Large-torque hydraulic motor crankshaft

A hydraulic motor and high torque technology, which is applied in the design field of hydraulic motor crankshaft, can solve the problems of large system loss, low utilization rate of oil source pressure, and decreased efficiency of hydraulic motor, so as to achieve large starting torque, ensure motion transmission accuracy, The effect of simplifying the structure of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

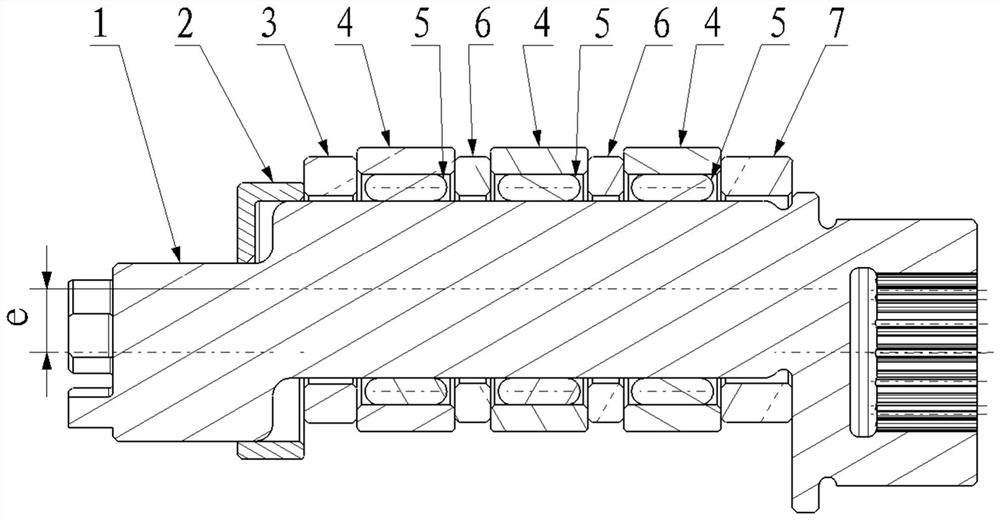

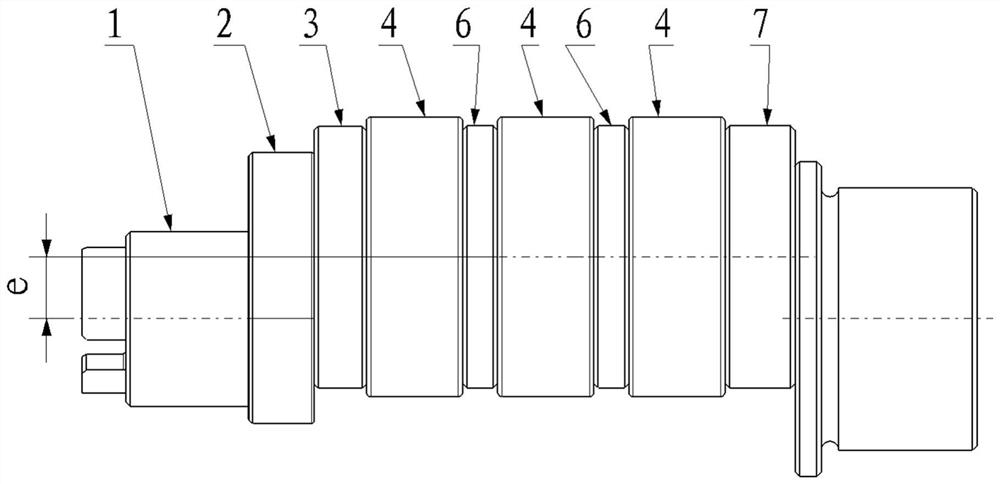

[0016] refer to Figure 1 ~ Figure 2 . In the preferred embodiment described below, a high-torque hydraulic motor crankshaft includes: a crankshaft 1 sealed in a housing through an end cover 2, and the extended end of the crankshaft 1 is the output shaft of the motor. The eccentric crank neck end of the crankshaft 1 and the eccentric wheel shaft end of the coaxial connecting rod are supported on the bearings of the end cover 2 and the rear end cover of the housing through a pair of tapered roller bearings, and rotate around the central axis of rotation of the bearings to limit the crankshaft 1 degrees of freedom of horizontal, up and down, forward and backward reciprocating motion, on the crankshaft 1 between the eccentric crank neck end and the eccentric shaft end, a pressure ring 4 that bears hydraulic pressure and a roller mounted in the pressure ring 4 are equipped. Needle 5, and each pressure ring 4 is arranged at intervals through the spacer ring 6, distributed in a lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com