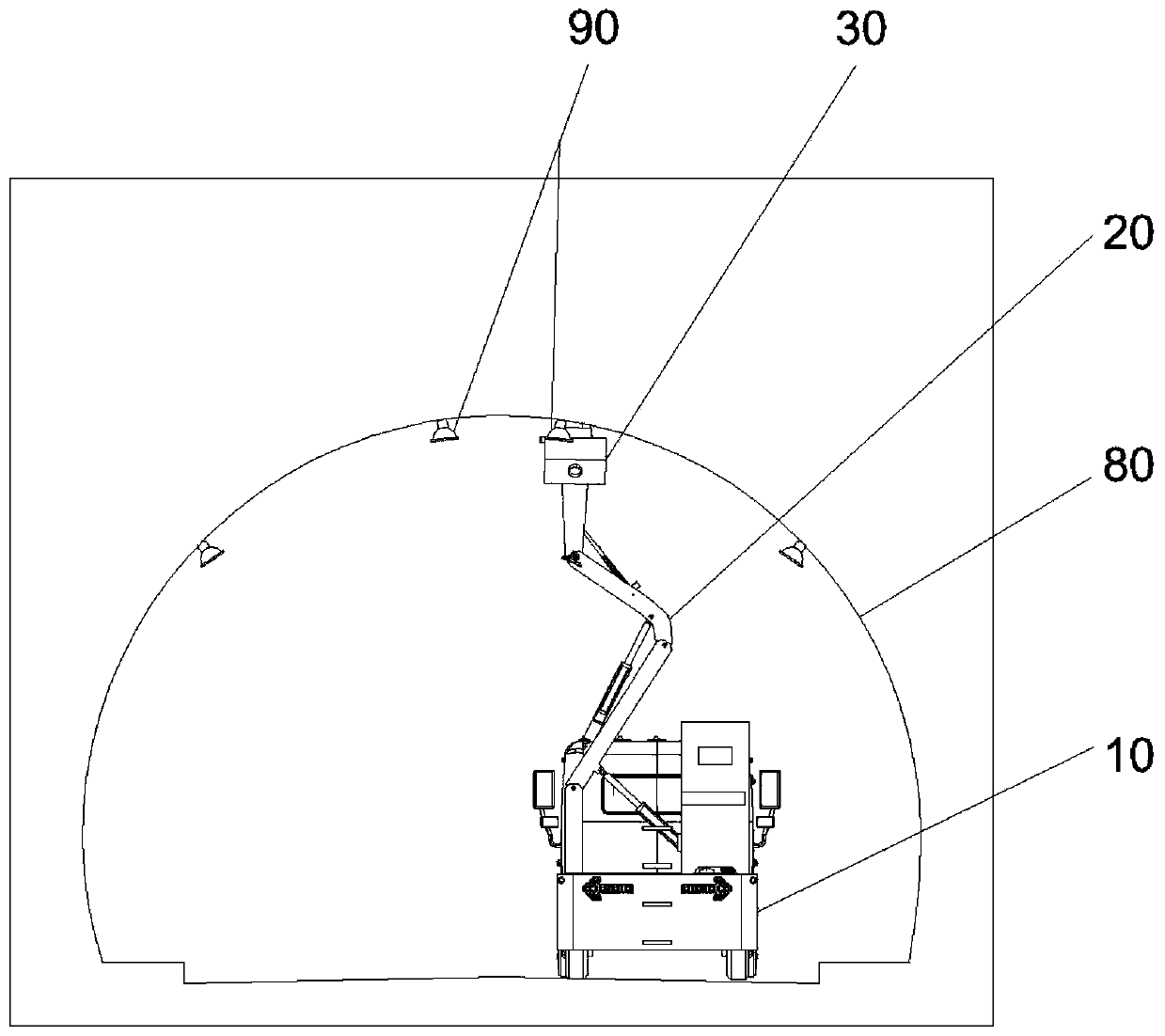

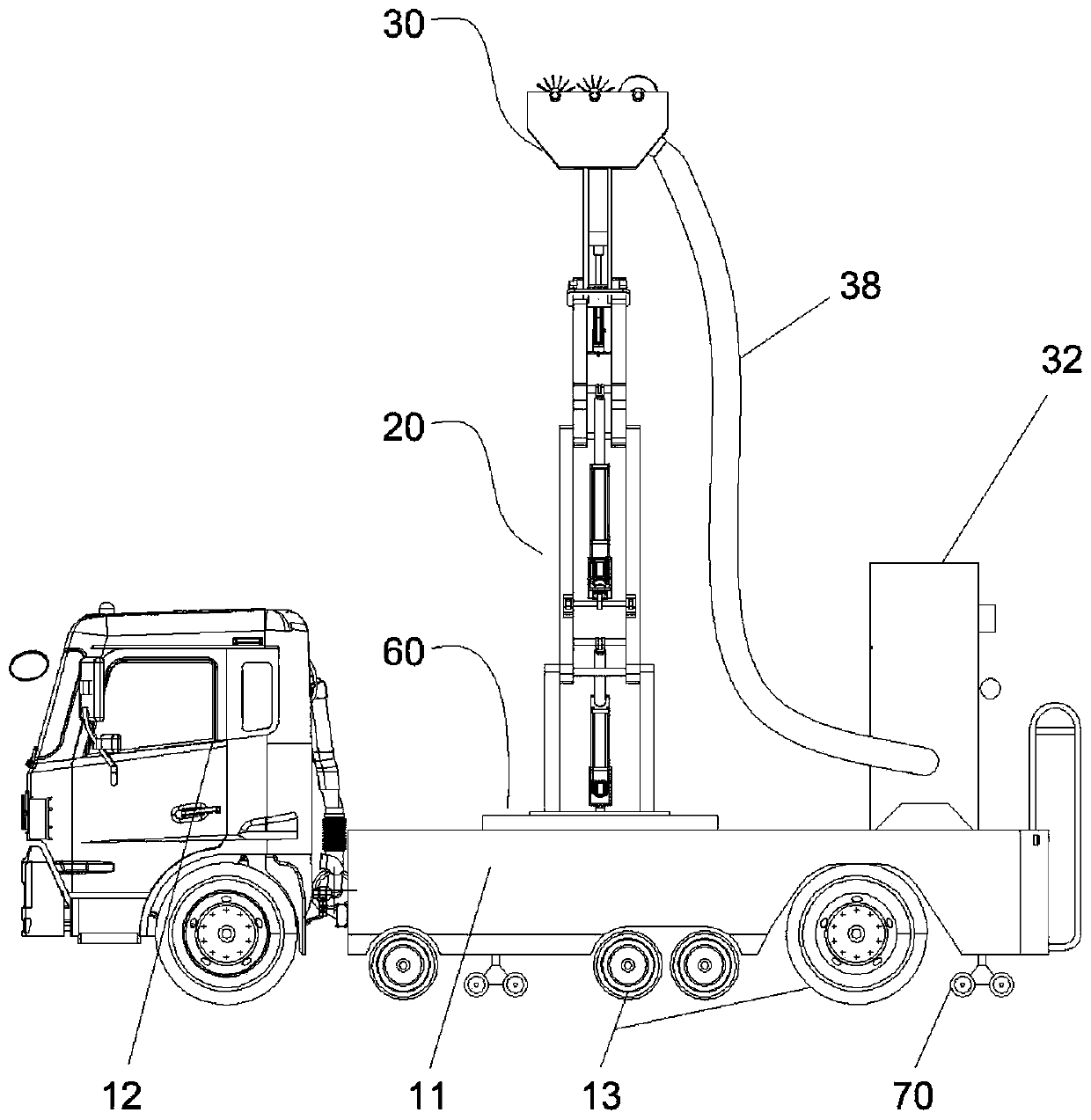

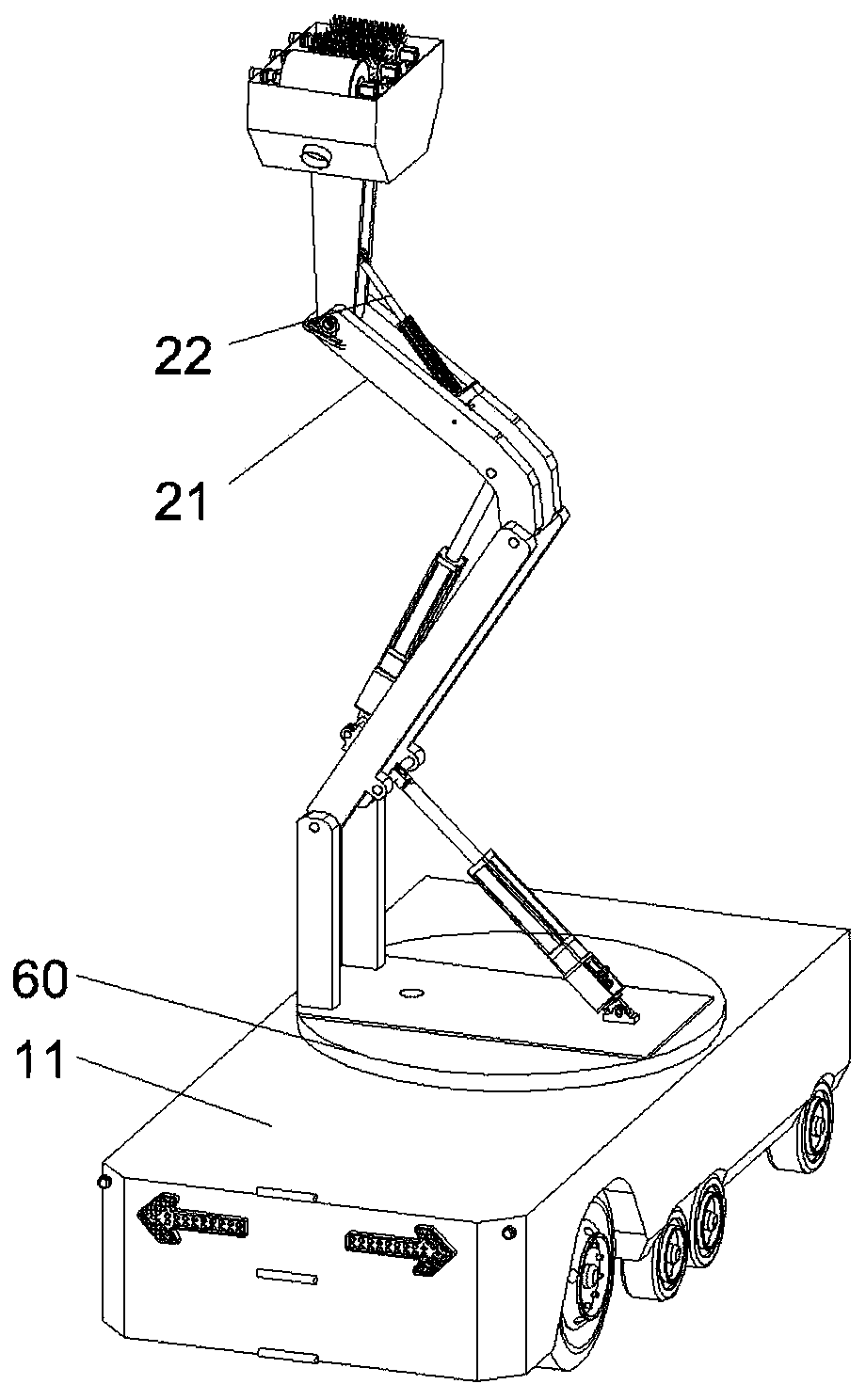

Dual-power-source vehicle-mounted tunnel lamp cleaning system

PendingCN110273400ASatisfy normal drivingMeet normal driving requirementsRoad cleaningLow speedEngineering

