Great-tonnage low-speed tractor

A tractor, large tonnage technology, applied to tractors, motor vehicles, vehicle parts, etc., can solve the problems of requiring a large work site, a large minimum turning radius, frequent heavy-load starting, etc., to achieve light and flexible steering, turning radius Small, good low speed stability effect

Inactive Publication Date: 2003-07-30

长沙凯瑞重工机械有限公司

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Under such transportation conditions, the use of ordinary tractors has the following disadvantages: 1. Poor stability at low speeds; 2. Frequent starting with heavy loads, serious damage to the clutch; 3. To generate large traction, a high-power engine is equipped, which seriously wastes power: 4 .The minimum turning radius is large, requiring a large operating site

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0024] According to the drawings and the above-mentioned structure of the tractor of the present invention, the engine power configuration is 158KW, the maximum towing weight is 170 tons, the full load maximum speed is 10Km / h, and the maximum traction force is 158KN; the relevant structural technical parameters and configuration refer to the commercially available (domestic) ZL50 wheel type Loaders are adopted accordingly.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

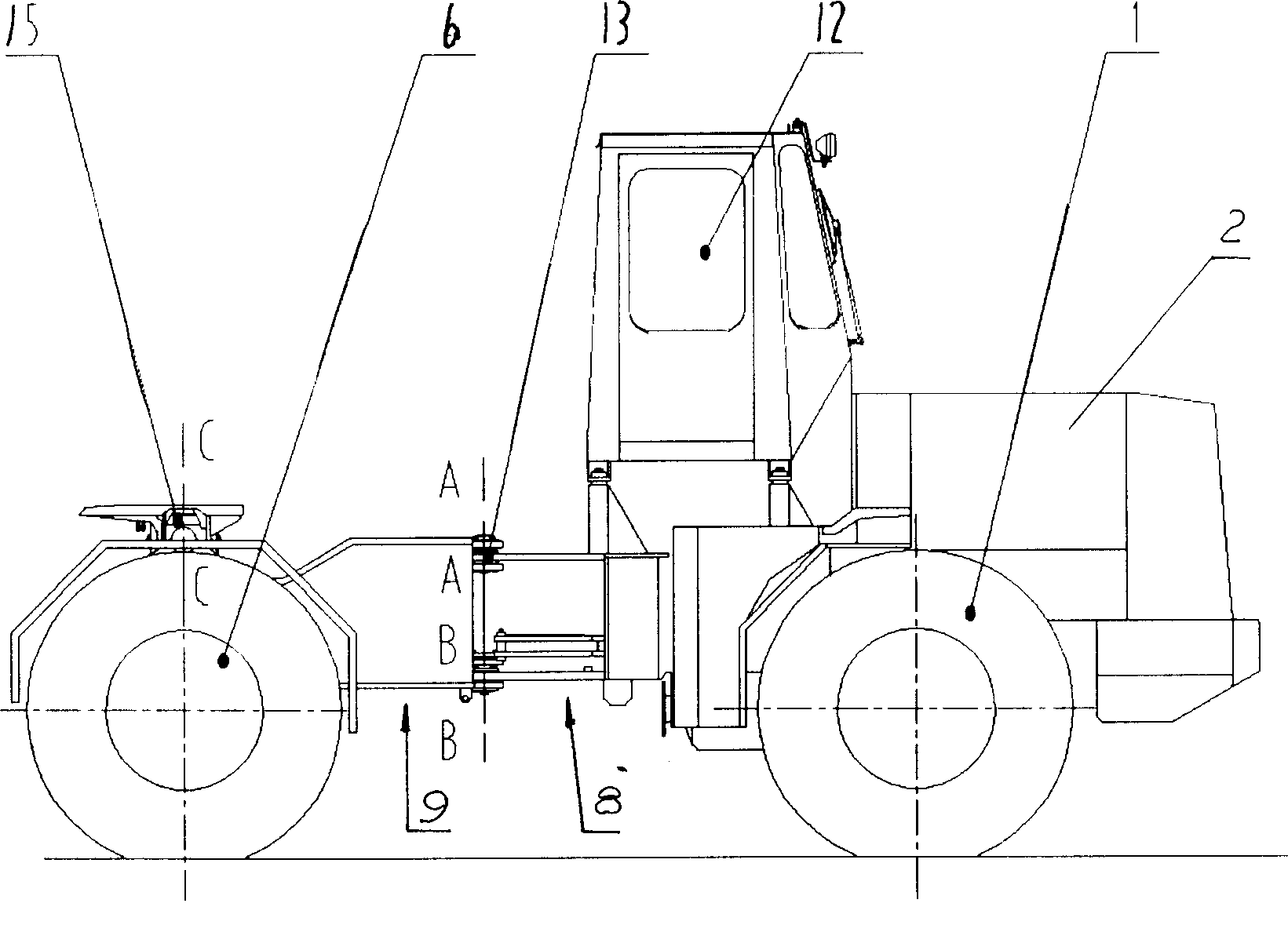

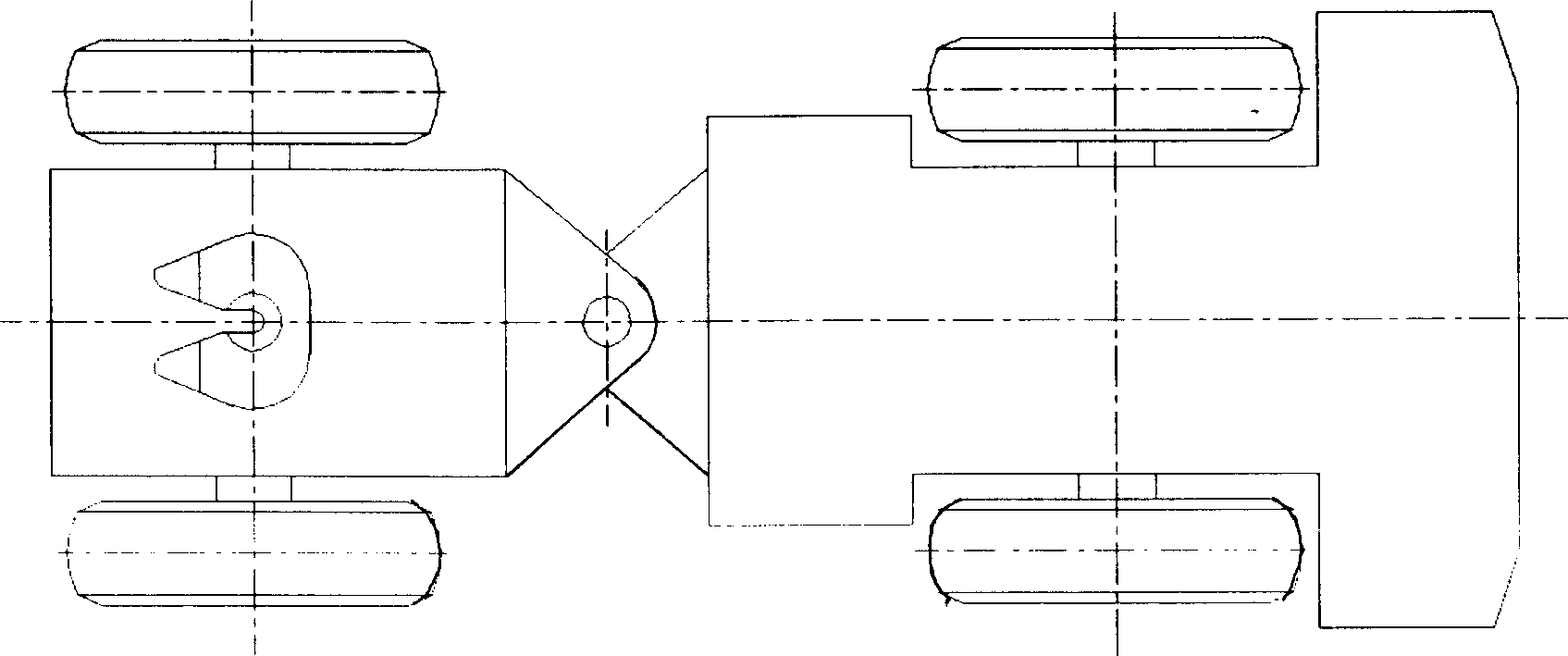

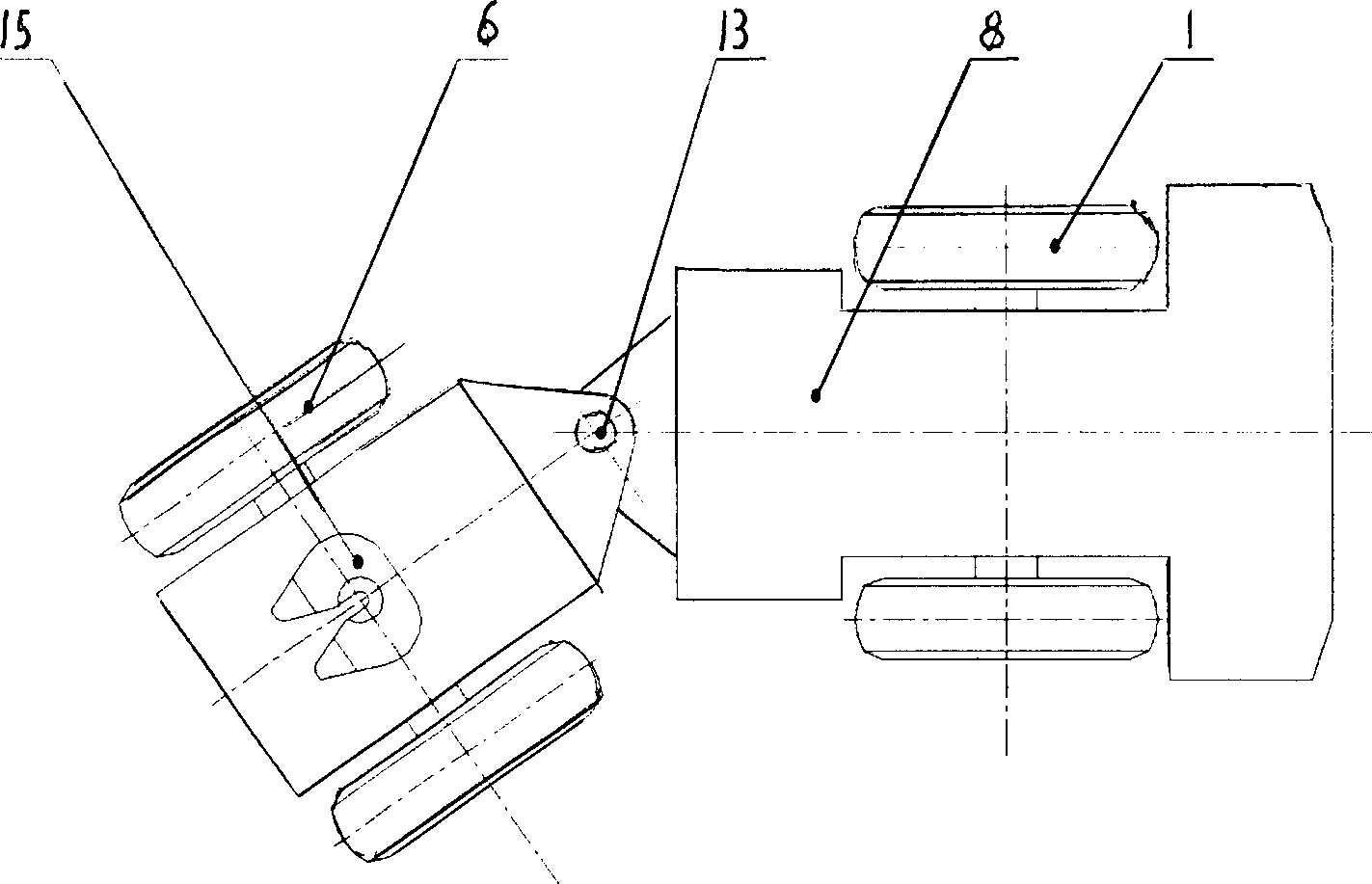

Login to View More Abstract

The great-tonnage low-speed tractor includes chassis with front drive axle, back drive axle, driver cab and engine, the engine is connected via hydraulic torque converter to gear box, the gear box isconnected to front and back drive axles via the transmission shaft, and the chassis includes the front chassis and the back chassis hinged together. The tractor has high low speed stability, good heavy load starting characteristic, smooth gear shift, all-wheel drive, great traction, disc brack suitable for frequency braking, light and flexible steering and small turn radius. It is suitable for iron and steel works and other enterprise to perform low-speed short-distance great-tonnage transportation in narrow space.

Description

Technical field [0001] The invention relates to a wheeled tractor, which belongs to a transportation vehicle. Background technique [0002] At present, ordinary tractors are mainly designed for long-distance and highway transportation, and the transmission system mainly adopts mechanical transmission. [0003] Special transportation in iron and steel enterprises, ports and other factories has the characteristics of large tonnage, low speed, short distance, frequent heavy-load starting, and good road conditions. Under such transportation conditions, the use of ordinary tractors has the following shortcomings: 1. Low speed and poor stability; 2. Frequent heavy-load starting and serious clutch damage; 3. In order to generate large traction, equipped with high-power engines, and serious power waste: 4. .The minimum turning radius is large and requires a larger work site. Summary of the invention [0004] The purpose of the present invention is to develop a large-tonnage low-speed tr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B60K17/34B62D49/00

Inventor 张卫东彭劲松伍小轲

Owner 长沙凯瑞重工机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com