Valve assembly at high-temperature end for exhaust gas recirculation

A valve assembly, high temperature technology, applied in the field of EGR valve, can solve the problems of large interference of connecting rod, easy damage, limited expansion torque of connecting rod, etc., to achieve the effect of improving stability and reliability, stable and reliable sealing, and improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

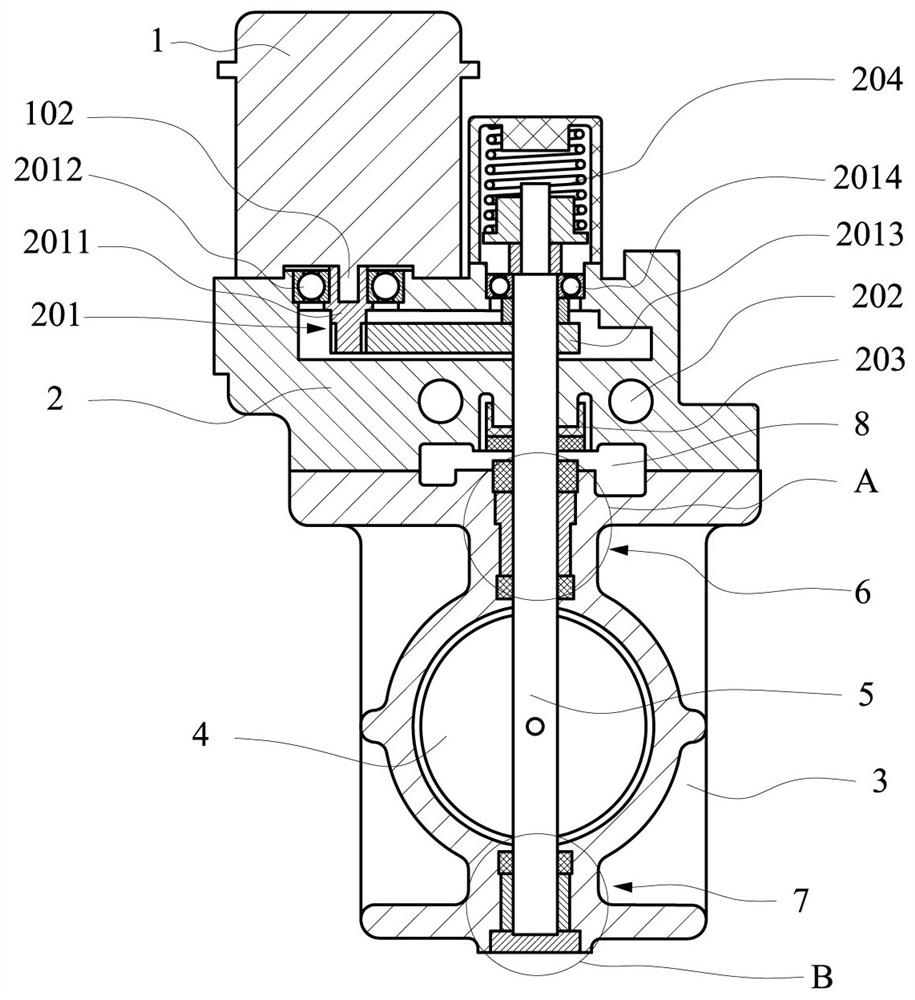

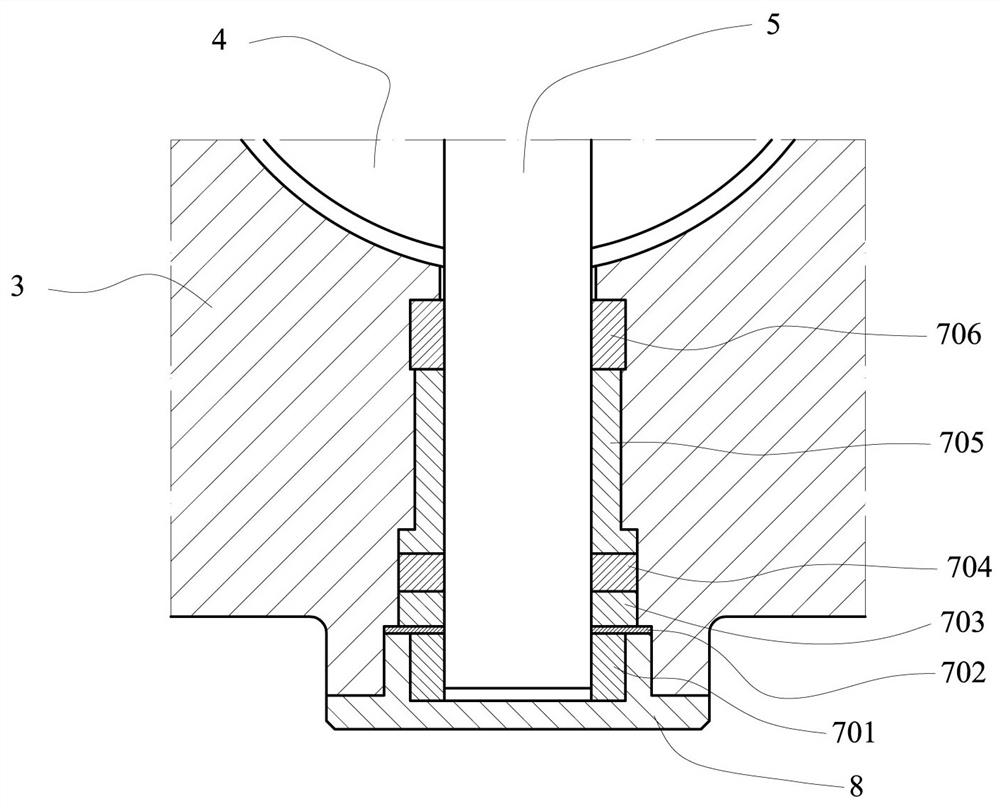

[0021] This embodiment is a high-temperature end valve assembly for exhaust gas recirculation, such as figure 1 shown. This embodiment includes: a motor 1, a valve cover set 2, and a valve body 3 installed in sequence. The valve body is provided with a valve plate 4 and a valve stem 5 that drives the valve plate to rotate, and the valve stem passes through the valve cover set. The transmission pair 201 in the middle is connected with the motor shaft 102, and the upper and lower ends of the valve plate are provided with an upper metal seal set 6 and a lower metal seal set 7 along the valve stem; a vent is provided between the valve cover set and the valve body In the space 8, a cooling water channel 202 and a guide ring 203 are arranged around the valve stem in the valve cover kit.

[0022] The "upper" and "lower" in this embodiment refer to figure 1 The assembly position state of the valve assembly shown in is also the installation position state of the valve assembly descri...

Embodiment 2

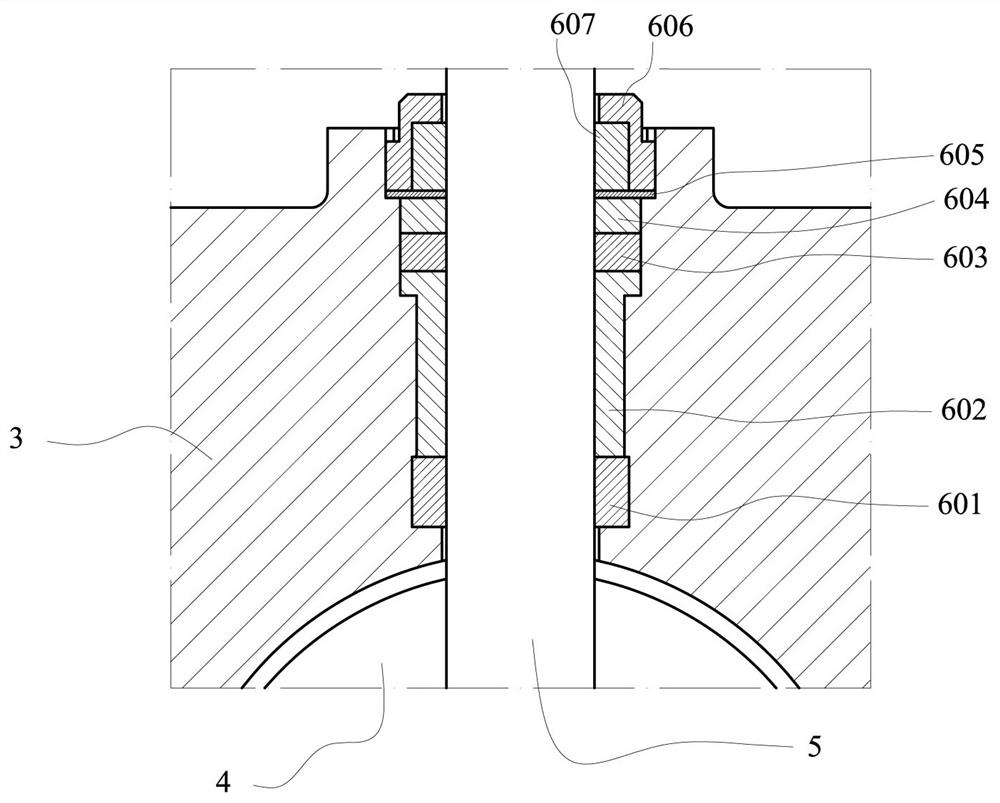