The invention discloses a dual-power-source vehicle-mounted tunnel lamp cleaning system. The dual-power-source vehicle-mounted tunnel lamp cleaning system comprises a vehicle-mounted platform, a lifting platform installed on the vehicle-mounted platform and a cleaning device installed on the lifting platform, the lifting platform is connected to the vehicle-mounted platform in ways of lifting and orientationchanging, the vehicle-mounted platform comprises two sets of power sources which are the high-speed power source andthe low-speed power source, and a switching device is arranged between the high-speed power source and the low-speed power source and used for switching the power sources to achieve normal running of the vehicle-mounted platform and low-speed running during lampcleaning. According to the cleaning system, the two sets of power sources are arranged, thus the normal running requirements of the vehicle-mounted platform can be met, and low-speed and stable runningduring lampscleaning can also be met.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

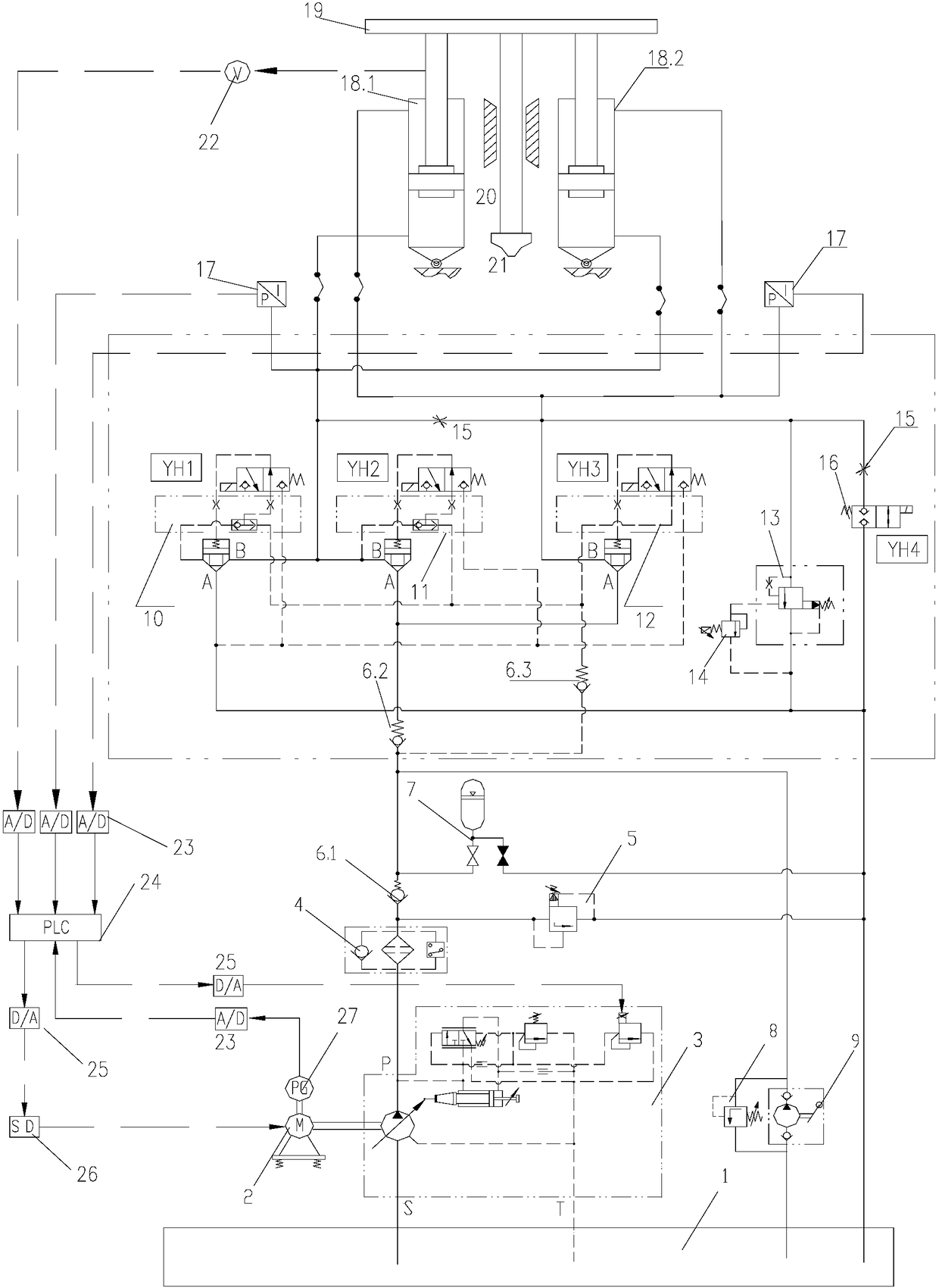

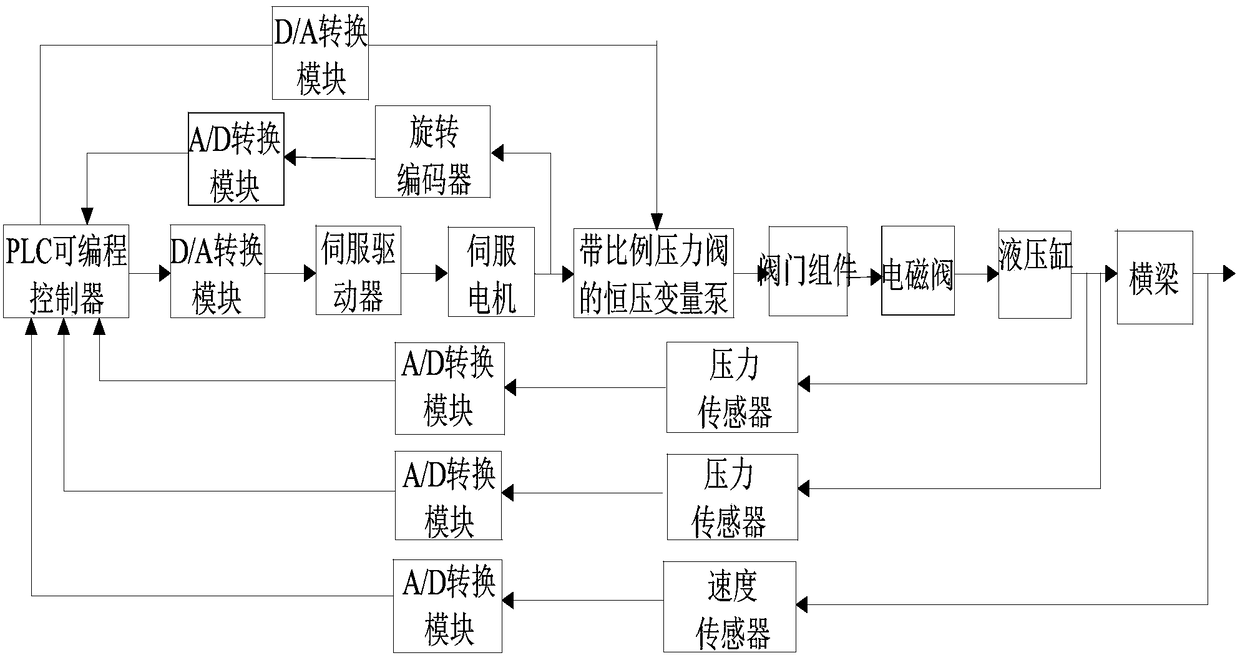

Internal mixer upper jacking bolt oil cylinder hydraulic control system

PendingCN108286545AGuaranteed uptimeReduce consumptionFluid-pressure actuator testingServomotorsControl systemProgrammable logic controller

The invention discloses an internal mixer upper jacking bolt oil cylinder hydraulic control system. Signals of the movement speed of an oil cylinder piston rod, the pressure of two cavities of an oilcylinder, and the rotation speed of a servo motor are monitored in real time and are fed back to a programmable logic controller (PLC), logical operation is conducted through a built-in PID, an inputsignal of a servo drive is given, the rotation speed of the servo motor is controlled, meanwhile the set pressure of a proportional pressure valve arranged on a constant pressure variable pump is controlled, finally closed-loop control of the speed of the internal mixer upper jacking bolt and the pressure of a pressing weight is achieved, namely rising, falling and pressurization of the upper jacking bolt and the working process of a floating weight are monitored and adjusted in real time, energy consumption is reduced to a great extent, and system work efficiency is improved. The rotation speed of the servo motor is controlled by the servo drive, then the output flow of the constant pressure variable pump is adjusted to adapt to system requirements, overflow loss is reduced maximally, system throttling loss is reduced, and the oil calorific value is lowered.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

