High-performance hydraulic system of small four-wheel laser leveling machine

A technology of laser leveling machine and hydraulic system, applied in the direction of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation device, etc., can solve the problem of air suction and cavitation in the oil circuit of walking motor, uncontrolled vehicle speed, braking And problems such as abnormal noise of the parking motor, to achieve the effect of reducing cavitation and noise, avoiding the dispersion of the system, and increasing the walking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

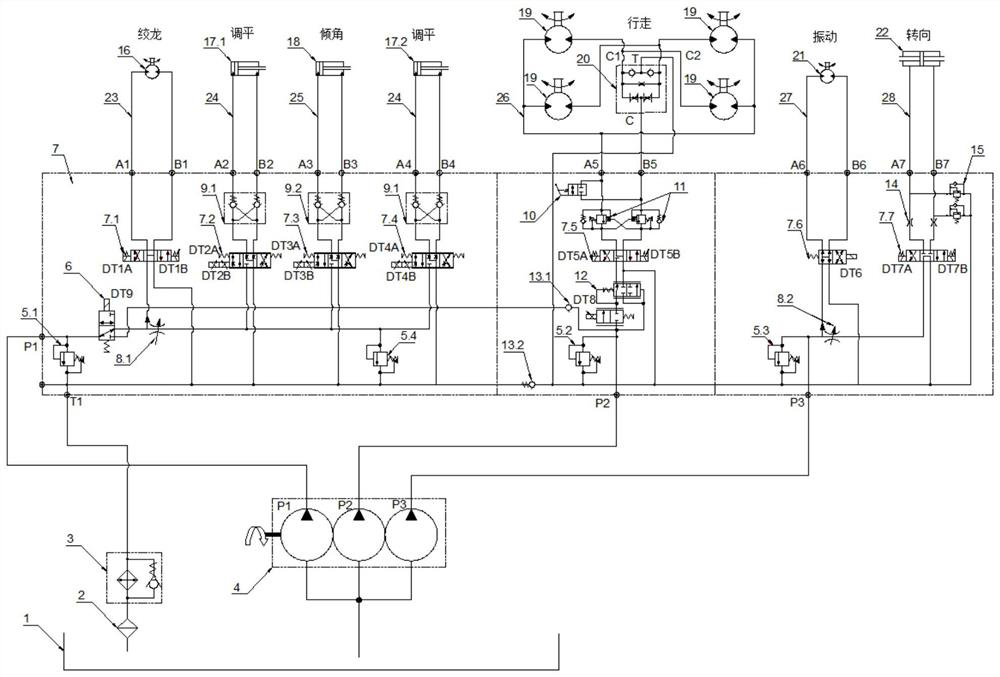

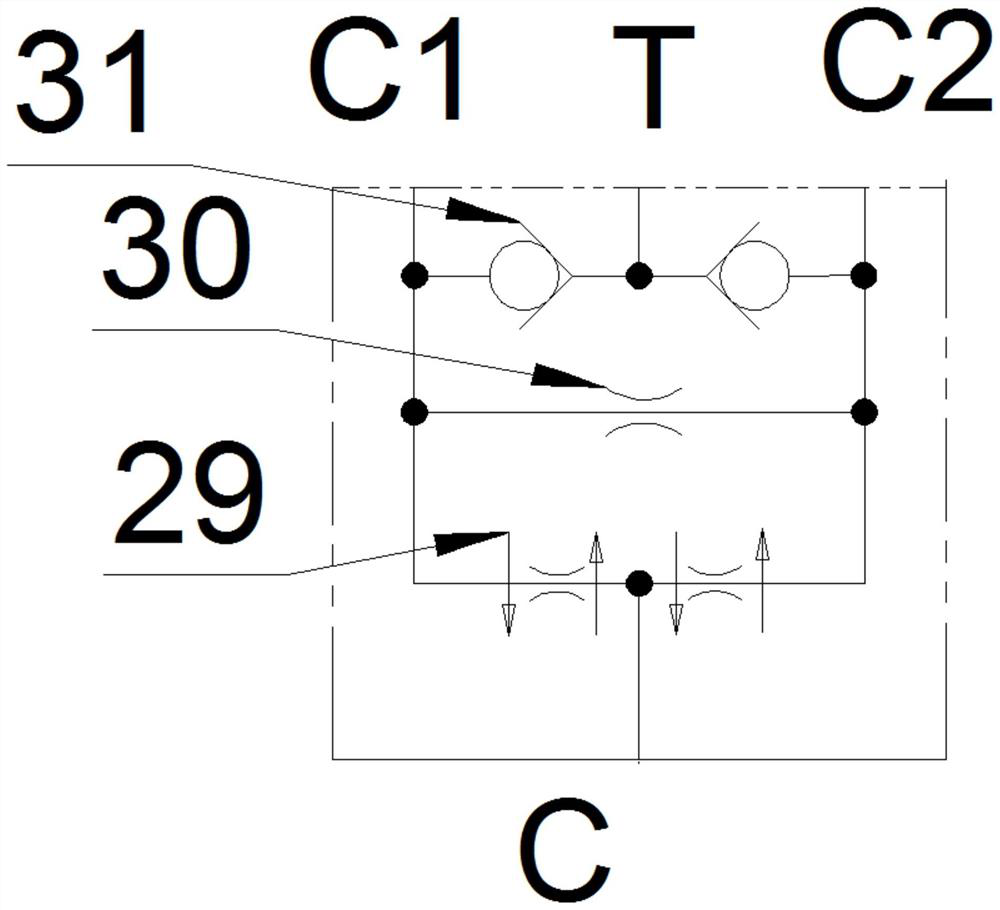

[0034] A hydraulic system of a high-performance small four-wheel laser leveler, including a fuel tank 1, an auger motor 16, a left leveling cylinder 17.1, a right leveling cylinder 17.2, an inclination cylinder 18, a travel motor 19, a vibration motor 21 and a steering cylinder 22 , the auger motor 16 is used to drive the auger mechanism of the laser leveling machine to scrape and divide the concrete material evenly, and the left leveling oil cylinder 17.1 and the right leveling oil cylinder 17.2 drive the leveling head mechanism of the laser leveling machine to rise and fall respectively for The left and right sides are leveled, the inclination cylinder 18 is used to telescopically drive the inclination angle of the leveling head mechanism, the travel motor 19 and steering cylinder 22 are used to drive the laser leveler to travel and turn resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com