[0033] This embodiment is an improvement of the first embodiment, and is a refinement of the upper metal sealing sleeve of the first embodiment. The upper metal seal set described in this embodiment includes: a lower metal filter screen 601, a shaft sleeve 602, a gasket 603, a metal sealing ring 604, a metal sealing gasket 605, a pressure ring 606 and a package installed on the valve body in sequence along the valve stem. The upper metal filter screen 607 in the pressure ring, such as figure 2 shown.

[0034] The upper sealing structure described in this embodiment is a sealing structure completely made of metal materials. The sealing parts are all made of metal materials and cooperate with metal filter screens, which can meet the working conditions of 650°C high temperature and 5Bar pressure.

[0035] The upper sealing structure is specifically: a metal filter screen at the lower end is arranged on the valve plate along the valve stem to prevent exhaust gas particles and ca...

Embodiment 3

[0042] This embodiment is an improvement of the above embodiment, and is a refinement of the above embodiment regarding the sealing material. The material of the metal sealing ring and the metal sealing gasket in this embodiment is austenitic stainless steel.

[0043] The metal sealing ring and the metal sealing gasket are made of austenitic stainless steel, which can withstand high temperatures below 700°C. The sealing ring and the valve body can adopt a transition fit, and the valve stem can adopt a clearance fit. The gasket is pressed on the gap between the valve body and the sealing ring. After the pressure ring is pressed, the sealing ring and the gasket will not shrink or deform. Rod drives generate no frictional torque. The sealing gasket is made of heat-resistant stainless steel, and is pressed flat against the gap between the valve body and the shaft sleeve to perform radial sealing during assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com