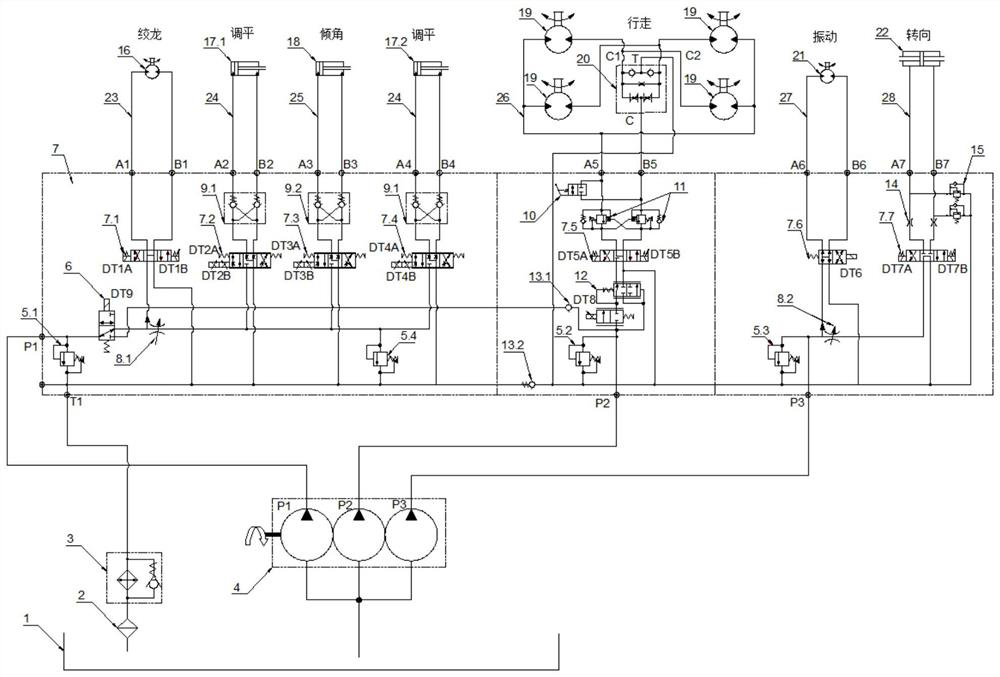

High-performance hydraulic system of small four-wheel laser leveling machine

PendingCN112145487AImprove passabilityGreat tractionServomotor componentsServomotorsGear pumpDownhill running

The invention relates to a high-performance hydraulic system of a small four-wheel laser leveling machine. The high-performance hydraulic system of the small four-wheel laser leveling machine comprises an oil tank, an auger motor, a left leveling oil cylinder, a right leveling oil cylinder, an inclination angle oil cylinder, a walking motor, a vibration motor and a steering oil cylinder. The oil tank is connected with a seven-linkage electromagnetic reversing valve and a three-linkage gear pump; and the seven-linkage electromagnetic reversing valve comprises a confluence electromagnetic valve,a first linkage electromagnetic valve, a second linkage electric proportional valve, a third linkage electric proportional valve, a fourth linkage electric proportional valve, a fifth linkage electromagnetic valve, a sixth linkage electromagnetic valve and a seventh linkage electromagnetic valve which are integrated into a whole valve block or installed separately. The functions of auger scraping, left-right leveling of a leveling head mechanism, inclination angle adjusting, high-low-speed walking, priority, skid resistance, oscillation and vibration, steering, emergency movement, composite action and the like are achieved through the seven-linkage electromagnetic reversing valve, so that the high integration level is achieved, the convenience in installation and maintenance is realized,the climbing force of the equipment is effectively improved, the vehicle speed is controllable during downhill running, the stability in steering is realized, the performance of the laser leveling machine is remarkably improved, and rapid and high-precision leveling operation of a concrete floor is realized.

Owner:XUZHOU SHENGNUO POWER TRANSMISSION MASCH CO LTD

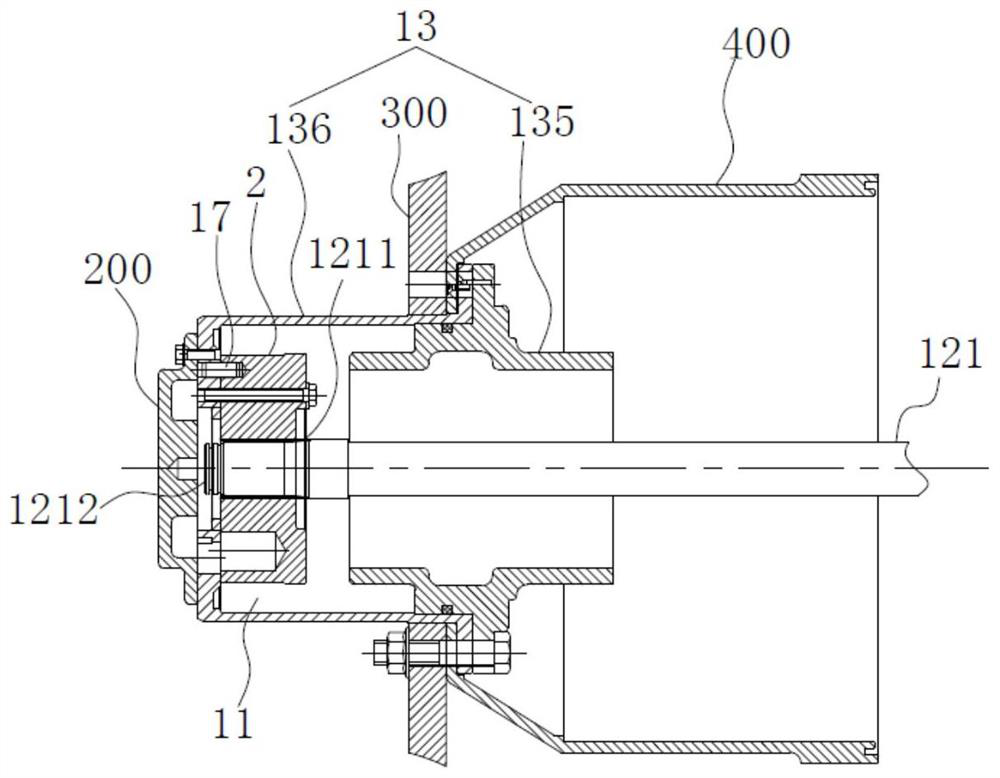

Modified chassis and airport ground support equipment

ActiveCN113460323AGood low speed stabilityReduce gear ratioUnderstructuresAxle unitsHydraulic motorReduction drive

The embodiment of the invention provides a modified chassis and airport ground support equipment, and belongs to the technical field of airport support equipment. A modified chassis comprises a commercial chassis, a transition disc, a modified transmission shaft, a hydraulic motor and a hydraulic pump. A first mounting area is formed on the commercial chassis, and the first mounting area is used for mounting a hub reduction gear of a drive axle of the commercial chassis. The transition disc is installed in the first mounting area and replaces the hub reduction gear to be in drive connection with a hub and a half shaft of the drive axle. The modified transmission shaft replaces an existing transmission shaft, and one end of the modified transmission shaft is in driving connection with the input shaft of the drive axle. An output shaft of the hydraulic motor is in driving connection with the other end of the modified transmission shaft. The hydraulic pump is configured to supply oil to the hydraulic motor to drive the hydraulic motor, and the hydraulic pump replaces a gearbox to be in driving connection with the engine. According to the modified chassis and the airport ground support equipment, both low-speed stability and high maximum running speed can be taken into account.

Owner:HUNAN SHUANGDA ELECTROMECHANICAL CO LTD

Hybrid transmission gearbox

The invention belongs to the technical field of gearboxes and provides a hybrid transmission gearbox. By means of the hybrid transmission gearbox, mechanical transmission and static hydraulic transmission are combined in parallel and are integrated in one shell. Power enters a box body through an input shaft of the gearbox and then is divided into two ways; one way is gear mechanical transmission,and six gears including five positive gears and one reverse gear are output after transmission of a connecting sleeve, a gear pair, an intermediate shaft and a reverse shaft is conducted; and the other way drives an integrated pump motor through a gear. The integrated pump motor is a set of closed static hydraulic transmission system, wherein the system converts input power into pressure oil, andthe pressure oil then enters the motor to be converted into mechanical torque to be output. Due to the fact that the inclination angle of an oblique plate of the pump and the oil pressure are controlled, the output rotating speed and the torque can be adjusted, and the output rotating speed and torque are steplessly adjusted continuously.

Owner:RG PETRO MACHINERY GROUP

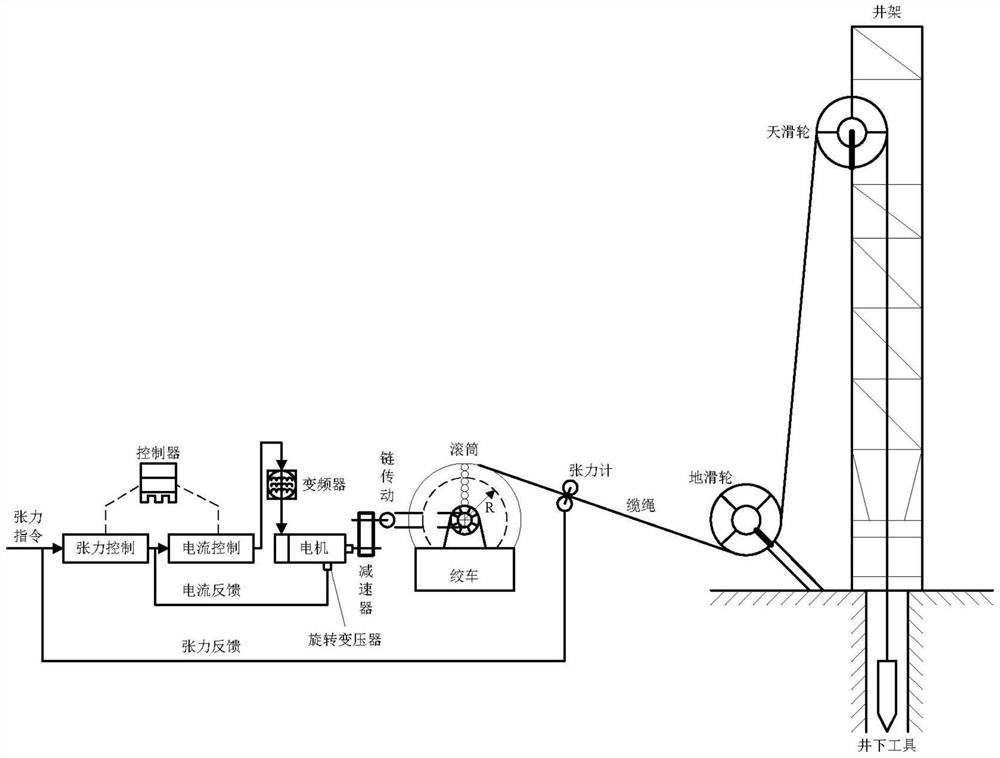

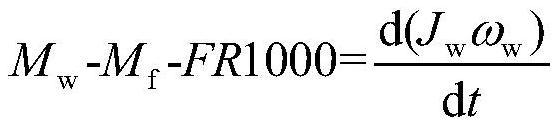

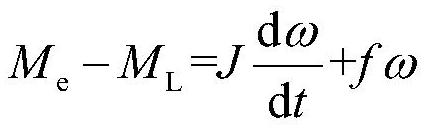

Petroleum machinery winch cable tension intelligent control method

PendingCN114660945AImprove stabilityHigh precision of tension controlWinding mechanismsAdaptive controlFrequency changerControl signal

The invention discloses an intelligent control method for cable tension of a petroleum mechanical winch. A tension feedback signal is directly transmitted to a controller in real time through a tensiometer which is independently and separately arranged between a ground pulley and a roller, the controller outputs a control signal to a driving motor through a frequency converter, the driving motor transmits motion to the roller, the output torque of the driving motor is dynamically adjusted, and a full-closed-loop tension control system is established. The control method comprises the following steps: calculating a layer index of hierarchical control according to the total length of a cable and the size of a roller, optimizing an initial value of a control parameter for each layer by combining analysis modeling and prior experience, and adaptively correcting a PID (Proportion Integration Differentiation) regulation value by using fuzzy control, a neural network or a fuzzy neural network intelligent control algorithm. The method can be used for cable car tension intelligent control of the winch for petroleum drilling, well logging, well repairing and the like, the tension control precision can be improved, the labor amount of operators is reduced, and a foundation is laid for achieving an intelligent winch system.

