Cable laying side pressure monitor and cable turning laying equipment

A cable laying and monitoring instrument technology, applied in cable laying equipment, force/torque/work measuring instruments, instruments, etc., can solve problems such as failure to meet strict requirements for cable laying, inability to detect cable side pressure, and delay in cable construction process, etc. Achieve the effect of improving laying quality, reducing cable failure rate, and eliminating illegal operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

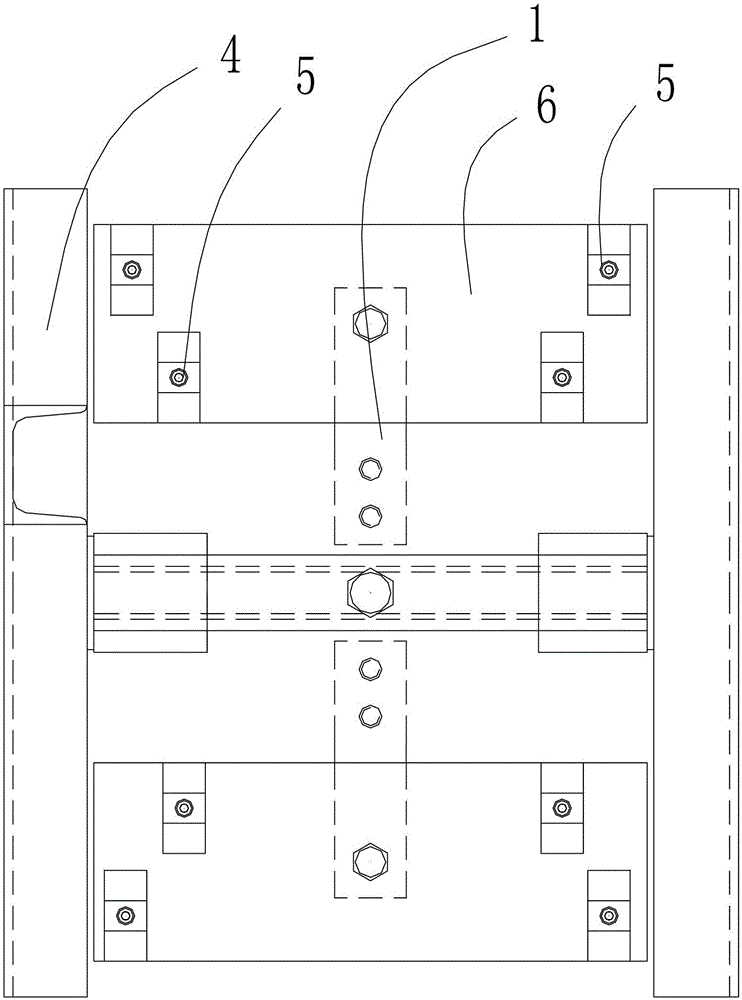

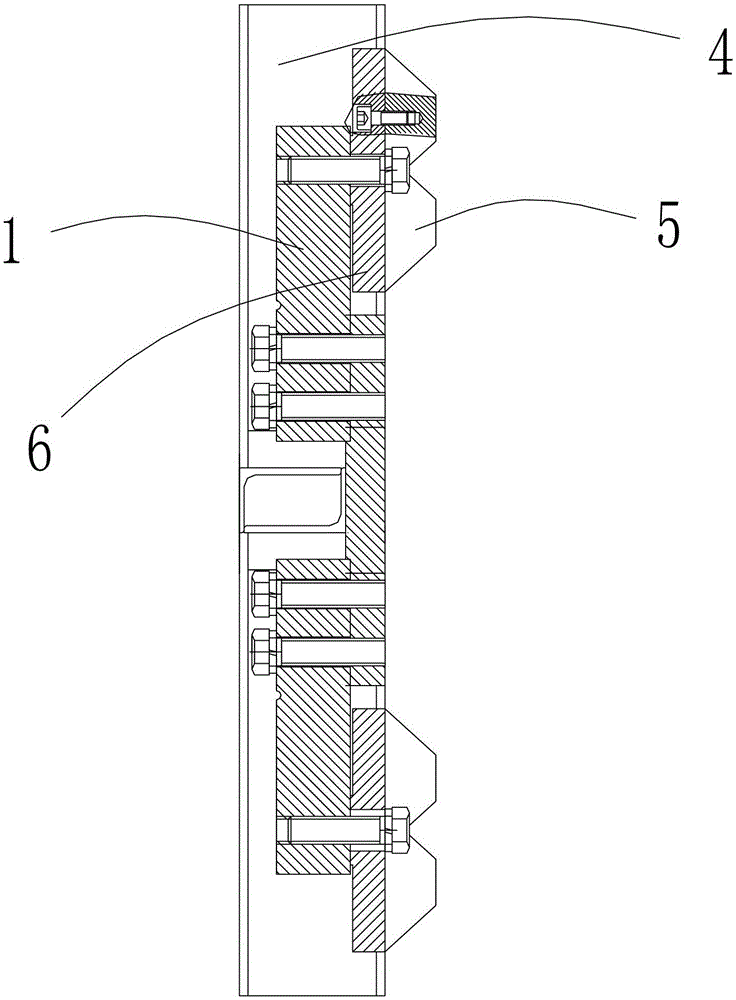

[0031] Such as figure 1 As shown, a cable laying side pressure monitor includes a signal acquisition mechanism and a signal processing mechanism; the signal acquisition mechanism includes a pressure sensor 1, and the pressure sensor 1 is installed on the side roller 2 of the turning block used for laying the cable 7. The base 3; the signal processing mechanism includes a signal processing device, a signal output device and a power supply connected to each other; the pressure sensor 1 is electrically connected to the signal processing device.

