Internal mixer upper jacking bolt oil cylinder hydraulic control system

A technology of hydraulic control system and internal mixer, which is applied in the direction of fluid pressure actuation system testing, fluid pressure actuation system components, mechanical equipment, etc. It can solve the complex problems of on-site debugging, reduce energy consumption, reduce calorific value, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

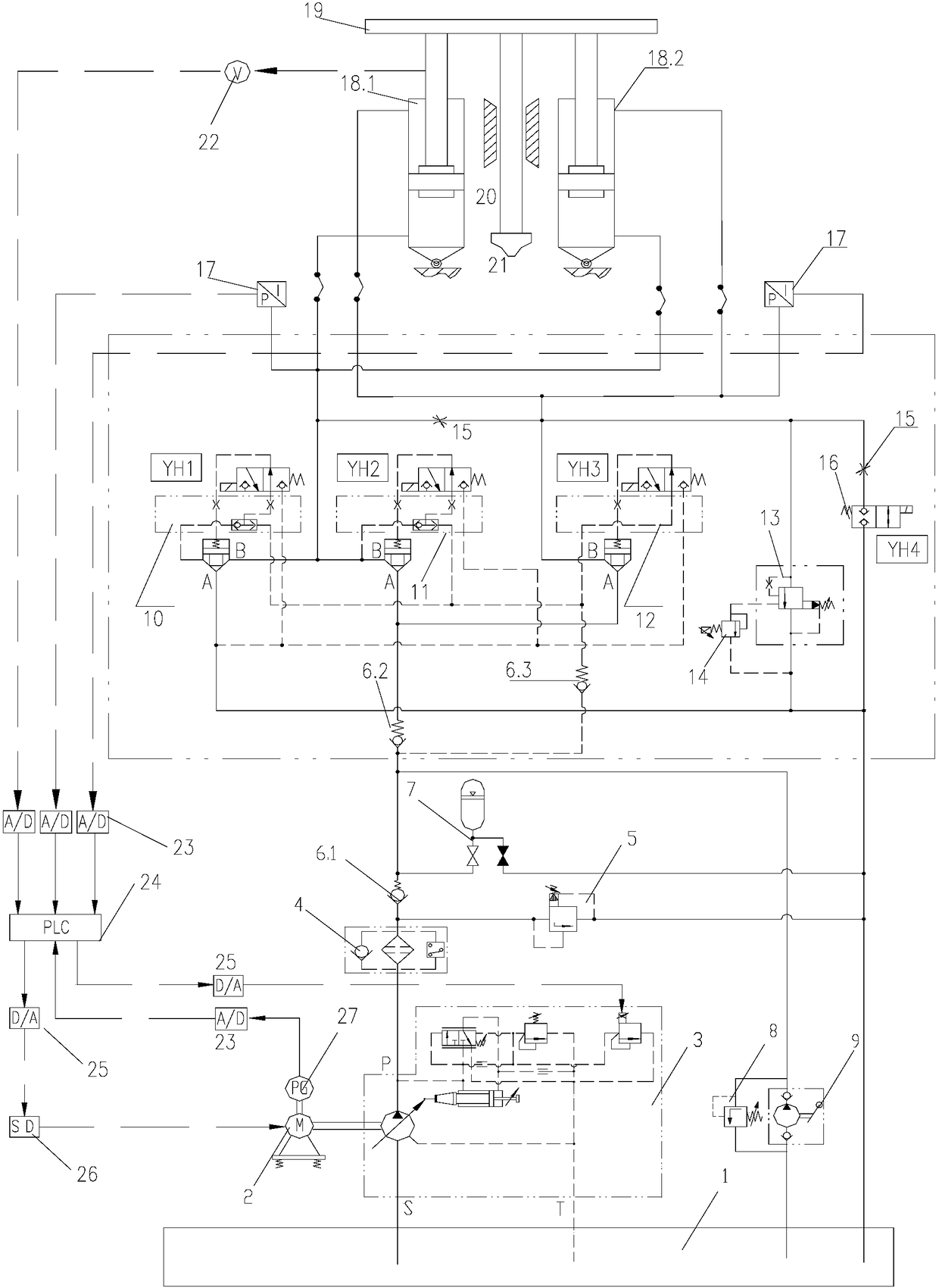

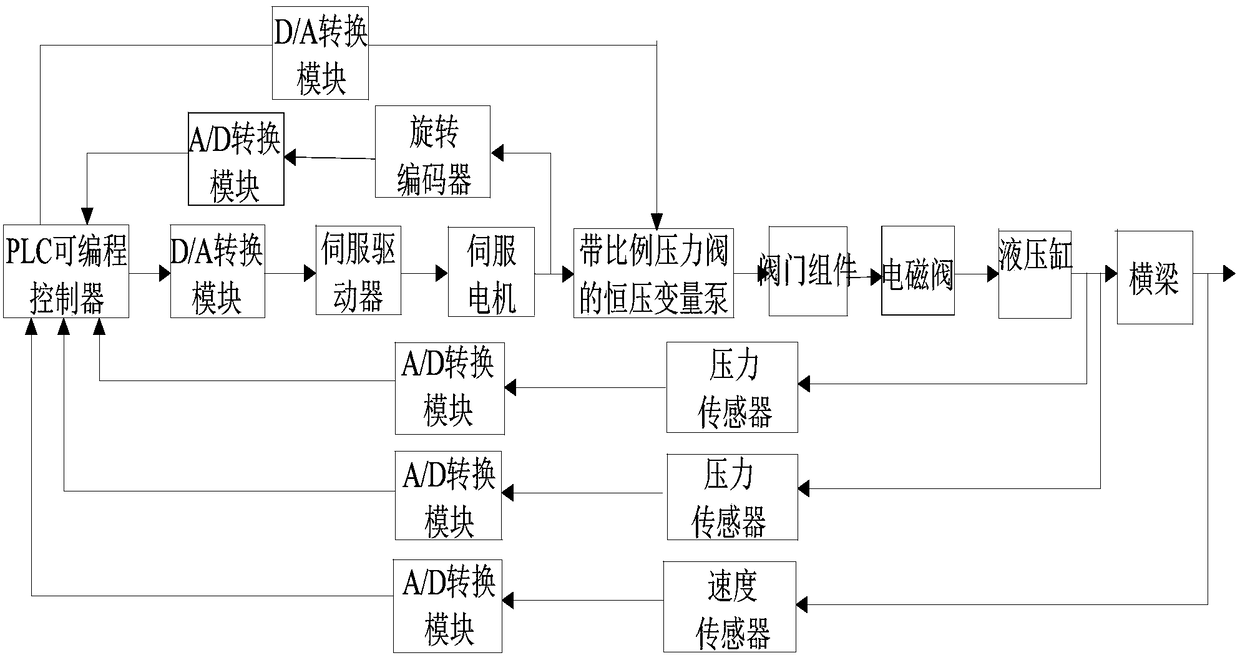

[0021] Such as Figure 1-Figure 2 The hydraulic control system of the upper bolt cylinder of the internal mixer is shown, and the specific scheme includes: a detection unit, a control unit and an actuator. The detection unit detects the speed signal information of the piston rod of the oil cylinder, the pressure signal information of the rodless cavity and the rod cavity, and the rotational speed information of the servo motor. According to the speed information of the piston rod of the oil cylinder, the pressure information of the rodless cavity and the rod cavity, and the rotational speed information of the servo motor, the control unit adopts the PID closed-loop control method to design t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com