Owner:SOUTHWEST PETROLEUM UNIV

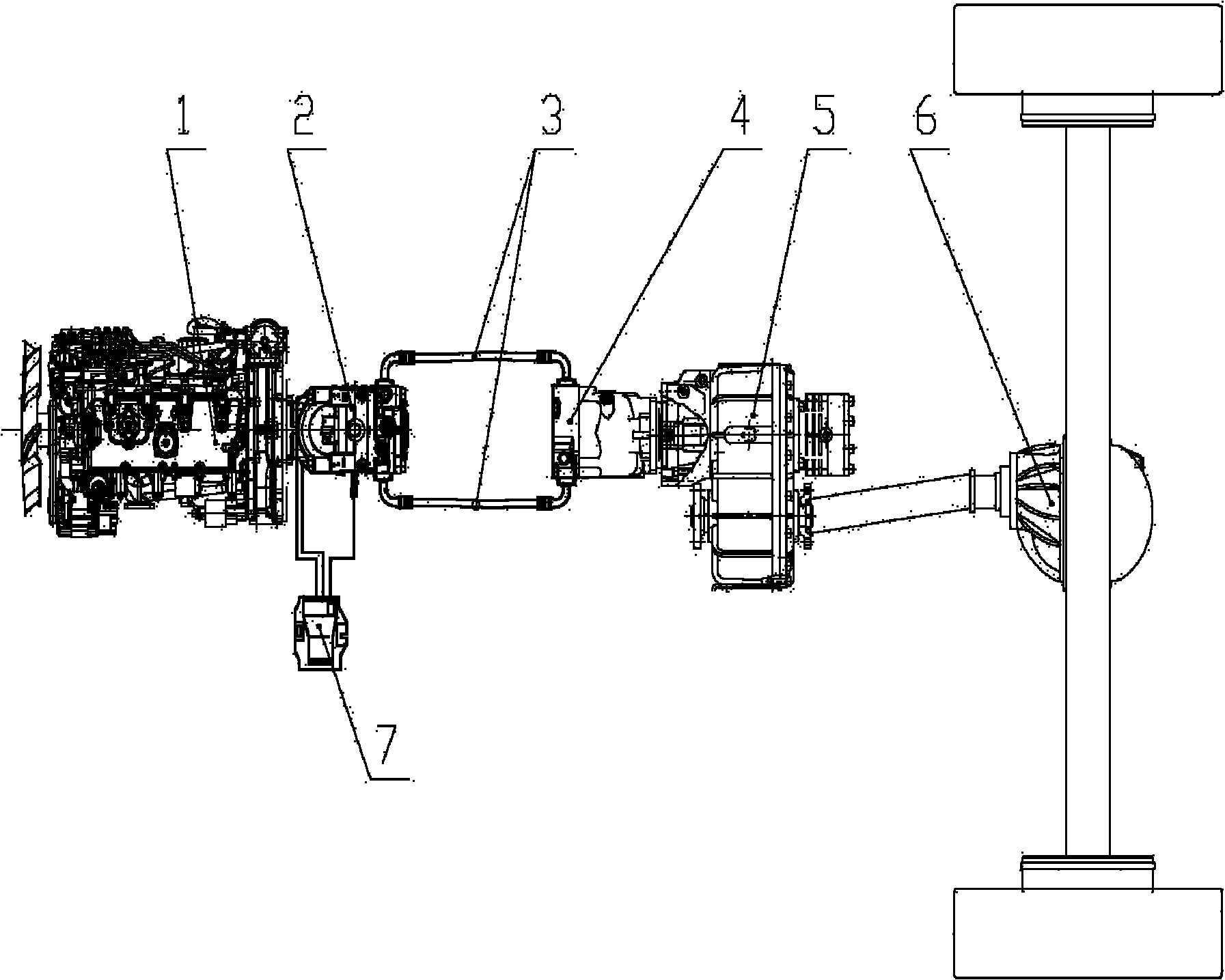

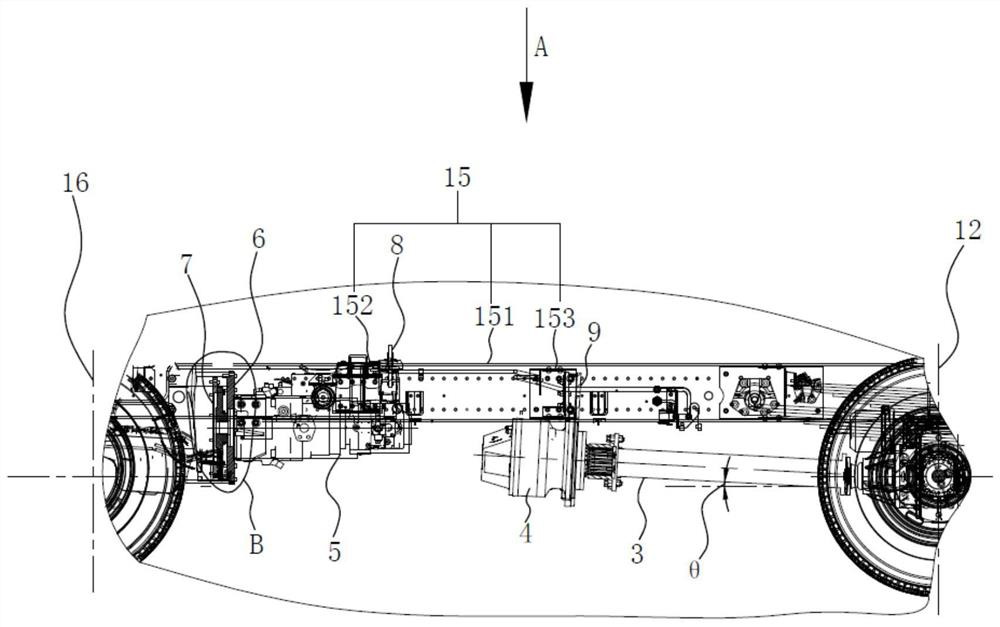

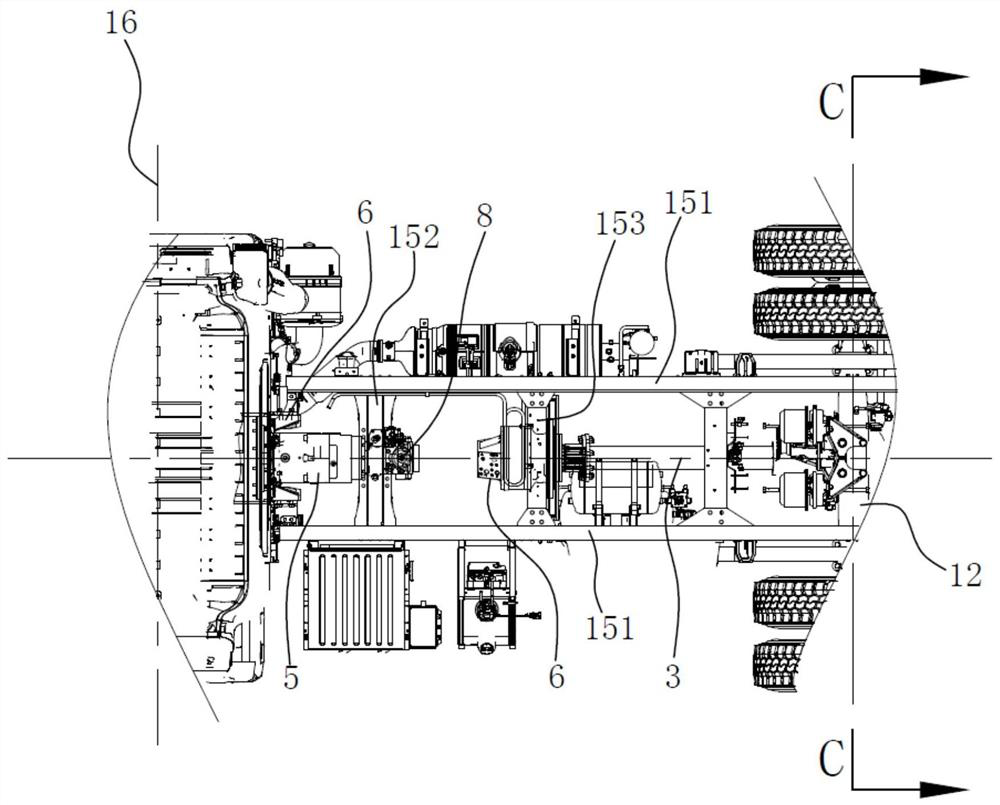

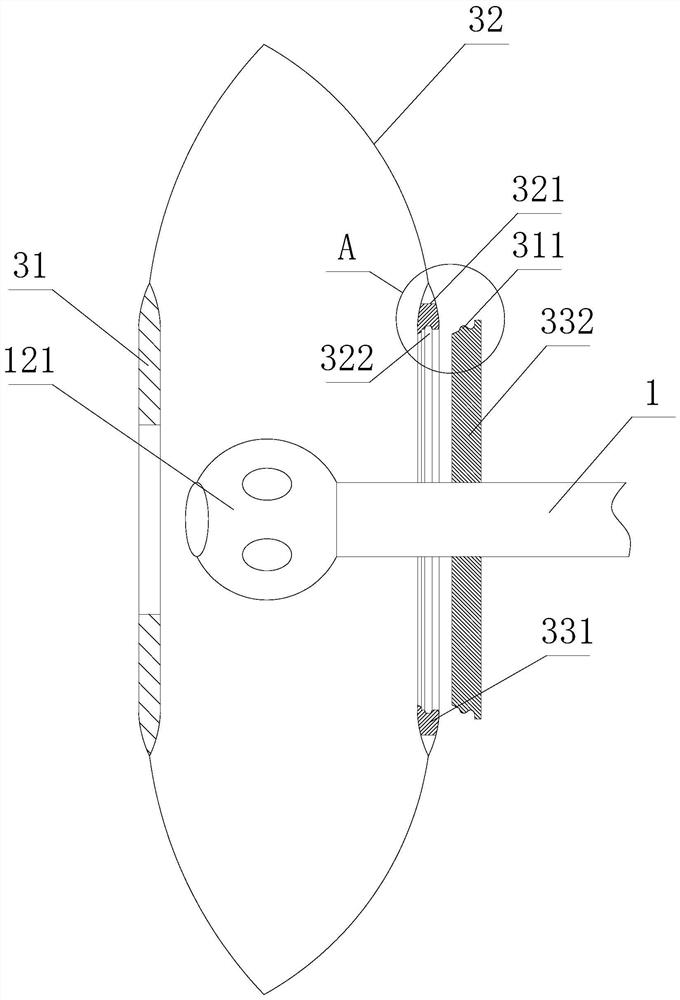

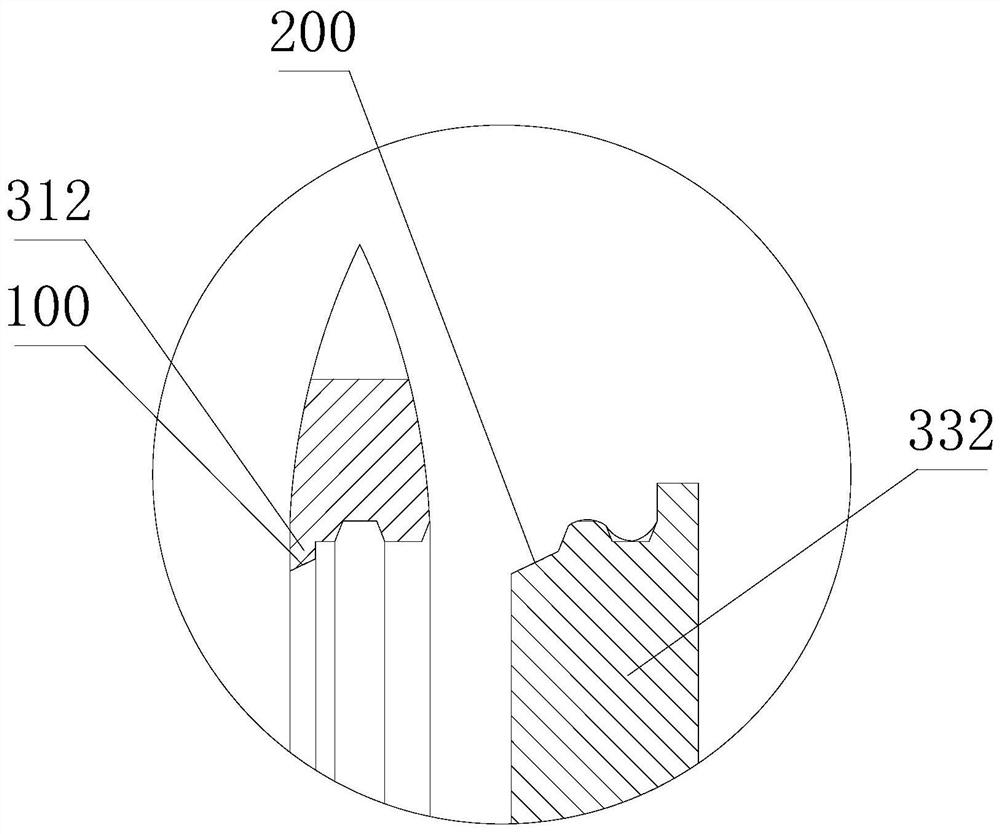

an aircraft tractor

The invention discloses an aircraft tractor. The aircraft tractor comprises a chassis assembly on which a frame is arranged, a cab installed on the frame, a plurality of tractor wheels assembled on the chassis assembly, a front axle and a rear axle, wherein at least some of the plurality of tractor wheels are steerable tractor wheels, an aircraft wheel support assembly and a power assembly are arranged at the middle part of the tractor, and a hydraulic steering assembly is installed at the steerable tractor wheels; the power assembly comprises an engine, the engine, a transmission and a torque converter are arranged in parallel, and the transmission is connected with the front axle and the rear axle of the tractor by drive shafts, and used for the rotation of the tractor wheels during the taxiing of an aircraft; the hydraulic steering assembly comprises a front-axle steering cylinder and a rear-axle steering cylinder, and used for the steering of the tractor wheels during the taxiing of the aircraft. The aircraft tractor disclosed by the invention is provided with the maximum traction force of 12000 kg, the maximum forward running speed of 25 km / h and the maximum reverse speed of 20 km / h.

Owner:上海航福机场设备有限公司

High-precision roller-spacing control system

Owner:大连橡胶塑料机械有限公司

Electro-hydraulic motor

ActiveCN104088751BExtend your lifeImprove volumetric efficiencyReciprocating piston enginesOil distributionReturn channel

The invention discloses an electrohydraulic motor which comprises a shell and a crankshaft, wherein the crankshaft penetrates through and is mounted on the shell; a swing disk, an oil feeding cylinder, an oil discharging cylinder, a balance cylinder, reversing valves, an oil feeding channel and an oil return channel are mounted in the shell; the oil feeding cylinder, the oil discharging cylinder and the balance cylinder are