Hybrid transmission gearbox

A hybrid transmission and gearbox technology, applied in the gearbox field, can solve problems such as low transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

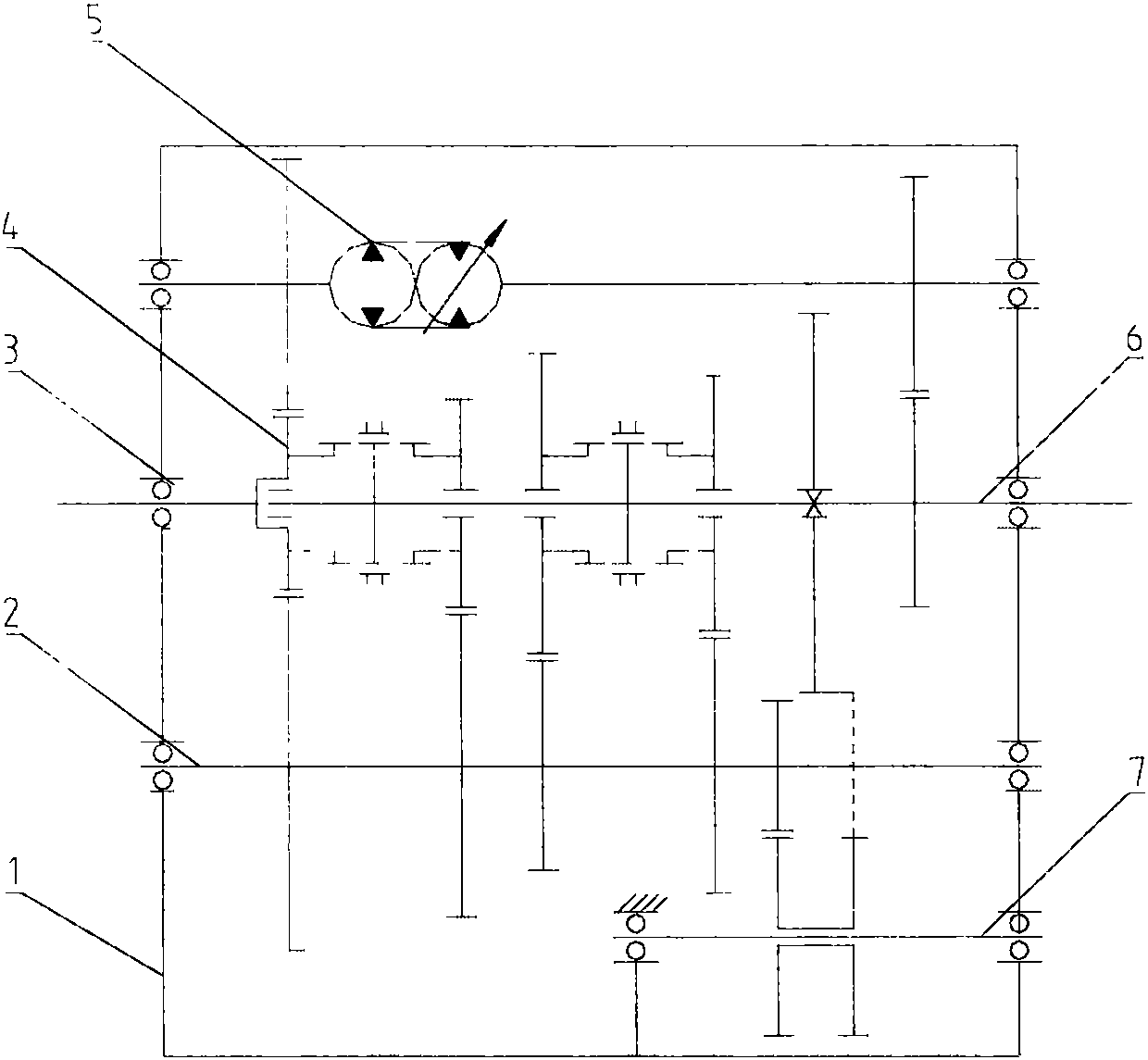

[0009] Referring to the accompanying drawings, a hybrid transmission gearbox has a structure comprising: a casing 1, in which an intermediate shaft 2, an input shaft 3, a gear set 4, an integrated pump motor 5, an output shaft 6 and a reverse gear are arranged. Axis 7. Inside the box body 1, the power enters the box body through the input shaft 3 and is divided into two roads, and one road passes through the gear set 4, the intermediate shaft 2, the reverse gear shaft 7, and the output shaft 6 to output five forwards and one reversed six gears. Mechanical transmission; the other channel transmits and outputs power through the integrated pump motor 5 and output shaft 6, and the output speed and torque are continuously and steplessly adjustable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com