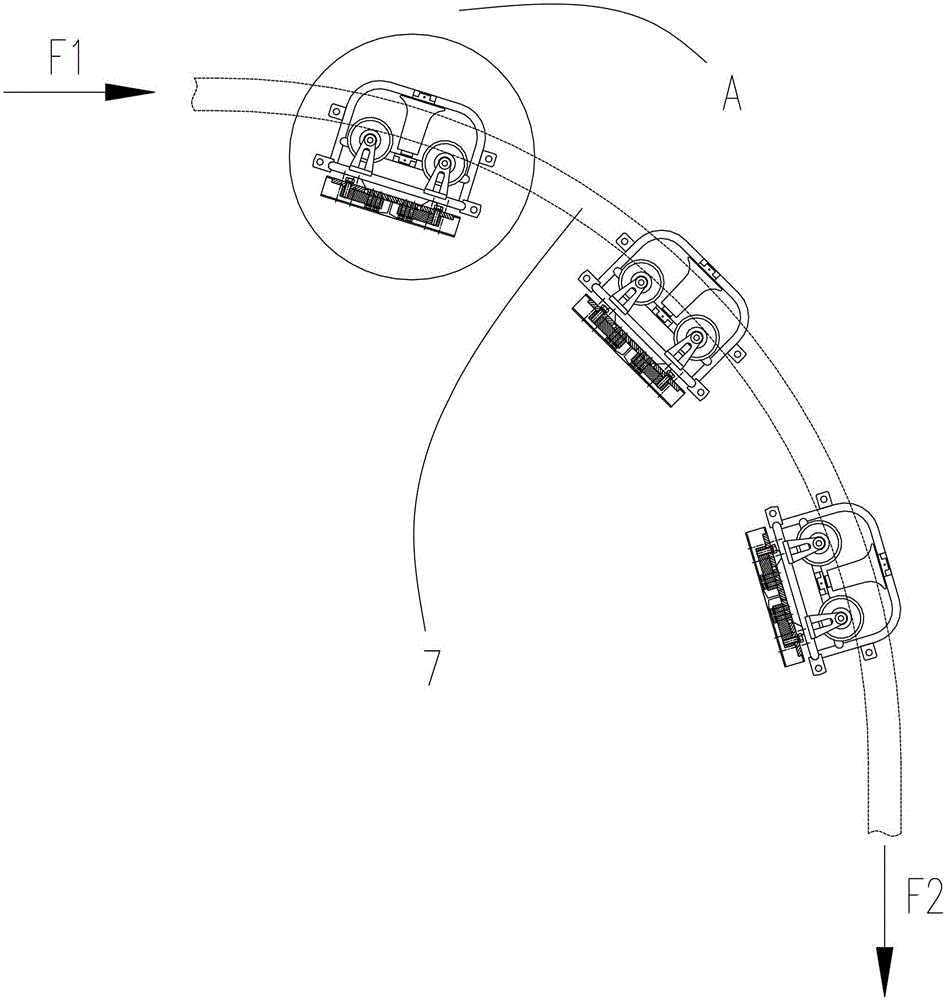

[0032]When the cable 7 is laid, use the turning block at the turning, evenly set the turning block on the arc with R as the radius, and fix it. When laying, the cable 7 is placed on the load-bearing roller 8 and moved forward by traction. Through the rotation of the load-bearing roller 8, the friction coefficient between the cable 7 and the turning block is reduced; and the cable 7 is close to the side of the turning block. The roller 2...

Embodiment 2

[0042] A cable turning and laying equipment, including a turning block and the above-mentioned cable laying side pressure monitor; the turning block includes a car body frame, lateral rollers 2 and load-bearing rollers 8, and the lateral rollers 2 are installed on the car body frame to turn On the base 3 on the side of the center of the radius; the monitor is installed on the base 3 .

[0043] The cable turning and laying equipment can not only increase the turning radius and reduce the friction coefficient to reduce the side pressure, but also detect and record the side pressure of the cable 7 in real time when turning, and provide the staff with real-time cable 7 Lateral pressure monitoring data to improve staff work efficiency.

[0044] Such as image 3 , Figure 4 As shown, when the cable 7 is laid, use the cable turning laying equipment at the turning point, evenly set the turning block on the arc with R as the radius, and fix it. When laying, the cable 7 is placed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com