respectively communicated with the reversing valves; each reversing valve is correspondingly communicated with the oil feeding channel and the oil return channel; the swing disk sleeves the crankshaft; pistons of the oil feeding cylinder, the oil discharging cylinder and the balance cylinder are respectively connected with the swing disk. The electrohydraulic motor has the advantages that oil distribution, clockwise rotation and anticlockwise rotation are easy to control, the operation is convenient, and the cost is lowered.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

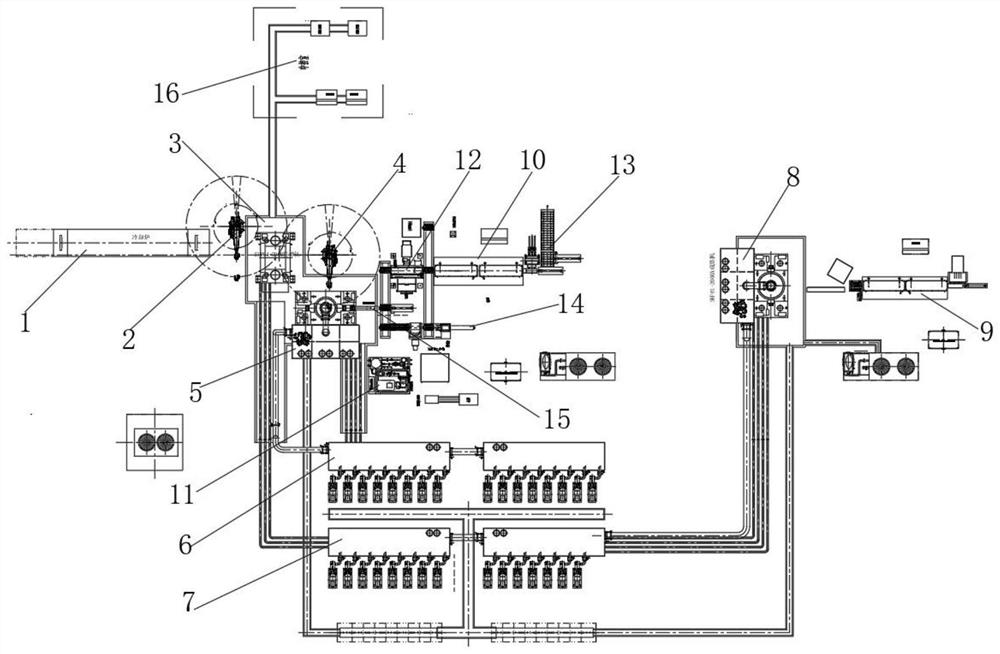

Hot stamping automatic production line with drawing, stretching and punching functions

PendingCN114713712AImprove efficiencyImprove processing qualityShaping toolsMetal-working feeding devicesHot stampingProduction line

The invention discloses a hot stamping automatic production line with a drawing and punching function. The hot stamping automatic production line comprises a cooling furnace used for cooling semi-finished products. The first pump station and the second pump station are used for providing hydraulic power; the hydraulic drawing machine, the hydraulic profiling punching flanging machine and the hydraulic secondary profiling punching machine are respectively used for drawing, profiling punching flanging and secondary profiling punching operation on the workpiece; the hydraulic drawing machine is arranged on one side of the cooling furnace, and a transfer manipulator is arranged between the hydraulic drawing machine and the cooling furnace; the hydraulic type profiling punching flanging machine is arranged on one side of the hydraulic type drawing machine and located in the feeding direction of the hydraulic type drawing machine, and a feeding mechanical arm is arranged between the hydraulic type profiling punching flanging machine and the hydraulic type drawing machine. The hot stamping automatic production line with the stretching and punching functions is reasonable in layout, and the projectile body forming machining efficiency and machining quality can be greatly improved.

