Azimuth rotation static-pressure support system of tower solar thermal power generation heliostat

A tower-type solar energy, static pressure support technology, applied in the direction of fluid pressure actuation system components, servo meter circuits, fluid pressure actuation devices, etc. Control accuracy, unfavorable development prospects of solar thermal power generation, etc., to achieve the effect of good transmission characteristics, increased stiffness, and reduced driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

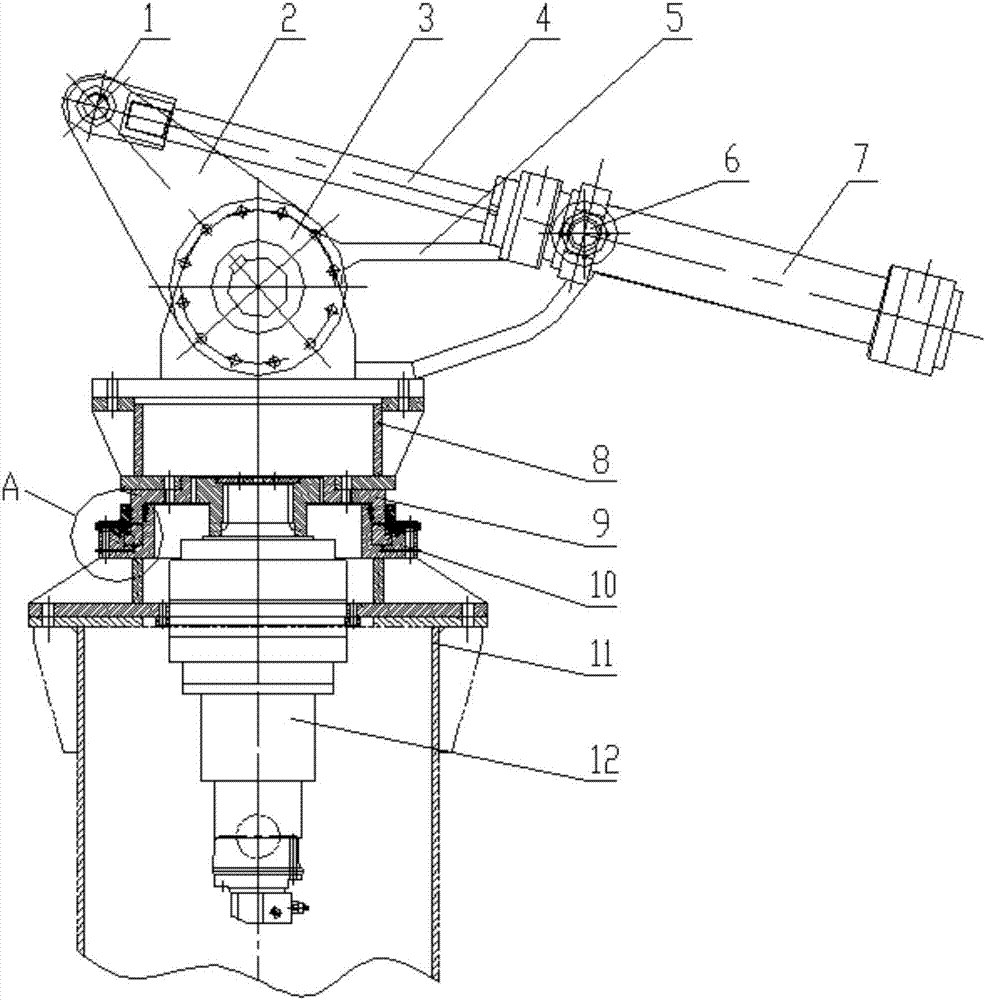

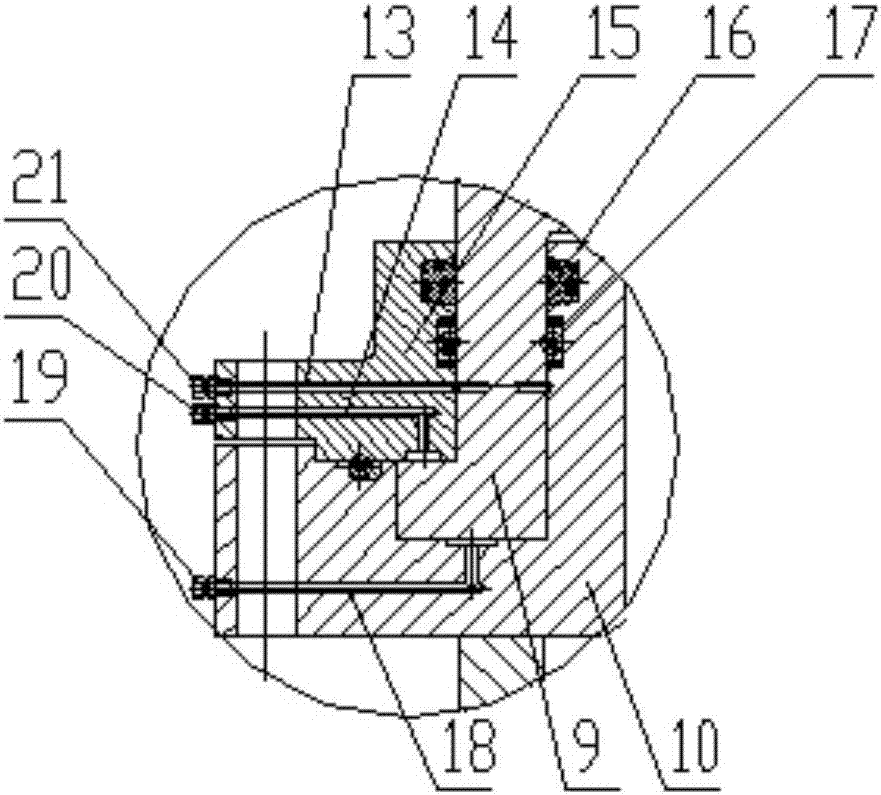

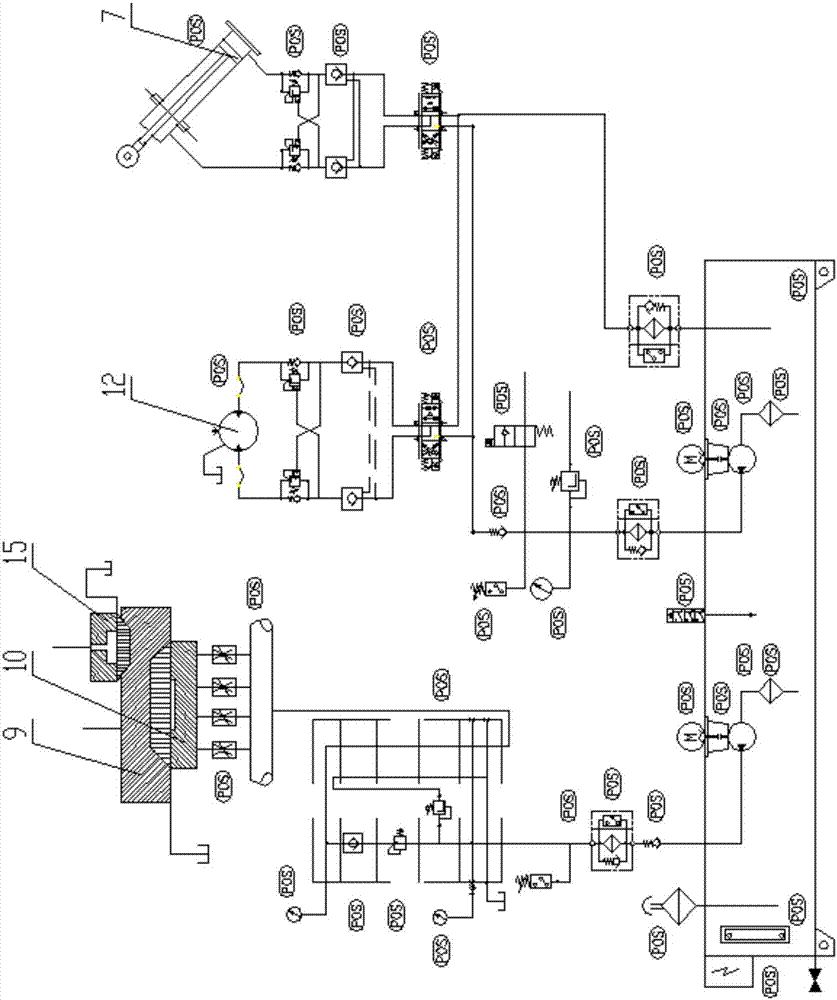

[0029] A tower-type solar thermal power heliostat azimuth rotation static pressure support system. The tower-type solar thermal power heliostat includes a tower 11, a hydraulic motor reducer 12, an azimuth angle rotation unit and a pitch motion unit. A coaxially fixed hydraulic motor reducer in the frame, the output shaft end of the hydraulic motor reducer is coaxially fixed with an azimuth angle rotation unit, the upper end of the azimuth angle rotation unit is coaxially fixed with a pitch motion unit, and the hydraulic motor reducer drives the azimuth angle rotation The unit realizes the change and positioning of the direction angle of the heliostat, the pitch movement unit realizes the change and positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com