A wind-assisted rotor structure

A rotor structure and boosting technology, which is applied in the direction of wind propulsion components, ship propulsion, propulsion components, etc., can solve the problems of complex wind boost rotor structure, inconvenient transportation and assembly, poor scheduling flexibility, etc., to achieve optimal angular vortex consumption performance, improved flexibility of use, and aerodynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

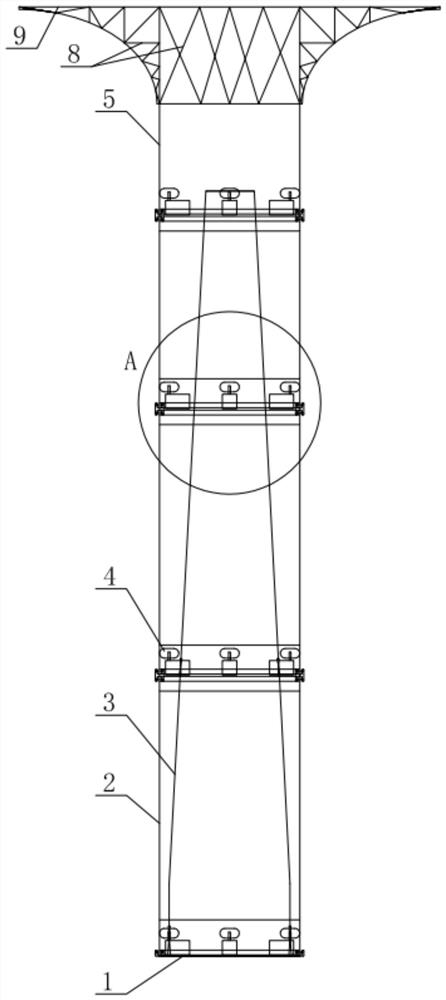

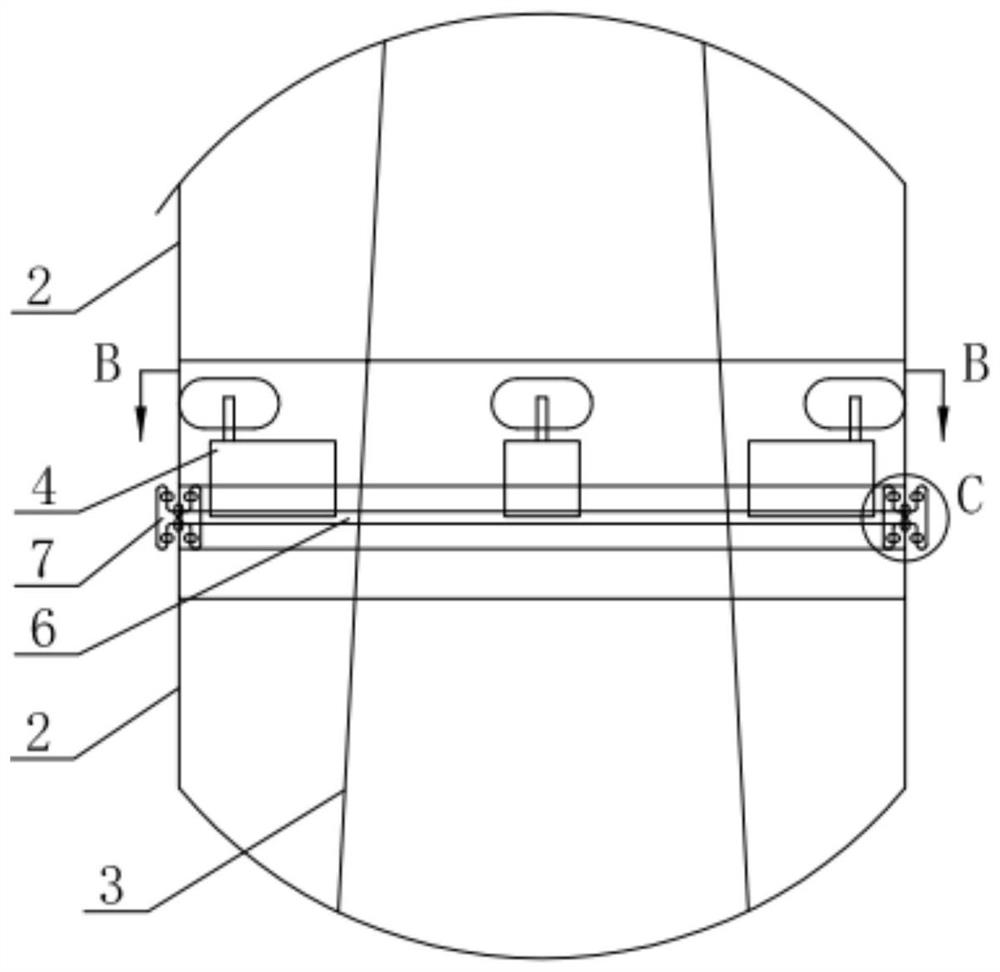

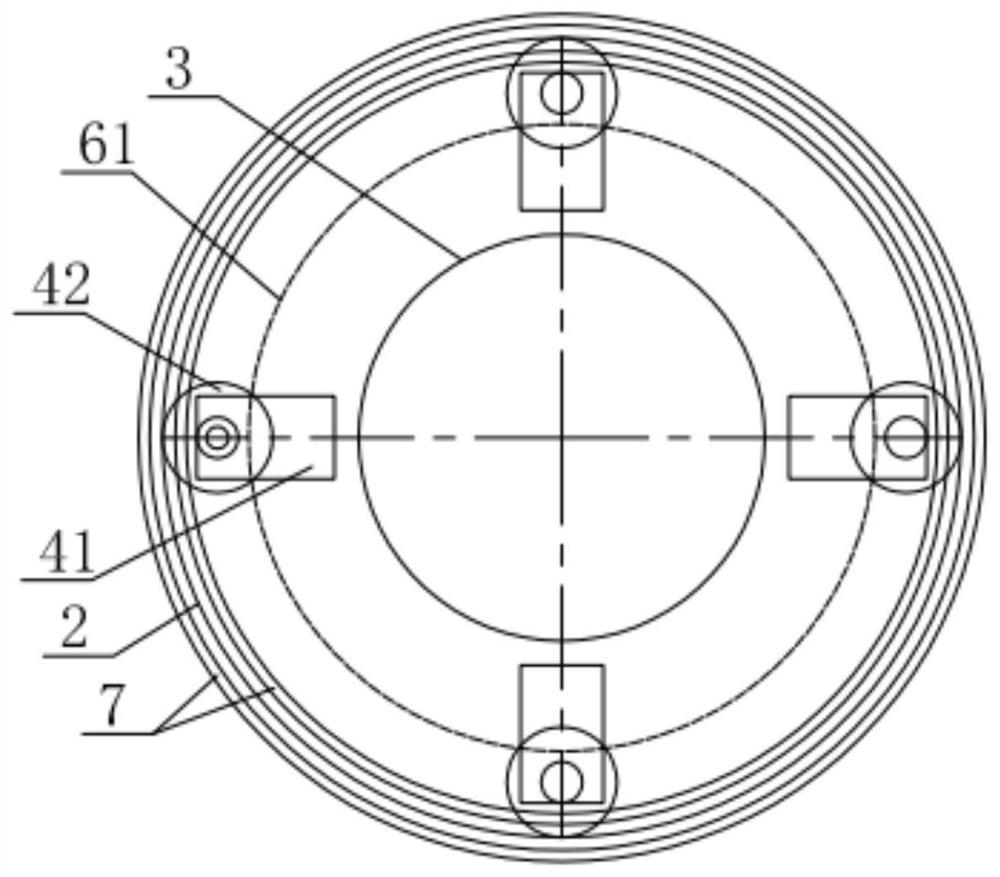

[0031] like figure 1 and figure 2 As shown, a wind-assisted rotor structure in this embodiment includes a base 1, an inner cylinder 3 is fixedly installed on the base 1, and a plurality of basic rotors are axially stacked and installed on the base 1 located outside the inner cylinder 3. Drum 2, the basic drum 2 is concentrically sleeved on the outside of the inner drum 3; the inner drum 3 located between the adjacent basic drums 2 is provided with a partition 6 in the circumferential direction. The plate 6 rotates independently; the top of the uppermost basic drum 2 is provided with the same baffle 6, and the top drum 5 is rotatably installed above the baffle 6; the inner drum 3 is accommodated inside the basic drum 2 and the top drum 5; The top of the top drum 5 is provided with an end plate 9, and the bottom surface of the end plate 9 and the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com