Owner:HEFEI HAIDE HYDRAULIC PRESS

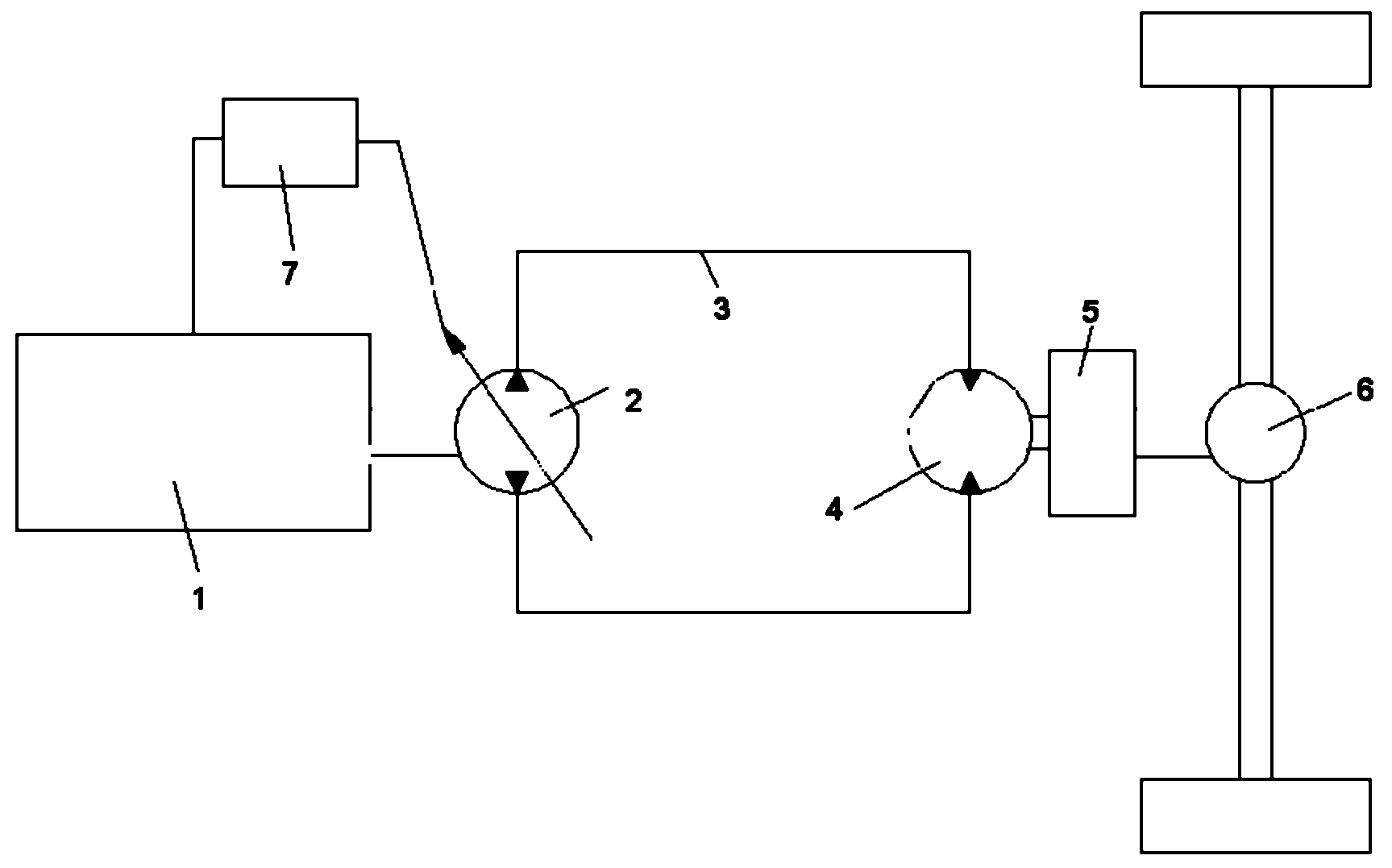

A valve-pump combined multi-mode hydraulic control system and control method thereof

ActiveCN108397447BTaking into account efficiencyVarious forms of controlServomotor componentsServomotorsHydraulic motorControl system

The invention relates to a valve-pump combined multi-mode hydraulic control system and a control method thereof. The multi-mode hydraulic system comprises a pump control motor main loop, a valve control branch circuit, a mode switching unit and a control unit, wherein the valve control branch circuit is connected with the pump control motor main loop in parallel through the mode switching unit. The control method is characterized in that a controller has two layers of control strategies, wherein the first layer of control strategy is a mode selection strategy, and the system can be in variousworking modes such as the valve control mode, pump control mode and valve-pump combined control mode by controlling the mode switching unit; and the second layer of control strategy is a flow controlstrategy, one circuit is used for controlling the displacement of a proportional variable pump so as to adjust the flow in the pump control mode, the other circuit is used for controlling an opening of a proportional reversing valve so as to adjust the flow in the valve control mode, and finally, the rotating speed of a hydraulic motor is controlled through a closed loop. The valve-pump combined multi-mode hydraulic control system can be used for hydraulic power devices with obvious speed regulation processes, such as a hydraulic elevator and an engineering machinery rotary table, different working modes are adopted in different speed regulation stages, so that the comprehensive speed regulation performance of the system is improved.

Owner:CHINA UNIV OF MINING & TECH

Hydrodynamic drive system for mine car

The invention relates to a hydrodynamic drive system for a mine car, which comprises an engine, a gear-shifting clutch and a mechanical speed changing box as well as an elastic plate, a hydrodynamic torque converter, a shell and a turbine shaft, wherein the output end of the engine is fixedly connected with the flexible plate, the output end of the turbine shaft is connected with the mechanical speed changing box, and the hydrodynamic torque converter is arranged in a working cavity formed by the elastic plate, the shell and the turbine shaft; and a torsional damper and a lockup clutch are arranged in a cover vortex working cavity formed by a cover wheel, a turbine body and a turbine hub, one end of the torsional damper is fixed on the turbine hub, the other end of the torsional damper is connected with the lockup clutch by a spine, and the other end of the lockup clutch is connected with the cover wheel by a spine. The hydrodynamic drive system solves the technical problem of higher car price caused by a conventional expensive automatic speed changing box with the hydrodynamic torque converter. The hydrodynamic drive system is additionally provided with the hydrodynamic torque converter so that the connection of the engine and the mechanical speed changing box is changed to be flexible connection, the clutch is protected, and then a torque is increased.

Owner:SHAANXI AEROSPACE POWER HIGH TECH

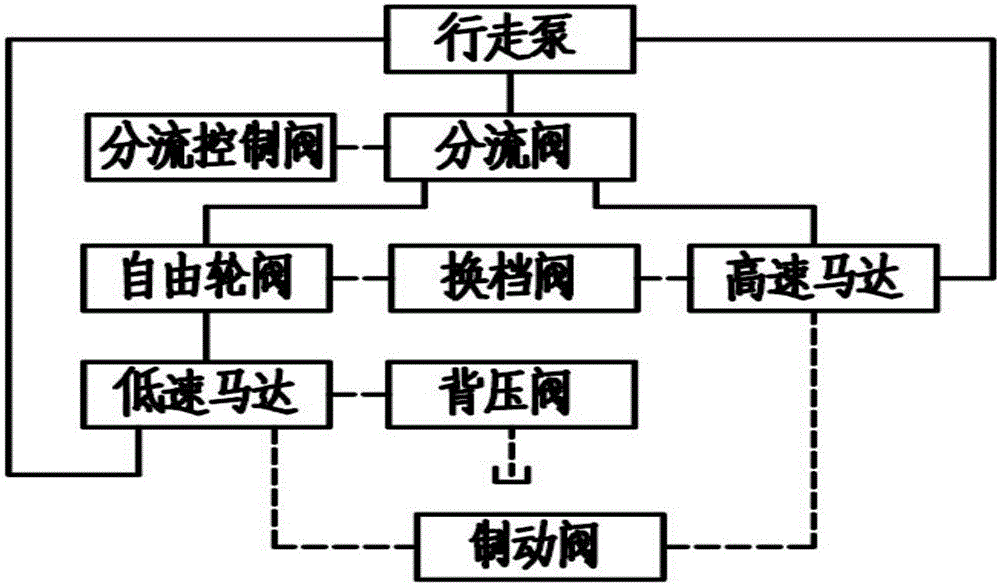

A walking control system of a small road milling machine

The invention relates to a traveling control system, in particular to a traveling control system which is particularly applicable to a small-sized pavement milling machine, and belongs to the field of an electric-hydraulic control system of a traveling machine. The small-sized pavement milling machine traveling control system comprises a traveling pump, a diverting valve, a control valve blank, a high-speed motor and two low-speed motors, wherein the traveling pump conveys the hydraulic oil respectively to the low-speed motors and the high-speed motor in parallel connection through the diverting valve, and then the hydraulic oil is returned to the traveling pump to form a closed loop. The small-sized pavement milling machine traveling control system is characterized in that by adopting the parallel connection way of the high-speed motor and the two low-speed motors, a rear wheel does not need to be connected with a reducer, so that the axial size of the rear wheel is reduced, the entire design is optimized, the swinging of the rear wheel is not influenced, and the rear wheel is more applicable to the small-sized pavement milling machine; meanwhile, the sufficient driving force also can be guaranteed, and the milling requirement of the milling machine can be met.

Owner:XUZHOU XUGONG ROAD CONSTR MACHINERY

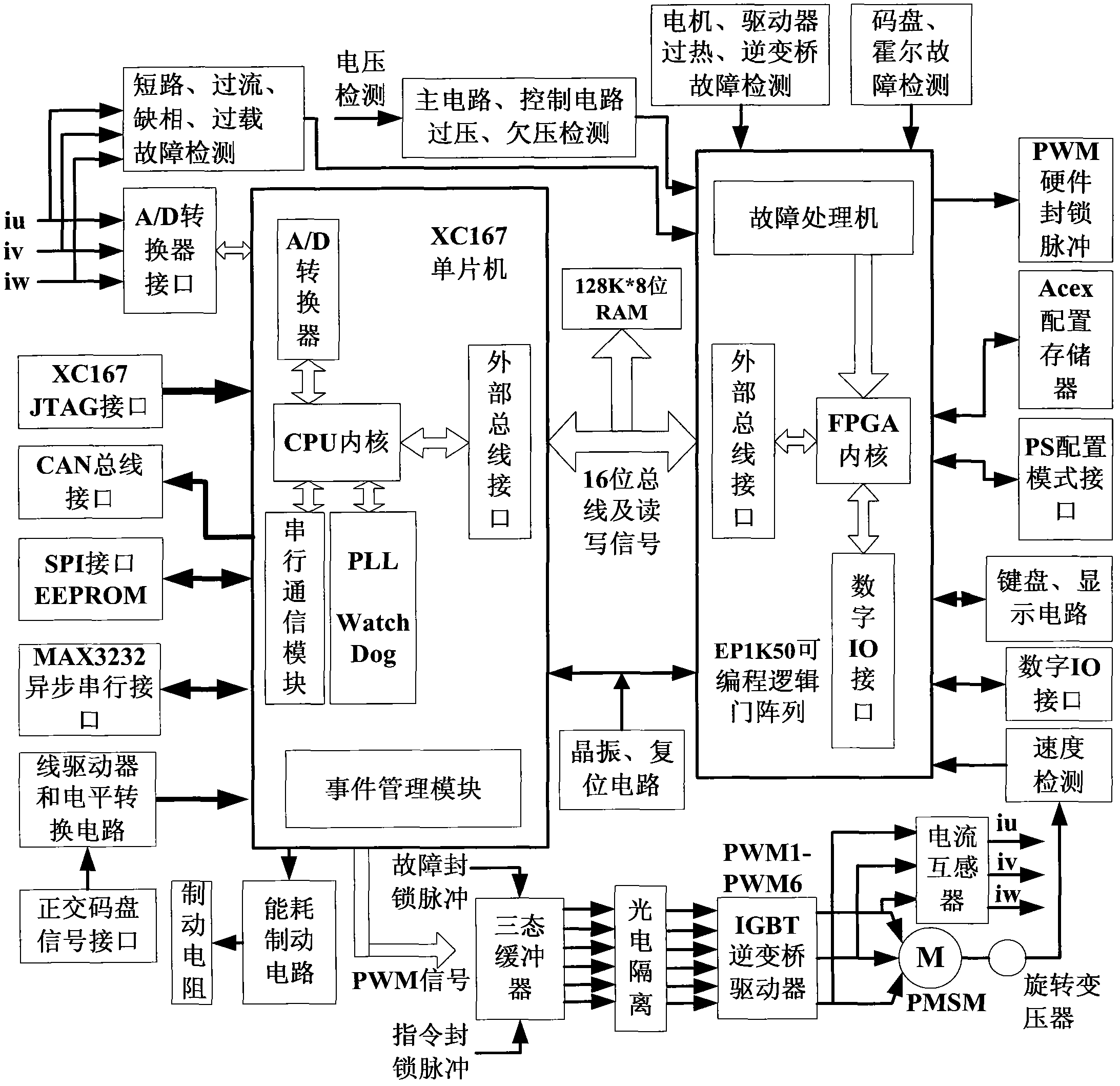

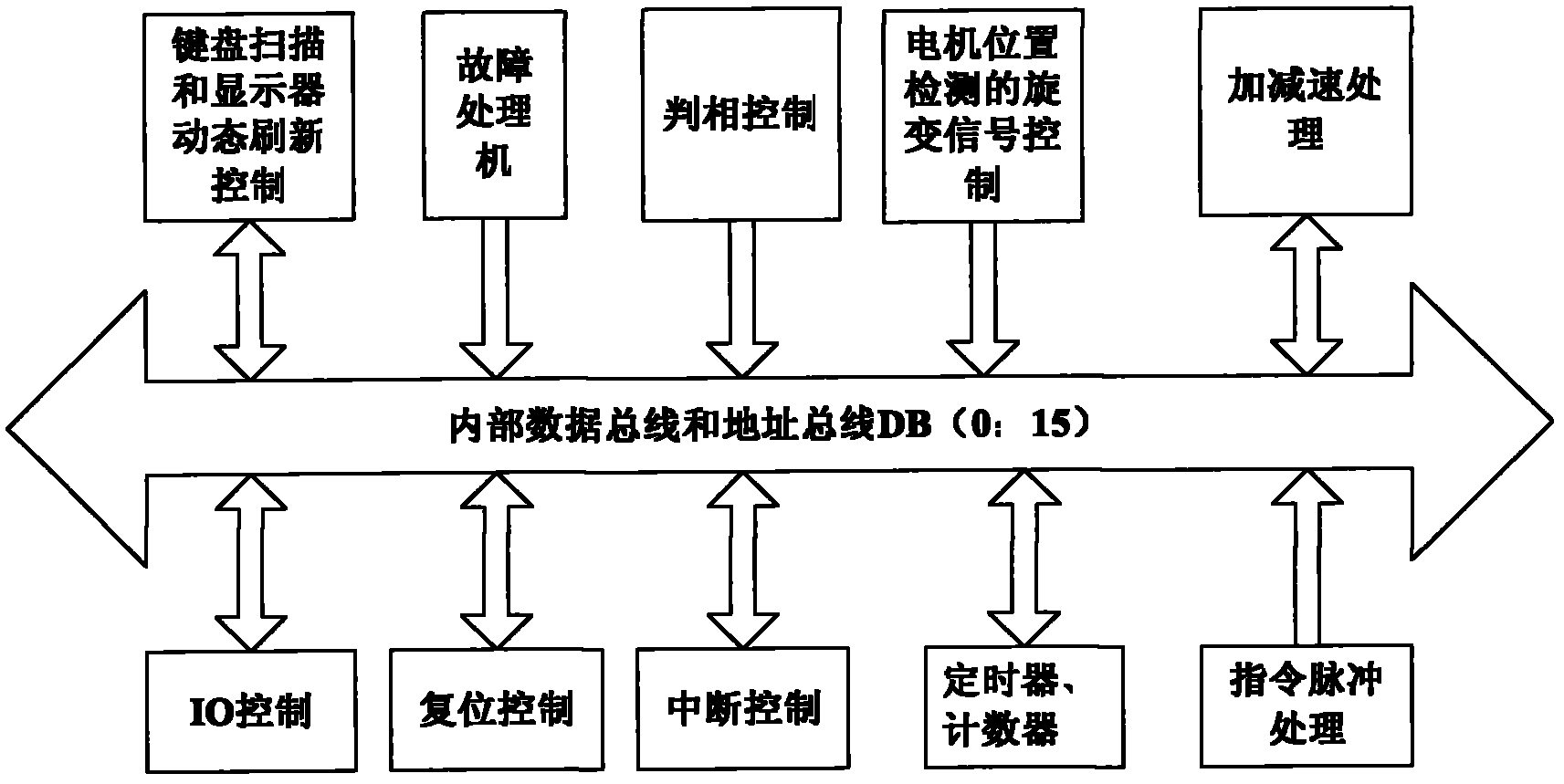

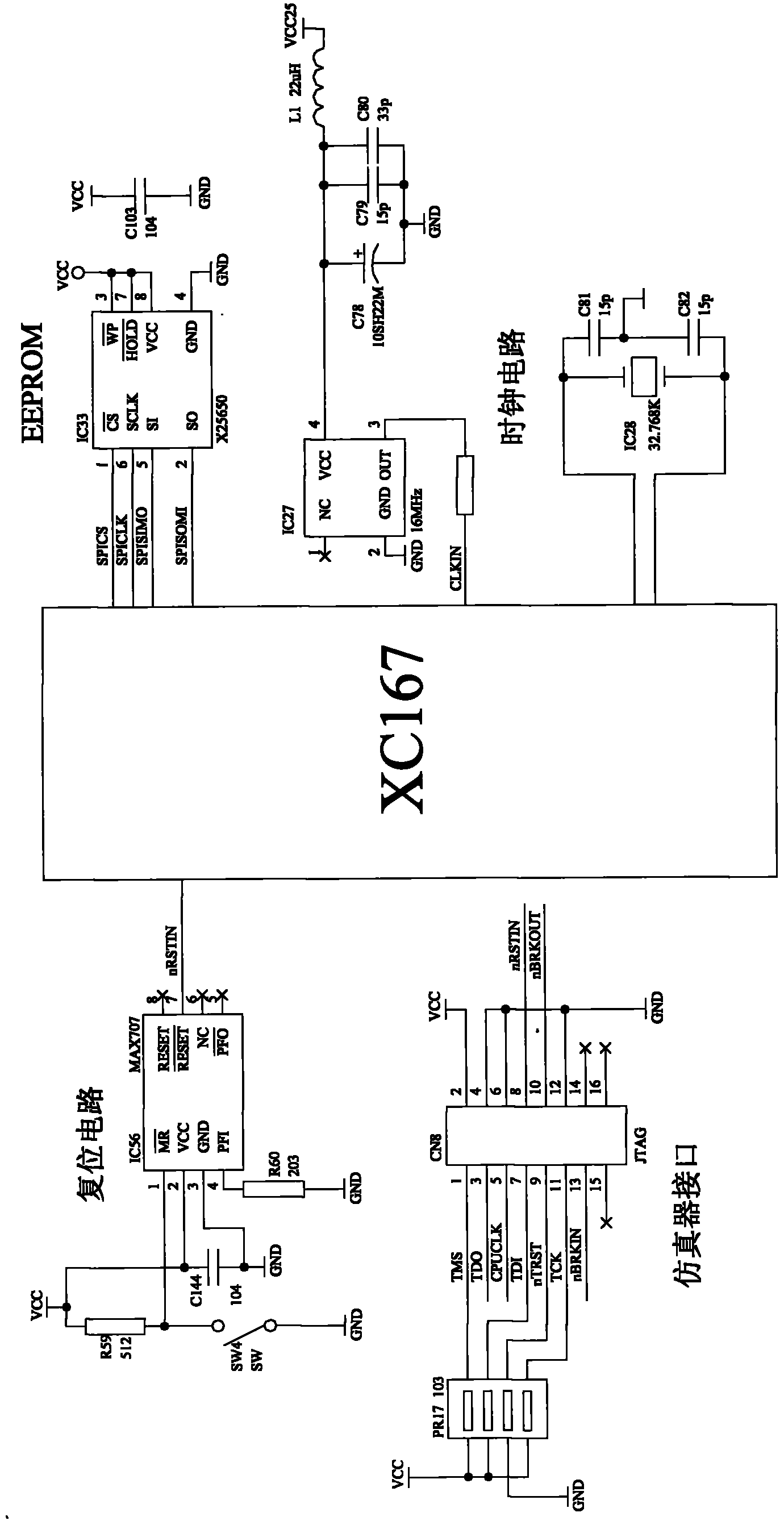

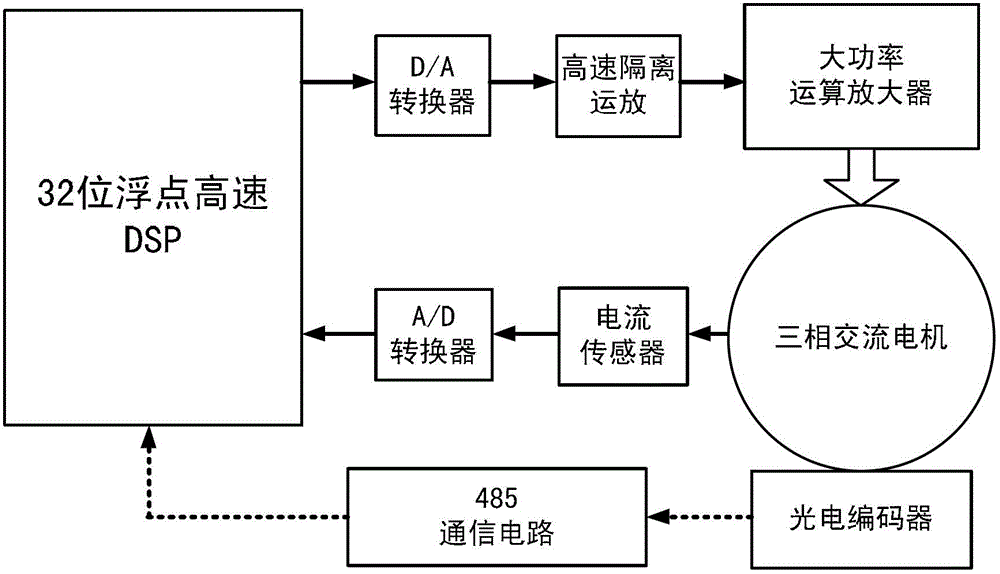

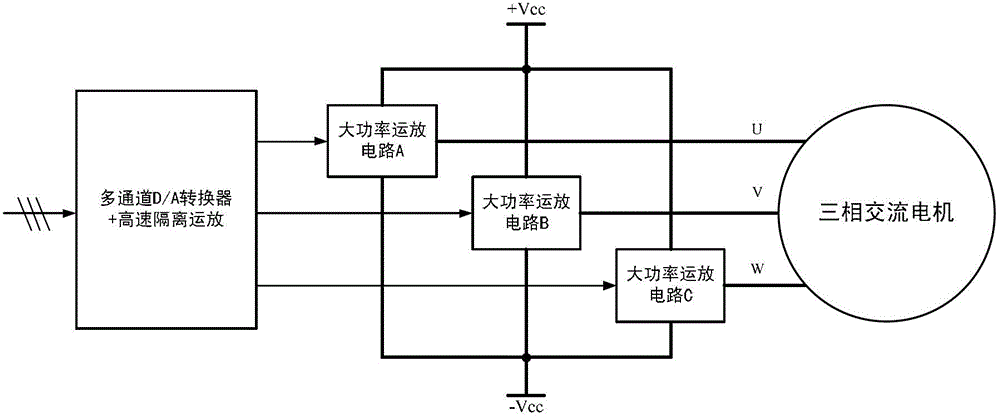

High torque starting method for high power alternating current (AC) servo driver

ActiveCN102497141BWeaken the ripple torqueGood low speed stabilityModelling/simulations for controlStarter arrangementsLow speedControl signal

Owner:BEIJING INST OF SPECIALIZED MACHINERY

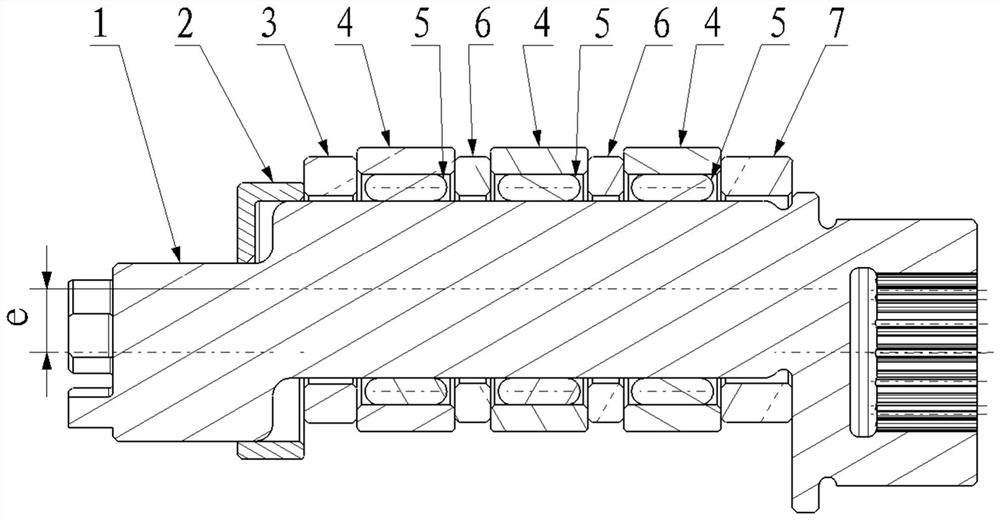

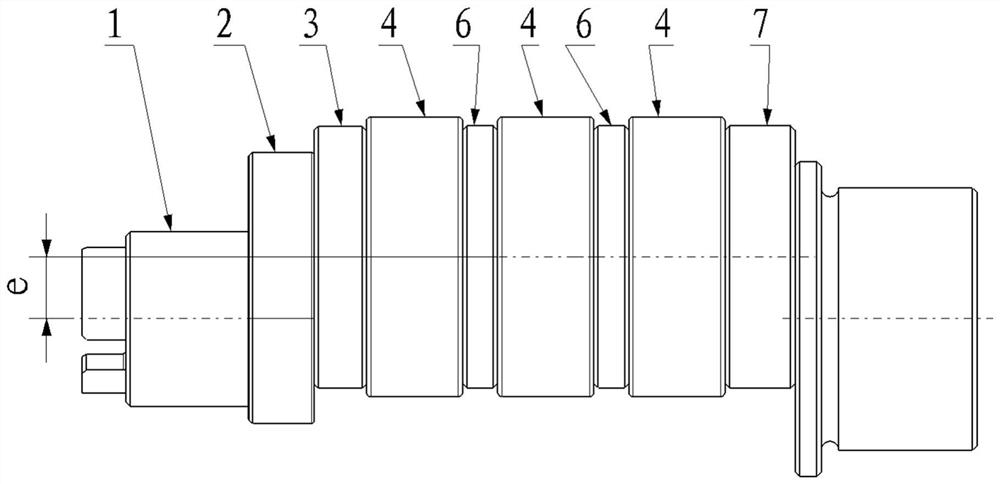

Large-torque hydraulic motor crankshaft

PendingCN112459959AReduce wearImprove the lubrication effectReciprocating piston enginesHydraulic motorReciprocating motion

The invention discloses a large-torque hydraulic motor crankshaft. By means of the large-torque hydraulic motor crankshaft, the starting torque and the transmission torque of a motor can be improved.According to the technical scheme, by means of the eccentric bent neck end of the motor crankshaft and an eccentric wheel shaft connected with a coaxial connecting rod, the degree of freedom of horizontal, vertical and front-back reciprocating motion of the crankshaft is limited, pressing rings for bearing hydraulic pressure and roller pins assembled in the pressing rings are assembled at the position, between the eccentric bent neck end and the eccentric wheel shaft end, of the crankshaft, the pressing rings are arranged at intervals through spacer rings and distributed between positioning spacer rings and baffle rings in a linear array manner, it is guaranteed that the roller pins make contact with the pressing rings all the time in the working process of the crankshaft, an axial positioning effect is achieved on the roller pins, and a static pressure balance structure is formed between the roller pins and a crankshaft motion pair; and hydraulic force applied to the pressing rings generates the torque enabling the crankshaft to rotate through the eccentric distance e of the crankshaft, and the roller pins convert a sliding friction motion pair between the inner surfaces of the pressing rings and the outer surface of the crankshaft into a rolling friction motion pair. Reliability of stable transmission efficiency and precision is ensured.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

A drive device for injector head for coiled tubing

ActiveCN103510891BEasy to installEfficient use ofDrilling rodsDrilling casingsHydraulic motorLow speed

The invention discloses a coiled tubing injection head driving device, which belongs to the petroleum field. The device includes two sets of hydraulic motor drive mechanisms arranged on the injection head box, each hydraulic motor drive mechanism includes a hydraulic motor, a hydraulic brake device, a connecting plate, a bearing seat, a planetary gear reducer, a bearing, a sprocket shaft and The central shaft, the hydraulic motor and the planetary gear reducer are respectively installed on both sides of the injection head box, the sprocket shaft is a hollow shaft, the central shaft passes through the sprocket shaft, and the center One end of the shaft is connected with the output end of the hydraulic motor, and the other end of the central shaft is connected with the input end of the planetary gear reducer. The embodiment of the present invention has the advantages of compact structure, symmetry, good balance, easy hoisting and operation installation, and also has the advantages of high driving efficiency and good low-speed stability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

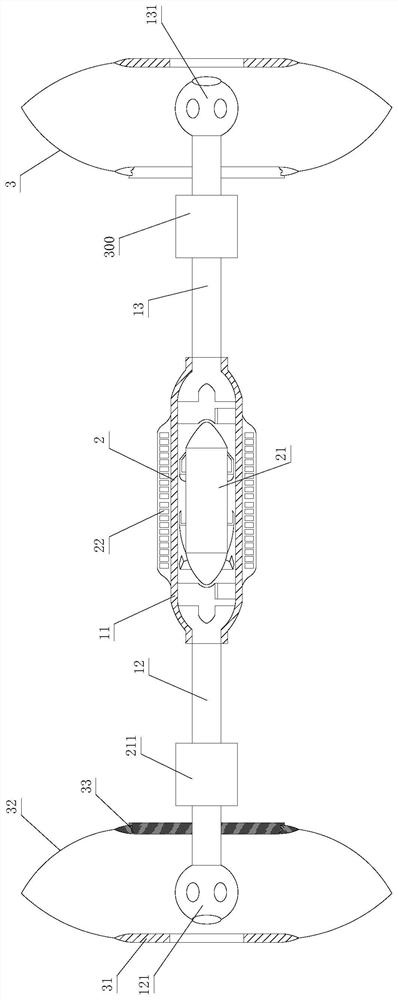

Direct-connection type intestinal juice back-conveying device

PendingCN112773725AImprove automationGood low speed stabilityColostomyFeeding-tubesEngineeringMechanical engineering

The invention discloses a direct-connection type intestinal juice back-conveying device, and belongs to the field of intestinal juice recovery devices. The direct-connection type intestinal juice back-conveying device comprises a back-conveying pipe and a magnetic suspension pump located in the middle of the back-conveying pipe, wherein a containing cavity is formed in the middle of the back-conveying pipe, and a rotor of the magnetic suspension pump is located in the containing cavity. The direct-connection type intestinal juice back-conveying device can directly pump back intestinal juice, is simple in structure, can keep good working stability when the human body is in a moving state, and is convenient to carry and easy to use.

Owner:GUANGDONG WOMEN & CHILDREN HOSPITAL

Linear power driving controller based on large-power operational amplifier for three-phase alternating current motor

ActiveCN102751924BSimultaneous sampling implementationIncrease throughputSingle motor speed/torque controlElectronic commutatorsAutomatic controlControl signal

Owner:北京北航天宇长鹰无人机科技有限公司

Azimuth rotating static pressure support system for tower solar thermal power generation heliostats

ActiveCN106949106BSmall turning torqueLow costServomotor componentsServomotorsHydraulic motorSupporting system

The invention relates to an azimuth rotation static-pressure support system of a tower solar thermal power generation heliostat. The tower solar thermal power generation heliostat includes a tower frame, a hydraulic motor speed reducer, an azimuth rotating unit and a pitching motion unit. The system designs chute and slide ring structures, and injects oil to the lower bottom end surface of a slide ring and the upper flat end surface of a chute through a pressure reducing valve, a one-way valve and a capillary throttling valve, so that the lubricating performance is greatly improved, the rotating torque of the tower heliostat azimuth is reduced by 70% compared with the torque of a mechanical drive, the azimuth rotation driving torque is largely reduced, the sizes of the driving device and the hydraulic motor are both largely reduced, and the cost of the azimuth driving device is correspondingly reduced.

Owner:TIANJIN OULU HEAVY MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com